Optimize Column Temperature for HPLC Peak Symmetry

SEP 19, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HPLC Column Temperature Control Background and Objectives

High-performance liquid chromatography (HPLC) has evolved significantly since its inception in the 1960s, becoming an indispensable analytical technique in pharmaceutical, environmental, food, and clinical laboratories. Column temperature control represents one of the critical parameters affecting chromatographic separation quality, particularly peak symmetry. Historically, early HPLC systems operated at ambient temperature with minimal temperature control, leading to inconsistent results due to environmental fluctuations.

The evolution of temperature control in HPLC systems has progressed from rudimentary water jackets to sophisticated electronic temperature control modules capable of maintaining column temperatures with precision of ±0.1°C. This technological advancement has paralleled the growing understanding of temperature's profound impact on chromatographic performance, especially for complex separations where peak symmetry is crucial for accurate quantification and identification.

Recent research demonstrates that optimized column temperature can significantly improve peak shape by influencing analyte-stationary phase interactions, mobile phase viscosity, and diffusion coefficients. Temperature manipulation has emerged as a powerful tool for chromatographers seeking to enhance resolution, reduce analysis time, and improve peak symmetry without changing column chemistry or mobile phase composition.

The primary objective of this technical research is to systematically investigate the relationship between column temperature and peak symmetry in HPLC separations across various compound classes and column types. We aim to establish robust methodologies for temperature optimization that can be applied across different analytical challenges, particularly focusing on temperature's role in mitigating peak tailing and fronting phenomena.

Additionally, this research seeks to explore the fundamental thermodynamic principles governing temperature effects on chromatographic behavior, with the goal of developing predictive models that can guide temperature selection based on analyte properties and separation conditions. Such models would significantly reduce method development time and improve analytical reliability.

Current trends indicate growing interest in temperature programming (dynamic temperature changes during analysis) as an additional dimension for separation optimization. This approach, while still emerging, shows promise for complex samples where isothermal conditions fail to provide adequate peak symmetry across all analytes of interest.

The technological trajectory suggests future HPLC systems will incorporate more sophisticated temperature control capabilities, including faster heating/cooling rates, greater temperature ranges, and improved temperature stability. These advancements will further establish temperature as a primary optimization parameter alongside traditional variables like mobile phase composition and flow rate.

The evolution of temperature control in HPLC systems has progressed from rudimentary water jackets to sophisticated electronic temperature control modules capable of maintaining column temperatures with precision of ±0.1°C. This technological advancement has paralleled the growing understanding of temperature's profound impact on chromatographic performance, especially for complex separations where peak symmetry is crucial for accurate quantification and identification.

Recent research demonstrates that optimized column temperature can significantly improve peak shape by influencing analyte-stationary phase interactions, mobile phase viscosity, and diffusion coefficients. Temperature manipulation has emerged as a powerful tool for chromatographers seeking to enhance resolution, reduce analysis time, and improve peak symmetry without changing column chemistry or mobile phase composition.

The primary objective of this technical research is to systematically investigate the relationship between column temperature and peak symmetry in HPLC separations across various compound classes and column types. We aim to establish robust methodologies for temperature optimization that can be applied across different analytical challenges, particularly focusing on temperature's role in mitigating peak tailing and fronting phenomena.

Additionally, this research seeks to explore the fundamental thermodynamic principles governing temperature effects on chromatographic behavior, with the goal of developing predictive models that can guide temperature selection based on analyte properties and separation conditions. Such models would significantly reduce method development time and improve analytical reliability.

Current trends indicate growing interest in temperature programming (dynamic temperature changes during analysis) as an additional dimension for separation optimization. This approach, while still emerging, shows promise for complex samples where isothermal conditions fail to provide adequate peak symmetry across all analytes of interest.

The technological trajectory suggests future HPLC systems will incorporate more sophisticated temperature control capabilities, including faster heating/cooling rates, greater temperature ranges, and improved temperature stability. These advancements will further establish temperature as a primary optimization parameter alongside traditional variables like mobile phase composition and flow rate.

