Perspective on the risks and rewards of V16 engine innovation investments

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V16 Engine Evolution

The V16 engine, a marvel of automotive engineering, has undergone significant evolution since its inception in the early 20th century. Initially developed for luxury automobiles and high-performance racing cars, the V16 configuration represented the pinnacle of power and prestige in the automotive world.

The evolution of the V16 engine can be traced through several key phases. In the 1930s, Cadillac and Marmon introduced V16 engines in their flagship models, setting new standards for smoothness and power delivery. These early V16 engines were characterized by their massive displacement and relatively low rpm limits, focusing on torque production rather than high-end horsepower.

During World War II, V16 engines found applications in military vehicles and aircraft, pushing the boundaries of power-to-weight ratios and reliability under extreme conditions. This period saw significant advancements in metallurgy and manufacturing techniques, which would later benefit civilian applications.

The post-war era witnessed a decline in V16 engine development for road cars, as V8 and V12 configurations became more prevalent due to their balance of power and efficiency. However, the concept remained alive in motorsports, particularly in Formula 1 during the 1950s, where manufacturers experimented with V16 designs to maximize power output within regulatory constraints.

In recent decades, the V16 engine has experienced a renaissance in the ultra-luxury and hypercar segments. Modern V16 engines, such as those developed by Bugatti for the Veyron and Chiron, showcase the integration of advanced technologies like direct injection, variable valve timing, and turbocharging. These innovations have allowed V16 engines to achieve unprecedented levels of power and efficiency while meeting stringent emissions standards.

The latest evolution of V16 engines incorporates hybrid and electric technologies, blending traditional internal combustion with electric motors to create powertrains that offer both extreme performance and improved fuel economy. This hybridization represents a bridge between the heritage of high-cylinder count engines and the future of automotive propulsion.

Looking forward, the V16 engine faces challenges in an increasingly electrified automotive landscape. However, its legacy as an engineering masterpiece and symbol of automotive excellence ensures ongoing interest from enthusiasts and collectors. Future developments may focus on limited production runs, bespoke creations, and integration with cutting-edge sustainable technologies to maintain relevance in a changing industry.

The evolution of the V16 engine can be traced through several key phases. In the 1930s, Cadillac and Marmon introduced V16 engines in their flagship models, setting new standards for smoothness and power delivery. These early V16 engines were characterized by their massive displacement and relatively low rpm limits, focusing on torque production rather than high-end horsepower.

During World War II, V16 engines found applications in military vehicles and aircraft, pushing the boundaries of power-to-weight ratios and reliability under extreme conditions. This period saw significant advancements in metallurgy and manufacturing techniques, which would later benefit civilian applications.

The post-war era witnessed a decline in V16 engine development for road cars, as V8 and V12 configurations became more prevalent due to their balance of power and efficiency. However, the concept remained alive in motorsports, particularly in Formula 1 during the 1950s, where manufacturers experimented with V16 designs to maximize power output within regulatory constraints.

In recent decades, the V16 engine has experienced a renaissance in the ultra-luxury and hypercar segments. Modern V16 engines, such as those developed by Bugatti for the Veyron and Chiron, showcase the integration of advanced technologies like direct injection, variable valve timing, and turbocharging. These innovations have allowed V16 engines to achieve unprecedented levels of power and efficiency while meeting stringent emissions standards.

The latest evolution of V16 engines incorporates hybrid and electric technologies, blending traditional internal combustion with electric motors to create powertrains that offer both extreme performance and improved fuel economy. This hybridization represents a bridge between the heritage of high-cylinder count engines and the future of automotive propulsion.

Looking forward, the V16 engine faces challenges in an increasingly electrified automotive landscape. However, its legacy as an engineering masterpiece and symbol of automotive excellence ensures ongoing interest from enthusiasts and collectors. Future developments may focus on limited production runs, bespoke creations, and integration with cutting-edge sustainable technologies to maintain relevance in a changing industry.

Market Demand Analysis

The market demand for V16 engines has been steadily declining over the past decades, primarily due to shifting consumer preferences, stringent environmental regulations, and advancements in smaller, more efficient engine technologies. Historically, V16 engines were synonymous with luxury, power, and prestige, finding their place in high-end automobiles and marine applications. However, the current automotive landscape prioritizes fuel efficiency, reduced emissions, and cost-effectiveness, which has significantly impacted the demand for these large displacement engines.

