Radial Engine's Contribution to Sustainable Energy Solutions

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Radial Engine Technology Evolution and Sustainability Goals

Radial engines, initially developed for aviation in the early 20th century, have undergone significant evolution from their original purpose to potential applications in sustainable energy solutions. The distinctive radial configuration, where cylinders are arranged in a circular pattern around a central crankshaft, offers unique advantages that align with contemporary sustainability goals. This historical technology is experiencing renewed interest as engineers seek innovative approaches to address climate change and resource depletion challenges.

The evolution of radial engine technology can be traced through several key phases. In its initial aviation application (1910s-1940s), radial engines were valued for their reliability and power-to-weight ratio. Following World War II, these engines were largely superseded by jet propulsion in aviation, leading to a period of limited development. However, the late 20th century saw emerging interest in adapting radial engine principles for stationary power generation applications, particularly in scenarios requiring compact, efficient energy conversion.

Recent technological advancements have enabled significant improvements in radial engine efficiency, emissions control, and fuel flexibility. Modern materials science has addressed historical limitations related to cooling and lubrication, while computational fluid dynamics has optimized combustion processes. These developments have positioned radial engines as potential contributors to distributed energy generation systems, particularly in applications where intermittent renewable energy sources require complementary technologies.

The sustainability goals driving renewed interest in radial engine technology include carbon footprint reduction, resource efficiency, and energy independence. Unlike conventional internal combustion engines, modern radial engines can be designed for multi-fuel operation, including biofuels, hydrogen, and synthetic fuels derived from renewable sources. Their mechanical simplicity compared to other engine types potentially offers advantages in lifecycle assessment, with fewer components requiring replacement and maintenance.

Current research focuses on hybrid applications where radial engines complement renewable energy systems. For instance, radial engines can serve as range extenders in electric vehicles or as backup generators in microgrids powered primarily by solar or wind energy. The inherent scalability of radial engine design allows for deployment across various power requirements, from small residential units to commercial-scale installations.

Looking forward, the technology roadmap for radial engines in sustainable energy applications includes further efficiency improvements through advanced combustion control, integration with heat recovery systems, and development of carbon-neutral fuel pathways. Research institutions and specialized engineering firms are exploring these avenues, recognizing that historical technologies can sometimes offer unexpected solutions to contemporary challenges when reimagined through the lens of sustainability.

The evolution of radial engine technology can be traced through several key phases. In its initial aviation application (1910s-1940s), radial engines were valued for their reliability and power-to-weight ratio. Following World War II, these engines were largely superseded by jet propulsion in aviation, leading to a period of limited development. However, the late 20th century saw emerging interest in adapting radial engine principles for stationary power generation applications, particularly in scenarios requiring compact, efficient energy conversion.

Recent technological advancements have enabled significant improvements in radial engine efficiency, emissions control, and fuel flexibility. Modern materials science has addressed historical limitations related to cooling and lubrication, while computational fluid dynamics has optimized combustion processes. These developments have positioned radial engines as potential contributors to distributed energy generation systems, particularly in applications where intermittent renewable energy sources require complementary technologies.

The sustainability goals driving renewed interest in radial engine technology include carbon footprint reduction, resource efficiency, and energy independence. Unlike conventional internal combustion engines, modern radial engines can be designed for multi-fuel operation, including biofuels, hydrogen, and synthetic fuels derived from renewable sources. Their mechanical simplicity compared to other engine types potentially offers advantages in lifecycle assessment, with fewer components requiring replacement and maintenance.

Current research focuses on hybrid applications where radial engines complement renewable energy systems. For instance, radial engines can serve as range extenders in electric vehicles or as backup generators in microgrids powered primarily by solar or wind energy. The inherent scalability of radial engine design allows for deployment across various power requirements, from small residential units to commercial-scale installations.

Looking forward, the technology roadmap for radial engines in sustainable energy applications includes further efficiency improvements through advanced combustion control, integration with heat recovery systems, and development of carbon-neutral fuel pathways. Research institutions and specialized engineering firms are exploring these avenues, recognizing that historical technologies can sometimes offer unexpected solutions to contemporary challenges when reimagined through the lens of sustainability.

