Radial Engine Reliability in Harsh Environments: Key Factors

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Radial Engine Development History and Reliability Goals

Radial engines emerged in the early 20th century as a revolutionary aircraft propulsion system, with their distinctive circular arrangement of cylinders around a central crankshaft. The first practical radial engine was developed by Charles Manly in 1903, though widespread adoption began during World War I when manufacturers like Gnome and Le Rhône pioneered rotary radial designs. These early engines, while innovative, suffered from reliability issues particularly in extreme operating conditions.

The interwar period (1918-1939) marked significant advancements in radial engine technology. Companies such as Pratt & Whitney and Wright Aeronautical introduced air-cooled radial engines that demonstrated improved reliability through enhanced metallurgy and more efficient cooling systems. The iconic Pratt & Whitney R-1340 Wasp, introduced in 1925, established new standards for power-to-weight ratio while maintaining operational stability across varying environmental conditions.

World War II catalyzed further development as radial engines were pushed to their limits in combat scenarios. Engineers focused on addressing reliability challenges in harsh environments, including extreme temperatures, high altitudes, and dusty conditions. The Wright R-3350 Duplex-Cyclone and Pratt & Whitney R-4360 Wasp Major represented the pinnacle of piston engine technology, incorporating solutions such as improved valve materials, enhanced lubrication systems, and more effective air filters to combat environmental contaminants.

Post-war evolution saw radial engines gradually supplanted by jet engines in aviation, though they maintained relevance in specialized applications where reliability under harsh conditions remained paramount. In these contexts, engineers established more rigorous reliability goals, including mean time between failures (MTBF) exceeding 1,000 hours, operational temperature ranges from -40°C to +50°C, and the ability to maintain performance despite exposure to sand, dust, and high humidity.

Modern radial engine reliability goals have evolved to meet contemporary standards while preserving the inherent advantages of the radial configuration. Current benchmarks include component lifespans of 2,000+ operational hours, maintenance intervals of at least 200 hours, and the capacity to withstand vibration levels of up to 20G. Additionally, modern applications demand start-up reliability in temperatures ranging from -65°F to 130°F and operation at altitudes exceeding 25,000 feet without significant performance degradation.

The historical progression of radial engine development reveals a consistent focus on improving reliability through materials science, design optimization, and systems engineering. Each generation of engines has built upon previous lessons learned, particularly regarding operation in harsh environments. This evolutionary path has established a comprehensive understanding of the key factors affecting radial engine reliability, including thermal management, lubrication efficiency, air filtration, materials selection, and vibration dampening.

The interwar period (1918-1939) marked significant advancements in radial engine technology. Companies such as Pratt & Whitney and Wright Aeronautical introduced air-cooled radial engines that demonstrated improved reliability through enhanced metallurgy and more efficient cooling systems. The iconic Pratt & Whitney R-1340 Wasp, introduced in 1925, established new standards for power-to-weight ratio while maintaining operational stability across varying environmental conditions.

World War II catalyzed further development as radial engines were pushed to their limits in combat scenarios. Engineers focused on addressing reliability challenges in harsh environments, including extreme temperatures, high altitudes, and dusty conditions. The Wright R-3350 Duplex-Cyclone and Pratt & Whitney R-4360 Wasp Major represented the pinnacle of piston engine technology, incorporating solutions such as improved valve materials, enhanced lubrication systems, and more effective air filters to combat environmental contaminants.

Post-war evolution saw radial engines gradually supplanted by jet engines in aviation, though they maintained relevance in specialized applications where reliability under harsh conditions remained paramount. In these contexts, engineers established more rigorous reliability goals, including mean time between failures (MTBF) exceeding 1,000 hours, operational temperature ranges from -40°C to +50°C, and the ability to maintain performance despite exposure to sand, dust, and high humidity.

Modern radial engine reliability goals have evolved to meet contemporary standards while preserving the inherent advantages of the radial configuration. Current benchmarks include component lifespans of 2,000+ operational hours, maintenance intervals of at least 200 hours, and the capacity to withstand vibration levels of up to 20G. Additionally, modern applications demand start-up reliability in temperatures ranging from -65°F to 130°F and operation at altitudes exceeding 25,000 feet without significant performance degradation.

