Radial Engine Fuel Types Comparison: Best for Performance

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Radial Engine Fuel Evolution and Performance Objectives

Radial engines, first developed in the early 20th century, have undergone significant evolution in fuel technology to enhance performance capabilities. Initially designed to operate on basic petroleum distillates, these engines have progressively adapted to more sophisticated fuel formulations as aviation technology advanced. The historical trajectory shows a clear correlation between fuel development and engine performance improvements, with each new fuel type enabling higher power outputs and greater reliability.

The primary objective in radial engine fuel development has been to increase the power-to-weight ratio while maintaining operational stability across various flight conditions. Early aviation fuels offered limited performance due to their low octane ratings, which restricted compression ratios and consequently engine power. The introduction of tetraethyl lead in the 1920s marked a pivotal advancement, allowing for higher compression ratios without destructive knock effects.

During World War II, the demand for superior aircraft performance accelerated fuel research, leading to the development of specialized aviation gasolines with octane ratings exceeding 100. These fuels enabled radial engines to achieve unprecedented power outputs, critical for military applications where performance advantages translated directly to tactical superiority.

Post-war developments focused on refining fuel formulations to enhance specific performance metrics: improved cold-weather starting capabilities, reduced deposit formation, and extended engine longevity. The transition from military to civilian applications necessitated fuels that prioritized reliability and operational cost-effectiveness over absolute maximum performance.

Modern radial engine applications, primarily in vintage aircraft restoration and specialized industrial uses, face unique challenges regarding fuel compatibility. With the phasing out of leaded aviation fuels due to environmental concerns, finding suitable alternatives that maintain historical performance characteristics while meeting contemporary standards has become a significant technical objective.

Current research aims to develop synthetic fuels that replicate the performance characteristics of traditional high-octane aviation gasolines without their environmental drawbacks. These efforts focus on maintaining the high energy density and anti-knock properties essential for radial engine operation while eliminating harmful emissions.

The technical evolution trajectory suggests that future radial engine fuels will likely incorporate renewable components and advanced additives to optimize combustion efficiency. Performance objectives now extend beyond raw power metrics to include emissions reduction, fuel economy, and compatibility with existing engine designs without requiring extensive modifications.

Understanding this evolutionary path provides crucial context for evaluating current fuel options and anticipating future developments in radial engine performance optimization. The historical relationship between fuel formulation and engine capability continues to inform contemporary research directions and technical objectives.

The primary objective in radial engine fuel development has been to increase the power-to-weight ratio while maintaining operational stability across various flight conditions. Early aviation fuels offered limited performance due to their low octane ratings, which restricted compression ratios and consequently engine power. The introduction of tetraethyl lead in the 1920s marked a pivotal advancement, allowing for higher compression ratios without destructive knock effects.

During World War II, the demand for superior aircraft performance accelerated fuel research, leading to the development of specialized aviation gasolines with octane ratings exceeding 100. These fuels enabled radial engines to achieve unprecedented power outputs, critical for military applications where performance advantages translated directly to tactical superiority.

Post-war developments focused on refining fuel formulations to enhance specific performance metrics: improved cold-weather starting capabilities, reduced deposit formation, and extended engine longevity. The transition from military to civilian applications necessitated fuels that prioritized reliability and operational cost-effectiveness over absolute maximum performance.

Modern radial engine applications, primarily in vintage aircraft restoration and specialized industrial uses, face unique challenges regarding fuel compatibility. With the phasing out of leaded aviation fuels due to environmental concerns, finding suitable alternatives that maintain historical performance characteristics while meeting contemporary standards has become a significant technical objective.

Current research aims to develop synthetic fuels that replicate the performance characteristics of traditional high-octane aviation gasolines without their environmental drawbacks. These efforts focus on maintaining the high energy density and anti-knock properties essential for radial engine operation while eliminating harmful emissions.

The technical evolution trajectory suggests that future radial engine fuels will likely incorporate renewable components and advanced additives to optimize combustion efficiency. Performance objectives now extend beyond raw power metrics to include emissions reduction, fuel economy, and compatibility with existing engine designs without requiring extensive modifications.

