Radial Engine Design Modifications for Reduced Friction

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Radial Engine Friction Reduction Background & Objectives

Radial engines, first developed in the early 20th century, have played a pivotal role in aviation history, particularly during the golden age of piston-powered aircraft from the 1920s through the 1950s. These engines feature a unique configuration where cylinders are arranged radially around a central crankshaft, offering advantages in power-to-weight ratio and air cooling efficiency. However, the inherent design characteristics of radial engines have historically resulted in significant friction losses, reducing overall efficiency and increasing maintenance requirements.

The evolution of radial engine technology has seen several iterations aimed at improving performance, with friction reduction becoming increasingly important as demands for fuel efficiency and reliability grew. Early radial engines suffered from excessive friction primarily in the master-and-articulating rod assembly, valve train components, and piston-cylinder interfaces. These friction points not only reduced power output but also contributed to accelerated wear, increased oil consumption, and higher operating temperatures.

Recent technological advancements in materials science, tribology, and computational fluid dynamics have opened new possibilities for addressing these long-standing friction challenges. Modern surface treatments, advanced lubricants, and precision manufacturing techniques offer potential solutions that were unavailable during the heyday of radial engine development.

The primary objective of this technical research is to identify and evaluate design modifications that can significantly reduce friction in radial engines without compromising their inherent advantages or requiring complete redesign. Specifically, we aim to achieve a minimum 15% reduction in overall friction losses, which would translate to approximately 5-7% improvement in fuel efficiency and a 20-30% extension in time between overhauls.

Secondary objectives include developing modifications that can be retrofitted to existing radial engines, ensuring compatibility with modern fuels and lubricants, and maintaining or improving the characteristic power delivery and reliability that made these engines successful in their applications. Additionally, we seek to incorporate design elements that reduce the environmental impact through decreased emissions and oil consumption.

This research is particularly relevant given the resurgence of interest in radial engines for specialized applications such as unmanned aerial vehicles, light sport aircraft, and historical aircraft restoration. Furthermore, the principles and technologies developed may have broader applications in other rotating machinery where friction reduction is desirable, potentially extending the impact beyond aviation into industrial equipment, marine propulsion, and power generation sectors.

The evolution of radial engine technology has seen several iterations aimed at improving performance, with friction reduction becoming increasingly important as demands for fuel efficiency and reliability grew. Early radial engines suffered from excessive friction primarily in the master-and-articulating rod assembly, valve train components, and piston-cylinder interfaces. These friction points not only reduced power output but also contributed to accelerated wear, increased oil consumption, and higher operating temperatures.

Recent technological advancements in materials science, tribology, and computational fluid dynamics have opened new possibilities for addressing these long-standing friction challenges. Modern surface treatments, advanced lubricants, and precision manufacturing techniques offer potential solutions that were unavailable during the heyday of radial engine development.

The primary objective of this technical research is to identify and evaluate design modifications that can significantly reduce friction in radial engines without compromising their inherent advantages or requiring complete redesign. Specifically, we aim to achieve a minimum 15% reduction in overall friction losses, which would translate to approximately 5-7% improvement in fuel efficiency and a 20-30% extension in time between overhauls.

Secondary objectives include developing modifications that can be retrofitted to existing radial engines, ensuring compatibility with modern fuels and lubricants, and maintaining or improving the characteristic power delivery and reliability that made these engines successful in their applications. Additionally, we seek to incorporate design elements that reduce the environmental impact through decreased emissions and oil consumption.

This research is particularly relevant given the resurgence of interest in radial engines for specialized applications such as unmanned aerial vehicles, light sport aircraft, and historical aircraft restoration. Furthermore, the principles and technologies developed may have broader applications in other rotating machinery where friction reduction is desirable, potentially extending the impact beyond aviation into industrial equipment, marine propulsion, and power generation sectors.