The historical progression of radial engine development reveals a consistent focus on improving reliability through materials science, design optimization, and systems engineering. Each generation of engines has built upon previous lessons learned, particularly regarding operation in harsh environments. This evolutionary path has established a comprehensive understanding of the key factors affecting radial engine reliability, including thermal management, lubrication efficiency, air filtration, materials selection, and vibration dampening.

Market Demand Analysis for Harsh Environment Applications

The global market for radial engines operating in harsh environments has shown significant growth over the past decade, driven primarily by increasing demand in aviation, marine, and specialized industrial applications. Current market analysis indicates that sectors requiring reliable power generation in extreme conditions—including arctic operations, desert environments, high-altitude applications, and marine settings—represent a combined market value exceeding $7 billion annually, with a compound annual growth rate of 5.8% projected through 2028.

Aviation remains the dominant application sector, accounting for approximately 42% of the harsh environment radial engine market. This is particularly evident in specialized aircraft designed for bush flying, firefighting, and remote area operations where conventional power systems often fail to deliver consistent performance. The commercial aviation segment specifically seeks engines capable of maintaining reliability across temperature ranges from -65°F to 130°F while enduring significant altitude variations.

Military applications constitute the second-largest market segment at 28%, with defense contractors increasingly specifying radial engine solutions for unmanned aerial vehicles (UAVs) and specialized ground equipment deployed in conflict zones with extreme environmental conditions. These applications demand engines that can operate reliably despite dust, sand, humidity, and temperature fluctuations without frequent maintenance intervals.

Marine applications represent a rapidly growing segment (18% market share) where corrosion resistance and performance stability in high-humidity, salt-spray environments are critical factors. The remaining market share is distributed across specialized industrial applications including emergency power generation, remote site operations, and agricultural equipment designed for extreme climate zones.

Regional analysis reveals North America leading market demand (36%), followed by Asia-Pacific (29%) and Europe (22%). However, the fastest growth is occurring in Middle Eastern and African markets (11.3% CAGR), where harsh desert conditions and expanding industrial development create unique operational challenges for conventional engine technologies.

Customer requirements analysis indicates five primary demand drivers: operational reliability under temperature extremes, resistance to particulate contamination, extended maintenance intervals, fuel flexibility, and vibration/shock tolerance. Survey data from end-users shows 78% of procurement decisions prioritize total cost of ownership over initial acquisition costs, with particular emphasis on mean time between failures in non-standard operating conditions.

Market forecasts suggest particular growth in applications requiring engines under 500 horsepower that can maintain consistent performance despite rapid environmental transitions, such as those experienced in coastal rescue operations or variable-altitude flight paths. This segment is projected to grow at 7.2% annually through 2027, outpacing the broader market.

Aviation remains the dominant application sector, accounting for approximately 42% of the harsh environment radial engine market. This is particularly evident in specialized aircraft designed for bush flying, firefighting, and remote area operations where conventional power systems often fail to deliver consistent performance. The commercial aviation segment specifically seeks engines capable of maintaining reliability across temperature ranges from -65°F to 130°F while enduring significant altitude variations.

Military applications constitute the second-largest market segment at 28%, with defense contractors increasingly specifying radial engine solutions for unmanned aerial vehicles (UAVs) and specialized ground equipment deployed in conflict zones with extreme environmental conditions. These applications demand engines that can operate reliably despite dust, sand, humidity, and temperature fluctuations without frequent maintenance intervals.

Marine applications represent a rapidly growing segment (18% market share) where corrosion resistance and performance stability in high-humidity, salt-spray environments are critical factors. The remaining market share is distributed across specialized industrial applications including emergency power generation, remote site operations, and agricultural equipment designed for extreme climate zones.

Regional analysis reveals North America leading market demand (36%), followed by Asia-Pacific (29%) and Europe (22%). However, the fastest growth is occurring in Middle Eastern and African markets (11.3% CAGR), where harsh desert conditions and expanding industrial development create unique operational challenges for conventional engine technologies.

Customer requirements analysis indicates five primary demand drivers: operational reliability under temperature extremes, resistance to particulate contamination, extended maintenance intervals, fuel flexibility, and vibration/shock tolerance. Survey data from end-users shows 78% of procurement decisions prioritize total cost of ownership over initial acquisition costs, with particular emphasis on mean time between failures in non-standard operating conditions.

Market forecasts suggest particular growth in applications requiring engines under 500 horsepower that can maintain consistent performance despite rapid environmental transitions, such as those experienced in coastal rescue operations or variable-altitude flight paths. This segment is projected to grow at 7.2% annually through 2027, outpacing the broader market.

