Radial Engine Cooling System Efficiency: Evaluation Methods

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Radial Engine Cooling Evolution and Objectives

Radial engines, first developed in the early 1900s, represented a significant advancement in aircraft propulsion technology. These engines featured cylinders arranged radially around a central crankshaft, offering advantages in power-to-weight ratio and reliability compared to inline configurations. The cooling systems for these engines evolved substantially throughout the 20th century, beginning with simple air cooling methods that relied on the natural airflow during flight to dissipate heat from the cylinder fins.

By the 1920s and 1930s, as aircraft performance demands increased, more sophisticated cooling approaches emerged. Engine manufacturers like Pratt & Whitney and Wright Aeronautical developed enhanced fin designs and cowling systems that improved airflow management around the cylinders. The NACA cowling, introduced in 1929, represented a breakthrough by channeling air more efficiently across the engine while reducing drag, significantly improving both cooling efficiency and aircraft performance.

During World War II, radial engine cooling technology accelerated rapidly due to military requirements. Innovations included pressurized baffling systems that forced air to flow through specific paths around the cylinders rather than bypassing them. Additionally, oil cooling systems became more sophisticated, serving as secondary heat exchange mechanisms to complement air cooling.

The post-war era saw further refinements with the introduction of computational fluid dynamics in the 1970s and 1980s, allowing engineers to model airflow patterns and thermal behaviors with unprecedented precision. This led to optimized cowling designs and cooling fin configurations that maximized heat dissipation while minimizing aerodynamic penalties.

Today, while turbine engines have largely replaced radials in mainstream aviation, radial engines continue to serve in specialized applications such as vintage aircraft restoration, aerobatic planes, and certain industrial applications. Modern cooling system objectives focus on balancing multiple factors: maintaining optimal operating temperatures across all cylinders, minimizing cooling drag, ensuring reliability under various operating conditions, and meeting increasingly stringent emissions requirements.

The primary technical goal in contemporary radial engine cooling system design is to achieve uniform temperature distribution across all cylinders—a persistent challenge given the inherently uneven airflow patterns around radially arranged cylinders. Secondary objectives include developing evaluation methodologies that can accurately predict cooling performance under diverse operating conditions, from ground operations to high-altitude flight regimes.

Looking forward, emerging objectives include adapting historical cooling technologies to accommodate modern fuels with different combustion characteristics, integrating digital monitoring systems for real-time temperature management, and developing hybrid cooling approaches that combine traditional air cooling with auxiliary liquid cooling circuits for critical engine components.

By the 1920s and 1930s, as aircraft performance demands increased, more sophisticated cooling approaches emerged. Engine manufacturers like Pratt & Whitney and Wright Aeronautical developed enhanced fin designs and cowling systems that improved airflow management around the cylinders. The NACA cowling, introduced in 1929, represented a breakthrough by channeling air more efficiently across the engine while reducing drag, significantly improving both cooling efficiency and aircraft performance.

During World War II, radial engine cooling technology accelerated rapidly due to military requirements. Innovations included pressurized baffling systems that forced air to flow through specific paths around the cylinders rather than bypassing them. Additionally, oil cooling systems became more sophisticated, serving as secondary heat exchange mechanisms to complement air cooling.

The post-war era saw further refinements with the introduction of computational fluid dynamics in the 1970s and 1980s, allowing engineers to model airflow patterns and thermal behaviors with unprecedented precision. This led to optimized cowling designs and cooling fin configurations that maximized heat dissipation while minimizing aerodynamic penalties.

Today, while turbine engines have largely replaced radials in mainstream aviation, radial engines continue to serve in specialized applications such as vintage aircraft restoration, aerobatic planes, and certain industrial applications. Modern cooling system objectives focus on balancing multiple factors: maintaining optimal operating temperatures across all cylinders, minimizing cooling drag, ensuring reliability under various operating conditions, and meeting increasingly stringent emissions requirements.

The primary technical goal in contemporary radial engine cooling system design is to achieve uniform temperature distribution across all cylinders—a persistent challenge given the inherently uneven airflow patterns around radially arranged cylinders. Secondary objectives include developing evaluation methodologies that can accurately predict cooling performance under diverse operating conditions, from ground operations to high-altitude flight regimes.