In the luxury and ultra-luxury vehicle segments, where V16 engines once reigned supreme, there has been a noticeable shift towards smaller, turbocharged engines that offer comparable power outputs with improved fuel economy. This trend is driven by both consumer demand for more environmentally friendly options and increasingly strict emissions standards worldwide. As a result, many automakers have phased out their V16 offerings or limited them to extremely low-volume, specialized models.

The marine industry, another traditional stronghold for V16 engines, has also experienced changes in demand. While there remains a niche market for high-performance marine engines, particularly in the yacht and commercial shipping sectors, the overall trend leans towards more efficient and environmentally friendly propulsion systems. This includes the adoption of hybrid and electric powertrains, even in larger vessels.

Despite the general decline, there exists a small but passionate market segment that still values the unique characteristics of V16 engines. This niche primarily consists of collectors, enthusiasts, and ultra-luxury vehicle manufacturers who cater to clients seeking exclusivity and heritage. However, this market is extremely limited and does not provide sufficient volume to justify significant investment in V16 engine innovation for most manufacturers.

The future market potential for V16 engines appears constrained, with little indication of a resurgence in mainstream demand. Industry forecasts suggest that the global push towards electrification and stricter emissions regulations will further diminish the viability of large displacement engines. This trend is evident across various markets, including Europe, North America, and Asia, where governments are implementing policies to phase out internal combustion engines in favor of electric and other alternative powertrains.

Given these market dynamics, any investment in V16 engine innovation must be carefully considered. The potential rewards are likely to be limited to highly specialized applications or as part of a brand's heritage preservation efforts. The risks, on the other hand, are substantial, including high development costs, limited market acceptance, and potential regulatory challenges. Manufacturers considering such investments should thoroughly assess the long-term viability and potential return on investment, given the shrinking market and evolving industry landscape.

In the luxury and ultra-luxury vehicle segments, where V16 engines once reigned supreme, there has been a noticeable shift towards smaller, turbocharged engines that offer comparable power outputs with improved fuel economy. This trend is driven by both consumer demand for more environmentally friendly options and increasingly strict emissions standards worldwide. As a result, many automakers have phased out their V16 offerings or limited them to extremely low-volume, specialized models.

The marine industry, another traditional stronghold for V16 engines, has also experienced changes in demand. While there remains a niche market for high-performance marine engines, particularly in the yacht and commercial shipping sectors, the overall trend leans towards more efficient and environmentally friendly propulsion systems. This includes the adoption of hybrid and electric powertrains, even in larger vessels.

Despite the general decline, there exists a small but passionate market segment that still values the unique characteristics of V16 engines. This niche primarily consists of collectors, enthusiasts, and ultra-luxury vehicle manufacturers who cater to clients seeking exclusivity and heritage. However, this market is extremely limited and does not provide sufficient volume to justify significant investment in V16 engine innovation for most manufacturers.

The future market potential for V16 engines appears constrained, with little indication of a resurgence in mainstream demand. Industry forecasts suggest that the global push towards electrification and stricter emissions regulations will further diminish the viability of large displacement engines. This trend is evident across various markets, including Europe, North America, and Asia, where governments are implementing policies to phase out internal combustion engines in favor of electric and other alternative powertrains.

Given these market dynamics, any investment in V16 engine innovation must be carefully considered. The potential rewards are likely to be limited to highly specialized applications or as part of a brand's heritage preservation efforts. The risks, on the other hand, are substantial, including high development costs, limited market acceptance, and potential regulatory challenges. Manufacturers considering such investments should thoroughly assess the long-term viability and potential return on investment, given the shrinking market and evolving industry landscape.

Technical Challenges

The development of V16 engines presents significant technical challenges that must be addressed to ensure their viability and competitiveness in the automotive market. One of the primary hurdles is the complexity of the engine design itself. With 16 cylinders, the engine requires intricate balancing and synchronization to operate smoothly, which demands advanced engineering solutions and precision manufacturing techniques.

Fuel efficiency is another major concern for V16 engines. The sheer size and power output of these engines typically result in high fuel consumption, which is at odds with increasingly stringent environmental regulations and consumer demand for more economical vehicles. Innovators must focus on developing technologies that can improve fuel economy without compromising the performance that is expected from a V16 engine.

Thermal management poses a substantial challenge due to the increased heat generation from 16 cylinders. Effective cooling systems must be designed to prevent overheating and ensure optimal performance, particularly under high-load conditions. This may require the development of new materials and cooling technologies capable of handling the extreme temperatures generated by these powerful engines.

