Optimizing Radial Engine Design for Aerodynamic Advantage

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Radial Engine Evolution and Design Objectives

Radial engines emerged in the early 20th century as a revolutionary aircraft propulsion system, characterized by their distinctive star-shaped cylinder arrangement around a central crankshaft. This configuration offered significant advantages in terms of power-to-weight ratio and cooling efficiency compared to inline engines of the era. The evolution of radial engines can be traced through several distinct phases, beginning with early designs like the Gnome rotary engine in 1908, progressing through the powerful Wright R-3350 that powered many WWII bombers, and culminating in sophisticated late-model designs before jet engines became predominant.

Despite being largely supplanted by turbine engines in mainstream aviation, radial engines continue to occupy specialized niches where their unique characteristics provide distinct advantages. Modern engineering techniques and materials science advancements have created opportunities to revisit and optimize radial engine designs for contemporary applications, particularly in light aircraft, unmanned aerial vehicles, and certain industrial applications where reliability and simplicity remain paramount.

The primary objective of optimizing radial engine design for aerodynamic advantage centers on addressing the inherent challenges of the radial configuration while maximizing its benefits. Key goals include reducing the frontal area to minimize drag, improving cooling efficiency without compromising aerodynamic performance, and enhancing power output while maintaining the favorable weight characteristics that made radial engines attractive initially.

Current technological trends point toward several promising directions for radial engine evolution. Advanced computational fluid dynamics (CFD) modeling now enables precise analysis of airflow patterns around and through radial engine installations, allowing for optimization that was impossible during the original development era. Composite materials offer potential weight reductions while maintaining structural integrity, addressing one of the historical limitations of metal-based radial designs.

Additionally, modern electronic engine management systems present opportunities to optimize fuel delivery and ignition timing with precision unimaginable to early radial engine designers, potentially yielding significant improvements in efficiency and power output. The integration of hybrid technologies may also represent a frontier for radial engine development, combining the reliability of radial configurations with electric augmentation for improved performance characteristics.

The technical trajectory for optimized radial engine design must balance historical strengths with contemporary requirements, focusing on aerodynamic refinement, thermal management innovation, and integration with modern aircraft systems. Success in this domain requires a multidisciplinary approach that leverages both the rich historical knowledge base of radial engine operation and cutting-edge computational and materials technologies.

Despite being largely supplanted by turbine engines in mainstream aviation, radial engines continue to occupy specialized niches where their unique characteristics provide distinct advantages. Modern engineering techniques and materials science advancements have created opportunities to revisit and optimize radial engine designs for contemporary applications, particularly in light aircraft, unmanned aerial vehicles, and certain industrial applications where reliability and simplicity remain paramount.

The primary objective of optimizing radial engine design for aerodynamic advantage centers on addressing the inherent challenges of the radial configuration while maximizing its benefits. Key goals include reducing the frontal area to minimize drag, improving cooling efficiency without compromising aerodynamic performance, and enhancing power output while maintaining the favorable weight characteristics that made radial engines attractive initially.

Current technological trends point toward several promising directions for radial engine evolution. Advanced computational fluid dynamics (CFD) modeling now enables precise analysis of airflow patterns around and through radial engine installations, allowing for optimization that was impossible during the original development era. Composite materials offer potential weight reductions while maintaining structural integrity, addressing one of the historical limitations of metal-based radial designs.

Additionally, modern electronic engine management systems present opportunities to optimize fuel delivery and ignition timing with precision unimaginable to early radial engine designers, potentially yielding significant improvements in efficiency and power output. The integration of hybrid technologies may also represent a frontier for radial engine development, combining the reliability of radial configurations with electric augmentation for improved performance characteristics.

The technical trajectory for optimized radial engine design must balance historical strengths with contemporary requirements, focusing on aerodynamic refinement, thermal management innovation, and integration with modern aircraft systems. Success in this domain requires a multidisciplinary approach that leverages both the rich historical knowledge base of radial engine operation and cutting-edge computational and materials technologies.

Aerodynamic Performance Market Analysis

The global market for radial engine technology has experienced significant transformation over the past decade, driven by increasing demands for more efficient and environmentally friendly propulsion systems in aviation. Current market analysis indicates that while radial engines have historically dominated certain aviation segments, their market share has been gradually declining due to the emergence of more aerodynamically efficient alternatives.