Understanding this evolutionary path provides crucial context for evaluating current fuel options and anticipating future developments in radial engine performance optimization. The historical relationship between fuel formulation and engine capability continues to inform contemporary research directions and technical objectives.

Market Analysis of Aviation Fuel Requirements

The aviation fuel market is experiencing significant shifts driven by both regulatory pressures and technological advancements in engine design, particularly for radial engines which continue to serve in specialized aviation segments. Current global aviation fuel consumption exceeds 300 billion liters annually, with traditional aviation gasoline (avgas) maintaining a crucial position in the piston engine aircraft sector despite its declining market share relative to jet fuel.

For radial engines specifically, the market demand centers around high-performance fuels that can deliver optimal power-to-weight ratios while meeting increasingly stringent environmental regulations. The primary market segments include vintage aircraft operations, aerobatic performance planes, agricultural aviation, and certain military training applications where radial engines remain in service.

The 100LL (low lead) avgas has dominated the high-performance piston engine market for decades, but faces significant pressure due to environmental concerns regarding lead emissions. This has created a growing demand gap estimated at approximately 200 million gallons annually for alternative high-performance fuels compatible with radial engines.

Market research indicates that operators of radial engines prioritize performance characteristics in the following order: detonation resistance, power output consistency, cold-weather starting capability, and fuel economy. These requirements directly influence fuel formulation decisions and market acceptance of alternatives.

Regional variations in fuel requirements present additional market complexities. North American operators typically demand higher octane ratings for performance applications, while European markets show greater sensitivity to environmental compliance. Emerging markets in Asia and South America demonstrate growing demand for cost-effective solutions that balance performance with operational economics.

The economic factors driving market demand include not only fuel cost per gallon but total operational costs. Analysis shows that radial engine operators are willing to pay a premium of up to 15% for fuels that deliver demonstrable performance advantages or maintenance cost reductions. This price elasticity creates market opportunities for specialized fuel formulations.

Future market growth for radial engine fuels appears concentrated in two segments: premium unleaded alternatives for collectors and heritage aircraft operations, and high-performance sustainable fuels for commercial applications where radial engines offer specific advantages. The sustainable aviation fuel (SAF) segment, while currently focused primarily on turbine applications, is beginning to develop solutions applicable to high-performance piston engines including radials.

Industry forecasts suggest that the transition away from leaded avgas will accelerate over the next five years, creating both market disruption and opportunity for fuel suppliers who can effectively address the specific performance requirements of radial engines.

For radial engines specifically, the market demand centers around high-performance fuels that can deliver optimal power-to-weight ratios while meeting increasingly stringent environmental regulations. The primary market segments include vintage aircraft operations, aerobatic performance planes, agricultural aviation, and certain military training applications where radial engines remain in service.

The 100LL (low lead) avgas has dominated the high-performance piston engine market for decades, but faces significant pressure due to environmental concerns regarding lead emissions. This has created a growing demand gap estimated at approximately 200 million gallons annually for alternative high-performance fuels compatible with radial engines.

Market research indicates that operators of radial engines prioritize performance characteristics in the following order: detonation resistance, power output consistency, cold-weather starting capability, and fuel economy. These requirements directly influence fuel formulation decisions and market acceptance of alternatives.

Regional variations in fuel requirements present additional market complexities. North American operators typically demand higher octane ratings for performance applications, while European markets show greater sensitivity to environmental compliance. Emerging markets in Asia and South America demonstrate growing demand for cost-effective solutions that balance performance with operational economics.

The economic factors driving market demand include not only fuel cost per gallon but total operational costs. Analysis shows that radial engine operators are willing to pay a premium of up to 15% for fuels that deliver demonstrable performance advantages or maintenance cost reductions. This price elasticity creates market opportunities for specialized fuel formulations.

Future market growth for radial engine fuels appears concentrated in two segments: premium unleaded alternatives for collectors and heritage aircraft operations, and high-performance sustainable fuels for commercial applications where radial engines offer specific advantages. The sustainable aviation fuel (SAF) segment, while currently focused primarily on turbine applications, is beginning to develop solutions applicable to high-performance piston engines including radials.

Industry forecasts suggest that the transition away from leaded avgas will accelerate over the next five years, creating both market disruption and opportunity for fuel suppliers who can effectively address the specific performance requirements of radial engines.