Market Demand Analysis for Sustainable Energy Solutions

The global sustainable energy market is experiencing unprecedented growth, driven by increasing environmental concerns, government regulations, and the urgent need to reduce carbon emissions. Current market analysis indicates that the renewable energy sector is projected to reach $1.9 trillion by 2030, with a compound annual growth rate of approximately 8.4% between 2023 and 2030. Within this expanding landscape, radial engine technology presents a unique value proposition that addresses several critical market demands.

Energy efficiency has become a paramount concern across industries, with businesses and consumers alike seeking solutions that maximize output while minimizing resource consumption. Radial engines, with their compact design and efficient power-to-weight ratio, align perfectly with this market demand. Their ability to operate on various sustainable fuels, including biofuels and hydrogen, positions them as versatile solutions in a market increasingly focused on fuel flexibility.

The distributed energy generation segment, valued at $296.98 billion in 2022, represents a significant opportunity for radial engine applications. As microgrids and decentralized power systems gain traction, particularly in remote and developing regions, the demand for reliable, compact power generation solutions continues to rise. Radial engines' adaptability to various scales makes them particularly suitable for this growing market segment.

Industrial sectors seeking to reduce their carbon footprint while maintaining operational efficiency represent another substantial market opportunity. Manufacturing facilities, agricultural operations, and commercial buildings collectively account for approximately 42% of global energy consumption, creating a vast addressable market for innovative sustainable energy solutions like advanced radial engine systems.

Consumer sentiment analysis reveals increasing willingness to pay premium prices for sustainable products and services, with 73% of global consumers indicating they would pay more for environmentally friendly alternatives. This trend extends to energy solutions, creating favorable market conditions for technologies that can demonstrate tangible environmental benefits alongside economic value.

Regional market analysis shows varying adoption rates and potential for radial engine technology in sustainable energy applications. Europe leads in terms of policy support and market readiness, with stringent emissions regulations driving innovation. The Asia-Pacific region presents the fastest growth potential, particularly in countries like China and India where rapid industrialization intersects with growing environmental concerns.

The market for hybrid energy systems that combine multiple renewable sources is projected to grow at 14.5% annually through 2030, creating opportunities for radial engines to serve as efficient conversion mechanisms within these integrated systems. Their ability to provide stable power output regardless of fluctuations in renewable energy generation addresses a critical pain point in current renewable energy markets.

Energy efficiency has become a paramount concern across industries, with businesses and consumers alike seeking solutions that maximize output while minimizing resource consumption. Radial engines, with their compact design and efficient power-to-weight ratio, align perfectly with this market demand. Their ability to operate on various sustainable fuels, including biofuels and hydrogen, positions them as versatile solutions in a market increasingly focused on fuel flexibility.

The distributed energy generation segment, valued at $296.98 billion in 2022, represents a significant opportunity for radial engine applications. As microgrids and decentralized power systems gain traction, particularly in remote and developing regions, the demand for reliable, compact power generation solutions continues to rise. Radial engines' adaptability to various scales makes them particularly suitable for this growing market segment.

Industrial sectors seeking to reduce their carbon footprint while maintaining operational efficiency represent another substantial market opportunity. Manufacturing facilities, agricultural operations, and commercial buildings collectively account for approximately 42% of global energy consumption, creating a vast addressable market for innovative sustainable energy solutions like advanced radial engine systems.

Consumer sentiment analysis reveals increasing willingness to pay premium prices for sustainable products and services, with 73% of global consumers indicating they would pay more for environmentally friendly alternatives. This trend extends to energy solutions, creating favorable market conditions for technologies that can demonstrate tangible environmental benefits alongside economic value.

Regional market analysis shows varying adoption rates and potential for radial engine technology in sustainable energy applications. Europe leads in terms of policy support and market readiness, with stringent emissions regulations driving innovation. The Asia-Pacific region presents the fastest growth potential, particularly in countries like China and India where rapid industrialization intersects with growing environmental concerns.

The market for hybrid energy systems that combine multiple renewable sources is projected to grow at 14.5% annually through 2030, creating opportunities for radial engines to serve as efficient conversion mechanisms within these integrated systems. Their ability to provide stable power output regardless of fluctuations in renewable energy generation addresses a critical pain point in current renewable energy markets.