The commercial aviation sector presents a complex landscape for radial engine applications. With fuel efficiency becoming a paramount concern for airlines worldwide, there is growing interest in propulsion systems that can deliver superior aerodynamic performance. Market research indicates that operators are willing to invest in advanced radial engine designs that can demonstrate measurable improvements in fuel consumption and operational costs.

In the general aviation segment, where radial engines maintain a stronger presence, market demand is increasingly focused on designs that balance traditional reliability with modern aerodynamic enhancements. This segment represents approximately 15% of the total aviation propulsion market, with annual growth rates showing modest but steady increases in regions where recreational flying remains popular.

Military applications continue to provide specialized market opportunities for optimized radial engine designs. Defense contractors are particularly interested in radial engine configurations that can deliver improved performance in extreme operational environments while maintaining the inherent reliability that has historically characterized these engines.

Market forecasts suggest that the global value of aerodynamically optimized radial engines could reach significant levels if breakthrough designs can demonstrate 10-15% improvements in fuel efficiency over current configurations. This potential market expansion is contingent upon successful integration of advanced aerodynamic principles into traditional radial engine architecture.

Competitive analysis reveals that several specialized engineering firms have begun investing in research programs specifically targeting aerodynamic enhancements for radial engine designs. These market entrants are primarily focused on niche applications where the unique characteristics of radial engines provide distinct advantages over alternative propulsion systems.

Consumer preference studies indicate growing interest in "heritage" aviation technologies that combine classic design elements with modern performance characteristics. This trend creates market opportunities for radial engine designs that can effectively balance nostalgic appeal with contemporary aerodynamic efficiency standards.

Regional market analysis shows particularly strong potential in emerging aviation markets across Asia-Pacific and Latin America, where cost-effective propulsion solutions are prioritized over cutting-edge technologies. These regions represent potential growth areas for aerodynamically optimized radial engines that can deliver improved performance at competitive price points.

The commercial aviation sector presents a complex landscape for radial engine applications. With fuel efficiency becoming a paramount concern for airlines worldwide, there is growing interest in propulsion systems that can deliver superior aerodynamic performance. Market research indicates that operators are willing to invest in advanced radial engine designs that can demonstrate measurable improvements in fuel consumption and operational costs.

In the general aviation segment, where radial engines maintain a stronger presence, market demand is increasingly focused on designs that balance traditional reliability with modern aerodynamic enhancements. This segment represents approximately 15% of the total aviation propulsion market, with annual growth rates showing modest but steady increases in regions where recreational flying remains popular.

Military applications continue to provide specialized market opportunities for optimized radial engine designs. Defense contractors are particularly interested in radial engine configurations that can deliver improved performance in extreme operational environments while maintaining the inherent reliability that has historically characterized these engines.

Market forecasts suggest that the global value of aerodynamically optimized radial engines could reach significant levels if breakthrough designs can demonstrate 10-15% improvements in fuel efficiency over current configurations. This potential market expansion is contingent upon successful integration of advanced aerodynamic principles into traditional radial engine architecture.

Competitive analysis reveals that several specialized engineering firms have begun investing in research programs specifically targeting aerodynamic enhancements for radial engine designs. These market entrants are primarily focused on niche applications where the unique characteristics of radial engines provide distinct advantages over alternative propulsion systems.

Consumer preference studies indicate growing interest in "heritage" aviation technologies that combine classic design elements with modern performance characteristics. This trend creates market opportunities for radial engine designs that can effectively balance nostalgic appeal with contemporary aerodynamic efficiency standards.

Regional market analysis shows particularly strong potential in emerging aviation markets across Asia-Pacific and Latin America, where cost-effective propulsion solutions are prioritized over cutting-edge technologies. These regions represent potential growth areas for aerodynamically optimized radial engines that can deliver improved performance at competitive price points.

Current Radial Engine Limitations and Technical Barriers

Despite their historical significance and unique operational characteristics, radial engines face several critical limitations that hinder their aerodynamic performance in modern aviation applications. The primary challenge stems from their inherently large frontal area, which creates substantial drag during flight. This fundamental design constraint significantly reduces fuel efficiency and limits maximum achievable speeds compared to inline or flat configurations with similar power outputs.