Weight reduction is crucial for improving overall vehicle performance and efficiency. The inherent mass of a V16 engine necessitates innovative approaches to materials science and engine component design to minimize weight without sacrificing durability or performance. This may involve the use of advanced lightweight alloys or composite materials in engine construction.

Emissions control is a critical area that demands significant attention. With more cylinders and greater fuel consumption, V16 engines face challenges in meeting increasingly strict emissions standards. Developing effective exhaust after-treatment systems and exploring alternative fuel technologies compatible with V16 architectures are essential for future viability.

The integration of V16 engines with modern vehicle systems presents another set of challenges. Engineers must develop sophisticated engine management systems capable of optimizing performance, fuel efficiency, and emissions across a wide range of operating conditions. This includes the potential integration with hybrid or electric powertrains to meet future regulatory requirements.

Manufacturing complexity is a significant hurdle in V16 engine production. The increased number of components and tighter tolerances required for these engines demand highly advanced production techniques and quality control measures. This complexity can lead to higher production costs and potential reliability issues that must be addressed through innovative manufacturing processes and materials.

Fuel efficiency is another major concern for V16 engines. The sheer size and power output of these engines typically result in high fuel consumption, which is at odds with increasingly stringent environmental regulations and consumer demand for more economical vehicles. Innovators must focus on developing technologies that can improve fuel economy without compromising the performance that is expected from a V16 engine.

Thermal management poses a substantial challenge due to the increased heat generation from 16 cylinders. Effective cooling systems must be designed to prevent overheating and ensure optimal performance, particularly under high-load conditions. This may require the development of new materials and cooling technologies capable of handling the extreme temperatures generated by these powerful engines.

Weight reduction is crucial for improving overall vehicle performance and efficiency. The inherent mass of a V16 engine necessitates innovative approaches to materials science and engine component design to minimize weight without sacrificing durability or performance. This may involve the use of advanced lightweight alloys or composite materials in engine construction.

Emissions control is a critical area that demands significant attention. With more cylinders and greater fuel consumption, V16 engines face challenges in meeting increasingly strict emissions standards. Developing effective exhaust after-treatment systems and exploring alternative fuel technologies compatible with V16 architectures are essential for future viability.

The integration of V16 engines with modern vehicle systems presents another set of challenges. Engineers must develop sophisticated engine management systems capable of optimizing performance, fuel efficiency, and emissions across a wide range of operating conditions. This includes the potential integration with hybrid or electric powertrains to meet future regulatory requirements.

Manufacturing complexity is a significant hurdle in V16 engine production. The increased number of components and tighter tolerances required for these engines demand highly advanced production techniques and quality control measures. This complexity can lead to higher production costs and potential reliability issues that must be addressed through innovative manufacturing processes and materials.

Current V16 Solutions

01 V16 engine design and configuration

V16 engines are characterized by their unique configuration of 16 cylinders arranged in a V-shape. This design allows for high power output while maintaining a relatively compact size. The V16 layout is often used in high-performance and luxury vehicles, as well as in some marine and industrial applications.- V16 engine design and configuration: V16 engines are characterized by their unique configuration of 16 cylinders arranged in a V-shape. This design allows for high power output while maintaining a relatively compact size. The V16 layout is often used in high-performance and luxury vehicles, as well as in some marine and industrial applications.

- V16 engine components and accessories: Various components and accessories are specifically designed for V16 engines, including engine blocks, crankshafts, pistons, and valve systems. These specialized parts are engineered to withstand the high power output and unique configuration of V16 engines, ensuring optimal performance and durability.

- V16 engine control systems: Advanced control systems are employed in V16 engines to manage fuel injection, ignition timing, and other critical parameters. These systems often incorporate sophisticated electronic controls and sensors to optimize engine performance, fuel efficiency, and emissions across various operating conditions.

- V16 engine applications in vehicles: V16 engines are utilized in a variety of vehicle applications, particularly in high-end luxury cars, supercars, and specialized racing vehicles. The implementation of V16 engines in these vehicles often requires custom design considerations for integration with the vehicle's chassis, cooling systems, and drivetrain components.

- V16 engine sound and acoustics: The unique configuration of V16 engines produces a distinctive sound profile. Acoustic engineering is often employed to enhance or modify the engine sound for desired characteristics, particularly in luxury and performance vehicles. This may involve the design of specialized exhaust systems and sound management technologies.