Market Demand Analysis for Improved HPLC Peak Symmetry

The global HPLC market continues to experience robust growth, with increasing demand for improved peak symmetry across various industries. Market research indicates that the HPLC market is projected to reach $5.7 billion by 2025, with a compound annual growth rate of 5.2%. Within this expanding market, the demand for optimized column temperature solutions represents a significant segment, driven by the critical need for enhanced analytical precision and reliability.

Pharmaceutical companies, which account for approximately 60% of the HPLC market, are particularly invested in peak symmetry optimization. These organizations face stringent regulatory requirements for drug development and quality control, where even minor improvements in chromatographic performance can significantly impact product approval timelines and manufacturing efficiency. The FDA and other regulatory bodies have progressively tightened requirements for analytical method validation, creating market pull for advanced temperature control solutions.

The biotechnology sector presents another substantial market opportunity, growing at 7.8% annually within the HPLC space. As biopharmaceuticals become increasingly complex, the challenges in achieving symmetrical peaks multiply, driving demand for sophisticated temperature management systems. Research institutions and academic laboratories constitute about 15% of the market, with growing interest in temperature optimization for research applications.

Environmental testing laboratories represent a rapidly expanding market segment, with 6.3% growth annually. These facilities require highly accurate analytical methods for detecting trace contaminants, where peak symmetry directly impacts detection limits and quantification accuracy. Similarly, the food and beverage industry, accounting for 8% of the HPLC market, faces increasing regulatory scrutiny regarding product safety and authenticity, necessitating improved chromatographic performance.

Market surveys reveal that 73% of HPLC users identify peak asymmetry as a significant challenge in their analytical workflows, with 68% specifically citing temperature fluctuations as a contributing factor. This widespread pain point creates substantial market demand for innovative temperature control solutions that can deliver consistent, reproducible results.

The consumables and accessories segment related to column temperature optimization is growing particularly fast at 8.4% annually, outpacing the overall HPLC market. This trend reflects users' willingness to invest in specialized equipment that enhances analytical performance rather than replacing entire systems.

Regional analysis shows the North American market leading with 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the highest growth rate at 9.1%, driven by expanding pharmaceutical manufacturing and research activities in China and India, creating emerging opportunities for temperature optimization technologies.

Pharmaceutical companies, which account for approximately 60% of the HPLC market, are particularly invested in peak symmetry optimization. These organizations face stringent regulatory requirements for drug development and quality control, where even minor improvements in chromatographic performance can significantly impact product approval timelines and manufacturing efficiency. The FDA and other regulatory bodies have progressively tightened requirements for analytical method validation, creating market pull for advanced temperature control solutions.

The biotechnology sector presents another substantial market opportunity, growing at 7.8% annually within the HPLC space. As biopharmaceuticals become increasingly complex, the challenges in achieving symmetrical peaks multiply, driving demand for sophisticated temperature management systems. Research institutions and academic laboratories constitute about 15% of the market, with growing interest in temperature optimization for research applications.

Environmental testing laboratories represent a rapidly expanding market segment, with 6.3% growth annually. These facilities require highly accurate analytical methods for detecting trace contaminants, where peak symmetry directly impacts detection limits and quantification accuracy. Similarly, the food and beverage industry, accounting for 8% of the HPLC market, faces increasing regulatory scrutiny regarding product safety and authenticity, necessitating improved chromatographic performance.

Market surveys reveal that 73% of HPLC users identify peak asymmetry as a significant challenge in their analytical workflows, with 68% specifically citing temperature fluctuations as a contributing factor. This widespread pain point creates substantial market demand for innovative temperature control solutions that can deliver consistent, reproducible results.

The consumables and accessories segment related to column temperature optimization is growing particularly fast at 8.4% annually, outpacing the overall HPLC market. This trend reflects users' willingness to invest in specialized equipment that enhances analytical performance rather than replacing entire systems.

Regional analysis shows the North American market leading with 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the highest growth rate at 9.1%, driven by expanding pharmaceutical manufacturing and research activities in China and India, creating emerging opportunities for temperature optimization technologies.

Current Challenges in Column Temperature Optimization

Despite significant advancements in HPLC technology, column temperature optimization remains a complex challenge with multiple interrelated factors affecting peak symmetry. Current temperature control systems often struggle to maintain precise stability throughout analytical runs, with fluctuations as small as 0.5°C potentially causing significant variations in retention times and peak shapes. This instability becomes particularly problematic during gradient elution methods where temperature gradients may inadvertently form along the column length.