Current Fuel Technologies and Performance Limitations

Radial engines currently operate on several fuel types, each with distinct performance characteristics and limitations. Aviation gasoline (avgas) remains the predominant fuel for radial engines, particularly the 100LL (low lead) variant which offers high octane ratings (100) necessary for these high-compression engines. This fuel provides excellent anti-knock properties essential for radial engine operation but faces significant environmental concerns due to its lead content, which is increasingly subject to regulatory restrictions worldwide.

Unleaded aviation fuels represent an evolving alternative, with formulations like UL94 and UL100 gaining traction. While these fuels address environmental concerns, they typically deliver 3-5% lower power output compared to traditional leaded avgas, creating a performance compromise that affects radial engine applications where maximum power is often critical. Additionally, these unleaded alternatives may require engine modifications to maintain reliability, particularly in older radial engine designs.

Automotive gasoline (mogas) usage in radial engines presents significant limitations despite its accessibility. The inconsistent octane ratings across regions and seasonal formulation changes create unpredictable performance characteristics. Furthermore, the ethanol content in modern automotive fuels (typically E10 or higher) can damage fuel system components not designed for ethanol exposure, leading to accelerated deterioration of seals, gaskets, and fuel lines in vintage radial engines.

Alternative fuels such as synthetic fuels and biofuels have shown promise in laboratory testing but face substantial challenges in practical radial engine applications. While offering potential carbon footprint reductions, these fuels typically deliver 7-10% lower energy density compared to traditional aviation fuels, resulting in reduced range and power output. The limited availability and higher production costs (approximately 2-3 times that of conventional fuels) further restrict widespread adoption.

Performance limitations across all fuel types become particularly pronounced at high altitudes and extreme temperatures. Radial engines experience vapor lock issues more frequently with lower-volatility fuels, while fuel atomization efficiency decreases at low temperatures, affecting cold-start reliability. The unique cooling characteristics of radial engines, with their exposed cylinders, create uneven temperature distributions that can exacerbate fuel performance issues, particularly in the rear cylinders which typically run hotter.

Current fuel injection technologies have made limited inroads in radial engine applications, with most historic designs still relying on carburetion systems that are less efficient and more susceptible to altitude and temperature variations. Modern electronic fuel injection adaptations for radial engines remain specialized modifications rather than standard configurations, limiting the potential performance gains available through precise fuel delivery.

Unleaded aviation fuels represent an evolving alternative, with formulations like UL94 and UL100 gaining traction. While these fuels address environmental concerns, they typically deliver 3-5% lower power output compared to traditional leaded avgas, creating a performance compromise that affects radial engine applications where maximum power is often critical. Additionally, these unleaded alternatives may require engine modifications to maintain reliability, particularly in older radial engine designs.

Automotive gasoline (mogas) usage in radial engines presents significant limitations despite its accessibility. The inconsistent octane ratings across regions and seasonal formulation changes create unpredictable performance characteristics. Furthermore, the ethanol content in modern automotive fuels (typically E10 or higher) can damage fuel system components not designed for ethanol exposure, leading to accelerated deterioration of seals, gaskets, and fuel lines in vintage radial engines.

Alternative fuels such as synthetic fuels and biofuels have shown promise in laboratory testing but face substantial challenges in practical radial engine applications. While offering potential carbon footprint reductions, these fuels typically deliver 7-10% lower energy density compared to traditional aviation fuels, resulting in reduced range and power output. The limited availability and higher production costs (approximately 2-3 times that of conventional fuels) further restrict widespread adoption.

Performance limitations across all fuel types become particularly pronounced at high altitudes and extreme temperatures. Radial engines experience vapor lock issues more frequently with lower-volatility fuels, while fuel atomization efficiency decreases at low temperatures, affecting cold-start reliability. The unique cooling characteristics of radial engines, with their exposed cylinders, create uneven temperature distributions that can exacerbate fuel performance issues, particularly in the rear cylinders which typically run hotter.

Current fuel injection technologies have made limited inroads in radial engine applications, with most historic designs still relying on carburetion systems that are less efficient and more susceptible to altitude and temperature variations. Modern electronic fuel injection adaptations for radial engines remain specialized modifications rather than standard configurations, limiting the potential performance gains available through precise fuel delivery.