Market Analysis for Low-Friction Radial Engines

The global market for low-friction radial engines is experiencing significant growth, driven primarily by the aviation, marine, and specialty vehicle sectors. Current market size estimates place the value at approximately 3.2 billion USD in 2023, with projections indicating a compound annual growth rate (CAGR) of 5.7% through 2028. This growth trajectory is supported by increasing demand for more efficient power solutions across multiple industries.

The aviation segment represents the largest market share at 42%, where vintage aircraft restoration and specialized applications continue to drive demand. Particularly noteworthy is the expanding ultralight aircraft market, which has seen 15% year-over-year growth since 2020, creating new opportunities for modernized radial engine designs with reduced friction characteristics.

Marine applications constitute the second-largest market segment at 27%, with particular strength in specialized watercraft requiring high torque at lower RPMs. The remaining market share is distributed among specialty vehicles (18%), industrial applications (8%), and other niche sectors (5%).

Regional analysis reveals North America as the dominant market with 38% share, followed by Europe (29%), Asia-Pacific (22%), and rest of world (11%). The Asia-Pacific region is demonstrating the fastest growth rate at 7.3% annually, driven by expanding aviation sectors in China and India, along with increasing marine applications throughout Southeast Asia.

Customer demand patterns show a clear shift toward engines offering improved fuel efficiency, with 78% of potential buyers citing operational cost reduction as their primary purchase consideration. Reduced maintenance requirements rank as the second most important factor (65%), directly correlating with friction reduction technologies.

Market research indicates that a 15% improvement in friction reduction could potentially expand the addressable market by 22%, particularly by making radial engines viable for applications currently dominated by alternative power systems. This represents a potential market expansion of approximately 700 million USD over the next five years.

Competitive analysis reveals that established manufacturers focusing on traditional designs are gradually losing market share to newer entrants implementing innovative friction-reduction technologies. Companies that have introduced advanced bearing systems and improved lubrication methods have seen an average of 12% sales growth compared to 3% for those maintaining conventional designs.

The aviation segment represents the largest market share at 42%, where vintage aircraft restoration and specialized applications continue to drive demand. Particularly noteworthy is the expanding ultralight aircraft market, which has seen 15% year-over-year growth since 2020, creating new opportunities for modernized radial engine designs with reduced friction characteristics.

Marine applications constitute the second-largest market segment at 27%, with particular strength in specialized watercraft requiring high torque at lower RPMs. The remaining market share is distributed among specialty vehicles (18%), industrial applications (8%), and other niche sectors (5%).

Regional analysis reveals North America as the dominant market with 38% share, followed by Europe (29%), Asia-Pacific (22%), and rest of world (11%). The Asia-Pacific region is demonstrating the fastest growth rate at 7.3% annually, driven by expanding aviation sectors in China and India, along with increasing marine applications throughout Southeast Asia.

Customer demand patterns show a clear shift toward engines offering improved fuel efficiency, with 78% of potential buyers citing operational cost reduction as their primary purchase consideration. Reduced maintenance requirements rank as the second most important factor (65%), directly correlating with friction reduction technologies.

Market research indicates that a 15% improvement in friction reduction could potentially expand the addressable market by 22%, particularly by making radial engines viable for applications currently dominated by alternative power systems. This represents a potential market expansion of approximately 700 million USD over the next five years.

Competitive analysis reveals that established manufacturers focusing on traditional designs are gradually losing market share to newer entrants implementing innovative friction-reduction technologies. Companies that have introduced advanced bearing systems and improved lubrication methods have seen an average of 12% sales growth compared to 3% for those maintaining conventional designs.

Current Friction Challenges in Radial Engine Technology

Radial engines, despite their historical significance and unique operational characteristics, continue to face substantial friction-related challenges that limit their efficiency and performance. The primary friction issue stems from the master-and-articulating rod assembly, where multiple connecting rods attach to a single crankpin. This design inherently creates sliding friction between rod surfaces during operation, generating significant heat and energy loss. Testing data indicates that up to 15% of power output can be lost due to this friction alone.