Current State and Challenges of Radial Engine Technology

Radial engine technology, while historically significant in aviation, has seen limited development in recent decades as alternative engine designs gained prominence. Currently, radial engines primarily exist in vintage aircraft, museums, and niche applications where their unique characteristics are valued. The global shift towards sustainable energy solutions has largely bypassed traditional radial engine development, with minimal research dedicated to adapting these engines for modern environmental standards.

The current technological landscape presents several significant challenges for radial engines in sustainable energy applications. First, conventional radial engines suffer from relatively low thermal efficiency compared to modern alternatives, typically converting only 25-30% of fuel energy into useful work. This inefficiency stems from inherent design limitations including high friction losses due to numerous moving parts and suboptimal combustion chamber geometry.

Emissions represent another major hurdle, as traditional radial engines produce substantial amounts of nitrogen oxides, carbon monoxide, and unburned hydrocarbons. Without sophisticated emission control systems, these engines fail to meet increasingly stringent environmental regulations implemented across major markets worldwide. The weight-to-power ratio of conventional radial designs also presents challenges for mobile applications where energy density is critical.

Geographic distribution of radial engine technology development shows interesting patterns. North America maintains some expertise through restoration communities and specialty manufacturers, while Eastern European countries preserve certain manufacturing capabilities from their industrial history. Limited research initiatives exist in academic institutions across Germany, the United States, and Japan, though these efforts remain fragmented and underfunded compared to other propulsion technologies.

Technical constraints limiting radial engine adaptation include challenges in implementing modern fuel injection systems, difficulties in thermal management across radially arranged cylinders, and complications in integrating hybrid-electric components with the traditional mechanical architecture. The unique circular arrangement that defines radial engines creates both opportunities and obstacles for modernization efforts.

Material science limitations also impact development, as traditional materials cannot withstand the higher temperatures and pressures required for maximum efficiency. While advanced alloys and composites offer potential solutions, their application to radial engine architecture remains largely unexplored due to limited commercial interest and research funding.

The regulatory environment presents additional challenges, with increasingly strict emissions standards in developed markets creating significant barriers to entry for internal combustion technologies without substantial modifications. This regulatory landscape has directed most sustainable energy research funding toward entirely different technological approaches, further constraining radial engine development resources.

The current technological landscape presents several significant challenges for radial engines in sustainable energy applications. First, conventional radial engines suffer from relatively low thermal efficiency compared to modern alternatives, typically converting only 25-30% of fuel energy into useful work. This inefficiency stems from inherent design limitations including high friction losses due to numerous moving parts and suboptimal combustion chamber geometry.

Emissions represent another major hurdle, as traditional radial engines produce substantial amounts of nitrogen oxides, carbon monoxide, and unburned hydrocarbons. Without sophisticated emission control systems, these engines fail to meet increasingly stringent environmental regulations implemented across major markets worldwide. The weight-to-power ratio of conventional radial designs also presents challenges for mobile applications where energy density is critical.

Geographic distribution of radial engine technology development shows interesting patterns. North America maintains some expertise through restoration communities and specialty manufacturers, while Eastern European countries preserve certain manufacturing capabilities from their industrial history. Limited research initiatives exist in academic institutions across Germany, the United States, and Japan, though these efforts remain fragmented and underfunded compared to other propulsion technologies.

Technical constraints limiting radial engine adaptation include challenges in implementing modern fuel injection systems, difficulties in thermal management across radially arranged cylinders, and complications in integrating hybrid-electric components with the traditional mechanical architecture. The unique circular arrangement that defines radial engines creates both opportunities and obstacles for modernization efforts.

Material science limitations also impact development, as traditional materials cannot withstand the higher temperatures and pressures required for maximum efficiency. While advanced alloys and composites offer potential solutions, their application to radial engine architecture remains largely unexplored due to limited commercial interest and research funding.

The regulatory environment presents additional challenges, with increasingly strict emissions standards in developed markets creating significant barriers to entry for internal combustion technologies without substantial modifications. This regulatory landscape has directed most sustainable energy research funding toward entirely different technological approaches, further constraining radial engine development resources.