Looking forward, emerging objectives include adapting historical cooling technologies to accommodate modern fuels with different combustion characteristics, integrating digital monitoring systems for real-time temperature management, and developing hybrid cooling approaches that combine traditional air cooling with auxiliary liquid cooling circuits for critical engine components.

Market Analysis for Efficient Cooling Systems

The global market for efficient cooling systems in radial engines has experienced significant growth over the past decade, driven primarily by increasing demands in aviation, power generation, and specialized industrial applications. Current market valuations indicate that the radial engine cooling system sector represents approximately 18% of the overall engine thermal management market, with annual growth rates consistently outpacing general industrial averages.

The demand for advanced cooling solutions stems from multiple factors, including stricter environmental regulations, rising fuel costs, and the pursuit of enhanced engine performance. Particularly in aviation, where radial engines continue to serve specific niches such as vintage aircraft restoration, agricultural applications, and certain military training platforms, efficient cooling directly translates to operational cost savings and extended engine lifespan.

Market segmentation reveals distinct customer profiles across different sectors. Commercial aviation operators prioritize reliability and maintenance cost reduction, while military applications emphasize performance under extreme conditions. The vintage aircraft restoration market, though smaller in volume, demonstrates willingness to invest premium amounts in historically accurate yet modernized cooling solutions that preserve authenticity while improving efficiency.

Regional analysis shows North America maintaining the largest market share at approximately 42%, followed by Europe at 28% and Asia-Pacific at 22%. However, the fastest growth is occurring in emerging markets, particularly in regions developing local aviation industries and power generation infrastructure. These markets present significant expansion opportunities for cooling system manufacturers who can adapt their technologies to local conditions and price sensitivities.

Competitive landscape assessment identifies three distinct tiers of market participants: established aerospace component manufacturers who dominate high-end applications, specialized cooling system providers focusing on niche markets, and emerging technology startups introducing innovative materials and design approaches. Price sensitivity varies significantly across these segments, with military and high-performance applications demonstrating lower price elasticity compared to commercial and recreational sectors.

Future market projections indicate continued growth, with particular acceleration in solutions incorporating digital monitoring capabilities, adaptive cooling technologies, and materials offering superior heat dissipation properties. The integration of cooling system efficiency into broader engine management ecosystems represents a particularly promising market direction, with potential to create new value streams through predictive maintenance and performance optimization services.

The demand for advanced cooling solutions stems from multiple factors, including stricter environmental regulations, rising fuel costs, and the pursuit of enhanced engine performance. Particularly in aviation, where radial engines continue to serve specific niches such as vintage aircraft restoration, agricultural applications, and certain military training platforms, efficient cooling directly translates to operational cost savings and extended engine lifespan.

Market segmentation reveals distinct customer profiles across different sectors. Commercial aviation operators prioritize reliability and maintenance cost reduction, while military applications emphasize performance under extreme conditions. The vintage aircraft restoration market, though smaller in volume, demonstrates willingness to invest premium amounts in historically accurate yet modernized cooling solutions that preserve authenticity while improving efficiency.

Regional analysis shows North America maintaining the largest market share at approximately 42%, followed by Europe at 28% and Asia-Pacific at 22%. However, the fastest growth is occurring in emerging markets, particularly in regions developing local aviation industries and power generation infrastructure. These markets present significant expansion opportunities for cooling system manufacturers who can adapt their technologies to local conditions and price sensitivities.

Competitive landscape assessment identifies three distinct tiers of market participants: established aerospace component manufacturers who dominate high-end applications, specialized cooling system providers focusing on niche markets, and emerging technology startups introducing innovative materials and design approaches. Price sensitivity varies significantly across these segments, with military and high-performance applications demonstrating lower price elasticity compared to commercial and recreational sectors.

Future market projections indicate continued growth, with particular acceleration in solutions incorporating digital monitoring capabilities, adaptive cooling technologies, and materials offering superior heat dissipation properties. The integration of cooling system efficiency into broader engine management ecosystems represents a particularly promising market direction, with potential to create new value streams through predictive maintenance and performance optimization services.