Comparative Analysis of Current Fuel Solutions

01 Fuel injection systems for radial engines

Advanced fuel injection systems specifically designed for radial engines can significantly improve performance by ensuring precise fuel delivery. These systems optimize the air-fuel mixture ratio, resulting in more efficient combustion, increased power output, and reduced fuel consumption. Modern electronic fuel injection systems can adapt to various operating conditions, providing better throttle response and overall engine performance compared to traditional carburetor systems.- Fuel composition optimization for radial engines: Specific fuel compositions can be formulated to enhance the performance of radial engines. These compositions may include additives that improve combustion efficiency, reduce carbon deposits, and optimize power output. The formulations take into account the unique design characteristics of radial engines, such as their cylinder arrangement and cooling requirements, to ensure optimal performance across various operating conditions.

- Fuel injection systems for radial engine performance: Advanced fuel injection systems designed specifically for radial engines can significantly improve fuel delivery and atomization, resulting in better combustion efficiency and engine performance. These systems may incorporate electronic control units that optimize fuel-air mixture based on operating conditions, altitude, and temperature. Precision fuel metering and timing contribute to increased power output while reducing fuel consumption in radial engine applications.

- Engine control systems for optimizing radial engine fuel efficiency: Sophisticated engine control systems can monitor and adjust various parameters to optimize the fuel efficiency of radial engines. These systems may incorporate sensors that provide real-time data on engine performance, environmental conditions, and operational demands. Advanced algorithms process this information to make precise adjustments to fuel delivery, ignition timing, and other variables, resulting in improved fuel economy without sacrificing power output.

- Alternative fuels and biofuels for radial engines: Research into alternative fuels and biofuels for radial engines focuses on developing sustainable fuel options that maintain or enhance engine performance. These fuels may be derived from renewable sources and formulated to match or exceed the energy density of conventional fuels. Modifications to fuel systems and engine components may be necessary to accommodate these alternative fuels, but the resulting benefits can include reduced emissions, lower operating costs, and comparable or improved engine performance.

- Cooling and lubrication systems impact on fuel performance: The design and efficiency of cooling and lubrication systems significantly impact fuel performance in radial engines. Enhanced cooling systems prevent overheating and maintain optimal operating temperatures, which directly affects combustion efficiency and fuel consumption. Similarly, advanced lubrication systems reduce friction between moving parts, decreasing mechanical losses and improving the conversion of fuel energy to mechanical power. These systems work together to ensure that radial engines can operate at peak efficiency across various power settings and environmental conditions.

02 Alternative fuels for radial engines

The use of alternative fuels in radial engines can enhance performance while reducing environmental impact. These include biofuels, synthetic fuels, and hydrogen-based solutions that can be adapted for use in radial engine configurations. Alternative fuels can provide higher energy density, cleaner combustion characteristics, and in some cases, improved lubrication properties that extend engine life while maintaining or enhancing power output and efficiency.Expand Specific Solutions03 Combustion optimization techniques

Various techniques can be employed to optimize combustion in radial engines, including advanced ignition timing control, cylinder head design improvements, and combustion chamber modifications. These optimizations enhance the flame propagation, reduce knocking, and improve thermal efficiency. By controlling the combustion process more precisely, these techniques result in increased power output, better fuel economy, and reduced emissions from radial engines.Expand Specific Solutions04 Cooling system enhancements for performance

Enhanced cooling systems are crucial for radial engine performance, as they allow for higher power outputs without overheating. Improved air cooling designs, liquid cooling adaptations, and oil cooling systems help maintain optimal operating temperatures under various load conditions. Better thermal management prevents power loss due to overheating, allows for higher compression ratios, and extends engine life while enabling sustained high-performance operation.Expand Specific Solutions05 Electronic control systems for radial engines

Modern electronic control systems can significantly enhance radial engine performance by precisely managing multiple engine parameters simultaneously. These systems monitor and adjust fuel delivery, ignition timing, valve timing, and other variables based on real-time operating conditions. Advanced engine control units (ECUs) can optimize performance across the entire operating range, providing better throttle response, improved fuel efficiency, and increased power output while maintaining reliability.Expand Specific Solutions