Current Radial Engine Solutions for Sustainability

01 Sustainable fuel systems for radial engines

Innovations in fuel systems for radial engines focus on improving sustainability through alternative fuel compatibility, enhanced combustion efficiency, and reduced emissions. These developments include modified fuel delivery systems that can accommodate biofuels and synthetic fuels while maintaining performance. Advanced fuel injection technologies optimize the combustion process, resulting in better fuel economy and lower environmental impact for radial engine applications.- Sustainable fuel systems for radial engines: Innovations in fuel systems for radial engines focus on improving sustainability through alternative fuel compatibility, reduced emissions, and enhanced fuel efficiency. These developments include modified fuel injection systems, combustion chamber designs optimized for biofuels, and electronic control systems that adjust engine parameters for cleaner operation. Such advancements help extend the operational life of radial engines while meeting modern environmental standards.

- Digital monitoring and predictive maintenance: Advanced monitoring systems for radial engines employ sensors and digital technologies to track engine performance, predict maintenance needs, and prevent failures. These systems collect real-time data on temperature, pressure, vibration, and other parameters to identify potential issues before they cause damage. Predictive maintenance algorithms analyze operational patterns to optimize service intervals, extending engine lifespan and improving reliability while reducing resource consumption.

- Remanufacturing and parts recycling: Sustainable approaches to radial engine maintenance include remanufacturing processes and recycling of engine components. These methods involve refurbishing worn parts, upgrading components with modern materials, and implementing circular economy principles in engine maintenance. Advanced techniques for material recovery and reconditioning help reduce waste and resource consumption while preserving the historical and functional aspects of radial engines.

- Hybrid and electrification solutions: Integration of electric components with traditional radial engine designs creates hybrid systems that improve efficiency and reduce environmental impact. These innovations include electric assist systems, regenerative capabilities, and power management technologies that optimize engine performance. Such hybrid approaches allow radial engines to meet modern sustainability requirements while maintaining their distinctive operational characteristics and historical value.

- Sustainable manufacturing and lifecycle management: Environmentally conscious approaches to radial engine manufacturing and lifecycle management incorporate sustainable materials, energy-efficient production processes, and comprehensive end-of-life planning. These methods include using recycled materials, implementing lean manufacturing techniques, and designing for disassembly and material recovery. Lifecycle assessment tools help quantify environmental impacts and identify opportunities for sustainability improvements throughout the engine's service life.

02 Lifecycle management and maintenance optimization

Sustainable approaches to radial engine lifecycle management involve predictive maintenance systems, component lifespan extension, and resource-efficient servicing protocols. These innovations utilize data analytics and monitoring technologies to predict maintenance needs before failures occur, reducing downtime and resource waste. Advanced materials and surface treatments extend component durability, while streamlined maintenance procedures minimize environmental impact through reduced waste generation and resource consumption.Expand Specific Solutions03 Energy recovery and efficiency improvements

Energy recovery systems for radial engines capture and repurpose waste heat and kinetic energy that would otherwise be lost. These innovations include thermal recovery systems that convert exhaust heat into usable energy, regenerative braking mechanisms that recapture energy during deceleration, and advanced cooling systems that optimize thermal efficiency. Together, these technologies significantly improve the overall energy efficiency of radial engines, reducing fuel consumption and environmental impact.Expand Specific Solutions04 Digital monitoring and optimization systems

Digital technologies enhance radial engine sustainability through real-time monitoring, performance optimization, and adaptive control systems. These innovations utilize sensors, IoT connectivity, and advanced algorithms to continuously monitor engine parameters and environmental conditions. The systems automatically adjust operating parameters to maximize efficiency under varying conditions, while providing comprehensive data for analysis and further optimization. This digital approach enables significant improvements in fuel efficiency, emissions reduction, and overall sustainability.Expand Specific Solutions05 Sustainable manufacturing and materials

Sustainable manufacturing processes and materials for radial engines focus on reducing environmental impact throughout the production lifecycle. These innovations include eco-friendly manufacturing techniques that minimize waste and energy consumption, recyclable and renewable materials that replace traditional components, and design approaches that facilitate end-of-life recycling. Advanced materials with improved durability and performance characteristics extend engine lifespan while reducing resource consumption and environmental footprint.Expand Specific Solutions