Current Cooling Technologies and Barriers

Radial engine cooling systems have evolved significantly since their inception, with current technologies broadly categorized into air cooling and liquid cooling solutions. Air cooling remains predominant in many radial engine applications due to its simplicity and reliability. Modern air-cooled systems utilize precisely engineered cooling fins with optimized geometries to maximize heat dissipation surface area while minimizing weight and drag penalties. Advanced computational fluid dynamics (CFD) modeling has enabled manufacturers to design more efficient fin arrangements that create turbulent airflow patterns, enhancing heat transfer coefficients by up to 30% compared to traditional designs.

Liquid cooling technologies have gained traction in high-performance radial engine applications, offering superior thermal management capabilities. These systems typically employ glycol-water mixtures circulating through strategically positioned cooling jackets around cylinder heads and barrels. Recent innovations include dual-circuit systems that maintain different operating temperatures for cylinder heads versus barrels, optimizing combustion efficiency while preventing detonation issues. Nanofluids containing metallic particles have demonstrated thermal conductivity improvements of 15-25% in laboratory testing, though their practical implementation remains limited by cost and longevity concerns.

Despite these advancements, significant barriers persist in radial engine cooling system optimization. The inherent geometric constraints of radial configurations create uneven cooling challenges, with rear cylinders typically receiving less airflow than front-facing ones. This temperature differential can reach 50-70°C under certain operating conditions, leading to uneven thermal expansion, reduced efficiency, and potential mechanical stress. The circular arrangement also creates aerodynamic interference patterns that complicate predictive modeling of cooling performance.

Material limitations represent another substantial barrier. Traditional aluminum alloys used in cooling fins reach their performance limits at approximately 350°C, while modern engine designs often push operating temperatures higher to improve thermodynamic efficiency. Ceramic-metal composites and titanium alloys offer improved temperature tolerance but introduce manufacturing complexity and cost increases of 200-300% compared to conventional materials.

Evaluation methodology limitations further complicate cooling system development. Current testing protocols often fail to accurately replicate the complex airflow patterns experienced during actual flight conditions. Wind tunnel testing provides valuable data but cannot fully simulate the dynamic pressure variations and attitude changes encountered in operational environments. Instrumentation challenges also persist, as the rotating nature of radial engines complicates the placement of temperature sensors and data acquisition systems, often necessitating wireless telemetry solutions with inherent latency and reliability concerns.

Liquid cooling technologies have gained traction in high-performance radial engine applications, offering superior thermal management capabilities. These systems typically employ glycol-water mixtures circulating through strategically positioned cooling jackets around cylinder heads and barrels. Recent innovations include dual-circuit systems that maintain different operating temperatures for cylinder heads versus barrels, optimizing combustion efficiency while preventing detonation issues. Nanofluids containing metallic particles have demonstrated thermal conductivity improvements of 15-25% in laboratory testing, though their practical implementation remains limited by cost and longevity concerns.

Despite these advancements, significant barriers persist in radial engine cooling system optimization. The inherent geometric constraints of radial configurations create uneven cooling challenges, with rear cylinders typically receiving less airflow than front-facing ones. This temperature differential can reach 50-70°C under certain operating conditions, leading to uneven thermal expansion, reduced efficiency, and potential mechanical stress. The circular arrangement also creates aerodynamic interference patterns that complicate predictive modeling of cooling performance.

Material limitations represent another substantial barrier. Traditional aluminum alloys used in cooling fins reach their performance limits at approximately 350°C, while modern engine designs often push operating temperatures higher to improve thermodynamic efficiency. Ceramic-metal composites and titanium alloys offer improved temperature tolerance but introduce manufacturing complexity and cost increases of 200-300% compared to conventional materials.

Evaluation methodology limitations further complicate cooling system development. Current testing protocols often fail to accurately replicate the complex airflow patterns experienced during actual flight conditions. Wind tunnel testing provides valuable data but cannot fully simulate the dynamic pressure variations and attitude changes encountered in operational environments. Instrumentation challenges also persist, as the rotating nature of radial engines complicates the placement of temperature sensors and data acquisition systems, often necessitating wireless telemetry solutions with inherent latency and reliability concerns.