Commercial HPLC systems frequently exhibit limitations in temperature equilibration speed, creating delays between set point changes and actual column temperature stabilization. This lag time, which can range from 5-15 minutes depending on system design, significantly impacts method development efficiency and throughput. Furthermore, the thermal mass of different column dimensions creates inconsistent heating and cooling rates, making method transfer between instruments and laboratories challenging.

Another significant challenge lies in the differential heating effects observed between the column wall and its center. This radial temperature gradient can cause band broadening and peak distortion, particularly in columns with larger internal diameters (≥4.6mm). Current technology struggles to ensure uniform heat distribution across the entire column cross-section, leading to inconsistent analyte migration rates and compromised separation efficiency.

The interaction between mobile phase preheating and column temperature represents another critical challenge. Inadequate mobile phase temperature equilibration before entering the column creates thermal mismatch zones that contribute to peak fronting or tailing. Most commercial systems provide limited capabilities for independent mobile phase temperature control relative to column temperature, restricting optimization possibilities.

Method robustness across varying ambient laboratory conditions presents ongoing difficulties. Temperature-sensitive separations optimized under specific conditions may perform inconsistently when transferred to environments with different ambient temperatures or air circulation patterns. This variability undermines reproducibility across different laboratory settings and complicates regulatory compliance for pharmaceutical analyses.

Temperature effects on stationary phase stability and lifetime constitute another significant challenge. Elevated temperatures can accelerate column degradation through increased hydrolysis of bonded phases or silica dissolution, particularly under extreme pH conditions. Current temperature optimization approaches often fail to adequately balance separation efficiency against column longevity considerations, forcing analysts to compromise between performance and consumable costs.

Finally, there exists a knowledge gap regarding the mechanistic understanding of temperature effects on specific analyte-stationary phase interactions. This limited theoretical framework makes temperature optimization largely empirical, requiring extensive trial-and-error experimentation rather than predictive modeling approaches that could streamline method development.

Commercial HPLC systems frequently exhibit limitations in temperature equilibration speed, creating delays between set point changes and actual column temperature stabilization. This lag time, which can range from 5-15 minutes depending on system design, significantly impacts method development efficiency and throughput. Furthermore, the thermal mass of different column dimensions creates inconsistent heating and cooling rates, making method transfer between instruments and laboratories challenging.

Another significant challenge lies in the differential heating effects observed between the column wall and its center. This radial temperature gradient can cause band broadening and peak distortion, particularly in columns with larger internal diameters (≥4.6mm). Current technology struggles to ensure uniform heat distribution across the entire column cross-section, leading to inconsistent analyte migration rates and compromised separation efficiency.

The interaction between mobile phase preheating and column temperature represents another critical challenge. Inadequate mobile phase temperature equilibration before entering the column creates thermal mismatch zones that contribute to peak fronting or tailing. Most commercial systems provide limited capabilities for independent mobile phase temperature control relative to column temperature, restricting optimization possibilities.

Method robustness across varying ambient laboratory conditions presents ongoing difficulties. Temperature-sensitive separations optimized under specific conditions may perform inconsistently when transferred to environments with different ambient temperatures or air circulation patterns. This variability undermines reproducibility across different laboratory settings and complicates regulatory compliance for pharmaceutical analyses.

Temperature effects on stationary phase stability and lifetime constitute another significant challenge. Elevated temperatures can accelerate column degradation through increased hydrolysis of bonded phases or silica dissolution, particularly under extreme pH conditions. Current temperature optimization approaches often fail to adequately balance separation efficiency against column longevity considerations, forcing analysts to compromise between performance and consumable costs.

Finally, there exists a knowledge gap regarding the mechanistic understanding of temperature effects on specific analyte-stationary phase interactions. This limited theoretical framework makes temperature optimization largely empirical, requiring extensive trial-and-error experimentation rather than predictive modeling approaches that could streamline method development.