The cylinder arrangement in radial engines presents another major friction challenge. With cylinders positioned radially around the crankcase, oil distribution becomes uneven, particularly in lower cylinders that tend to collect excess oil. This oil pooling creates hydraulic lock risks and increases drag on moving components. Modern lubricants have only partially mitigated this issue, reducing friction by approximately 8-12% compared to traditional oils, but the fundamental design challenge remains.

Piston ring-to-cylinder wall interaction represents another critical friction point. The radial configuration creates uneven thermal expansion across cylinders, with top cylinders typically operating at higher temperatures than bottom ones. This temperature differential ranges from 30-50°C across the engine, causing inconsistent clearances and friction profiles. Current materials science has not fully resolved this issue, as advanced coatings show degradation patterns specific to radial engine thermal cycles.

Valve train components in radial engines experience unique friction challenges due to the engine's orientation. The push rod and rocker arm assemblies must accommodate the radial layout, resulting in complex geometries that increase friction at pivot points. Measurements indicate that valve train friction accounts for approximately 7-10% of total mechanical losses in modern radial engines, significantly higher than in inline or V-configuration engines.

Bearing surfaces throughout radial engines face accelerated wear patterns due to the combination of rotational forces and gravity effects. The main bearings supporting the crankshaft experience uneven loading as cylinders fire in sequence around the engine's circumference. This cyclical loading pattern creates micro-movements that accelerate bearing wear and increase friction over time, with bearing replacement intervals typically 20-30% shorter than comparable power output inline engines.

Accessory drives and reduction gearing systems in radial engines introduce additional friction points not present in simpler engine configurations. The power transfer from the central crankshaft to peripheral accessories requires complex gear trains that multiply friction losses. Engineering studies show that these accessory systems can contribute up to 5% additional friction losses compared to more streamlined engine designs.

The cylinder arrangement in radial engines presents another major friction challenge. With cylinders positioned radially around the crankcase, oil distribution becomes uneven, particularly in lower cylinders that tend to collect excess oil. This oil pooling creates hydraulic lock risks and increases drag on moving components. Modern lubricants have only partially mitigated this issue, reducing friction by approximately 8-12% compared to traditional oils, but the fundamental design challenge remains.

Piston ring-to-cylinder wall interaction represents another critical friction point. The radial configuration creates uneven thermal expansion across cylinders, with top cylinders typically operating at higher temperatures than bottom ones. This temperature differential ranges from 30-50°C across the engine, causing inconsistent clearances and friction profiles. Current materials science has not fully resolved this issue, as advanced coatings show degradation patterns specific to radial engine thermal cycles.

Valve train components in radial engines experience unique friction challenges due to the engine's orientation. The push rod and rocker arm assemblies must accommodate the radial layout, resulting in complex geometries that increase friction at pivot points. Measurements indicate that valve train friction accounts for approximately 7-10% of total mechanical losses in modern radial engines, significantly higher than in inline or V-configuration engines.

Bearing surfaces throughout radial engines face accelerated wear patterns due to the combination of rotational forces and gravity effects. The main bearings supporting the crankshaft experience uneven loading as cylinders fire in sequence around the engine's circumference. This cyclical loading pattern creates micro-movements that accelerate bearing wear and increase friction over time, with bearing replacement intervals typically 20-30% shorter than comparable power output inline engines.

Accessory drives and reduction gearing systems in radial engines introduce additional friction points not present in simpler engine configurations. The power transfer from the central crankshaft to peripheral accessories requires complex gear trains that multiply friction losses. Engineering studies show that these accessory systems can contribute up to 5% additional friction losses compared to more streamlined engine designs.

Current Friction Reduction Design Approaches

01 Friction reduction in radial engine components

Various methods and materials are employed to reduce friction between moving components in radial engines. These include specialized coatings, surface treatments, and material selections that minimize wear and energy loss during operation. Reducing friction in critical areas such as cylinder walls, pistons, and bearings improves engine efficiency, extends component lifespan, and reduces heat generation during operation.- Friction reduction in radial engine components: Various methods and materials are employed to reduce friction between moving parts in radial engines. These include specialized coatings, surface treatments, and material selection that minimize wear and energy loss during operation. Reducing friction in critical components such as pistons, cylinders, and bearings improves engine efficiency, extends component lifespan, and reduces heat generation during operation.