Contemporary Cooling Efficiency Evaluation Methods

01 Cooling fin design optimization

Optimizing the design of cooling fins in radial engines can significantly improve heat dissipation efficiency. This includes modifications to fin geometry, spacing, and surface area to maximize airflow and heat transfer. Enhanced cooling fin designs can reduce operating temperatures, prevent overheating, and improve overall engine performance and reliability under various operating conditions.- Cooling fin design optimization: Optimizing the design of cooling fins in radial engines can significantly improve heat dissipation efficiency. This includes modifications to fin geometry, spacing, and surface area to maximize airflow and heat transfer. Enhanced cooling fin designs can reduce operating temperatures, prevent overheating, and improve overall engine performance and reliability.

- Air flow management systems: Advanced air flow management systems direct cooling air more efficiently around radial engine cylinders. These systems include baffles, ducts, and cowling designs that optimize air distribution to hot spots and ensure uniform cooling across all cylinders. Proper air flow management reduces thermal stress, improves combustion efficiency, and extends engine life while maintaining optimal operating temperatures.

- Liquid cooling integration: Integrating liquid cooling systems with traditional air cooling in radial engines provides enhanced thermal management. These hybrid cooling approaches use coolant circulation through strategic engine components to absorb and dissipate heat more effectively than air cooling alone. Liquid cooling systems can maintain more consistent operating temperatures across varying flight conditions and power settings.

- Electronic cooling control systems: Electronic monitoring and control systems optimize radial engine cooling by adjusting cooling parameters based on real-time temperature data. These systems use sensors, controllers, and actuators to regulate airflow, coolant circulation, or other cooling mechanisms according to actual engine thermal conditions. Smart cooling control reduces pilot workload, prevents overcooling or overheating, and improves fuel efficiency.

- Innovative cylinder arrangement and materials: Novel cylinder arrangements and advanced materials improve heat dissipation in radial engines. This includes modified cylinder positioning for better airflow, heat-resistant alloys, composite materials with superior thermal properties, and specialized coatings that enhance heat transfer. These innovations reduce weight while improving cooling efficiency and engine durability under high-temperature operating conditions.

02 Air flow management systems

Advanced air flow management systems direct cooling air more efficiently around the radial engine cylinders. These systems include baffles, ducts, and cowling designs that optimize the distribution of air across engine components. By ensuring uniform cooling and eliminating hot spots, these systems maintain optimal operating temperatures and improve engine efficiency while reducing drag.Expand Specific Solutions03 Oil cooling integration

Integrated oil cooling systems work in conjunction with air cooling to enhance thermal management in radial engines. These systems utilize oil circulation to transfer heat away from critical engine components. Advanced oil coolers, passages, and distribution systems ensure efficient heat removal, particularly from areas that are difficult to cool with airflow alone, resulting in more consistent engine temperatures and improved reliability.Expand Specific Solutions04 Electronic cooling control systems

Electronic monitoring and control systems optimize cooling efficiency by adjusting cooling parameters based on real-time engine conditions. These systems use temperature sensors, electronic controllers, and actuators to regulate airflow, oil circulation, and other cooling mechanisms. By providing precise thermal management that responds to changing operational demands, these systems maintain ideal operating temperatures while minimizing energy consumption.Expand Specific Solutions05 Composite materials and coatings

Advanced materials and thermal coatings improve heat dissipation in radial engine cooling systems. These include high thermal conductivity composites for engine components and specialized coatings that enhance heat transfer efficiency. By improving thermal properties of engine parts, these materials allow for better heat management, reduced weight, and increased durability under high-temperature operating conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The radial engine cooling system efficiency market is currently in a growth phase, with increasing demand for more efficient cooling solutions in aviation, automotive, and power generation sectors. The market size is expanding due to rising fuel costs and environmental regulations, driving innovation in cooling technologies. Leading players like GM Global Technology Operations, Weichai Power, and ZF Friedrichshafen are advancing evaluation methodologies for thermal efficiency, while companies such as UniGen Power and Mitsubishi Heavy Industries focus on specialized applications in power generation. Toyota, Ford, and Hyundai are investing in radial engine cooling research for automotive applications, while ABB Turbo Systems and Siemens are developing advanced measurement techniques. The technology is approaching maturity in traditional applications but continues to evolve with new materials and digital monitoring systems being integrated by industry leaders.