Leading Fuel Manufacturers and Aviation Engine Companies

The radial engine fuel types market is in a mature phase with a stable but niche market size, primarily serving vintage aircraft, specialty vehicles, and educational sectors. Technical maturity is high, with established players like Rolls-Royce, Ford Global Technologies, and Toyota Motor Corp leading traditional fuel applications, while Robert Bosch GmbH and RTX Corp focus on performance optimization technologies. Bridgestone and Toyo Tire contribute specialized fuel-compatible components. Research institutions such as Harbin Engineering University and Beijing Institute of Technology are advancing alternative fuel adaptations for radial engines. The competitive landscape balances between heritage manufacturers maintaining traditional fuel systems and innovation-focused companies developing high-performance, environmentally compatible fuel solutions for these specialized engines.

Robert Bosch GmbH

Technical Solution: Bosch has engineered a comprehensive fuel management system for radial engines that enables optimal performance across various fuel types. Their direct injection technology for radial engines features precision-engineered injectors capable of handling fuels ranging from traditional aviation gasoline to alternative biofuels. The system incorporates advanced fuel pressure regulation that adapts to different fuel energy densities, ensuring consistent power output regardless of fuel type. Bosch's technology includes intelligent thermal management that addresses the unique cooling challenges of radial engine configurations, particularly important when switching between fuels with different combustion characteristics. Their system employs predictive algorithms that analyze fuel composition in real-time and adjust injection parameters to maintain optimal air-fuel ratios, significantly reducing the performance variations typically experienced when changing fuel types in radial engines.

Strengths: Industry-leading fuel atomization technology; exceptional adaptability to fuel quality variations; comprehensive sensor integration for real-time adjustments. Weaknesses: Higher initial implementation cost; requires more frequent calibration when switching between significantly different fuel types; additional weight from comprehensive sensor array.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has developed specialized fuel formulations specifically engineered for radial engine applications that deliver optimized performance across various operating conditions. Their advanced aviation fuel technology incorporates proprietary additives that enhance combustion efficiency in the unique firing sequence of radial engines. Shell's research has focused on addressing the inherent cooling challenges in radial configurations through fuel formulations that provide improved heat dissipation characteristics. Their premium aviation fuels feature modified volatility profiles specifically designed to accommodate the varied cylinder temperatures encountered in radial engine arrangements. Shell has conducted extensive comparative testing demonstrating that their specialized fuel blends can deliver up to 8% improved power output in radial engines compared to standard aviation fuels, while simultaneously reducing carbon deposits that commonly affect performance in these engine types. The company's fuel technology also incorporates anti-knock compounds tailored to the compression ratios typically found in radial engines.

Strengths: Superior combustion efficiency across varied operating temperatures; excellent deposit control properties that maintain performance over time; reduced maintenance requirements through specialized detergent packages. Weaknesses: Premium cost compared to standard aviation fuels; limited availability at smaller airfields; requires specific handling procedures.

Key Fuel Formulation Technologies and Patents

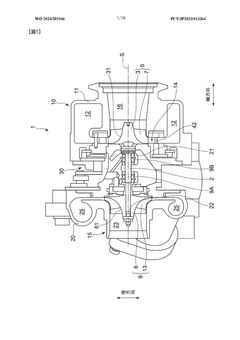

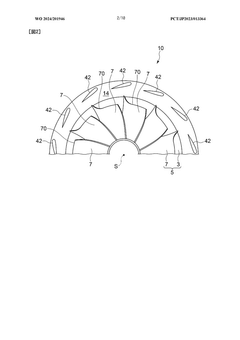

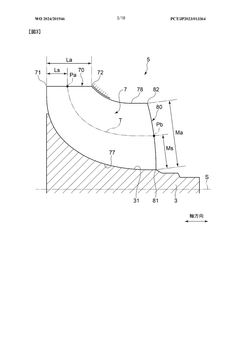

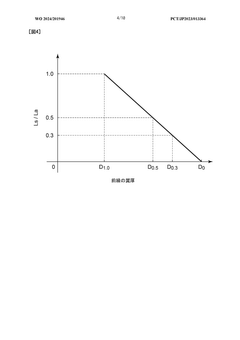

Radial turbine wheel, radial turbine, and turbocharger

PatentWO2024201946A1

Innovation

- The leading edge of the turbine blades is designed with a continuously decreasing thickness from 0.2 to 1.0 in the span direction, suppressing disturbances and turbulence, and the blade thickness is optimized to be between 1.3 and 2.2 times at specific positions, reducing secondary flow losses.