Cooling inefficiencies represent another major technical barrier. The rear cylinders in radial configurations often receive inadequate airflow, leading to uneven temperature distribution across the engine. This thermal imbalance not only reduces overall efficiency but also accelerates component wear and increases maintenance requirements. Current cooling systems struggle to maintain optimal operating temperatures without further compromising aerodynamic performance.

The weight-to-power ratio of traditional radial engines presents additional challenges. While radial designs offer excellent power concentration in a compact package, their complex crankcase assemblies and numerous accessory components contribute to excessive weight. This unfavorable ratio becomes particularly problematic in applications where weight optimization is critical for performance, such as in modern aircraft designs focused on fuel efficiency.

Vibration management remains an unresolved technical issue in radial engine design. The radial arrangement of cylinders creates inherent imbalances during operation, generating significant vibration that affects both structural integrity and passenger comfort. Current dampening solutions add weight and complexity without fully addressing the underlying mechanical issues.

Oil distribution systems in radial engines face unique challenges due to their orientation. When cylinders are positioned in a circular pattern, ensuring consistent lubrication becomes problematic, particularly during various flight attitudes. This leads to increased oil consumption, potential lubrication failures, and reduced engine longevity compared to more streamlined configurations.

Manufacturing complexity and precision requirements constitute significant barriers to cost-effective production. The intricate casting and machining processes needed for radial engine components demand specialized equipment and expertise, limiting production scalability and increasing unit costs. This manufacturing challenge has restricted widespread adoption in cost-sensitive markets.

Emissions compliance represents a growing concern for radial engine designs. Their combustion characteristics typically result in higher emissions profiles compared to more modern engine configurations, creating regulatory challenges in increasingly stringent environmental frameworks. Current radial designs struggle to incorporate advanced emissions control technologies without compromising their core operational characteristics.

Cooling inefficiencies represent another major technical barrier. The rear cylinders in radial configurations often receive inadequate airflow, leading to uneven temperature distribution across the engine. This thermal imbalance not only reduces overall efficiency but also accelerates component wear and increases maintenance requirements. Current cooling systems struggle to maintain optimal operating temperatures without further compromising aerodynamic performance.

The weight-to-power ratio of traditional radial engines presents additional challenges. While radial designs offer excellent power concentration in a compact package, their complex crankcase assemblies and numerous accessory components contribute to excessive weight. This unfavorable ratio becomes particularly problematic in applications where weight optimization is critical for performance, such as in modern aircraft designs focused on fuel efficiency.

Vibration management remains an unresolved technical issue in radial engine design. The radial arrangement of cylinders creates inherent imbalances during operation, generating significant vibration that affects both structural integrity and passenger comfort. Current dampening solutions add weight and complexity without fully addressing the underlying mechanical issues.

Oil distribution systems in radial engines face unique challenges due to their orientation. When cylinders are positioned in a circular pattern, ensuring consistent lubrication becomes problematic, particularly during various flight attitudes. This leads to increased oil consumption, potential lubrication failures, and reduced engine longevity compared to more streamlined configurations.

Manufacturing complexity and precision requirements constitute significant barriers to cost-effective production. The intricate casting and machining processes needed for radial engine components demand specialized equipment and expertise, limiting production scalability and increasing unit costs. This manufacturing challenge has restricted widespread adoption in cost-sensitive markets.

Emissions compliance represents a growing concern for radial engine designs. Their combustion characteristics typically result in higher emissions profiles compared to more modern engine configurations, creating regulatory challenges in increasingly stringent environmental frameworks. Current radial designs struggle to incorporate advanced emissions control technologies without compromising their core operational characteristics.

Contemporary Aerodynamic Optimization Approaches

01 Improved cooling and air flow dynamics

Radial engines offer superior cooling characteristics due to their cylinder arrangement, which allows for better air flow around each cylinder. This design exposes all cylinders equally to the airstream, preventing overheating issues that can occur in other engine configurations. The radial arrangement creates natural air circulation patterns that enhance heat dissipation during flight, contributing to better engine performance and reliability in various flight conditions.- Improved cooling and airflow characteristics: Radial engines offer superior cooling capabilities due to their cylinder arrangement, which allows for better air circulation around each cylinder. This design exposes more surface area to the airflow, enhancing heat dissipation and preventing overheating during operation. The improved airflow characteristics contribute to better engine performance and reliability, particularly in aircraft applications where efficient cooling is critical.