02 V16 engine components and accessories

Various components and accessories are specifically designed for V16 engines to enhance their performance and functionality. These may include specialized intake and exhaust systems, cooling systems, and electronic control units tailored to the unique requirements of a V16 configuration.Expand Specific Solutions03 V16 engine applications in vehicles

V16 engines are often utilized in high-end luxury vehicles and supercars, providing exceptional power and prestige. The integration of V16 engines into vehicle designs requires careful consideration of weight distribution, cooling, and overall vehicle dynamics to maximize performance and efficiency.Expand Specific Solutions04 V16 engine control systems and technologies

Advanced control systems and technologies are employed in V16 engines to optimize performance, fuel efficiency, and emissions. These may include electronic fuel injection, variable valve timing, and sophisticated engine management systems tailored to the unique characteristics of a V16 configuration.Expand Specific Solutions05 V16 engine aesthetics and visual design

The visual design of V16 engines often emphasizes their power and complexity. Engine covers, intake manifolds, and other visible components may be styled to showcase the engine's impressive configuration. This attention to aesthetics extends to the overall vehicle design, highlighting the presence of a V16 powerplant.Expand Specific Solutions

Key Industry Players

The V16 engine innovation landscape is characterized by a mature market with limited growth potential, primarily due to environmental concerns and shifting automotive trends. Major players like Toyota, Ford, and BMW are focusing on more sustainable technologies, while niche manufacturers such as Astron Aerospace explore specialized applications. The market size for V16 engines is relatively small, with most investments directed towards improving efficiency and reducing emissions rather than expanding production. Technologically, V16 engines are well-established, but ongoing research by companies like AVL List GmbH and Delphi Technology aims to enhance performance and compatibility with alternative fuels, balancing the risks of investment against potential rewards in high-end and specialized markets.

Toyota Motor Corp.

Technical Solution: Toyota's approach to V16 engine innovation is cautious but forward-thinking. While not actively pursuing V16 engines for production vehicles, Toyota is researching large-displacement engine technologies that could be applied to V16 configurations. Their focus is on improving thermal efficiency and reducing friction losses in multi-cylinder engines[8]. Toyota is also exploring the integration of hydrogen combustion technology in large engines, which could potentially make V16 engines more environmentally friendly[9]. Additionally, they are developing advanced manufacturing techniques to reduce the cost and complexity of producing large, multi-cylinder engines.

Strengths: Potential for technological breakthroughs applicable to various engine configurations, not limited to V16. Weaknesses: Limited direct investment in V16 technology, focusing more on broader engine innovations.

GM Global Technology Operations LLC

Technical Solution: GM's approach to V16 engine innovation focuses on integrating advanced materials and precision engineering. Their research includes the use of 3D-printed components to reduce weight and improve thermal efficiency[2]. GM is also exploring hybrid V16 configurations, combining electric motors with the V16 engine to boost performance while meeting stringent emissions standards[4]. The company's V16 concept incorporates active aerodynamics and advanced cooling systems to manage the heat generated by such a large powerplant.

Strengths: Potential for unparalleled power in large luxury vehicles and specialized applications. Weaknesses: Extremely high development costs, limited market potential, and challenges in meeting future emissions regulations.