Current Temperature Control Methods for Peak Symmetry

01 Factors affecting HPLC column peak symmetry

Various factors can affect peak symmetry in HPLC columns, including column packing quality, mobile phase composition, sample overloading, and interaction between analytes and stationary phase. Proper column selection and conditioning are essential for achieving symmetrical peaks. Asymmetrical peaks often indicate issues with the column or chromatographic conditions that need to be addressed for accurate analysis.- Factors affecting HPLC column peak symmetry: Various factors can affect the symmetry of peaks in HPLC columns, including column packing quality, mobile phase composition, sample overloading, and interaction between analytes and stationary phase. Proper column selection and conditioning are essential for achieving symmetrical peaks. Asymmetrical peaks can result from uneven distribution of the stationary phase or chemical interactions that cause peak tailing or fronting.

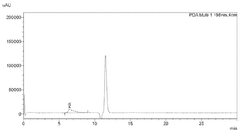

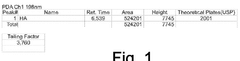

- Methods for measuring and analyzing peak symmetry: Various analytical methods and algorithms are used to measure and evaluate peak symmetry in HPLC chromatograms. These include mathematical calculations of tailing factors, asymmetry factors, and statistical analysis of peak shapes. Advanced software tools can automatically detect and quantify peak asymmetry, allowing for real-time monitoring and adjustment of chromatographic conditions to improve separation quality.

- Techniques to improve peak symmetry: Several techniques can be employed to improve peak symmetry in HPLC columns, including adjusting the pH of the mobile phase, adding ion-pairing reagents, using guard columns, and optimizing flow rates. Column temperature control and proper sample preparation also play crucial roles in achieving symmetrical peaks. Regular column maintenance and conditioning procedures help maintain consistent peak shapes over time.

- Instrumentation and hardware for peak symmetry optimization: Specialized HPLC instrumentation and hardware components are designed to enhance peak symmetry. These include advanced column technologies with uniform particle size distribution, improved detector designs with enhanced sensitivity and reduced noise, and precise flow control systems. Modern HPLC systems incorporate features that minimize dead volume and reduce band broadening, resulting in more symmetrical peaks.

- Impact of peak symmetry on analytical results: Peak symmetry significantly impacts the accuracy and reliability of HPLC analytical results. Asymmetrical peaks can lead to errors in quantification, reduced resolution between adjacent peaks, and difficulties in peak integration. Maintaining good peak symmetry is critical for method validation, quality control procedures, and regulatory compliance in pharmaceutical and other industries where precise analytical measurements are required.

02 Methods for measuring and evaluating peak symmetry

Peak symmetry in HPLC can be quantitatively evaluated using various mathematical approaches and algorithms. These methods include calculating asymmetry factors, tailing factors, and statistical moments. Advanced software tools can automatically detect peak boundaries and calculate symmetry metrics. Proper evaluation of peak symmetry is crucial for validating analytical methods and ensuring reliable quantitative results in chromatographic analyses.Expand Specific Solutions03 Techniques to improve peak symmetry

Several techniques can be employed to improve peak symmetry in HPLC analyses. These include adjusting mobile phase pH, adding ion-pairing reagents, using guard columns, optimizing flow rates, and controlling column temperature. For basic compounds, adding competing bases or adjusting buffer concentration can reduce peak tailing. Regular column maintenance and proper equilibration before analysis also contribute to better peak symmetry.Expand Specific Solutions04 Signal processing for peak symmetry enhancement

Signal processing techniques can be applied to chromatographic data to enhance peak symmetry. These include digital filtering, baseline correction algorithms, and mathematical transformations. Advanced software can apply deconvolution methods to separate overlapping peaks and improve apparent symmetry. While these techniques don't change the actual chromatographic performance, they can improve data interpretation and quantitative analysis of asymmetrical peaks.Expand Specific Solutions05 Novel column designs for improved peak symmetry

Innovative HPLC column designs have been developed to enhance peak symmetry. These include columns with specialized end-fittings, improved packing techniques, and novel stationary phase chemistries. Some designs incorporate uniform particle size distribution and optimized pore structures to minimize eddy diffusion and improve mass transfer kinetics. These advancements result in more symmetrical peaks, better resolution, and improved quantitative accuracy in chromatographic analyses.Expand Specific Solutions