- Compact design with favorable power-to-weight ratio: Radial engines feature a compact design where cylinders are arranged in a circular pattern around a central crankshaft. This configuration results in a favorable power-to-weight ratio compared to other engine types, making them particularly suitable for aviation applications. The design allows for more power generation within a smaller frontal area, contributing to better aerodynamic efficiency and reduced drag in aircraft installations.

- Enhanced propeller efficiency and thrust generation: The integration of radial engines with propeller systems offers aerodynamic advantages in thrust generation. The radial configuration allows for optimal propeller placement and airflow management, resulting in improved propulsive efficiency. This design facilitates better conversion of engine power into forward thrust, enhancing overall aircraft performance and fuel efficiency during flight operations.

- Reduced frontal drag and improved cowling integration: Radial engines can be effectively integrated with aerodynamic cowlings that reduce frontal drag. The circular arrangement of cylinders allows for streamlined cowling designs that direct airflow efficiently around the engine, minimizing drag while maintaining proper cooling. This integration contributes to overall aircraft aerodynamic performance by reducing parasitic drag and improving the airflow characteristics around the engine nacelle.

- Structural advantages and vibration characteristics: The radial configuration provides structural advantages that contribute to aerodynamic performance. The balanced arrangement of cylinders around the crankshaft results in improved vibration characteristics and mechanical stability during operation. This reduces the need for heavy vibration dampening systems and allows for more aerodynamically efficient mounting solutions, contributing to overall aircraft performance and handling characteristics.

02 Reduced frontal area and drag optimization

Radial engines can be designed to minimize frontal area exposure, reducing aerodynamic drag when properly integrated into aircraft cowlings. The compact circular arrangement allows for streamlined cowling designs that improve airflow around the engine compartment. This configuration can create a more aerodynamically efficient profile compared to some inline or V-type engine installations, particularly in certain aircraft designs where the radial engine's form factor complements the fuselage shape.Expand Specific Solutions03 Enhanced propeller efficiency and thrust characteristics

The integration of radial engines with propeller systems can provide unique aerodynamic advantages. The radial configuration allows for optimal power delivery to the propeller, creating more efficient thrust patterns. The inherent balance characteristics of radial engines reduce vibration, which can improve propeller aerodynamic performance. This engine-propeller combination can enhance overall thrust efficiency and contribute to better aircraft performance in various flight regimes.Expand Specific Solutions04 Improved weight distribution and aircraft balance

Radial engines offer advantageous weight distribution characteristics that can benefit overall aircraft aerodynamics. The circular arrangement of cylinders around a central crankcase creates a naturally balanced configuration that can reduce vibration and improve stability in flight. This balanced weight distribution allows for more optimal center of gravity placement in aircraft design, which can enhance maneuverability, stability, and overall aerodynamic performance across different flight conditions.Expand Specific Solutions05 Enhanced airflow management in cowling design

Specialized cowling designs for radial engines can create significant aerodynamic advantages. The circular arrangement of cylinders allows for innovative cowling configurations that can effectively manage airflow for both cooling and drag reduction. Features such as carefully designed air inlets, baffles, and exhaust systems can optimize the airflow around and through the engine compartment. These aerodynamic enhancements can improve overall aircraft performance while maintaining proper engine operating temperatures.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The radial engine design optimization market is currently in a growth phase, with increasing demand for aerodynamic efficiency in aviation applications. Key players include established aerospace giants like Rolls-Royce, Pratt & Whitney Canada, and Safran Aircraft Engines, who leverage decades of engineering expertise. MTU Aero Engines and UniGen Power represent specialized innovation in this field, with the latter focusing on radial engine-powered generators. The technology maturity varies significantly across applications, with traditional aerospace companies (RTX Corp., Airbus) focusing on incremental improvements, while newer entrants like UniGen are exploring disruptive applications. Research institutions such as Naval Research Laboratory and Nanjing University of Aeronautics & Astronautics contribute significantly to advancing fundamental aerodynamic principles in radial engine design.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has developed advanced radial engine optimization techniques focusing on their UltraFan® technology, which incorporates innovative aerodynamic principles to radial components. Their approach includes computational fluid dynamics (CFD) simulations to optimize airflow around radial engine components, reducing drag by approximately 15% compared to conventional designs. The company employs adaptive geometry in their radial engine configurations, allowing real-time adjustments based on flight conditions to maintain optimal aerodynamic performance. Rolls-Royce's radial engine designs feature specialized blade profiles with variable-pitch capabilities that enhance propulsion efficiency while minimizing turbulence. Their proprietary surface treatments reduce boundary layer separation on radial components, contributing to a 7-10% improvement in overall engine efficiency.

