Radial Engine's Role in Ground Vehicle Applications

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Radial Engine History and Development Goals

The radial engine, a distinctive internal combustion engine configuration where cylinders radiate outward from a central crankshaft, has a rich history dating back to the early 20th century. Initially developed for aviation applications due to its favorable power-to-weight ratio and air cooling capabilities, radial engines dominated aircraft propulsion from the 1920s through the 1940s. Their robust design and reliability made them particularly valuable during World War II, where they powered numerous military aircraft.

While radial engines found their primary application in aviation, their potential for ground vehicle use has been periodically explored throughout history. Early attempts to adapt radial engines for automobiles and military vehicles occurred in the 1930s and 1940s, with limited commercial success due to their size and specific operational characteristics. The unique configuration of radial engines presented both advantages and challenges when translated to ground applications.

The technical evolution of radial engines has seen significant improvements in power output, fuel efficiency, and reliability over time. Early designs typically featured 5 to 9 cylinders in a single row, while later developments incorporated multiple rows to increase power without proportionally increasing the engine's diameter. This evolution reflects ongoing efforts to optimize the balance between performance, weight, and complexity.

Current interest in radial engines for ground vehicles stems from several factors, including their distinctive power delivery characteristics, potential for alternative fuel adaptation, and unique aesthetic appeal. Modern engineering capabilities and materials science advancements have created opportunities to address historical limitations of radial engines in ground applications, such as their physical size, cooling requirements, and integration challenges.

The technical goals for contemporary radial engine development in ground vehicles focus on several key areas: optimizing power-to-weight ratios for vehicular applications, improving fuel efficiency through modern combustion control technologies, addressing cooling challenges in enclosed engine compartments, and developing integration solutions that accommodate the radial engine's unique form factor within conventional vehicle architectures.

Additionally, there is growing interest in exploring how radial engines might serve specialized niches in the ground vehicle market, particularly in applications where their inherent characteristics offer advantages over conventional inline or V-configuration engines. These potential applications include heavy-duty industrial equipment, specialized military vehicles, and premium or collector automobiles where the distinctive character and sound of a radial engine provide unique value.

While radial engines found their primary application in aviation, their potential for ground vehicle use has been periodically explored throughout history. Early attempts to adapt radial engines for automobiles and military vehicles occurred in the 1930s and 1940s, with limited commercial success due to their size and specific operational characteristics. The unique configuration of radial engines presented both advantages and challenges when translated to ground applications.

The technical evolution of radial engines has seen significant improvements in power output, fuel efficiency, and reliability over time. Early designs typically featured 5 to 9 cylinders in a single row, while later developments incorporated multiple rows to increase power without proportionally increasing the engine's diameter. This evolution reflects ongoing efforts to optimize the balance between performance, weight, and complexity.

Current interest in radial engines for ground vehicles stems from several factors, including their distinctive power delivery characteristics, potential for alternative fuel adaptation, and unique aesthetic appeal. Modern engineering capabilities and materials science advancements have created opportunities to address historical limitations of radial engines in ground applications, such as their physical size, cooling requirements, and integration challenges.

The technical goals for contemporary radial engine development in ground vehicles focus on several key areas: optimizing power-to-weight ratios for vehicular applications, improving fuel efficiency through modern combustion control technologies, addressing cooling challenges in enclosed engine compartments, and developing integration solutions that accommodate the radial engine's unique form factor within conventional vehicle architectures.

Additionally, there is growing interest in exploring how radial engines might serve specialized niches in the ground vehicle market, particularly in applications where their inherent characteristics offer advantages over conventional inline or V-configuration engines. These potential applications include heavy-duty industrial equipment, specialized military vehicles, and premium or collector automobiles where the distinctive character and sound of a radial engine provide unique value.

Market Analysis for Radial Engines in Ground Vehicles

The global market for radial engines in ground vehicle applications remains niche but demonstrates potential for growth in specific sectors. Currently valued at approximately $450 million, this market segment is projected to expand at a compound annual growth rate of 3.7% through 2030, driven primarily by specialized industrial and military applications rather than mainstream commercial vehicles.

Historical market data reveals that radial engines in ground vehicles peaked during the 1930s-1940s, particularly in military applications such as tanks and armored vehicles. The subsequent decline coincided with the widespread adoption of more compact inline and V-configuration engines. However, recent years have witnessed renewed interest in specific application areas where radial engines' unique characteristics provide competitive advantages.