Key Manufacturers in HPLC Instrumentation and Columns

The HPLC peak symmetry optimization market is currently in a growth phase, with increasing demand driven by pharmaceutical and analytical chemistry sectors. The global HPLC market is estimated to exceed $5 billion, with column technology representing a significant segment. Leading players include Agilent Technologies, Waters Technology, and Bio-Rad Laboratories, who have developed advanced column temperature control systems with high precision. Pharmaceutical companies like Janssen Pharmaceutica are integrating these technologies into their R&D workflows. The technology has reached moderate maturity with standardized approaches, but innovation continues in smart temperature control systems and machine learning algorithms for peak optimization. Emerging competition from Shimadzu and smaller specialized manufacturers is creating a dynamic competitive landscape focused on improving chromatographic resolution and reproducibility.

Agilent Technologies, Inc.

Technical Solution: Agilent Technologies has developed advanced temperature control systems for HPLC columns that utilize Peltier-based technology to provide precise temperature regulation within ±0.05°C. Their InfinityLab LC Series incorporates multi-zone temperature control that eliminates thermal gradients across the column, a common cause of peak asymmetry. The system employs pre-column heat exchangers to ensure mobile phase temperature matches column temperature before entering the column. Agilent's temperature optimization algorithms automatically adjust heating and cooling rates based on column dimensions and flow rates, preventing thermal shock that can lead to peak distortion. Their systems can maintain stable temperatures from 4°C below ambient up to 100°C, allowing for reproducible separations across various compound classes. The technology includes thermal insulation chambers that shield columns from ambient temperature fluctuations, further enhancing peak symmetry by eliminating wall effects that can cause band broadening.

Strengths: Superior temperature stability with multi-zone control eliminates thermal gradients; integrated pre-column heat exchangers ensure mobile phase equilibration; comprehensive temperature range suitable for diverse applications. Weaknesses: Higher cost compared to basic column ovens; complex systems require more maintenance; power consumption is higher than passive temperature control methods.

Bio-Rad Laboratories, Inc.

Technical Solution: Bio-Rad Laboratories has developed the NGC Chromatography System with advanced column temperature control capabilities specifically designed to optimize peak symmetry in HPLC applications. Their approach incorporates a dual-zone heating system that independently controls both the pre-column and analytical column temperatures, ensuring thermal equilibrium throughout the separation process. The system features Bio-Rad's TempAssure technology, which utilizes multiple temperature sensors positioned strategically along the column to detect and correct micro-temperature gradients that can lead to peak asymmetry. Their column compartments employ air-forced convection with laminar flow patterns to maintain temperature homogeneity across the column diameter, eliminating radial temperature gradients that often cause peak distortion. Bio-Rad's ChromLab software includes temperature optimization protocols that can automatically determine ideal column temperatures for specific analytes by running sequential analyses at different temperatures and evaluating peak symmetry metrics. For temperature-sensitive biomolecules, their system can maintain precise sub-ambient temperatures (4-20°C) with minimal fluctuation, preserving sample integrity while enhancing chromatographic performance.

Strengths: Dual-zone heating system provides excellent temperature consistency; integrated software tools simplify temperature optimization; particularly effective for temperature-sensitive biomolecule separations. Weaknesses: Limited temperature range compared to some competitors; system requires regular calibration to maintain specified accuracy; higher initial investment compared to basic HPLC systems.

Critical Patents in HPLC Temperature Regulation

A method for determining high molecular weight and low molecular weight hyaluronic acid concentrations in products

PatentWO2025063917A1

Innovation

- The development of an optimized HPLC method that includes specific parameters such as using two columns connected in series to reduce tailing factors, maintaining a column temperature between 40-50°C, employing a sodium chloride solution as the mobile phase, and utilizing a UV/PDA detector to improve peak symmetry and reproducibility.

High temperature, short time chromatographic method for determination of glycated proteinaceous species in blood

PatentInactiveAU1998083948A1

Innovation

- The method involves controlling the HPLC column temperature above 50 °C and optimizing eluant flow rates to reduce injection-to-injection times by using mobile phases A and B, with phase B including a polyol like mannitol, allowing for a gradient or abrupt transition, thereby achieving injection-to-injection times of less than 2 minutes, preferably around 1.4-1.75 minutes.