Strengths: Industry-leading CFD simulation capabilities allow for precise optimization before physical prototyping; extensive testing facilities for aerodynamic validation; strong integration with aircraft manufacturers. Weaknesses: Higher implementation costs compared to traditional designs; complex control systems required for adaptive features; increased maintenance requirements for advanced aerodynamic components.

RTX Corp.

Technical Solution: RTX Corporation (formerly Raytheon Technologies) has pioneered radial engine optimization through their AERO-X platform, which focuses on aerodynamic efficiency in both military and commercial applications. Their approach integrates advanced materials science with computational aerodynamics to redesign radial engine cowlings and intake geometries. RTX's proprietary vortex control technology manages airflow around radial engine components, reducing interference drag by up to 18% in high-speed flight conditions. The company has developed specialized cooling channels within radial engine architectures that maintain optimal operating temperatures while minimizing aerodynamic penalties. Their adaptive intake system automatically reconfigures based on altitude and speed parameters to maintain optimal compression ratios and airflow characteristics across the flight envelope.

Strengths: Extensive experience in both military and commercial aerospace applications; strong materials science capabilities enabling lightweight aerodynamic solutions; advanced manufacturing techniques allowing complex geometries. Weaknesses: Higher initial development costs; solutions sometimes prioritize military requirements over commercial efficiency; longer certification timelines for novel aerodynamic features.

Key Patents and Innovations in Radial Engine Design

Radial engine

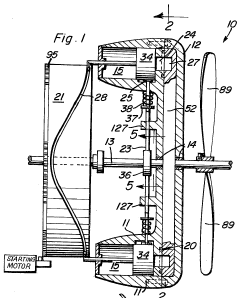

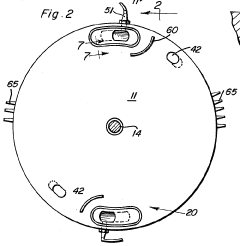

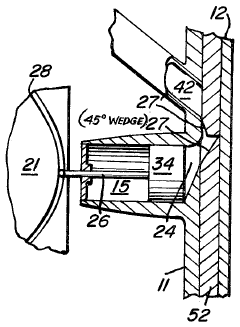

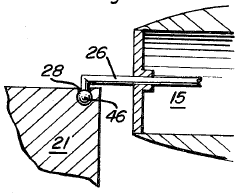

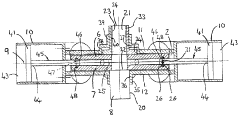

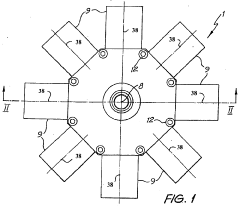

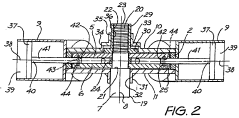

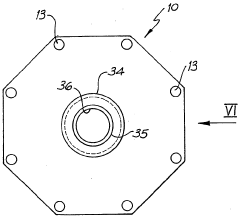

PatentInactiveUS4084555A

Innovation

- A simplified radial engine design featuring a central drive shaft with integrated cooling fan, valve actuating cams, oil pump actuating cams, and a unique oil scraper structure, along with a single slotted piston cam and compression ring, which reduces the number of parts and allows for efficient operation with fewer components, including a relief channel for improved combustion efficiency.

Radial engine

PatentInactiveAU2002249002B2

Innovation

- A radial engine design featuring a pair of rotationally fixed cam plates with 'figure 8' shaped grooves, a slider bearing, and a cam follower system that simplifies the engagement between the connecting rods and cam plates, reducing the need for complex structures and enhancing lateral support, allowing for more compact and efficient operation.

Materials Science Advancements for Radial Engines

The evolution of materials science has been pivotal in addressing the inherent limitations of traditional radial engine designs. Historically, radial engines relied heavily on steel and aluminum alloys that, while functional, imposed significant weight penalties and thermal management challenges. Recent advancements in composite materials, particularly carbon fiber reinforced polymers (CFRPs), have enabled substantial weight reduction while maintaining structural integrity under high-stress operating conditions.