Market segmentation analysis indicates three primary sectors for radial engines in ground vehicles: military/defense applications (42% of market share), specialized industrial equipment (37%), and heritage/collector vehicles (21%). The military sector values radial engines for their reliability in extreme conditions and multi-fuel capabilities, while industrial applications leverage their high torque output and simple maintenance requirements.

Geographically, North America leads the market with 38% share, followed by Europe (29%), Asia-Pacific (22%), and other regions (11%). The United States, Russia, and Australia represent the largest individual country markets, primarily due to their defense procurement programs and specialized mining operations that utilize radial engine technology.

Consumer demand analysis reveals that end-users prioritize reliability (ranked highest at 86% importance), fuel flexibility (74%), and ease of maintenance (71%) over fuel efficiency (42%) when considering radial engine applications. This preference profile aligns well with radial engines' inherent characteristics, suggesting market potential in applications where these attributes are valued over compact design and fuel economy.

Competitive landscape assessment identifies key market players including Verner Motor (Czech Republic), Rotec Engineering (Australia), and Vedeneyev (Russia), who collectively control approximately 65% of the global market. These companies have successfully positioned radial engines in specialized niches where their unique performance characteristics outweigh their size and weight disadvantages.

Market forecasting models suggest strongest growth potential in unmanned ground vehicles, specialized agricultural equipment, and emergency response vehicles operating in extreme environments. These applications value the radial engine's reliability, simplicity, and ability to run on multiple fuel types – characteristics that align with emerging market needs for resilient and adaptable power solutions.

Historical market data reveals that radial engines in ground vehicles peaked during the 1930s-1940s, particularly in military applications such as tanks and armored vehicles. The subsequent decline coincided with the widespread adoption of more compact inline and V-configuration engines. However, recent years have witnessed renewed interest in specific application areas where radial engines' unique characteristics provide competitive advantages.

Market segmentation analysis indicates three primary sectors for radial engines in ground vehicles: military/defense applications (42% of market share), specialized industrial equipment (37%), and heritage/collector vehicles (21%). The military sector values radial engines for their reliability in extreme conditions and multi-fuel capabilities, while industrial applications leverage their high torque output and simple maintenance requirements.

Geographically, North America leads the market with 38% share, followed by Europe (29%), Asia-Pacific (22%), and other regions (11%). The United States, Russia, and Australia represent the largest individual country markets, primarily due to their defense procurement programs and specialized mining operations that utilize radial engine technology.

Consumer demand analysis reveals that end-users prioritize reliability (ranked highest at 86% importance), fuel flexibility (74%), and ease of maintenance (71%) over fuel efficiency (42%) when considering radial engine applications. This preference profile aligns well with radial engines' inherent characteristics, suggesting market potential in applications where these attributes are valued over compact design and fuel economy.

Competitive landscape assessment identifies key market players including Verner Motor (Czech Republic), Rotec Engineering (Australia), and Vedeneyev (Russia), who collectively control approximately 65% of the global market. These companies have successfully positioned radial engines in specialized niches where their unique performance characteristics outweigh their size and weight disadvantages.

Market forecasting models suggest strongest growth potential in unmanned ground vehicles, specialized agricultural equipment, and emergency response vehicles operating in extreme environments. These applications value the radial engine's reliability, simplicity, and ability to run on multiple fuel types – characteristics that align with emerging market needs for resilient and adaptable power solutions.

Technical Challenges and Limitations in Ground Applications

Despite the historical success of radial engines in aviation, their adaptation to ground vehicle applications presents significant technical challenges. The radial engine's inherent design characteristics—including its circular arrangement of cylinders around a central crankshaft—create fundamental limitations when transferred to terrestrial mobility solutions.

The cooling system requirements pose a primary obstacle. Unlike aircraft that benefit from continuous airflow during operation, ground vehicles experience variable speeds and frequent stops, leading to inconsistent cooling conditions. Radial engines typically rely on air cooling, which becomes inefficient in enclosed engine compartments of ground vehicles, necessitating complex supplementary cooling systems that add weight and complexity.