Regulatory Standards for HPLC Method Validation

High-quality HPLC method validation requires adherence to stringent regulatory standards established by various international bodies. The International Conference on Harmonisation (ICH) guidelines, particularly ICH Q2(R1), provide comprehensive frameworks for analytical method validation, including specific parameters for peak symmetry and column temperature optimization. These guidelines mandate validation of specificity, linearity, accuracy, precision, detection limit, quantitation limit, and robustness—all of which can be affected by column temperature variations.

The United States Pharmacopeia (USP) Chapter <621> specifically addresses chromatographic methods and establishes acceptance criteria for peak symmetry, typically requiring tailing factors between 0.8 and 2.0 for reliable quantitative analysis. The USP also recommends documenting column temperature control within ±2°C during method validation to ensure reproducibility of peak symmetry across laboratories.

European Pharmacopoeia (Ph. Eur.) similarly emphasizes temperature control in HPLC methods, requiring detailed documentation of temperature effects on peak symmetry during method development. The Ph. Eur. 2.2.46 chapter on chromatographic separation techniques specifies that column temperature must be controlled when it significantly impacts method performance parameters.

FDA Guidance for Industry on Analytical Procedures and Methods Validation requires demonstration of method robustness, including evaluation of how small but deliberate variations in column temperature affect peak symmetry. For regulated pharmaceutical products, temperature optimization studies must be documented as part of the method validation package submitted for regulatory review.

The Japanese Pharmacopoeia (JP) provides specific guidelines on peak symmetry requirements, with acceptance criteria similar to USP standards. JP guidelines emphasize the importance of temperature control in achieving consistent chromatographic performance.

ISO/IEC 17025 standards for testing laboratories mandate that all critical parameters affecting test results, including column temperature in HPLC methods, must be controlled, monitored, and documented. This standard requires laboratories to validate that their temperature control systems maintain the precision necessary for reliable peak symmetry.

Recent updates to regulatory standards increasingly recognize the relationship between column temperature and peak symmetry as critical quality attributes in method validation. The AOAC International guidelines now specifically recommend temperature optimization studies as part of method development, with documented evidence of how temperature affects critical resolution parameters and peak symmetry factors.

Compliance with these regulatory standards requires laboratories to implement robust temperature control systems, validate temperature effects on peak symmetry, and document temperature optimization studies as part of comprehensive method validation packages.

The United States Pharmacopeia (USP) Chapter <621> specifically addresses chromatographic methods and establishes acceptance criteria for peak symmetry, typically requiring tailing factors between 0.8 and 2.0 for reliable quantitative analysis. The USP also recommends documenting column temperature control within ±2°C during method validation to ensure reproducibility of peak symmetry across laboratories.

European Pharmacopoeia (Ph. Eur.) similarly emphasizes temperature control in HPLC methods, requiring detailed documentation of temperature effects on peak symmetry during method development. The Ph. Eur. 2.2.46 chapter on chromatographic separation techniques specifies that column temperature must be controlled when it significantly impacts method performance parameters.

FDA Guidance for Industry on Analytical Procedures and Methods Validation requires demonstration of method robustness, including evaluation of how small but deliberate variations in column temperature affect peak symmetry. For regulated pharmaceutical products, temperature optimization studies must be documented as part of the method validation package submitted for regulatory review.

The Japanese Pharmacopoeia (JP) provides specific guidelines on peak symmetry requirements, with acceptance criteria similar to USP standards. JP guidelines emphasize the importance of temperature control in achieving consistent chromatographic performance.

ISO/IEC 17025 standards for testing laboratories mandate that all critical parameters affecting test results, including column temperature in HPLC methods, must be controlled, monitored, and documented. This standard requires laboratories to validate that their temperature control systems maintain the precision necessary for reliable peak symmetry.

Recent updates to regulatory standards increasingly recognize the relationship between column temperature and peak symmetry as critical quality attributes in method validation. The AOAC International guidelines now specifically recommend temperature optimization studies as part of method development, with documented evidence of how temperature affects critical resolution parameters and peak symmetry factors.