Current Reliability Challenges in Extreme Operating Conditions

Radial engines operating in harsh environments face significant reliability challenges that have become increasingly critical as these engines find applications in remote locations and extreme conditions. Temperature extremes represent one of the most pressing concerns, with both extreme cold and heat affecting material properties and lubrication effectiveness. In sub-zero environments, lubricants may become excessively viscous, impeding proper circulation and increasing wear during startup. Conversely, in high-temperature settings, lubricants can break down prematurely, leading to inadequate protection of moving components.

Moisture and humidity present another major challenge, particularly in coastal or tropical environments. Water ingress can accelerate corrosion of critical engine components, especially in the complex arrangement of cylinders and connecting rods characteristic of radial engines. Salt-laden air compounds this problem, creating an electrochemical environment highly conducive to accelerated corrosion of aluminum components and steel fasteners.

Particulate contamination has emerged as an increasingly significant reliability factor. Dust, sand, and volcanic ash can infiltrate even well-sealed engines, causing abrasive wear on precision surfaces and potentially clogging oil galleries and filters. This is particularly problematic in desert operations or regions with significant airborne particulate matter, where fine particles can bypass conventional air filtration systems.

Vibration and shock loading represent inherent challenges for radial engines due to their design characteristics. The radial arrangement of cylinders creates unique vibration patterns that can lead to fatigue cracking in mounting points and accessory components. This is exacerbated in applications involving rough terrain or high-impact operations, where sudden shock loads can propagate through the engine structure.

Fuel quality variations across different operational theaters introduce additional reliability concerns. Modern radial engines must contend with varying fuel compositions, contaminants, and storage conditions that can affect combustion efficiency and potentially damage fuel system components. This is particularly problematic in remote locations where fuel quality control may be limited.

Maintenance accessibility presents a significant operational challenge. The complex arrangement of cylinders in a radial configuration makes certain components difficult to inspect and service, particularly in field conditions. This can lead to delayed identification of developing problems and potentially catastrophic failures when operating in harsh environments with limited support infrastructure.

Recent field data indicates that thermal cycling—the repeated heating and cooling of the engine—creates particularly severe reliability challenges in harsh environments. The differential expansion rates between various materials used in modern radial engines can accelerate seal degradation and fastener loosening, creating progressive reliability deterioration that may not be apparent until significant damage has occurred.

Moisture and humidity present another major challenge, particularly in coastal or tropical environments. Water ingress can accelerate corrosion of critical engine components, especially in the complex arrangement of cylinders and connecting rods characteristic of radial engines. Salt-laden air compounds this problem, creating an electrochemical environment highly conducive to accelerated corrosion of aluminum components and steel fasteners.

Particulate contamination has emerged as an increasingly significant reliability factor. Dust, sand, and volcanic ash can infiltrate even well-sealed engines, causing abrasive wear on precision surfaces and potentially clogging oil galleries and filters. This is particularly problematic in desert operations or regions with significant airborne particulate matter, where fine particles can bypass conventional air filtration systems.

Vibration and shock loading represent inherent challenges for radial engines due to their design characteristics. The radial arrangement of cylinders creates unique vibration patterns that can lead to fatigue cracking in mounting points and accessory components. This is exacerbated in applications involving rough terrain or high-impact operations, where sudden shock loads can propagate through the engine structure.

Fuel quality variations across different operational theaters introduce additional reliability concerns. Modern radial engines must contend with varying fuel compositions, contaminants, and storage conditions that can affect combustion efficiency and potentially damage fuel system components. This is particularly problematic in remote locations where fuel quality control may be limited.

Maintenance accessibility presents a significant operational challenge. The complex arrangement of cylinders in a radial configuration makes certain components difficult to inspect and service, particularly in field conditions. This can lead to delayed identification of developing problems and potentially catastrophic failures when operating in harsh environments with limited support infrastructure.

Recent field data indicates that thermal cycling—the repeated heating and cooling of the engine—creates particularly severe reliability challenges in harsh environments. The differential expansion rates between various materials used in modern radial engines can accelerate seal degradation and fastener loosening, creating progressive reliability deterioration that may not be apparent until significant damage has occurred.