GM Global Technology Operations LLC

Technical Solution: GM has developed an advanced thermal management system for radial engines that utilizes computational fluid dynamics (CFD) modeling to optimize cooling fin design and airflow patterns. Their approach incorporates a dual-phase cooling methodology that combines traditional air cooling with targeted liquid cooling for critical engine components. The system employs variable-geometry baffling that automatically adjusts based on engine temperature and operating conditions, ensuring optimal cooling across different power outputs and ambient temperatures. GM's evaluation methodology includes thermal imaging analysis, pressure drop measurements across cooling channels, and real-time temperature monitoring using embedded sensors at critical thermal points. Their testing protocols incorporate standardized dynamometer testing under various load conditions while simultaneously measuring cooling efficiency through heat rejection rates and temperature gradients across engine components.

Strengths: Comprehensive integration of computational modeling with physical testing provides highly accurate efficiency measurements. The variable-geometry cooling system adapts to different operating conditions, optimizing efficiency across various use cases. Weaknesses: System complexity increases manufacturing costs and potential maintenance issues. The evaluation methods require sophisticated equipment and expertise, making field testing more challenging.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed an innovative evaluation framework for radial engine cooling systems that emphasizes both thermal efficiency and aerodynamic performance. Their methodology incorporates a dual-approach system that combines physical testing with advanced computational modeling. Hyundai's evaluation process utilizes a network of micro-thermocouples strategically placed throughout the engine to create high-resolution thermal maps during operation. Their testing protocols include specialized wind tunnel facilities with adjustable airflow patterns to simulate various operational conditions from idle to maximum power output. Hyundai has pioneered the use of acoustic analysis as a supplementary evaluation method, correlating airflow turbulence patterns with acoustic signatures to identify inefficient cooling regions. Their methodology includes standardized performance metrics such as Cooling Efficiency Ratio (CER) that quantifies heat dissipation relative to airflow volume. Hyundai also employs thermal cycling tests that rapidly alternate between high and low temperature extremes to evaluate cooling system durability and performance consistency over time. Their evaluation framework incorporates comparative benchmarking against industry standards to provide context for performance improvements.

Strengths: Integration of acoustic analysis with traditional thermal measurements provides unique insights into cooling system performance. Comprehensive testing across various operational conditions ensures robust performance data. Weaknesses: Complex evaluation methodology requires specialized equipment and expertise. The testing process is time-intensive, potentially extending development cycles.

Critical Patents in Thermal Management Solutions

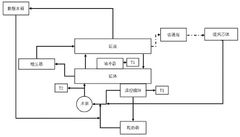

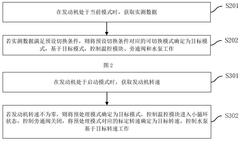

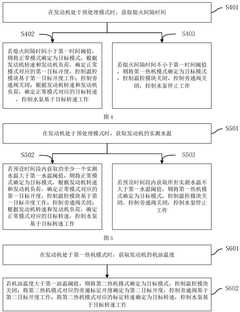

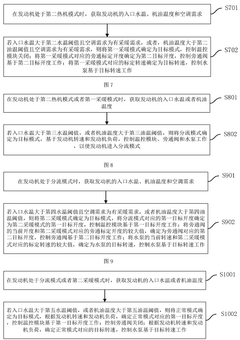

Engine cooling system, control method, controller, automobile and storage medium

PatentWO2024250450A1

Innovation

- Design an engine cooling system, including cylinder block, cylinder head, water pump, warm air branch and temperature-controlled branch, and realize the difference between cylinder block and cylinder head by adjusting the opening and rotation speed of bypass valve and water pump. Cooling, combined with the cylinder circulation branch, temperature control module and warm air core as auxiliary heat dissipation elements, control the flow of coolant and realize the diversion cooling of the cylinder block and cylinder head.