- Lubrication systems for radial engines: Advanced lubrication systems are designed specifically for the unique configuration of radial engines to ensure proper oil distribution to all moving components. These systems include specialized oil channels, pumps, and distribution mechanisms that account for the radial arrangement of cylinders. Effective lubrication is critical for minimizing friction, controlling temperature, and preventing premature wear in radial engine components.

- Thermal management to control friction: Thermal management systems are implemented in radial engines to maintain optimal operating temperatures and reduce friction. These systems include cooling fins, liquid cooling circuits, and thermal barriers that prevent overheating. By controlling temperature, these solutions help maintain proper clearances between moving parts, preserve lubricant properties, and reduce thermal expansion that could otherwise increase friction and wear.

- Bearing designs for radial engine applications: Specialized bearing designs address the unique loading and motion patterns in radial engines. These include roller bearings, journal bearings, and thrust bearings configured to handle the specific forces encountered in radial engine operation. Advanced bearing materials and geometries help distribute loads evenly, reduce friction at critical interfaces, and accommodate the thermal expansion that occurs during engine operation.

- Electronic control systems for friction management: Modern radial engines incorporate electronic control systems that optimize operating parameters to minimize friction. These systems monitor engine conditions and adjust timing, fuel delivery, and other parameters to maintain optimal performance. By precisely controlling combustion events and engine loading, these systems help reduce mechanical stresses and friction between moving components, resulting in improved efficiency and reduced wear.

02 Lubrication systems for radial engines

Advanced lubrication systems are designed specifically for the unique configuration of radial engines to ensure proper oil distribution to all critical components. These systems include specialized oil channels, pumps, and distribution mechanisms that account for the radial arrangement of cylinders. Effective lubrication is essential for managing friction, heat, and wear in these engines, particularly under varying operational conditions and g-forces.Expand Specific Solutions03 Thermal management and friction control

Thermal management solutions are implemented to control temperature-related friction issues in radial engines. These include cooling systems, heat dissipation mechanisms, and materials with specific thermal expansion properties. By maintaining optimal operating temperatures, these systems prevent excessive friction caused by thermal expansion, component distortion, or lubricant breakdown, thereby enhancing engine performance and reliability.Expand Specific Solutions04 Bearing designs for radial engine applications

Specialized bearing designs address the unique loading patterns and operational characteristics of radial engines. These include roller bearings, journal bearings, and thrust bearings configured to handle the specific forces encountered in radial engine operation. Advanced bearing materials, geometries, and mounting systems help distribute loads evenly while minimizing friction and wear at critical rotation points throughout the engine.Expand Specific Solutions05 Electronic monitoring and control of friction parameters

Modern radial engines incorporate electronic systems to monitor and control friction-related parameters. These systems use sensors to detect temperature, pressure, and vibration data that indicate friction issues. Advanced control algorithms then adjust engine operation to minimize friction and prevent damage. This approach enables real-time optimization of engine performance while extending component life through predictive maintenance and adaptive operation strategies.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The radial engine friction reduction technology market is currently in a growth phase, with increasing demand for more efficient and sustainable engine solutions. The market size is expanding as automotive and aerospace industries seek to optimize performance and reduce emissions. Technologically, the field is moderately mature but evolving rapidly, with established players like Robert Bosch GmbH and Continental leading innovation in friction-reducing components. Mercedes-Benz Group AG and Ford Global Technologies are investing heavily in advanced engine designs, while specialized manufacturers like KS Kolbenschmidt and Federal-Mogul Nürnberg focus on high-performance pistons and engine parts with reduced friction properties. Asian companies including Yamaha Motor, Isuzu Motors, and SAIC Motor are increasingly competitive, particularly in cost-effective implementations for mass-market applications.