Current Engineering Solutions for Harsh Environment Operation

01 Improved cooling systems for radial engines

Enhanced cooling systems are critical for improving radial engine reliability. These innovations include optimized air flow designs, advanced heat dissipation mechanisms, and improved cylinder cooling arrangements that prevent overheating during operation. Better thermal management reduces thermal stress on engine components, prevents premature wear, and ensures consistent performance under various operating conditions.- Improved radial engine cooling systems: Enhanced cooling systems are critical for improving radial engine reliability. These innovations include advanced air cooling designs, improved heat dissipation mechanisms, and optimized cooling fin configurations. By effectively managing engine temperature, these systems prevent overheating issues that commonly lead to engine failure, thereby significantly increasing operational reliability and extending engine lifespan under various operating conditions.

- Advanced lubrication and sealing mechanisms: Specialized lubrication systems and enhanced sealing mechanisms substantially improve radial engine reliability. These innovations include pressurized oil delivery systems, improved oil circulation pathways, and advanced sealing technologies that prevent oil leakage. Proper lubrication reduces friction between moving parts, minimizes wear, and ensures consistent performance, while effective seals maintain system integrity under varying operational pressures and temperatures.

- Structural reinforcements and material innovations: Structural improvements and advanced materials significantly enhance radial engine reliability. These developments include reinforced engine blocks, strengthened cylinder arrangements, and the use of high-performance alloys that can withstand extreme conditions. Such innovations reduce mechanical stress, prevent component fatigue, and improve overall durability, resulting in engines that maintain performance integrity over extended operational periods.

- Electronic monitoring and control systems: Integration of electronic monitoring and control systems significantly enhances radial engine reliability. These systems include real-time performance monitoring, automated diagnostic capabilities, and precise control mechanisms that optimize engine operation. By continuously tracking critical parameters and making automatic adjustments, these technologies prevent operational issues before they lead to failures, ensuring consistent performance and reducing maintenance requirements.

- Vibration reduction and balance improvements: Advanced vibration dampening and balance mechanisms substantially improve radial engine reliability. These innovations include counterweight systems, harmonic balancers, and specialized mounting arrangements that minimize operational vibration. By reducing mechanical stress caused by vibration, these systems prevent premature component wear, structural fatigue, and connection failures, resulting in smoother operation and extended service life for radial engines.

02 Advanced lubrication systems for radial engines

Specialized lubrication systems significantly enhance radial engine reliability by ensuring proper oil distribution to all moving parts. These systems include pressurized oil delivery mechanisms, improved oil filtration methods, and strategic oil passage designs that reach critical bearing surfaces and friction points. Effective lubrication reduces wear, prevents seizure, and extends the operational lifespan of engine components.Expand Specific Solutions03 Structural reinforcements and material improvements

Structural enhancements and advanced materials significantly improve radial engine reliability. These include reinforced crankcase designs, stronger connecting rods, improved cylinder mounting methods, and the use of high-performance alloys that can withstand higher temperatures and stresses. These improvements reduce mechanical failures, increase durability, and extend service intervals under demanding operational conditions.Expand Specific Solutions04 Electronic monitoring and control systems

Integration of electronic monitoring and control systems enhances radial engine reliability through real-time performance tracking and automated adjustments. These systems include sensors for temperature, pressure, and vibration monitoring, electronic ignition control, and computerized engine management that can detect potential failures before they occur. Advanced diagnostics allow for predictive maintenance and optimal engine operation across various flight conditions.Expand Specific Solutions05 Vibration reduction and balance improvements

Techniques for reducing vibration and improving balance are essential for radial engine reliability. These include counterweight designs, precision manufacturing of rotating components, vibration dampening systems, and improved mounting arrangements. Reduced vibration prevents fatigue failures, extends component life, improves operational comfort, and maintains the structural integrity of both the engine and the aircraft frame during extended operation.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The radial engine reliability market in harsh environments is currently in a growth phase, with increasing demand driven by aerospace, defense, and industrial applications. The market size is estimated to be expanding at 5-7% annually, reaching approximately $3.5 billion globally. Technologically, the field is moderately mature but evolving rapidly with innovations in materials science and digital monitoring. Leading players include Wärtsilä Finland and Winterthur Gas & Diesel focusing on marine applications, while aerospace solutions are dominated by GE and Siemens. Academic institutions like Beihang University and Nanjing University of Aeronautics & Astronautics are advancing fundamental research, while Bridgestone and Michelin contribute specialized sealing technologies critical for harsh environment operations.