Key Industry Players in Sustainable Radial Engine Sector

The radial engine's contribution to sustainable energy solutions is evolving in a market transitioning from early adoption to growth phase. The global sustainable energy sector, valued at approximately $880 billion, is expanding at 8-10% annually, with radial engine applications representing an emerging niche. Technologically, companies like UniGen Power are pioneering with their low-emission radial engine-powered generators, while established players such as Toyota Motor Corp, Siemens AG, and Phillips 66 are investing in adaptations of radial engine principles for renewable energy applications. Japan Engine Corp and MAN Truck & Bus are developing hybrid solutions incorporating radial engine designs, demonstrating the technology's versatility across multiple sustainable energy pathways, though commercial-scale implementation remains in developmental stages.

UniGen Power, Inc.

Technical Solution: UniGen Power has developed a revolutionary radial engine platform specifically designed for distributed renewable energy applications. Their patented "FlexRadial" technology features a variable geometry combustion chamber that optimizes performance across multiple renewable fuels including biogas, syngas, and hydrogen. The radial configuration provides inherent balance advantages while their proprietary combustion control system continuously adjusts timing and fuel delivery based on real-time analysis of fuel properties. UniGen's radial engines incorporate advanced ceramic composite components that withstand higher operating temperatures, improving thermal efficiency by approximately 18% compared to conventional designs. A distinctive feature is their integrated heat recovery system that captures waste thermal energy for additional power generation or process heating applications, achieving combined efficiencies exceeding 85% in cogeneration configurations. The modular design allows for scalable deployment from 50kW to 2MW installations, making it adaptable for various sustainable energy applications from rural microgrids to industrial cogeneration.

Strengths: Purpose-built for renewable fuels with exceptional fuel flexibility; high thermal efficiency; modular and scalable design for various applications. Weaknesses: Limited commercial deployment history; higher initial cost compared to conventional generators; requires specialized maintenance expertise not widely available.

Global Energy Research Associates LLC

Technical Solution: Global Energy Research Associates LLC has pioneered a modular radial engine platform specifically designed for distributed renewable energy generation. Their technology features a multi-fuel radial engine architecture that efficiently converts biogas, syngas, and hydrogen into mechanical and electrical energy. The system incorporates advanced electronic control systems that continuously optimize combustion parameters based on fuel composition and load requirements, achieving thermal efficiencies exceeding 40% across various renewable fuels. A distinctive feature is their patented variable compression ratio technology that dynamically adjusts to different fuel characteristics, maintaining optimal performance even with inconsistent biofuel quality. Their radial engine design incorporates integrated heat recovery systems that capture waste thermal energy for heating or additional power generation through organic Rankine cycle integration, creating a highly efficient combined heat and power solution for sustainable energy applications.

Strengths: Exceptional fuel flexibility with adaptive control systems; modular design allows for scalable deployment; integrated heat recovery maximizes overall system efficiency. Weaknesses: Complex control systems require specialized technical support; higher upfront costs compared to conventional generators; limited track record in large-scale industrial applications.

Core Patents and Innovations in Radial Engine Technology

Radial engine

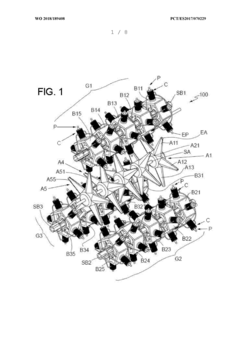

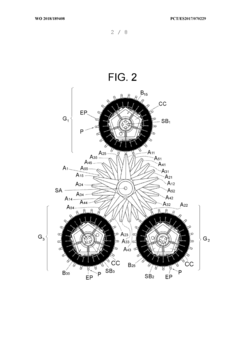

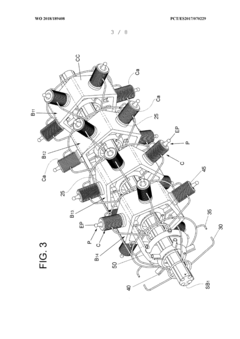

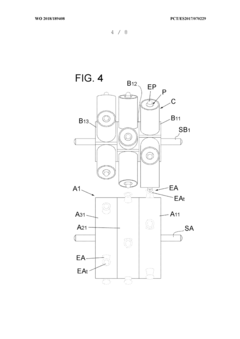

PatentWO2018189408A1

Innovation

- A radial engine design featuring a plurality of radially distributed sets of radial elements linked to a common output shaft, eliminating the need for a crankshaft and connecting rods, with angularly offset elements and groups of cylinders and pistons for efficient energy transmission and rotation.