Core V16 Innovations

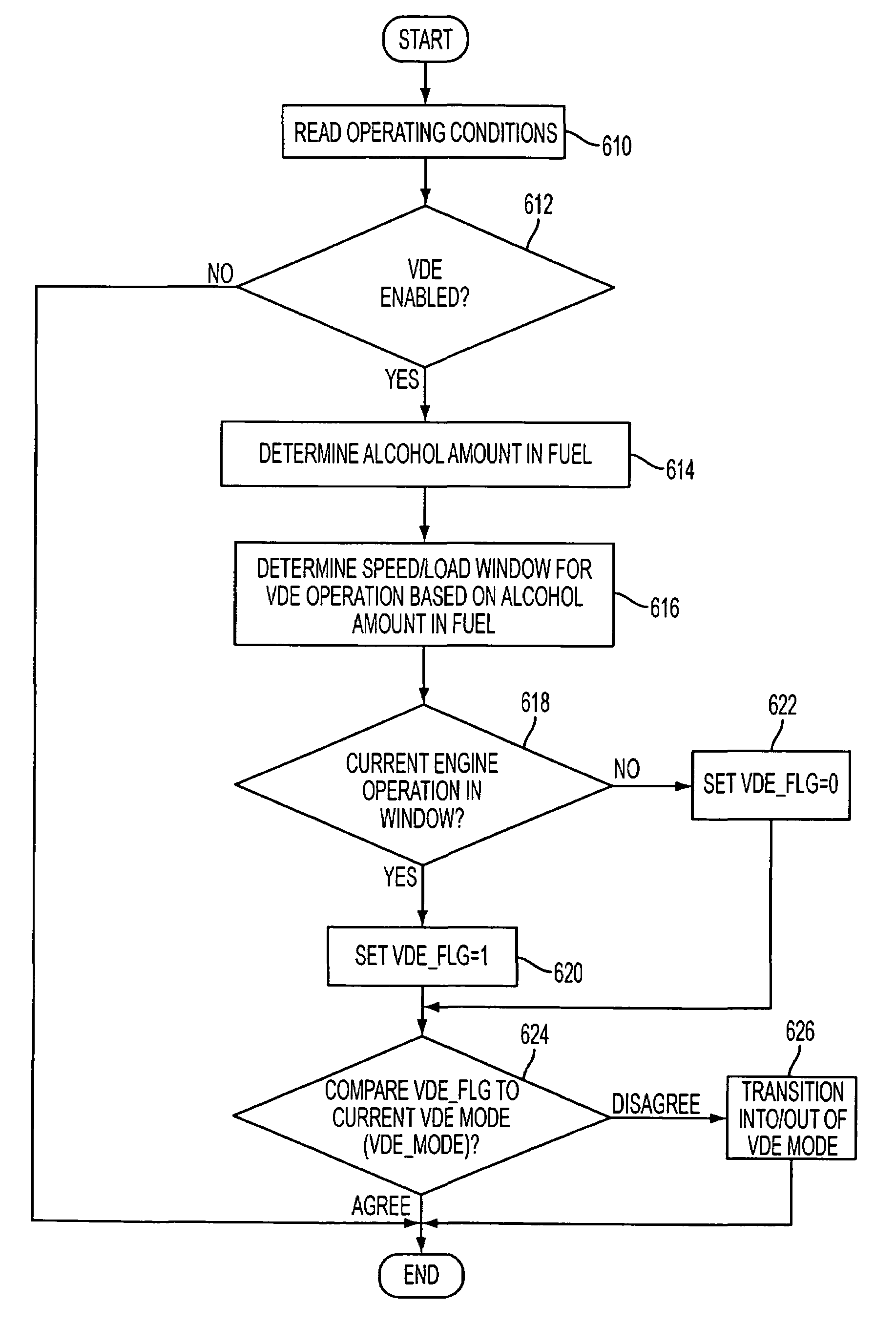

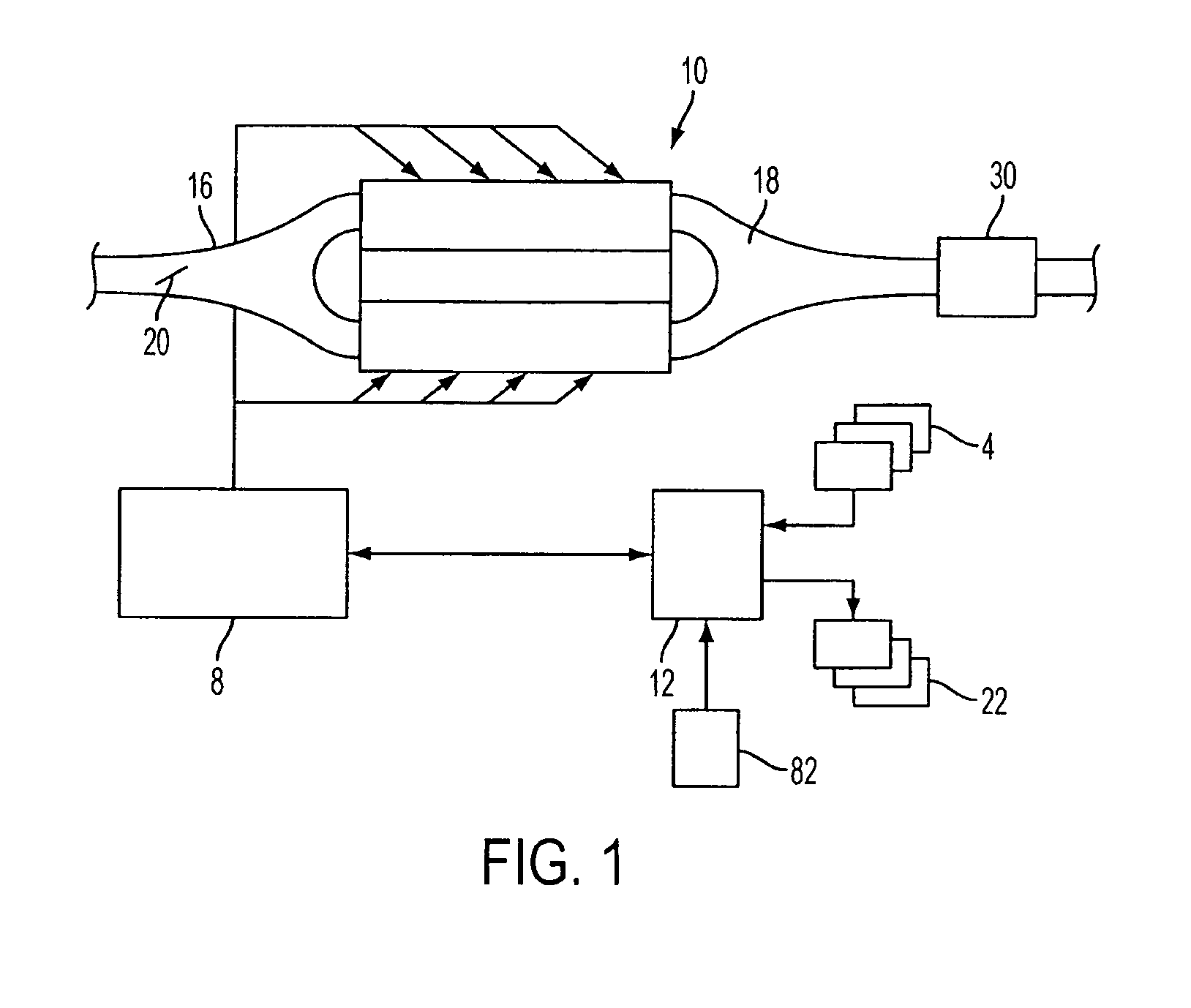

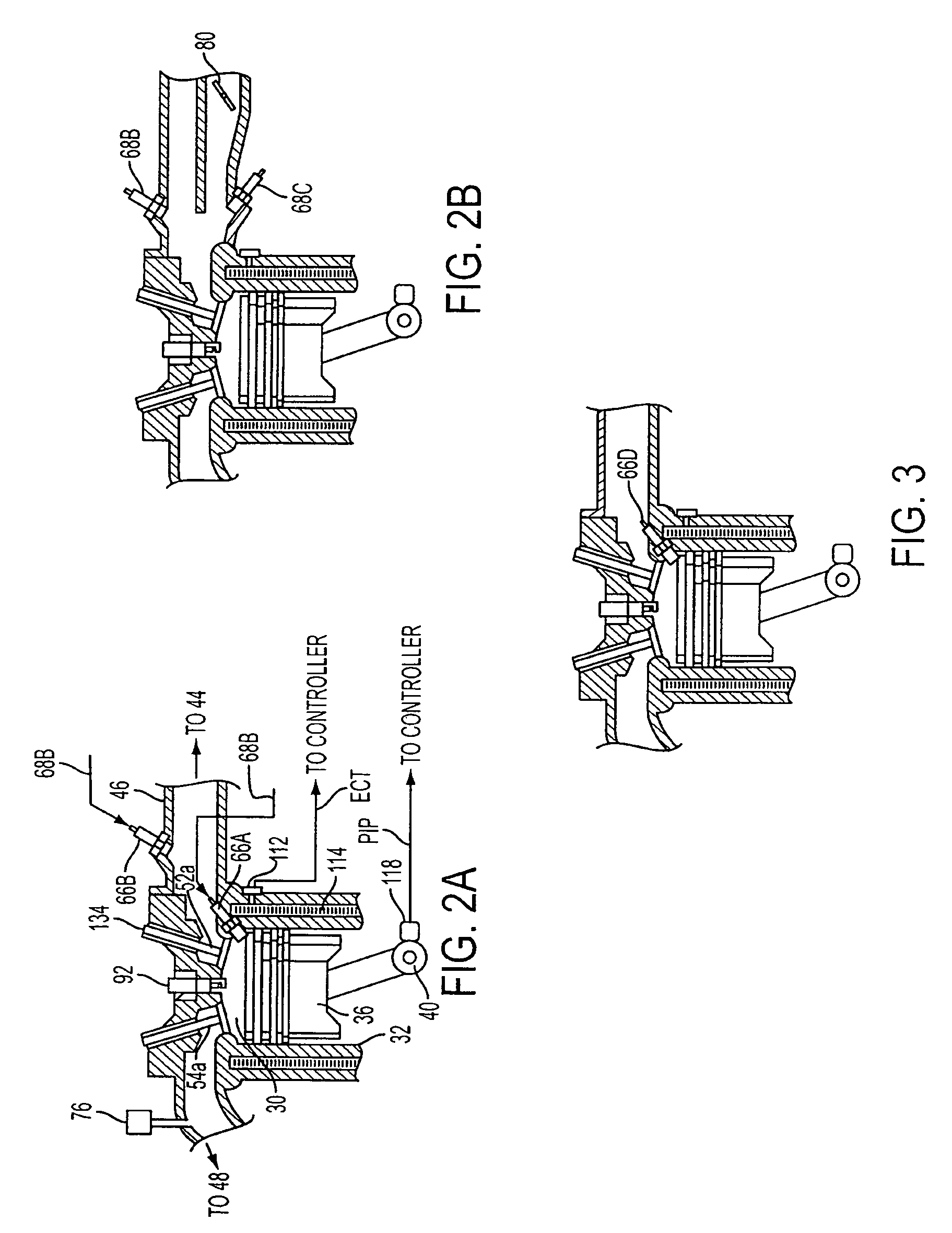

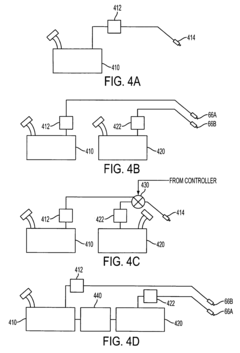

Flex-fuel variable displacement engine control system and method

PatentInactiveUS7549408B2

Innovation

- A flex-fuel variable cylinder combustion engine system that adjusts VDE operation to leverage the knock-abatement properties of alcohol-blended fuels, using direct injection and port injection with open valve injection to exploit charge cooling characteristics, and dynamically adjusts fuel blends to extend VDE operating conditions.

Economic Feasibility

The economic feasibility of V16 engine innovation investments is a complex consideration that requires careful analysis of both potential rewards and associated risks. From a financial perspective, the development and production of V16 engines represent a significant capital investment. The costs involved include research and development, tooling, manufacturing equipment, and skilled labor. These upfront expenses can be substantial and may take years to recoup through sales and revenue generation.

Market demand is a crucial factor in determining the economic viability of V16 engine innovations. Historically, V16 engines have been limited to niche markets, primarily in luxury and high-performance vehicles. The potential customer base is relatively small, which can impact the overall return on investment. However, if successfully marketed, V16 engines can command premium prices, potentially offsetting the high development and production costs.