Weichai Power

Technical Solution: Weichai Power has pioneered innovative radial engine reliability solutions for harsh environment applications, particularly in extreme temperature and dusty conditions. Their technology incorporates advanced filtration systems that effectively trap particulates as small as 1 micron, preventing abrasive damage to internal engine components. Weichai's radial engines feature specialized high-temperature alloys in critical components that maintain structural integrity even when operating in environments exceeding 50°C. Their proprietary lubrication system includes temperature-adaptive viscosity control that ensures optimal oil flow regardless of ambient conditions, significantly reducing wear on bearing surfaces and rotating assemblies. Additionally, Weichai has developed sealed cooling systems with enhanced heat exchange efficiency, allowing reliable operation in environments with limited cooling resources or high ambient temperatures.

Strengths: Exceptional dust and particulate resistance; superior high-temperature performance; adaptive lubrication systems that respond to environmental conditions. Weaknesses: Higher manufacturing costs due to specialized materials; increased weight compared to standard designs; more complex maintenance procedures requiring specialized training.

Wärtsilä Finland Oy

Technical Solution: Wärtsilä has developed comprehensive radial engine reliability solutions for harsh marine and industrial environments. Their technology incorporates advanced materials science with ceramic-coated components that resist corrosion and thermal degradation even in extreme conditions. Wärtsilä's radial engines feature intelligent monitoring systems that continuously analyze over 200 operational parameters to predict potential failures before they occur, allowing for preventative maintenance. Their proprietary combustion technology adapts to fuel quality variations, maintaining optimal performance even with lower-grade fuels often encountered in remote or challenging environments. Additionally, Wärtsilä has implemented modular design principles that allow for rapid component replacement in field conditions, reducing downtime by up to 40% compared to traditional engine designs. The company's engines also incorporate specialized sealing technologies that prevent contamination ingress in high-dust or high-humidity environments.

Strengths: Exceptional predictive maintenance capabilities; adaptability to varying fuel qualities; modular design enabling efficient field repairs; superior contamination resistance. Weaknesses: Higher initial acquisition costs; requires more sophisticated diagnostic equipment; greater complexity in control systems that may require specialized technical support.

Critical Patents and Innovations in Radial Engine Reliability

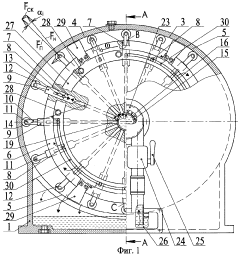

Radial engine

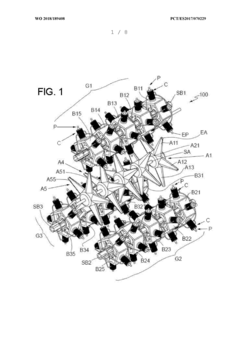

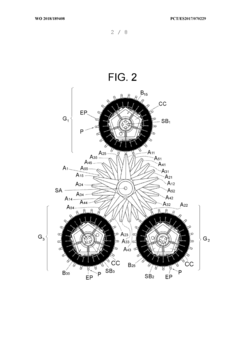

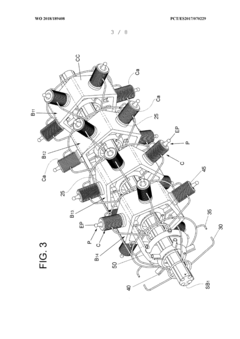

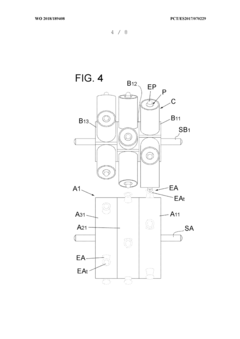

PatentWO2018189408A1

Innovation

- A radial engine design featuring a plurality of radially distributed sets of radial elements linked to a common output shaft, eliminating the need for a crankshaft and connecting rods, with angularly offset elements and groups of cylinders and pistons for efficient energy transmission and rotation.

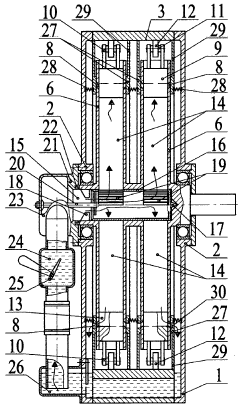

Radial hydraulic engine

PatentWO2011025408A1

Innovation

- A hydraulic radial engine with an unstable mechanical balance, featuring multiple rotors on a shaft, elliptical cylindrical surfaces, rollers interacting with pistons, and a unique drainage system to utilize centrifugal forces for piston movement and rotation, allowing regulation of engine revolutions.