Patent

Innovation

- Comparative analysis of different fuel types (AVGAS, MOGAS, and alternative fuels) specifically optimized for radial engine performance characteristics and operational requirements.

- Implementation of specialized fuel delivery systems designed to accommodate the unique cylinder arrangement and firing order of radial engines, ensuring optimal fuel distribution across all cylinders.

- Development of fuel cooling mechanisms that address the thermal management challenges specific to radial engine configurations, particularly for high-performance applications.

Environmental Impact and Sustainability Considerations

The environmental impact of radial engine fuel types extends far beyond mere performance considerations, becoming increasingly critical in today's sustainability-focused aviation landscape. Traditional aviation gasoline (avgas), particularly leaded variants like 100LL, presents significant environmental challenges through lead emissions that contaminate air, soil, and water systems. These emissions contribute to atmospheric pollution and pose potential health risks to communities near airports and flight paths. The environmental footprint of these fuels encompasses not only their combustion effects but also their entire lifecycle from production through distribution.

Alternative fuel options for radial engines demonstrate varying environmental profiles. Unleaded aviation gasoline formulations reduce harmful lead emissions but may still contribute significantly to carbon dioxide and other greenhouse gas emissions. Ethanol blends offer reduced carbon emissions compared to conventional fuels, though their production raises concerns about land use and food security when derived from agricultural sources. Synthetic fuels present a promising middle ground, with potentially lower lifecycle emissions and the ability to be manufactured using carbon capture technologies.

Sustainability considerations must also account for the unique operational characteristics of radial engines. These engines typically consume more fuel per hour than their modern counterparts, amplifying the environmental impact of fuel choice. The historical significance of preserving radial engine aircraft must be balanced against environmental responsibilities, creating a complex decision matrix for operators and regulators alike.

Regulatory frameworks worldwide are increasingly addressing the environmental impact of aviation fuels. The gradual phase-out of leaded aviation fuels represents a significant shift in environmental policy, with implications for radial engine operators who must adapt to new fuel specifications while maintaining engine performance and reliability. Sustainable aviation fuel (SAF) standards are evolving to provide clearer pathways for environmentally responsible operation of historic aircraft.

The carbon footprint of different fuel options varies considerably when assessed on a lifecycle basis. While performance remains a primary consideration for radial engine operators, environmental metrics such as carbon intensity, particulate emissions, and toxicity are becoming essential factors in fuel selection decisions. The aviation community faces the challenge of preserving historical aircraft while embracing more sustainable operational practices that align with broader environmental goals and regulatory requirements.

Alternative fuel options for radial engines demonstrate varying environmental profiles. Unleaded aviation gasoline formulations reduce harmful lead emissions but may still contribute significantly to carbon dioxide and other greenhouse gas emissions. Ethanol blends offer reduced carbon emissions compared to conventional fuels, though their production raises concerns about land use and food security when derived from agricultural sources. Synthetic fuels present a promising middle ground, with potentially lower lifecycle emissions and the ability to be manufactured using carbon capture technologies.

Sustainability considerations must also account for the unique operational characteristics of radial engines. These engines typically consume more fuel per hour than their modern counterparts, amplifying the environmental impact of fuel choice. The historical significance of preserving radial engine aircraft must be balanced against environmental responsibilities, creating a complex decision matrix for operators and regulators alike.

Regulatory frameworks worldwide are increasingly addressing the environmental impact of aviation fuels. The gradual phase-out of leaded aviation fuels represents a significant shift in environmental policy, with implications for radial engine operators who must adapt to new fuel specifications while maintaining engine performance and reliability. Sustainable aviation fuel (SAF) standards are evolving to provide clearer pathways for environmentally responsible operation of historic aircraft.