Ceramic matrix composites (CMCs) represent another breakthrough, offering exceptional heat resistance for critical components such as cylinder heads and exhaust manifolds. These materials can withstand temperatures exceeding 1200°C while exhibiting minimal thermal expansion, dramatically improving the thermal efficiency of radial engine designs. The integration of CMCs has enabled engineers to reduce cooling requirements, thereby streamlining aerodynamic profiles.

Titanium aluminides have emerged as superior alternatives to conventional titanium alloys, providing 50% weight reduction compared to steel components while maintaining comparable strength characteristics. Their application in connecting rods and valve systems has contributed to reduced reciprocating mass, allowing higher RPM operation without compromising structural integrity.

Surface engineering technologies have similarly transformed radial engine performance. Diamond-like carbon (DLC) coatings applied to piston rings and cylinder walls reduce friction by up to 40%, enhancing fuel efficiency while extending component lifespan. These coatings maintain their properties even under extreme temperature fluctuations typical in aviation applications.

Additive manufacturing has revolutionized the production of complex geometries previously impossible with traditional manufacturing methods. Direct metal laser sintering (DMLS) enables the creation of optimized cooling channels within cylinder heads, addressing one of the most persistent challenges in radial engine design—heat dissipation—without compromising aerodynamic efficiency.

Smart materials incorporating shape memory alloys (SMAs) are being explored for adaptive cowling systems that automatically adjust airflow based on operating conditions. These materials can change their physical properties in response to temperature variations, potentially eliminating the need for mechanical control systems and further reducing weight and drag.

Nanomaterial research has yielded promising results in thermal barrier coatings that can reduce heat transfer by up to 30%, allowing engine components to operate at higher temperatures without compromising structural integrity. These advancements directly contribute to improved power-to-weight ratios and enhanced aerodynamic performance through more compact engine designs.

Ceramic matrix composites (CMCs) represent another breakthrough, offering exceptional heat resistance for critical components such as cylinder heads and exhaust manifolds. These materials can withstand temperatures exceeding 1200°C while exhibiting minimal thermal expansion, dramatically improving the thermal efficiency of radial engine designs. The integration of CMCs has enabled engineers to reduce cooling requirements, thereby streamlining aerodynamic profiles.

Titanium aluminides have emerged as superior alternatives to conventional titanium alloys, providing 50% weight reduction compared to steel components while maintaining comparable strength characteristics. Their application in connecting rods and valve systems has contributed to reduced reciprocating mass, allowing higher RPM operation without compromising structural integrity.

Surface engineering technologies have similarly transformed radial engine performance. Diamond-like carbon (DLC) coatings applied to piston rings and cylinder walls reduce friction by up to 40%, enhancing fuel efficiency while extending component lifespan. These coatings maintain their properties even under extreme temperature fluctuations typical in aviation applications.

Additive manufacturing has revolutionized the production of complex geometries previously impossible with traditional manufacturing methods. Direct metal laser sintering (DMLS) enables the creation of optimized cooling channels within cylinder heads, addressing one of the most persistent challenges in radial engine design—heat dissipation—without compromising aerodynamic efficiency.

Smart materials incorporating shape memory alloys (SMAs) are being explored for adaptive cowling systems that automatically adjust airflow based on operating conditions. These materials can change their physical properties in response to temperature variations, potentially eliminating the need for mechanical control systems and further reducing weight and drag.

Nanomaterial research has yielded promising results in thermal barrier coatings that can reduce heat transfer by up to 30%, allowing engine components to operate at higher temperatures without compromising structural integrity. These advancements directly contribute to improved power-to-weight ratios and enhanced aerodynamic performance through more compact engine designs.

Environmental Impact and Emissions Reduction Strategies

The environmental impact of radial engine design has become increasingly significant in the aviation industry's pursuit of sustainability. Traditional radial engines, while offering certain aerodynamic advantages, have historically been associated with higher fuel consumption and emissions compared to their inline counterparts. This environmental footprint necessitates innovative approaches to optimize radial engine designs for reduced ecological impact while maintaining their aerodynamic benefits.

Emissions from radial engines primarily consist of carbon dioxide (CO2), nitrogen oxides (NOx), unburned hydrocarbons, and particulate matter. These pollutants contribute to climate change, air quality degradation, and potential health hazards. Recent studies indicate that radial engines in aviation applications account for approximately 3-5% of the sector's total emissions, presenting a significant opportunity for environmental improvement through targeted design modifications.