Materials Science Advancements for Extreme Conditions

Recent advancements in materials science have revolutionized the reliability of radial engines operating in harsh environments. Traditional materials like aluminum alloys and steel components have been enhanced through innovative metallurgical processes, significantly improving their performance under extreme conditions. These developments include high-temperature resistant superalloys incorporating nickel, cobalt, and chromium that maintain structural integrity at temperatures exceeding 1000°C, critical for radial engine components exposed to intense heat cycles.

Ceramic matrix composites (CMCs) represent another breakthrough, offering exceptional thermal resistance while reducing overall engine weight. These materials combine ceramic fibers within a ceramic matrix, creating components that withstand thermal shock and maintain dimensional stability under severe temperature fluctuations commonly experienced in radial engines operating in desert or arctic environments.

Surface engineering technologies have evolved to address corrosion and wear issues prevalent in harsh environments. Advanced coating systems such as thermal barrier coatings (TBCs) provide critical protection for combustion chamber components, while physical vapor deposition (PVD) techniques create nanoscale protective layers that significantly extend component lifespan in corrosive environments like maritime applications where salt exposure accelerates degradation.

Polymer composites reinforced with carbon or glass fibers have been developed specifically for non-load-bearing components in radial engines. These materials offer excellent vibration damping properties and chemical resistance, crucial for maintaining operational integrity in environments with extreme pH levels or chemical exposure. Recent innovations in self-healing polymers show promise for components that can autonomously repair minor damage during operation.

Smart materials incorporating embedded sensors represent the cutting edge of materials science applications for radial engines. These materials can monitor their own structural health, detecting microfractures or thermal fatigue before catastrophic failure occurs. Shape memory alloys that respond to temperature changes are being integrated into critical components to provide adaptive performance across varying environmental conditions.

Nanotechnology has enabled the development of materials with precisely engineered microstructures, optimizing properties at the molecular level. Nanostructured metals exhibit superior strength-to-weight ratios and enhanced fatigue resistance, while nanoscale lubricant additives reduce friction between moving parts even under boundary lubrication conditions common in extreme temperature operations.

These materials science advancements collectively address the primary failure modes of radial engines in harsh environments, significantly improving reliability metrics while extending maintenance intervals and overall service life. The integration of these advanced materials into radial engine design represents a critical factor in ensuring operational reliability across diverse and challenging environmental conditions.

Ceramic matrix composites (CMCs) represent another breakthrough, offering exceptional thermal resistance while reducing overall engine weight. These materials combine ceramic fibers within a ceramic matrix, creating components that withstand thermal shock and maintain dimensional stability under severe temperature fluctuations commonly experienced in radial engines operating in desert or arctic environments.

Surface engineering technologies have evolved to address corrosion and wear issues prevalent in harsh environments. Advanced coating systems such as thermal barrier coatings (TBCs) provide critical protection for combustion chamber components, while physical vapor deposition (PVD) techniques create nanoscale protective layers that significantly extend component lifespan in corrosive environments like maritime applications where salt exposure accelerates degradation.

Polymer composites reinforced with carbon or glass fibers have been developed specifically for non-load-bearing components in radial engines. These materials offer excellent vibration damping properties and chemical resistance, crucial for maintaining operational integrity in environments with extreme pH levels or chemical exposure. Recent innovations in self-healing polymers show promise for components that can autonomously repair minor damage during operation.

Smart materials incorporating embedded sensors represent the cutting edge of materials science applications for radial engines. These materials can monitor their own structural health, detecting microfractures or thermal fatigue before catastrophic failure occurs. Shape memory alloys that respond to temperature changes are being integrated into critical components to provide adaptive performance across varying environmental conditions.

Nanotechnology has enabled the development of materials with precisely engineered microstructures, optimizing properties at the molecular level. Nanostructured metals exhibit superior strength-to-weight ratios and enhanced fatigue resistance, while nanoscale lubricant additives reduce friction between moving parts even under boundary lubrication conditions common in extreme temperature operations.

These materials science advancements collectively address the primary failure modes of radial engines in harsh environments, significantly improving reliability metrics while extending maintenance intervals and overall service life. The integration of these advanced materials into radial engine design represents a critical factor in ensuring operational reliability across diverse and challenging environmental conditions.