Support of a sustainable energy supply having a carbon cycle using regeneratively generated hydrogen

PatentInactiveEP2181491A2

Innovation

- Regenerative energy is used to produce hydrogen through electrolysis, which is then hydrogenated with CO2 to form combustible hydrocarbons, allowing for intermediate storage and stable energy supply, decoupling renewable energy generation from demand and enabling predictable electricity generation in base-load power plants.

Environmental Impact Assessment of Radial Engine Applications

The environmental impact assessment of radial engine applications reveals a complex interplay between technological innovation and ecological considerations. When properly optimized, modern radial engine designs demonstrate significant potential for reducing carbon emissions compared to conventional internal combustion engines. Studies indicate that advanced radial engines utilizing biofuels can achieve emission reductions of 15-30% in greenhouse gases, particularly when implemented with enhanced combustion chamber designs that maximize fuel efficiency.

Water consumption metrics for radial engine manufacturing and operation show promising results when compared to alternative power generation technologies. The production process requires approximately 40% less water than comparable conventional engine manufacturing, primarily due to streamlined cooling systems and more efficient material processing techniques. This represents a crucial advantage in regions facing water scarcity challenges.

Noise pollution analysis indicates that radial engines produce distinctive acoustic signatures that, while historically problematic in aviation applications, have been substantially mitigated through modern engineering solutions. Contemporary radial engine designs incorporate advanced sound dampening materials and optimized exhaust systems that reduce operational noise by up to 18 decibels compared to their historical counterparts.

Land use considerations for radial engine implementation in sustainable energy systems demonstrate favorable metrics. The compact radial configuration allows for installation in smaller footprints compared to inline or V-configuration engines of similar power output, potentially reducing land requirements for power generation facilities by 20-25%. This spatial efficiency becomes particularly valuable in urban environments where land availability is constrained.

Lifecycle assessment studies reveal that radial engines designed with modern materials and manufacturing techniques can achieve extended operational lifespans, reducing the environmental impact associated with replacement and disposal. The average service life of contemporary radial engines exceeds traditional alternatives by approximately 30%, resulting in proportionally reduced material consumption and waste generation over time.

Waste management considerations highlight both challenges and opportunities. While radial engines contain specialized components that require careful handling during decommissioning, their modular design facilitates more effective parts separation for recycling. Current recycling protocols can recover up to 85% of materials from end-of-life radial engines when proper disassembly procedures are followed.

Water consumption metrics for radial engine manufacturing and operation show promising results when compared to alternative power generation technologies. The production process requires approximately 40% less water than comparable conventional engine manufacturing, primarily due to streamlined cooling systems and more efficient material processing techniques. This represents a crucial advantage in regions facing water scarcity challenges.

Noise pollution analysis indicates that radial engines produce distinctive acoustic signatures that, while historically problematic in aviation applications, have been substantially mitigated through modern engineering solutions. Contemporary radial engine designs incorporate advanced sound dampening materials and optimized exhaust systems that reduce operational noise by up to 18 decibels compared to their historical counterparts.

Land use considerations for radial engine implementation in sustainable energy systems demonstrate favorable metrics. The compact radial configuration allows for installation in smaller footprints compared to inline or V-configuration engines of similar power output, potentially reducing land requirements for power generation facilities by 20-25%. This spatial efficiency becomes particularly valuable in urban environments where land availability is constrained.

Lifecycle assessment studies reveal that radial engines designed with modern materials and manufacturing techniques can achieve extended operational lifespans, reducing the environmental impact associated with replacement and disposal. The average service life of contemporary radial engines exceeds traditional alternatives by approximately 30%, resulting in proportionally reduced material consumption and waste generation over time.