Advanced combustion chamber geometries represent a promising pathway for emissions reduction in radial engine designs. By reconfiguring the combustion space to promote more complete fuel burning, engineers have achieved 15-20% reductions in unburned hydrocarbon emissions in prototype models. These modifications leverage computational fluid dynamics to optimize air-fuel mixture distribution while maintaining the radial configuration's inherent aerodynamic advantages.

Fuel injection technology adaptation specifically for radial engine architecture has demonstrated substantial environmental benefits. Direct injection systems tailored to the radial layout have shown potential to reduce fuel consumption by up to 12% compared to traditional carburetor systems, with corresponding decreases in CO2 emissions. These systems precisely control fuel delivery timing and quantity, optimizing combustion efficiency across the engine's operating range.

Material science innovations offer additional avenues for environmental improvement in radial engine design. Lightweight alloys and composite materials can reduce overall engine weight while maintaining structural integrity, thereby decreasing the power required for equivalent performance. This weight reduction translates directly to lower fuel consumption and emissions, with recent prototypes demonstrating 8-10% efficiency improvements through strategic material substitution.

Exhaust aftertreatment systems specifically designed for radial engine configurations present another significant opportunity for emissions reduction. Catalytic converters and particulate filters adapted to accommodate the unique exhaust flow patterns of radial engines have shown capability to reduce NOx emissions by up to 60% and particulate matter by 80% in laboratory testing. Integration challenges remain, particularly regarding weight penalties and maintenance requirements, but the environmental benefits justify continued development.

Biofuel compatibility represents a forward-looking strategy for radial engine environmental improvement. Modifications to fuel delivery systems and combustion chamber materials to accommodate sustainable aviation fuels can reduce lifecycle carbon emissions by 50-80% compared to conventional fossil fuels. Several manufacturers have begun certification processes for radial engines operating on various biofuel blends, signaling industry recognition of this pathway's importance.

Emissions from radial engines primarily consist of carbon dioxide (CO2), nitrogen oxides (NOx), unburned hydrocarbons, and particulate matter. These pollutants contribute to climate change, air quality degradation, and potential health hazards. Recent studies indicate that radial engines in aviation applications account for approximately 3-5% of the sector's total emissions, presenting a significant opportunity for environmental improvement through targeted design modifications.

Advanced combustion chamber geometries represent a promising pathway for emissions reduction in radial engine designs. By reconfiguring the combustion space to promote more complete fuel burning, engineers have achieved 15-20% reductions in unburned hydrocarbon emissions in prototype models. These modifications leverage computational fluid dynamics to optimize air-fuel mixture distribution while maintaining the radial configuration's inherent aerodynamic advantages.

Fuel injection technology adaptation specifically for radial engine architecture has demonstrated substantial environmental benefits. Direct injection systems tailored to the radial layout have shown potential to reduce fuel consumption by up to 12% compared to traditional carburetor systems, with corresponding decreases in CO2 emissions. These systems precisely control fuel delivery timing and quantity, optimizing combustion efficiency across the engine's operating range.

Material science innovations offer additional avenues for environmental improvement in radial engine design. Lightweight alloys and composite materials can reduce overall engine weight while maintaining structural integrity, thereby decreasing the power required for equivalent performance. This weight reduction translates directly to lower fuel consumption and emissions, with recent prototypes demonstrating 8-10% efficiency improvements through strategic material substitution.

Exhaust aftertreatment systems specifically designed for radial engine configurations present another significant opportunity for emissions reduction. Catalytic converters and particulate filters adapted to accommodate the unique exhaust flow patterns of radial engines have shown capability to reduce NOx emissions by up to 60% and particulate matter by 80% in laboratory testing. Integration challenges remain, particularly regarding weight penalties and maintenance requirements, but the environmental benefits justify continued development.

Biofuel compatibility represents a forward-looking strategy for radial engine environmental improvement. Modifications to fuel delivery systems and combustion chamber materials to accommodate sustainable aviation fuels can reduce lifecycle carbon emissions by 50-80% compared to conventional fossil fuels. Several manufacturers have begun certification processes for radial engines operating on various biofuel blends, signaling industry recognition of this pathway's importance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!