Fuel efficiency and environmental regulations pose significant challenges to the economic feasibility of V16 engines. As global emissions standards become increasingly stringent, the cost of compliance for large displacement engines rises. This may necessitate additional investments in technologies such as hybrid systems or advanced fuel management, further increasing the overall cost of V16 engine development.

On the other hand, V16 engines offer unique selling propositions that can justify their economic pursuit. The prestige and exclusivity associated with V16 power plants can enhance brand image and create halo effects for automotive manufacturers. This can lead to increased sales across product lines and potentially higher profit margins on other models.

The longevity of V16 engine technology investments must also be considered. While the initial costs are high, the knowledge and expertise gained from developing these complex powertrains can be applied to other engine configurations and technologies. This transfer of knowledge can provide long-term economic benefits beyond the direct sales of V16 engines.

Ultimately, the economic feasibility of V16 engine innovation investments depends on a company's overall strategy, market positioning, and financial capabilities. For niche manufacturers focusing on ultra-luxury or high-performance segments, the investment may be justified by brand differentiation and premium pricing. For mainstream manufacturers, the economic risks may outweigh the potential rewards unless there are clear pathways to technology transfer or market expansion.

Market demand is a crucial factor in determining the economic viability of V16 engine innovations. Historically, V16 engines have been limited to niche markets, primarily in luxury and high-performance vehicles. The potential customer base is relatively small, which can impact the overall return on investment. However, if successfully marketed, V16 engines can command premium prices, potentially offsetting the high development and production costs.

Fuel efficiency and environmental regulations pose significant challenges to the economic feasibility of V16 engines. As global emissions standards become increasingly stringent, the cost of compliance for large displacement engines rises. This may necessitate additional investments in technologies such as hybrid systems or advanced fuel management, further increasing the overall cost of V16 engine development.

On the other hand, V16 engines offer unique selling propositions that can justify their economic pursuit. The prestige and exclusivity associated with V16 power plants can enhance brand image and create halo effects for automotive manufacturers. This can lead to increased sales across product lines and potentially higher profit margins on other models.