Compliance with these regulatory standards requires laboratories to implement robust temperature control systems, validate temperature effects on peak symmetry, and document temperature optimization studies as part of comprehensive method validation packages.

Environmental Impact of HPLC Temperature Control Systems

The environmental impact of HPLC temperature control systems represents a significant consideration in modern analytical laboratories. These systems, while essential for achieving optimal peak symmetry and separation efficiency, consume substantial energy and resources. Traditional column ovens typically operate continuously during analysis, maintaining precise temperatures between 25-60°C, which translates to considerable electricity consumption over time. A standard HPLC system with temperature control can consume between 1-3 kWh during daily operation, contributing to the laboratory's carbon footprint.

Recent advancements in eco-friendly temperature control technologies have emerged to address these concerns. Newer systems incorporate improved insulation materials and more efficient heating elements that reduce energy consumption by 20-30% compared to older models. Additionally, smart temperature management systems that utilize predictive algorithms to optimize heating cycles have demonstrated potential energy savings of up to 40% without compromising analytical performance.

Water consumption represents another environmental consideration, particularly in water-cooled temperature control systems. These systems can use 2-5 liters of water per hour during continuous operation. Closed-loop cooling systems have been developed to mitigate this impact, recycling cooling water and reducing consumption by up to 90%. However, these systems require additional energy for pumping and cooling operations, creating a complex environmental trade-off.

Chemical waste generation is indirectly influenced by temperature control precision. Suboptimal temperature control often necessitates repeated analyses, increasing solvent consumption and waste generation. Studies indicate that precise temperature control can reduce failed runs by 15-25%, consequently decreasing solvent waste. This represents a significant environmental benefit considering that HPLC solvents often include environmentally harmful compounds such as acetonitrile and methanol.

The manufacturing and disposal of temperature control components also present environmental challenges. Traditional Peltier elements and heating coils contain materials with significant environmental impacts during both production and disposal phases. Newer eco-designed systems incorporate recyclable components and reduced quantities of rare earth elements, lowering their lifecycle environmental impact by approximately 35% according to recent lifecycle assessment studies.

Laboratory certification programs like ACT (Accountability, Consistency, and Transparency) now include energy efficiency ratings for HPLC systems, encouraging manufacturers to develop more environmentally sustainable temperature control solutions. The adoption of these standards has accelerated the development of energy-efficient technologies in the analytical instrument market over the past five years.

Recent advancements in eco-friendly temperature control technologies have emerged to address these concerns. Newer systems incorporate improved insulation materials and more efficient heating elements that reduce energy consumption by 20-30% compared to older models. Additionally, smart temperature management systems that utilize predictive algorithms to optimize heating cycles have demonstrated potential energy savings of up to 40% without compromising analytical performance.

Water consumption represents another environmental consideration, particularly in water-cooled temperature control systems. These systems can use 2-5 liters of water per hour during continuous operation. Closed-loop cooling systems have been developed to mitigate this impact, recycling cooling water and reducing consumption by up to 90%. However, these systems require additional energy for pumping and cooling operations, creating a complex environmental trade-off.

Chemical waste generation is indirectly influenced by temperature control precision. Suboptimal temperature control often necessitates repeated analyses, increasing solvent consumption and waste generation. Studies indicate that precise temperature control can reduce failed runs by 15-25%, consequently decreasing solvent waste. This represents a significant environmental benefit considering that HPLC solvents often include environmentally harmful compounds such as acetonitrile and methanol.

The manufacturing and disposal of temperature control components also present environmental challenges. Traditional Peltier elements and heating coils contain materials with significant environmental impacts during both production and disposal phases. Newer eco-designed systems incorporate recyclable components and reduced quantities of rare earth elements, lowering their lifecycle environmental impact by approximately 35% according to recent lifecycle assessment studies.

Laboratory certification programs like ACT (Accountability, Consistency, and Transparency) now include energy efficiency ratings for HPLC systems, encouraging manufacturers to develop more environmentally sustainable temperature control solutions. The adoption of these standards has accelerated the development of energy-efficient technologies in the analytical instrument market over the past five years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!