Environmental Compliance and Sustainability Considerations

Environmental regulations and sustainability considerations have become increasingly critical factors in radial engine design and operation, particularly in harsh environments. Modern radial engines must comply with stringent emission standards that vary significantly across global jurisdictions. The Environmental Protection Agency (EPA) in the United States, the European Union's Euro standards, and similar regulatory frameworks in Asia impose progressively tighter limits on exhaust emissions, noise pollution, and waste byproducts from engine operations.

These compliance requirements present unique challenges for radial engines operating in harsh environments, where extreme temperatures, humidity, or particulate matter can affect combustion efficiency and emissions profiles. Manufacturers must implement advanced fuel injection systems, exhaust after-treatment technologies, and precision electronic controls to maintain compliance while preserving reliability under adverse conditions.

Sustainability considerations extend beyond mere regulatory compliance to encompass the entire lifecycle of radial engines. Material selection has evolved to incorporate recycled components and reduce dependence on rare earth elements or environmentally problematic substances. Advanced alloys and composites that offer superior durability in harsh environments often present better sustainability profiles by extending service intervals and reducing resource consumption over the engine's operational life.

Fuel efficiency remains a paramount sustainability concern, with modern radial engine designs incorporating variable valve timing, optimized combustion chambers, and precision fuel metering to maximize energy extraction while minimizing environmental impact. Alternative fuel compatibility has emerged as a significant design consideration, with newer radial engines engineered to accommodate sustainable aviation fuels (SAF), biofuels, and synthetic alternatives that offer reduced carbon footprints.

Maintenance protocols for harsh-environment radial engines increasingly incorporate sustainability metrics, with emphasis on minimizing consumable usage, extending component lifecycles, and reducing hazardous waste generation during service operations. Predictive maintenance technologies help optimize service intervals based on actual operating conditions rather than fixed schedules, further reducing environmental impact while maintaining reliability.

End-of-life considerations have gained prominence in radial engine design, with manufacturers implementing design-for-disassembly principles that facilitate component recovery and material recycling. This circular economy approach reduces the environmental footprint of engine disposal while potentially recovering valuable materials for reuse in new manufacturing processes.

The intersection of environmental compliance and sustainability with harsh-environment reliability presents both challenges and opportunities for radial engine advancement. Innovations that enhance durability in extreme conditions often align with sustainability goals by reducing resource consumption and environmental impact throughout the operational lifecycle.

These compliance requirements present unique challenges for radial engines operating in harsh environments, where extreme temperatures, humidity, or particulate matter can affect combustion efficiency and emissions profiles. Manufacturers must implement advanced fuel injection systems, exhaust after-treatment technologies, and precision electronic controls to maintain compliance while preserving reliability under adverse conditions.

Sustainability considerations extend beyond mere regulatory compliance to encompass the entire lifecycle of radial engines. Material selection has evolved to incorporate recycled components and reduce dependence on rare earth elements or environmentally problematic substances. Advanced alloys and composites that offer superior durability in harsh environments often present better sustainability profiles by extending service intervals and reducing resource consumption over the engine's operational life.

Fuel efficiency remains a paramount sustainability concern, with modern radial engine designs incorporating variable valve timing, optimized combustion chambers, and precision fuel metering to maximize energy extraction while minimizing environmental impact. Alternative fuel compatibility has emerged as a significant design consideration, with newer radial engines engineered to accommodate sustainable aviation fuels (SAF), biofuels, and synthetic alternatives that offer reduced carbon footprints.

Maintenance protocols for harsh-environment radial engines increasingly incorporate sustainability metrics, with emphasis on minimizing consumable usage, extending component lifecycles, and reducing hazardous waste generation during service operations. Predictive maintenance technologies help optimize service intervals based on actual operating conditions rather than fixed schedules, further reducing environmental impact while maintaining reliability.

End-of-life considerations have gained prominence in radial engine design, with manufacturers implementing design-for-disassembly principles that facilitate component recovery and material recycling. This circular economy approach reduces the environmental footprint of engine disposal while potentially recovering valuable materials for reuse in new manufacturing processes.

The intersection of environmental compliance and sustainability with harsh-environment reliability presents both challenges and opportunities for radial engine advancement. Innovations that enhance durability in extreme conditions often align with sustainability goals by reducing resource consumption and environmental impact throughout the operational lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!