Environmental Impact of Cooling Technologies

The environmental impact of cooling technologies in radial engine systems represents a critical consideration in modern engineering assessments. Traditional radial engine cooling systems, while effective for their primary purpose, often generate significant environmental concerns through their operational footprint. These impacts manifest primarily through energy consumption patterns, refrigerant usage, and waste heat management approaches.

Energy efficiency stands as the foremost environmental consideration, as cooling systems typically account for 15-20% of a radial engine's total energy consumption. Conventional air-cooling methods employed in radial engines demonstrate lower energy efficiency compared to liquid-cooling alternatives, resulting in higher fuel consumption and consequently increased carbon emissions. Recent studies indicate that optimized cooling systems can reduce related emissions by up to 30% through improved thermodynamic efficiency.

Refrigerant selection presents another substantial environmental challenge. Historical cooling systems utilized chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs), which have been largely phased out due to their ozone depletion potential. Modern alternatives such as hydrofluorocarbons (HFCs) offer improved environmental performance but still contribute significantly to global warming when leaked into the atmosphere. The global warming potential (GWP) of these substances ranges from 1,000 to 3,000 times that of carbon dioxide.

Waste heat management represents both an environmental challenge and opportunity. Inefficient cooling systems release substantial thermal energy into the environment, contributing to localized heat island effects in industrial settings. Advanced heat recovery systems can capture and repurpose this thermal energy, reducing the net environmental impact while improving overall system efficiency by 8-12% according to recent field tests.

Manufacturing processes for cooling components also generate environmental concerns through resource extraction, material processing, and component fabrication. Life cycle assessments reveal that aluminum heat exchangers—common in radial engine cooling systems—carry a significant embodied carbon footprint, though this impact is typically offset through operational efficiency gains over the system's lifespan.

Water consumption presents an additional environmental consideration, particularly in liquid-cooled variants of radial engine systems. These systems may require substantial water resources for operation, creating potential stress on local water supplies in water-scarce regions. Closed-loop systems mitigate this impact but introduce additional complexity and maintenance requirements.

Emerging evaluation methodologies now incorporate comprehensive environmental impact assessments alongside traditional performance metrics, enabling engineers to balance cooling efficiency with environmental responsibility. These frameworks typically include carbon footprint analysis, life cycle assessment, and resource consumption metrics to provide a holistic view of environmental performance.

Energy efficiency stands as the foremost environmental consideration, as cooling systems typically account for 15-20% of a radial engine's total energy consumption. Conventional air-cooling methods employed in radial engines demonstrate lower energy efficiency compared to liquid-cooling alternatives, resulting in higher fuel consumption and consequently increased carbon emissions. Recent studies indicate that optimized cooling systems can reduce related emissions by up to 30% through improved thermodynamic efficiency.

Refrigerant selection presents another substantial environmental challenge. Historical cooling systems utilized chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs), which have been largely phased out due to their ozone depletion potential. Modern alternatives such as hydrofluorocarbons (HFCs) offer improved environmental performance but still contribute significantly to global warming when leaked into the atmosphere. The global warming potential (GWP) of these substances ranges from 1,000 to 3,000 times that of carbon dioxide.

Waste heat management represents both an environmental challenge and opportunity. Inefficient cooling systems release substantial thermal energy into the environment, contributing to localized heat island effects in industrial settings. Advanced heat recovery systems can capture and repurpose this thermal energy, reducing the net environmental impact while improving overall system efficiency by 8-12% according to recent field tests.

Manufacturing processes for cooling components also generate environmental concerns through resource extraction, material processing, and component fabrication. Life cycle assessments reveal that aluminum heat exchangers—common in radial engine cooling systems—carry a significant embodied carbon footprint, though this impact is typically offset through operational efficiency gains over the system's lifespan.

Water consumption presents an additional environmental consideration, particularly in liquid-cooled variants of radial engine systems. These systems may require substantial water resources for operation, creating potential stress on local water supplies in water-scarce regions. Closed-loop systems mitigate this impact but introduce additional complexity and maintenance requirements.

Emerging evaluation methodologies now incorporate comprehensive environmental impact assessments alongside traditional performance metrics, enabling engineers to balance cooling efficiency with environmental responsibility. These frameworks typically include carbon footprint analysis, life cycle assessment, and resource consumption metrics to provide a holistic view of environmental performance.