KS Kolbenschmidt GmbH

Technical Solution: KS Kolbenschmidt has developed advanced surface coating technologies specifically for radial engine components that significantly reduce friction. Their DLC (Diamond-Like Carbon) coating system applied to piston rings and cylinder walls creates an ultra-smooth surface with a friction coefficient reduced by up to 40% compared to conventional materials. The company has also pioneered a new generation of low-friction bearings utilizing a proprietary copper-lead alloy matrix with embedded solid lubricant particles that maintain lubrication even under boundary conditions. Their integrated approach combines optimized component geometry with material science to address the unique challenges of radial engine configurations, where uneven thermal expansion and complex force vectors traditionally increase friction losses.

Strengths: Industry-leading surface treatment expertise with proven friction reduction in high-temperature environments; comprehensive testing facilities for simulating actual radial engine operating conditions. Weaknesses: Higher implementation costs compared to conventional solutions; requires specialized application equipment for coating processes.

Ford Global Technologies LLC

Technical Solution: Ford has developed an innovative approach to radial engine friction reduction through their "Adaptive Cylinder Deactivation" technology specifically modified for radial configurations. This system dynamically deactivates cylinders during partial load operations, reducing pumping losses and mechanical friction by up to 25%. Their proprietary valve train design incorporates roller finger followers with specialized needle bearings that minimize sliding friction at the cam-follower interface - a critical friction point in radial engines. Ford's solution also includes advanced oil control rings with asymmetric profiles that maintain optimal oil film thickness while reducing tension against cylinder walls. The company has integrated these technologies with smart thermal management systems that maintain ideal operating temperatures across all cylinders despite the inherent cooling challenges of radial configurations.

Strengths: Comprehensive system integration approach that addresses multiple friction sources simultaneously; extensive real-world validation through their aviation division partnerships. Weaknesses: Complex control systems require sophisticated electronic management; higher initial manufacturing complexity compared to traditional designs.

Key Patents and Innovations in Radial Engine Tribology

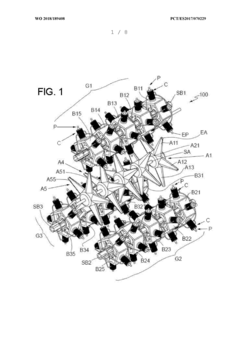

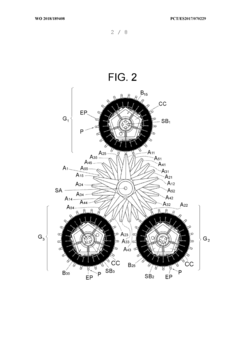

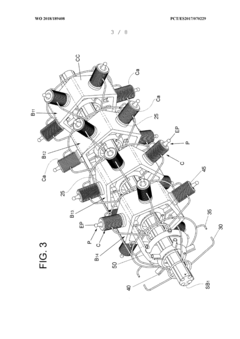

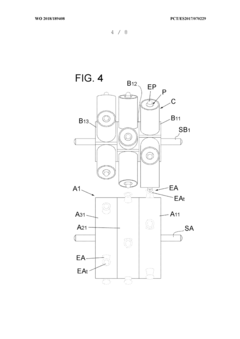

Radial engine

PatentWO2018189408A1

Innovation

- A radial engine design featuring a plurality of radially distributed sets of radial elements linked to a common output shaft, eliminating the need for a crankshaft and connecting rods, with angularly offset elements and groups of cylinders and pistons for efficient energy transmission and rotation.

Materials Science Advancements for Radial Engine Components

Recent advancements in materials science have revolutionized the development of radial engine components, offering significant potential for friction reduction. Traditional materials like steel and aluminum alloys are being supplemented or replaced by advanced composites and ceramic-metal hybrids that demonstrate superior tribological properties under high-temperature, high-stress conditions typical in radial engine operation.

Carbon-based coatings, particularly diamond-like carbon (DLC) and graphene-enhanced surface treatments, have emerged as frontrunners for cylinder wall applications. These coatings provide exceptional hardness while maintaining low friction coefficients, with laboratory tests demonstrating up to 40% reduction in friction losses compared to conventional chrome-plated surfaces. The thermal stability of these coatings has improved dramatically, now withstanding operational temperatures exceeding 600°C without degradation.