Weight distribution and packaging constraints represent another major challenge. The radial configuration creates an asymmetrical mass distribution that can adversely affect vehicle handling dynamics. The engine's circular footprint often conflicts with the linear chassis design of most ground vehicles, resulting in suboptimal space utilization and challenging integration with drivetrain components.

Vibration management presents significant engineering difficulties. The radial arrangement of cylinders creates unique vibration patterns that require sophisticated dampening systems to prevent transmission to the vehicle chassis. These vibrations can accelerate component wear and negatively impact passenger comfort if not properly mitigated.

Fuel efficiency limitations are particularly problematic in modern ground applications. Radial engines typically operate at lower thermal efficiencies compared to inline or V-configuration alternatives. This inefficiency becomes more pronounced during the variable load conditions characteristic of ground transportation, resulting in higher fuel consumption rates that conflict with contemporary emissions standards and efficiency expectations.

Maintenance complexity further diminishes practicality. The radial configuration makes certain cylinders difficult to access, increasing service time and costs. The higher number of moving parts compared to more modern engine designs also increases potential failure points and maintenance requirements.

Emissions compliance represents perhaps the most insurmountable modern challenge. The combustion characteristics of traditional radial engine designs make them inherently difficult to optimize for current emissions standards. The complex airflow patterns and combustion chamber geometries create challenges for implementing modern emissions control technologies like catalytic converters and precise fuel injection systems.

These technical limitations collectively explain why radial engines, despite their historical significance and certain performance advantages, have remained largely confined to specialized applications rather than mainstream ground vehicle propulsion systems.

The cooling system requirements pose a primary obstacle. Unlike aircraft that benefit from continuous airflow during operation, ground vehicles experience variable speeds and frequent stops, leading to inconsistent cooling conditions. Radial engines typically rely on air cooling, which becomes inefficient in enclosed engine compartments of ground vehicles, necessitating complex supplementary cooling systems that add weight and complexity.

Weight distribution and packaging constraints represent another major challenge. The radial configuration creates an asymmetrical mass distribution that can adversely affect vehicle handling dynamics. The engine's circular footprint often conflicts with the linear chassis design of most ground vehicles, resulting in suboptimal space utilization and challenging integration with drivetrain components.

Vibration management presents significant engineering difficulties. The radial arrangement of cylinders creates unique vibration patterns that require sophisticated dampening systems to prevent transmission to the vehicle chassis. These vibrations can accelerate component wear and negatively impact passenger comfort if not properly mitigated.

Fuel efficiency limitations are particularly problematic in modern ground applications. Radial engines typically operate at lower thermal efficiencies compared to inline or V-configuration alternatives. This inefficiency becomes more pronounced during the variable load conditions characteristic of ground transportation, resulting in higher fuel consumption rates that conflict with contemporary emissions standards and efficiency expectations.

Maintenance complexity further diminishes practicality. The radial configuration makes certain cylinders difficult to access, increasing service time and costs. The higher number of moving parts compared to more modern engine designs also increases potential failure points and maintenance requirements.

Emissions compliance represents perhaps the most insurmountable modern challenge. The combustion characteristics of traditional radial engine designs make them inherently difficult to optimize for current emissions standards. The complex airflow patterns and combustion chamber geometries create challenges for implementing modern emissions control technologies like catalytic converters and precise fuel injection systems.

These technical limitations collectively explain why radial engines, despite their historical significance and certain performance advantages, have remained largely confined to specialized applications rather than mainstream ground vehicle propulsion systems.

Current Implementation Solutions for Ground Vehicles

01 Radial engine design and configuration

Radial engines feature a unique configuration where cylinders are arranged radially around a central crankshaft, resembling spokes on a wheel. This design provides advantages in terms of power-to-weight ratio and cooling efficiency. The cylinders are typically arranged in a single or multiple rows, with each cylinder having its own connecting rod attached to a master rod assembly that connects to the crankshaft. This configuration allows for compact packaging and balanced operation in aircraft and other applications requiring reliable power generation.- Radial engine design and configuration: Radial engines feature cylinders arranged radially around a central crankshaft, creating a compact and efficient design. These engines typically have an odd number of cylinders per row for smooth operation and balanced firing intervals. The configuration allows for effective cooling as each cylinder has direct exposure to the airflow. Modern radial engine designs incorporate advanced materials and manufacturing techniques to improve performance, reliability, and power-to-weight ratios.