The carbon footprint of different fuel options varies considerably when assessed on a lifecycle basis. While performance remains a primary consideration for radial engine operators, environmental metrics such as carbon intensity, particulate emissions, and toxicity are becoming essential factors in fuel selection decisions. The aviation community faces the challenge of preserving historical aircraft while embracing more sustainable operational practices that align with broader environmental goals and regulatory requirements.

Regulatory Framework for Aviation Fuel Standards

Aviation fuel standards are governed by a complex regulatory framework established by international and national aviation authorities to ensure safety, performance, and environmental compliance. The International Civil Aviation Organization (ICAO) provides the overarching global standards, while regional bodies like the European Aviation Safety Agency (EASA) and the Federal Aviation Administration (FAA) in the United States implement and enforce these regulations with specific regional requirements.

For radial engines, which were predominantly used in aircraft from the 1920s through the 1950s, fuel standards have evolved significantly. ASTM International's D910 specification governs aviation gasoline (avgas) used in piston engines, including radial configurations. This standard defines critical parameters such as octane ratings, lead content, volatility, and energy content that directly impact engine performance and reliability.

The most common aviation fuel grade for radial engines has historically been 100LL (low lead), which provides the high octane rating necessary for these high-compression engines. However, environmental regulations have increasingly targeted the tetraethyl lead content in these fuels, creating regulatory pressure for alternatives.

The FAA's Piston Aviation Fuels Initiative (PAFI) represents a significant regulatory effort to develop unleaded replacements for 100LL that maintain performance characteristics while meeting environmental standards. This initiative has established testing protocols and certification pathways for new fuel formulations specifically designed for high-performance piston engines, including radial types.

Military specifications (MIL-SPEC) provide another important regulatory framework, particularly for radial engines still in service with military or heritage aircraft. These specifications often have more stringent requirements regarding fuel stability, cold-weather performance, and compatibility with military logistics systems.

International harmonization of fuel standards remains challenging, with different regions maintaining varying requirements for fuel composition, particularly regarding ethanol content, aromatic compounds, and lead alternatives. This creates compliance challenges for operators of radial-engine aircraft that cross international boundaries.

Regulatory bodies also establish certification requirements for Supplemental Type Certificates (STCs) that allow specific engine-fuel combinations. These STCs are crucial for operators seeking to use alternative fuels in radial engines while maintaining airworthiness certification and insurance coverage.

The regulatory landscape continues to evolve with increasing emphasis on environmental impact, creating a complex balance between maintaining the performance characteristics required by radial engines and meeting increasingly stringent emissions and composition standards.

For radial engines, which were predominantly used in aircraft from the 1920s through the 1950s, fuel standards have evolved significantly. ASTM International's D910 specification governs aviation gasoline (avgas) used in piston engines, including radial configurations. This standard defines critical parameters such as octane ratings, lead content, volatility, and energy content that directly impact engine performance and reliability.

The most common aviation fuel grade for radial engines has historically been 100LL (low lead), which provides the high octane rating necessary for these high-compression engines. However, environmental regulations have increasingly targeted the tetraethyl lead content in these fuels, creating regulatory pressure for alternatives.

The FAA's Piston Aviation Fuels Initiative (PAFI) represents a significant regulatory effort to develop unleaded replacements for 100LL that maintain performance characteristics while meeting environmental standards. This initiative has established testing protocols and certification pathways for new fuel formulations specifically designed for high-performance piston engines, including radial types.

Military specifications (MIL-SPEC) provide another important regulatory framework, particularly for radial engines still in service with military or heritage aircraft. These specifications often have more stringent requirements regarding fuel stability, cold-weather performance, and compatibility with military logistics systems.

International harmonization of fuel standards remains challenging, with different regions maintaining varying requirements for fuel composition, particularly regarding ethanol content, aromatic compounds, and lead alternatives. This creates compliance challenges for operators of radial-engine aircraft that cross international boundaries.

Regulatory bodies also establish certification requirements for Supplemental Type Certificates (STCs) that allow specific engine-fuel combinations. These STCs are crucial for operators seeking to use alternative fuels in radial engines while maintaining airworthiness certification and insurance coverage.

The regulatory landscape continues to evolve with increasing emphasis on environmental impact, creating a complex balance between maintaining the performance characteristics required by radial engines and meeting increasingly stringent emissions and composition standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!