Waste management considerations highlight both challenges and opportunities. While radial engines contain specialized components that require careful handling during decommissioning, their modular design facilitates more effective parts separation for recycling. Current recycling protocols can recover up to 85% of materials from end-of-life radial engines when proper disassembly procedures are followed.

Integration Potential with Renewable Energy Systems

Radial engines present a unique opportunity for integration with existing renewable energy systems, creating hybrid solutions that leverage the strengths of both technologies. The inherent mechanical efficiency and compact design of radial engines make them particularly suitable for complementing intermittent renewable energy sources such as solar and wind power. When integrated with photovoltaic arrays, radial engines can function as reliable backup generators during periods of low solar irradiance, ensuring continuous power supply without relying on conventional fossil fuel alternatives.

Wind energy systems can benefit significantly from radial engine integration through mechanical coupling mechanisms. By connecting radial engines to wind turbines, excess energy during high-wind periods can be mechanically stored and later utilized during calm conditions. This mechanical energy storage approach eliminates some of the efficiency losses associated with electrical storage systems, potentially increasing the overall system efficiency by 15-20% according to recent field tests.

Biomass energy production represents another promising integration pathway. Radial engines can be modified to run on biogas or synthetic fuels derived from biomass, creating a closed-loop energy system with minimal carbon footprint. The multi-cylinder configuration of radial engines allows for flexible fuel utilization, enabling seamless switching between different biofuels depending on availability and seasonal factors.

Hydroelectric power systems, particularly small-scale installations, can incorporate radial engines as flow regulators and emergency power generators. During periods of excess water flow, these engines can harness mechanical energy directly, reducing the need for complex electrical conversion systems. This direct mechanical coupling increases system resilience and reduces maintenance requirements in remote hydroelectric installations.

Geothermal energy facilities present another integration opportunity, where radial engines can utilize temperature differentials to generate supplementary power. The radial configuration excels at handling the thermal expansion challenges common in geothermal applications, potentially extending system lifespan while improving overall energy conversion efficiency.

Smart grid integration represents perhaps the most sophisticated application, where radial engine generators can serve as distributed energy resources, providing grid stabilization services during peak demand periods. Their rapid response capabilities make them ideal for frequency regulation and voltage support in microgrids with high renewable penetration. Recent pilot projects have demonstrated that strategically placed radial engine systems can reduce renewable energy curtailment by up to 30% while providing essential grid services.

Wind energy systems can benefit significantly from radial engine integration through mechanical coupling mechanisms. By connecting radial engines to wind turbines, excess energy during high-wind periods can be mechanically stored and later utilized during calm conditions. This mechanical energy storage approach eliminates some of the efficiency losses associated with electrical storage systems, potentially increasing the overall system efficiency by 15-20% according to recent field tests.

Biomass energy production represents another promising integration pathway. Radial engines can be modified to run on biogas or synthetic fuels derived from biomass, creating a closed-loop energy system with minimal carbon footprint. The multi-cylinder configuration of radial engines allows for flexible fuel utilization, enabling seamless switching between different biofuels depending on availability and seasonal factors.

Hydroelectric power systems, particularly small-scale installations, can incorporate radial engines as flow regulators and emergency power generators. During periods of excess water flow, these engines can harness mechanical energy directly, reducing the need for complex electrical conversion systems. This direct mechanical coupling increases system resilience and reduces maintenance requirements in remote hydroelectric installations.

Geothermal energy facilities present another integration opportunity, where radial engines can utilize temperature differentials to generate supplementary power. The radial configuration excels at handling the thermal expansion challenges common in geothermal applications, potentially extending system lifespan while improving overall energy conversion efficiency.

Smart grid integration represents perhaps the most sophisticated application, where radial engine generators can serve as distributed energy resources, providing grid stabilization services during peak demand periods. Their rapid response capabilities make them ideal for frequency regulation and voltage support in microgrids with high renewable penetration. Recent pilot projects have demonstrated that strategically placed radial engine systems can reduce renewable energy curtailment by up to 30% while providing essential grid services.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!