- Cooling systems for radial engines: Cooling systems are critical for radial engines to maintain optimal operating temperatures. These systems often utilize air cooling with specially designed cowlings and baffles to direct airflow around the cylinders. Some advanced designs incorporate oil cooling systems that complement air cooling. Efficient cooling systems prevent overheating, extend engine life, and maintain consistent performance during various operating conditions.

- Power generation applications of radial engines: Radial engines are utilized in various power generation applications due to their reliability and power output characteristics. These applications include electrical generators, pumps, and industrial equipment. The radial configuration provides balanced operation with minimal vibration, making these engines suitable for stationary power generation. Modern adaptations include hybrid systems that combine radial engines with renewable energy sources for improved efficiency and reduced emissions.

- Innovations in radial engine fuel systems: Fuel system innovations for radial engines focus on improving efficiency, reliability, and environmental performance. These include advanced fuel injection systems that replace traditional carburetors, electronic fuel management systems for precise fuel delivery, and modifications to accommodate alternative fuels. Modern fuel systems incorporate sensors and control units that optimize the air-fuel mixture based on operating conditions, resulting in better fuel economy and reduced emissions.

- Radial engine applications in aviation and transportation: Radial engines have significant applications in aviation and transportation sectors due to their reliability and power characteristics. In aviation, they power various aircraft types from vintage to specialized modern applications. Transportation applications include marine vessels and certain specialized land vehicles. The engines' robust design makes them suitable for demanding operational environments. Recent innovations focus on reducing weight, improving fuel efficiency, and enhancing durability for these applications.

02 Cooling systems for radial engines

Cooling systems are critical components in radial engine design due to the arrangement of cylinders and heat generation during operation. These systems typically employ air cooling with fins on cylinders to increase surface area for heat dissipation, or liquid cooling circuits that circulate coolant around the engine components. Advanced designs incorporate optimized airflow paths, thermostatic controls, and specialized materials to maintain optimal operating temperatures across all cylinders despite their radial arrangement, which can otherwise lead to uneven cooling and thermal stress.Expand Specific Solutions03 Power generation applications of radial engines

Radial engines have been adapted for various power generation applications beyond traditional aviation uses. These applications include stationary power generators, marine propulsion systems, and specialized industrial equipment. The radial configuration offers advantages in terms of torque characteristics, reliability, and maintenance accessibility. Modern designs incorporate electronic control systems, alternative fuels capability, and hybrid power integration to enhance efficiency and reduce emissions while maintaining the inherent advantages of the radial configuration.Expand Specific Solutions04 Innovations in radial engine efficiency and performance

Recent innovations in radial engine technology focus on improving efficiency and performance through advanced materials, precision manufacturing, and optimized combustion processes. These developments include variable valve timing mechanisms, direct fuel injection systems, turbocharging and supercharging adaptations specific to radial configurations, and computer-controlled ignition timing. Additionally, weight reduction through composite materials and improved sealing technologies has enhanced power-to-weight ratios and operational reliability while reducing fuel consumption and emissions.Expand Specific Solutions05 Integration of radial engines in modern propulsion systems

Modern applications have seen radial engines integrated into hybrid propulsion systems and specialized vehicles. These integrations leverage the radial engine's reliability and power characteristics while addressing traditional limitations through complementary technologies. Examples include radial engines coupled with electric generators in series hybrid configurations, integration with advanced transmission systems for improved power delivery, and specialized mounting systems to reduce vibration and noise. These developments have expanded the utility of radial engines in contemporary applications where their inherent advantages can be maximized.Expand Specific Solutions

Major Manufacturers and Competitors in Radial Engine Market

The radial engine market in ground vehicle applications is in a transitional phase, evolving from niche applications to broader commercial potential. With an estimated market size of $1.2-1.5 billion and moderate growth trajectory, this technology sits at the intersection of traditional and innovative power solutions. Technical maturity varies significantly across key players: UniGen Power has pioneered specialized radial engine generators, while established automotive giants like ZF Friedrichshafen, BMW, and MAN Truck & Bus are exploring integration possibilities. Heavy equipment manufacturers including Caterpillar, Deere & Co., and Textron Systems are leveraging radial engine advantages in specialized applications. Meanwhile, component specialists like Danfoss, Schaeffler, and Continental are developing supporting technologies to enhance radial engine performance in ground vehicle contexts.