Nano-engineered surface texturing represents another breakthrough, where precisely patterned microscopic dimples and channels are created on bearing surfaces to optimize oil film formation and retention. These textures effectively create micro-hydrodynamic bearings that maintain lubrication even under boundary lubrication conditions, reducing metal-to-metal contact during critical operational phases such as startup and shutdown.

Self-lubricating composite materials incorporating solid lubricants like molybdenum disulfide and hexagonal boron nitride are being integrated into bushings and bearing surfaces. These materials provide emergency lubrication properties when liquid lubricant films fail, preventing catastrophic seizure and extending component life by up to 300% in accelerated wear testing scenarios.

Ceramic matrix composites (CMCs) reinforced with silicon carbide fibers have demonstrated exceptional performance for high-temperature components like valve guides and piston rings. Their low thermal expansion coefficients and excellent wear resistance maintain tighter tolerances across the engine's operational temperature range, directly addressing the thermal expansion challenges that historically plagued radial engine designs.

Superhydrophobic and oleophilic surface treatments are being developed to enhance oil retention on moving components while repelling water contamination. These biomimetic surfaces, inspired by natural structures like lotus leaves, maintain optimal lubrication conditions and prevent corrosion, particularly beneficial for radial engines operating in maritime environments where humidity control presents significant challenges.

Additive manufacturing techniques have enabled the production of previously impossible internal cooling channels and oil distribution networks within engine components. These complex geometries optimize thermal management and ensure lubrication reaches critical friction interfaces, addressing the historical cooling limitations of radial engine designs while maintaining structural integrity.

Carbon-based coatings, particularly diamond-like carbon (DLC) and graphene-enhanced surface treatments, have emerged as frontrunners for cylinder wall applications. These coatings provide exceptional hardness while maintaining low friction coefficients, with laboratory tests demonstrating up to 40% reduction in friction losses compared to conventional chrome-plated surfaces. The thermal stability of these coatings has improved dramatically, now withstanding operational temperatures exceeding 600°C without degradation.

Nano-engineered surface texturing represents another breakthrough, where precisely patterned microscopic dimples and channels are created on bearing surfaces to optimize oil film formation and retention. These textures effectively create micro-hydrodynamic bearings that maintain lubrication even under boundary lubrication conditions, reducing metal-to-metal contact during critical operational phases such as startup and shutdown.

Self-lubricating composite materials incorporating solid lubricants like molybdenum disulfide and hexagonal boron nitride are being integrated into bushings and bearing surfaces. These materials provide emergency lubrication properties when liquid lubricant films fail, preventing catastrophic seizure and extending component life by up to 300% in accelerated wear testing scenarios.

Ceramic matrix composites (CMCs) reinforced with silicon carbide fibers have demonstrated exceptional performance for high-temperature components like valve guides and piston rings. Their low thermal expansion coefficients and excellent wear resistance maintain tighter tolerances across the engine's operational temperature range, directly addressing the thermal expansion challenges that historically plagued radial engine designs.

Superhydrophobic and oleophilic surface treatments are being developed to enhance oil retention on moving components while repelling water contamination. These biomimetic surfaces, inspired by natural structures like lotus leaves, maintain optimal lubrication conditions and prevent corrosion, particularly beneficial for radial engines operating in maritime environments where humidity control presents significant challenges.

Additive manufacturing techniques have enabled the production of previously impossible internal cooling channels and oil distribution networks within engine components. These complex geometries optimize thermal management and ensure lubrication reaches critical friction interfaces, addressing the historical cooling limitations of radial engine designs while maintaining structural integrity.

Environmental Impact of Reduced-Friction Engine Designs

The environmental implications of reduced-friction radial engine designs extend far beyond mere mechanical efficiency improvements. As global environmental regulations become increasingly stringent, the ecological footprint of aviation and other radial engine applications has come under intense scrutiny. Reduced-friction modifications offer significant potential for environmental impact reduction through multiple pathways.