The longevity of V16 engine technology investments must also be considered. While the initial costs are high, the knowledge and expertise gained from developing these complex powertrains can be applied to other engine configurations and technologies. This transfer of knowledge can provide long-term economic benefits beyond the direct sales of V16 engines.

Ultimately, the economic feasibility of V16 engine innovation investments depends on a company's overall strategy, market positioning, and financial capabilities. For niche manufacturers focusing on ultra-luxury or high-performance segments, the investment may be justified by brand differentiation and premium pricing. For mainstream manufacturers, the economic risks may outweigh the potential rewards unless there are clear pathways to technology transfer or market expansion.

Environmental Impact

The environmental impact of V16 engine innovation investments is a critical consideration in today's automotive landscape. These large, powerful engines have traditionally been associated with high fuel consumption and significant emissions, posing challenges in an era of increasing environmental awareness and stringent regulations.

V16 engines, known for their impressive power output and smooth operation, have historically been used in luxury and high-performance vehicles. However, their environmental footprint has been substantial, with carbon dioxide emissions often exceeding those of smaller engines. This has led to a decline in their popularity and production in recent years, as automakers focus on more fuel-efficient and environmentally friendly alternatives.

Despite these challenges, investments in V16 engine innovation could potentially yield environmental benefits. Advanced technologies such as direct injection, variable valve timing, and cylinder deactivation can significantly improve fuel efficiency and reduce emissions. Furthermore, the integration of hybrid or electric systems with V16 engines could create a unique powertrain that combines high performance with improved environmental credentials.

Research into alternative fuels compatible with V16 engines, such as synthetic fuels or hydrogen, could also mitigate their environmental impact. These innovations might allow V16 engines to meet increasingly strict emissions standards while maintaining their distinctive characteristics.

However, the environmental rewards of V16 engine innovation must be weighed against the risks. The development costs for these technologies are substantial, and there is no guarantee that they will result in a commercially viable or environmentally competitive product. Moreover, the global shift towards electric vehicles and the phasing out of internal combustion engines in many markets could limit the long-term viability of V16 engines, regardless of technological advancements.

The environmental impact of V16 engine innovation investments extends beyond emissions and fuel consumption. The production process, including the sourcing of materials and manufacturing techniques, also contributes to the overall environmental footprint. Innovations in these areas, such as the use of recycled materials or more efficient production methods, could further improve the environmental profile of V16 engines.

In conclusion, while V16 engine innovation investments face significant environmental challenges, they also present opportunities for technological advancements that could reduce their ecological impact. The success of these investments will largely depend on their ability to align with global environmental goals and regulations, as well as shifting consumer preferences towards more sustainable transportation options.

V16 engines, known for their impressive power output and smooth operation, have historically been used in luxury and high-performance vehicles. However, their environmental footprint has been substantial, with carbon dioxide emissions often exceeding those of smaller engines. This has led to a decline in their popularity and production in recent years, as automakers focus on more fuel-efficient and environmentally friendly alternatives.

Despite these challenges, investments in V16 engine innovation could potentially yield environmental benefits. Advanced technologies such as direct injection, variable valve timing, and cylinder deactivation can significantly improve fuel efficiency and reduce emissions. Furthermore, the integration of hybrid or electric systems with V16 engines could create a unique powertrain that combines high performance with improved environmental credentials.

Research into alternative fuels compatible with V16 engines, such as synthetic fuels or hydrogen, could also mitigate their environmental impact. These innovations might allow V16 engines to meet increasingly strict emissions standards while maintaining their distinctive characteristics.

However, the environmental rewards of V16 engine innovation must be weighed against the risks. The development costs for these technologies are substantial, and there is no guarantee that they will result in a commercially viable or environmentally competitive product. Moreover, the global shift towards electric vehicles and the phasing out of internal combustion engines in many markets could limit the long-term viability of V16 engines, regardless of technological advancements.

The environmental impact of V16 engine innovation investments extends beyond emissions and fuel consumption. The production process, including the sourcing of materials and manufacturing techniques, also contributes to the overall environmental footprint. Innovations in these areas, such as the use of recycled materials or more efficient production methods, could further improve the environmental profile of V16 engines.

In conclusion, while V16 engine innovation investments face significant environmental challenges, they also present opportunities for technological advancements that could reduce their ecological impact. The success of these investments will largely depend on their ability to align with global environmental goals and regulations, as well as shifting consumer preferences towards more sustainable transportation options.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!