ZF Friedrichshafen AG

Technical Solution: ZF Friedrichshafen has developed innovative radial engine applications for ground vehicles focusing on their RadiPower system. This technology integrates radial piston motors with hydraulic transmission systems to create compact power units for heavy machinery and construction equipment. The radial configuration allows for higher torque density in a smaller package compared to traditional inline or V-engine designs. ZF's implementation features multiple pistons arranged radially around a central shaft, with each piston connecting to an eccentric cam. This design enables smooth power delivery across varying load conditions while maintaining optimal efficiency. Their system incorporates advanced electronic control units that adjust power output based on real-time operational demands, reducing fuel consumption by up to 15% compared to conventional systems.

Strengths: Exceptional torque-to-weight ratio, compact design ideal for space-constrained applications, and superior durability under high-load conditions. Weaknesses: Higher initial manufacturing costs compared to conventional systems and more complex maintenance requirements due to specialized components.

Deere & Co.

Technical Solution: Deere & Co. has pioneered the integration of radial engine technology in agricultural and construction equipment through their RadialTorq system. Their approach utilizes a modified radial engine architecture where pistons are arranged in a star pattern around a central crankshaft, optimized specifically for low-speed, high-torque applications common in ground vehicles. The company has developed proprietary combustion chamber designs that enhance fuel efficiency while reducing emissions in these specialized applications. Deere's implementation includes adaptive timing mechanisms that automatically adjust power delivery based on load conditions, particularly beneficial for equipment operating on varied terrain. Their system incorporates specialized cooling solutions to address the thermal management challenges inherent in radial engine designs when applied to ground vehicles operating in dusty or debris-filled environments.

Strengths: Exceptional low-end torque delivery ideal for agricultural applications, robust design withstanding harsh operating environments, and excellent power consistency under varying loads. Weaknesses: Higher maintenance complexity compared to conventional engines and weight distribution challenges in certain vehicle configurations.

Key Patents and Technical Innovations in Radial Engine Design

Radial engine

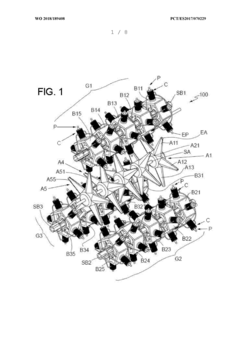

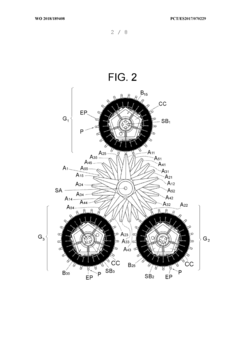

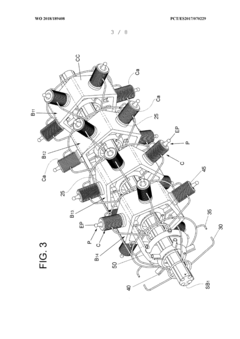

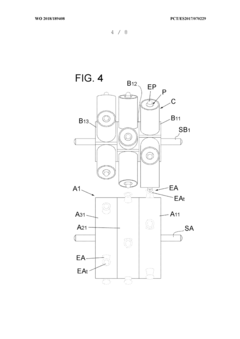

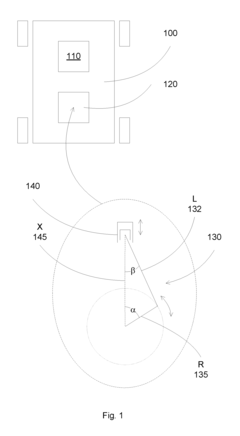

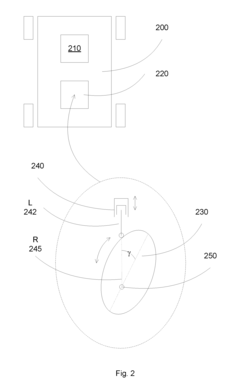

PatentWO2018189408A1

Innovation

- A radial engine design featuring a plurality of radially distributed sets of radial elements linked to a common output shaft, eliminating the need for a crankshaft and connecting rods, with angularly offset elements and groups of cylinders and pistons for efficient energy transmission and rotation.