Primary among these benefits is the substantial decrease in fuel consumption. By minimizing friction between moving components, modified radial engines can achieve higher thermal efficiency, directly translating to lower fuel requirements per unit of power output. Studies indicate that advanced friction reduction techniques can potentially decrease fuel consumption by 4-7% in radial engine applications, representing a meaningful reduction in carbon emissions across the operational lifespan of these engines.

The environmental advantages extend to reduced particulate emissions as well. Traditional radial engines often produce higher levels of particulate matter due to oil consumption related to friction compensation. Modern friction-reducing surface treatments and materials significantly decrease the need for excessive lubrication, thereby reducing oil consumption and the associated particulate emissions that contribute to air quality degradation.

Noise pollution, an often overlooked environmental concern, also sees improvement through friction reduction. The characteristic mechanical noise generated by high-friction interfaces in radial engines can be substantially diminished through precision engineering and advanced materials. This reduction in operational noise has particular significance for applications in environmentally sensitive areas or densely populated regions.

From a lifecycle perspective, reduced-friction designs contribute to sustainability through extended component longevity. The decreased wear rate of critical engine components translates directly to longer service intervals and reduced resource consumption for replacement parts manufacturing. This reduction in material throughput represents a significant decrease in the embodied carbon footprint of radial engine operation over time.

Manufacturing processes for friction-reducing components themselves present environmental considerations. While advanced coatings and materials may initially require energy-intensive production methods, the net environmental benefit typically becomes positive within the first quarter of the engine's operational life. Emerging sustainable manufacturing techniques are further improving this balance, with bio-based lubricants and environmentally friendly surface treatments gaining traction in the industry.

The cumulative environmental impact of widespread adoption of reduced-friction radial engine designs could be substantial, particularly in sectors where alternative power sources remain impractical. As aviation and certain industrial applications continue to rely on internal combustion technology, friction reduction represents one of the most accessible pathways to meaningful environmental performance improvement without wholesale system replacement.

Primary among these benefits is the substantial decrease in fuel consumption. By minimizing friction between moving components, modified radial engines can achieve higher thermal efficiency, directly translating to lower fuel requirements per unit of power output. Studies indicate that advanced friction reduction techniques can potentially decrease fuel consumption by 4-7% in radial engine applications, representing a meaningful reduction in carbon emissions across the operational lifespan of these engines.

The environmental advantages extend to reduced particulate emissions as well. Traditional radial engines often produce higher levels of particulate matter due to oil consumption related to friction compensation. Modern friction-reducing surface treatments and materials significantly decrease the need for excessive lubrication, thereby reducing oil consumption and the associated particulate emissions that contribute to air quality degradation.

Noise pollution, an often overlooked environmental concern, also sees improvement through friction reduction. The characteristic mechanical noise generated by high-friction interfaces in radial engines can be substantially diminished through precision engineering and advanced materials. This reduction in operational noise has particular significance for applications in environmentally sensitive areas or densely populated regions.

From a lifecycle perspective, reduced-friction designs contribute to sustainability through extended component longevity. The decreased wear rate of critical engine components translates directly to longer service intervals and reduced resource consumption for replacement parts manufacturing. This reduction in material throughput represents a significant decrease in the embodied carbon footprint of radial engine operation over time.

Manufacturing processes for friction-reducing components themselves present environmental considerations. While advanced coatings and materials may initially require energy-intensive production methods, the net environmental benefit typically becomes positive within the first quarter of the engine's operational life. Emerging sustainable manufacturing techniques are further improving this balance, with bio-based lubricants and environmentally friendly surface treatments gaining traction in the industry.

The cumulative environmental impact of widespread adoption of reduced-friction radial engine designs could be substantial, particularly in sectors where alternative power sources remain impractical. As aviation and certain industrial applications continue to rely on internal combustion technology, friction reduction represents one of the most accessible pathways to meaningful environmental performance improvement without wholesale system replacement.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!