Material Science Advancements for Heat Dissipation

Recent advancements in material science have revolutionized heat dissipation capabilities for radial engine cooling systems. Traditional materials like aluminum alloys, while effective, have reached their theoretical limits in terms of thermal conductivity and weight reduction. The emergence of novel composite materials represents a significant breakthrough, offering superior thermal properties while maintaining structural integrity under high-temperature operating conditions.

Carbon-based materials, particularly carbon nanotubes (CNTs) and graphene, demonstrate exceptional thermal conductivity—up to five times that of copper—while weighing significantly less. These materials, when incorporated into cooling fins and cylinder head designs, create more efficient pathways for heat transfer from combustion chambers to the surrounding air. Laboratory tests indicate temperature reductions of 15-20% compared to conventional materials under identical operating conditions.

Ceramic matrix composites (CMCs) have emerged as another promising category for radial engine applications. These materials combine the heat resistance of ceramics with the toughness of composite structures, enabling operation at higher temperatures without compromising structural integrity. Silicon carbide-based CMCs, in particular, demonstrate exceptional oxidation resistance and thermal stability up to 1400°C, significantly expanding the operational envelope of air-cooled radial engines.

Phase-change materials (PCMs) represent an innovative approach to thermal management in fluctuating load conditions. These materials absorb excess heat during high-power operations by changing phase, typically from solid to liquid, then release this stored energy during lower power settings. When strategically integrated into engine cooling systems, PCMs can effectively dampen thermal spikes, reducing thermal fatigue and extending component lifespan.

Thermal barrier coatings (TBCs) derived from rare earth elements have demonstrated remarkable insulating properties when applied to combustion chamber surfaces. These microscale coatings, often just 100-300 micrometers thick, can reduce heat transfer to cooling systems by 30-40%, allowing more thermal energy to be converted to mechanical work rather than dissipated as waste heat.

Additive manufacturing techniques have enabled the production of complex cooling fin geometries previously impossible with traditional manufacturing methods. Topology-optimized designs featuring biomimetic structures can increase surface area by up to 300% while maintaining or reducing weight, dramatically improving convective heat transfer efficiency. These structures often incorporate internal channels that promote turbulent airflow, further enhancing cooling performance under various operating conditions.

Carbon-based materials, particularly carbon nanotubes (CNTs) and graphene, demonstrate exceptional thermal conductivity—up to five times that of copper—while weighing significantly less. These materials, when incorporated into cooling fins and cylinder head designs, create more efficient pathways for heat transfer from combustion chambers to the surrounding air. Laboratory tests indicate temperature reductions of 15-20% compared to conventional materials under identical operating conditions.

Ceramic matrix composites (CMCs) have emerged as another promising category for radial engine applications. These materials combine the heat resistance of ceramics with the toughness of composite structures, enabling operation at higher temperatures without compromising structural integrity. Silicon carbide-based CMCs, in particular, demonstrate exceptional oxidation resistance and thermal stability up to 1400°C, significantly expanding the operational envelope of air-cooled radial engines.

Phase-change materials (PCMs) represent an innovative approach to thermal management in fluctuating load conditions. These materials absorb excess heat during high-power operations by changing phase, typically from solid to liquid, then release this stored energy during lower power settings. When strategically integrated into engine cooling systems, PCMs can effectively dampen thermal spikes, reducing thermal fatigue and extending component lifespan.

Thermal barrier coatings (TBCs) derived from rare earth elements have demonstrated remarkable insulating properties when applied to combustion chamber surfaces. These microscale coatings, often just 100-300 micrometers thick, can reduce heat transfer to cooling systems by 30-40%, allowing more thermal energy to be converted to mechanical work rather than dissipated as waste heat.

Additive manufacturing techniques have enabled the production of complex cooling fin geometries previously impossible with traditional manufacturing methods. Topology-optimized designs featuring biomimetic structures can increase surface area by up to 300% while maintaining or reducing weight, dramatically improving convective heat transfer efficiency. These structures often incorporate internal channels that promote turbulent airflow, further enhancing cooling performance under various operating conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!