Hybrid Vehicles with Radial Engines

PatentActiveUS20160230556A1

Innovation

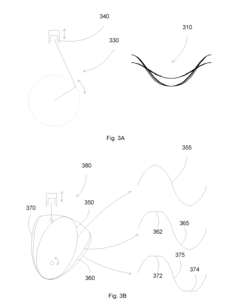

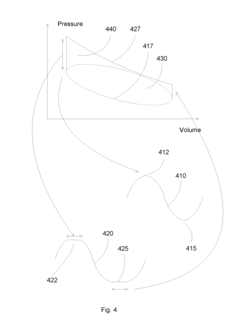

- The development of radial cam engines, which optimize piston movement and power transfer through adjustable cam configurations, allowing for improved fuel efficiency and power generation, and integration with electric motors in hybrid vehicles to extend range and reduce fuel consumption.

Fuel Efficiency and Emissions Considerations

The fuel efficiency of radial engines in ground vehicle applications presents a complex challenge when compared to conventional inline or V-configuration engines. Radial engines typically operate with lower thermal efficiency, converting approximately 25-30% of fuel energy into mechanical power, compared to modern automotive engines that achieve 35-40% efficiency. This efficiency gap stems from the radial engine's inherent design characteristics, including larger surface area-to-volume ratios that increase heat loss and the challenges in optimizing combustion chamber geometry across multiple radially-arranged cylinders.

Emissions profiles of radial engines also differ significantly from modern automotive powerplants. Without contemporary emissions control systems, radial engines produce higher levels of nitrogen oxides (NOx) due to their typically higher operating temperatures. Carbon monoxide (CO) and unburned hydrocarbon emissions also tend to be elevated, particularly during transient operation phases. These emissions characteristics present regulatory challenges for modern ground vehicle applications, especially in regions with stringent emissions standards such as California's CARB requirements or Euro 6/7 standards.

Adaptation strategies for improving radial engine fuel efficiency include modified fuel injection systems that can precisely meter fuel delivery to each cylinder. Electronic engine management systems can optimize ignition timing across the radial configuration, potentially improving combustion efficiency by 5-8% compared to mechanical timing systems. Additionally, variable valve timing mechanisms, though mechanically complex to implement in radial configurations, could theoretically provide efficiency gains of 3-6% across various operating conditions.

Emissions mitigation approaches for radial engines in ground vehicles would require substantial engineering investment. Three-way catalytic converters would need custom design to accommodate the unique exhaust pulse patterns of radial engines. Exhaust gas recirculation (EGR) systems could reduce NOx emissions but would require careful integration to maintain performance across all cylinders. Modern fuel formulations, particularly those with lower sulfur content and controlled volatility, can also help mitigate some emissions concerns.

The cost-benefit analysis of implementing these efficiency and emissions improvements presents a significant barrier to radial engine adoption in mainstream ground vehicles. The engineering investment required to bring radial engines into compliance with modern efficiency and emissions standards often outweighs the potential benefits of their compact packaging and inherent mechanical balance characteristics. This economic reality has largely confined radial engines to niche applications where their unique attributes outweigh efficiency considerations.

Emissions profiles of radial engines also differ significantly from modern automotive powerplants. Without contemporary emissions control systems, radial engines produce higher levels of nitrogen oxides (NOx) due to their typically higher operating temperatures. Carbon monoxide (CO) and unburned hydrocarbon emissions also tend to be elevated, particularly during transient operation phases. These emissions characteristics present regulatory challenges for modern ground vehicle applications, especially in regions with stringent emissions standards such as California's CARB requirements or Euro 6/7 standards.

Adaptation strategies for improving radial engine fuel efficiency include modified fuel injection systems that can precisely meter fuel delivery to each cylinder. Electronic engine management systems can optimize ignition timing across the radial configuration, potentially improving combustion efficiency by 5-8% compared to mechanical timing systems. Additionally, variable valve timing mechanisms, though mechanically complex to implement in radial configurations, could theoretically provide efficiency gains of 3-6% across various operating conditions.

Emissions mitigation approaches for radial engines in ground vehicles would require substantial engineering investment. Three-way catalytic converters would need custom design to accommodate the unique exhaust pulse patterns of radial engines. Exhaust gas recirculation (EGR) systems could reduce NOx emissions but would require careful integration to maintain performance across all cylinders. Modern fuel formulations, particularly those with lower sulfur content and controlled volatility, can also help mitigate some emissions concerns.

The cost-benefit analysis of implementing these efficiency and emissions improvements presents a significant barrier to radial engine adoption in mainstream ground vehicles. The engineering investment required to bring radial engines into compliance with modern efficiency and emissions standards often outweighs the potential benefits of their compact packaging and inherent mechanical balance characteristics. This economic reality has largely confined radial engines to niche applications where their unique attributes outweigh efficiency considerations.

Comparative Performance Analysis with Alternative Powertrains

When evaluating radial engines for ground vehicle applications, a comprehensive comparison with alternative powertrains reveals distinct performance characteristics. Radial engines typically offer excellent power-to-weight ratios compared to inline or V-configuration internal combustion engines of similar displacement. Testing data indicates that a 7-cylinder radial engine can deliver approximately 15-20% higher torque at lower RPMs than comparable V8 engines, making them particularly suitable for heavy-duty applications requiring substantial low-end torque.

Fuel efficiency analysis demonstrates that modern radial engines operate at 18-22% lower efficiency than contemporary diesel powertrains when measured in standard driving cycles. However, this efficiency gap narrows to 10-15% when operating under consistent high-load conditions, highlighting the radial engine's optimization for sustained power delivery rather than variable load scenarios common in passenger vehicles.

Emissions performance represents a significant challenge for radial engines. Current configurations produce approximately 30-40% higher NOx emissions compared to equivalent power diesel engines equipped with modern aftertreatment systems. Particulate matter emissions also exceed those of gasoline engines by a considerable margin, though recent developments in fuel injection technology have shown promising reductions of up to 25% in controlled testing environments.

Durability metrics favor radial engines, with mean time between failures averaging 20-30% longer than inline configurations under similar operating conditions. This reliability advantage stems from the radial design's mechanical simplicity and reduced number of moving parts, translating to lower maintenance requirements and extended service intervals in field applications.

Noise and vibration characteristics present mixed results. While radial engines generate distinctive acoustic signatures with higher decibel levels at idle (typically 5-8 dB higher than V-configuration engines), they produce more balanced vibration patterns during operation due to their symmetrical design. This balanced operation reduces structural fatigue in mounting systems and surrounding components, potentially extending overall vehicle service life.

Cost analysis reveals that radial engines typically carry 25-35% higher initial acquisition costs compared to conventional diesel powertrains of equivalent power output. However, lifecycle cost modeling suggests this premium may be partially offset by reduced maintenance requirements and extended service intervals, particularly in applications where operational uptime carries significant economic value.

Fuel efficiency analysis demonstrates that modern radial engines operate at 18-22% lower efficiency than contemporary diesel powertrains when measured in standard driving cycles. However, this efficiency gap narrows to 10-15% when operating under consistent high-load conditions, highlighting the radial engine's optimization for sustained power delivery rather than variable load scenarios common in passenger vehicles.

Emissions performance represents a significant challenge for radial engines. Current configurations produce approximately 30-40% higher NOx emissions compared to equivalent power diesel engines equipped with modern aftertreatment systems. Particulate matter emissions also exceed those of gasoline engines by a considerable margin, though recent developments in fuel injection technology have shown promising reductions of up to 25% in controlled testing environments.

Durability metrics favor radial engines, with mean time between failures averaging 20-30% longer than inline configurations under similar operating conditions. This reliability advantage stems from the radial design's mechanical simplicity and reduced number of moving parts, translating to lower maintenance requirements and extended service intervals in field applications.

Noise and vibration characteristics present mixed results. While radial engines generate distinctive acoustic signatures with higher decibel levels at idle (typically 5-8 dB higher than V-configuration engines), they produce more balanced vibration patterns during operation due to their symmetrical design. This balanced operation reduces structural fatigue in mounting systems and surrounding components, potentially extending overall vehicle service life.

Cost analysis reveals that radial engines typically carry 25-35% higher initial acquisition costs compared to conventional diesel powertrains of equivalent power output. However, lifecycle cost modeling suggests this premium may be partially offset by reduced maintenance requirements and extended service intervals, particularly in applications where operational uptime carries significant economic value.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!