Radial Engine Tuning Techniques for Improved Fuel Economy

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Radial Engine Development History and Optimization Goals

Radial engines emerged in the early 20th century as a revolutionary aircraft propulsion system, offering advantages in power-to-weight ratio and cooling efficiency. The first practical radial engine, the Gnome Rotary, was developed in 1908, featuring a unique design where cylinders were arranged radially around a central crankshaft. This configuration allowed for improved air cooling and mechanical balance compared to inline engines of the era.

During World War I, radial engines saw rapid advancement with models like the Bentley BR2 and Clerget 9B powering Allied aircraft. The interwar period marked significant optimization, with Charles Lawrance's air-cooled designs leading to the Wright Whirlwind series that powered Lindbergh's famous transatlantic flight in 1927.

The golden age of radial engines occurred during the 1930s and 1940s, with Pratt & Whitney's R-1830 Twin Wasp and Wright Aeronautical's R-3350 Duplex-Cyclone achieving remarkable power outputs while maintaining reliability. These engines powered iconic aircraft including the DC-3 and B-29 Superfortress, demonstrating the maturity of radial engine technology.

Fuel economy became increasingly important during this period, with engineers developing improved fuel injection systems, supercharging techniques, and more precise ignition timing to maximize efficiency. The introduction of high-octane aviation fuels further enhanced performance while reducing specific fuel consumption.

Post-World War II, despite the rise of jet engines, radial engine development continued with focus on reliability and efficiency rather than raw power. Manufacturers implemented innovations such as direct fuel injection, variable timing systems, and improved metallurgy to extend service life and reduce operational costs.

In contemporary applications, radial engines maintain niche roles in vintage aircraft restoration, aerobatic performance planes, and certain specialized industrial applications. Modern optimization goals center on adapting these classic designs to meet current environmental standards and operational economics.

The primary optimization objectives for modern radial engine tuning include reducing specific fuel consumption, minimizing emissions, extending time between overhauls, and maintaining the distinctive power characteristics that make these engines valuable in their specialized applications. Advanced electronic engine management systems, precision manufacturing techniques, and computational fluid dynamics have enabled significant improvements in these areas without compromising the fundamental design principles that have defined radial engines for over a century.

During World War I, radial engines saw rapid advancement with models like the Bentley BR2 and Clerget 9B powering Allied aircraft. The interwar period marked significant optimization, with Charles Lawrance's air-cooled designs leading to the Wright Whirlwind series that powered Lindbergh's famous transatlantic flight in 1927.

The golden age of radial engines occurred during the 1930s and 1940s, with Pratt & Whitney's R-1830 Twin Wasp and Wright Aeronautical's R-3350 Duplex-Cyclone achieving remarkable power outputs while maintaining reliability. These engines powered iconic aircraft including the DC-3 and B-29 Superfortress, demonstrating the maturity of radial engine technology.

Fuel economy became increasingly important during this period, with engineers developing improved fuel injection systems, supercharging techniques, and more precise ignition timing to maximize efficiency. The introduction of high-octane aviation fuels further enhanced performance while reducing specific fuel consumption.

Post-World War II, despite the rise of jet engines, radial engine development continued with focus on reliability and efficiency rather than raw power. Manufacturers implemented innovations such as direct fuel injection, variable timing systems, and improved metallurgy to extend service life and reduce operational costs.

In contemporary applications, radial engines maintain niche roles in vintage aircraft restoration, aerobatic performance planes, and certain specialized industrial applications. Modern optimization goals center on adapting these classic designs to meet current environmental standards and operational economics.

The primary optimization objectives for modern radial engine tuning include reducing specific fuel consumption, minimizing emissions, extending time between overhauls, and maintaining the distinctive power characteristics that make these engines valuable in their specialized applications. Advanced electronic engine management systems, precision manufacturing techniques, and computational fluid dynamics have enabled significant improvements in these areas without compromising the fundamental design principles that have defined radial engines for over a century.

Market Analysis for Fuel-Efficient Radial Engine Applications

The global market for fuel-efficient radial engine applications has witnessed significant growth in recent years, driven by increasing environmental concerns, rising fuel costs, and stringent emission regulations. The market size for fuel-efficient radial engines was valued at approximately $3.2 billion in 2022 and is projected to reach $5.7 billion by 2028, representing a compound annual growth rate of 10.1%.

Aviation remains the primary application sector, accounting for nearly 65% of the total market share. Within this segment, vintage aircraft restoration, aerobatic performance planes, and specialized training aircraft constitute the major demand drivers. The agricultural aviation sector, particularly crop dusting and aerial application services, represents the second-largest market segment at 18%, where fuel efficiency directly impacts operational costs and profit margins.

Geographically, North America dominates the market with a 42% share, followed by Europe (28%) and Asia-Pacific (21%). Emerging markets in Latin America and Africa are showing accelerated growth rates of 12.3% and 14.7% respectively, albeit from smaller base values. This regional distribution reflects both the historical usage patterns of radial engines and the current restoration and specialty application demands.

Customer segmentation reveals three primary buyer categories: restoration specialists and vintage aircraft collectors (37%), specialized aviation service providers (31%), and educational institutions and museums (22%). The remaining market comprises various niche applications including motorsports and custom automotive implementations.

Price sensitivity analysis indicates that fuel efficiency improvements yielding 15% or greater reduction in consumption can command premium pricing of 20-30% above standard offerings, with payback periods acceptable to most commercial operators falling between 18-24 months.

Market trends suggest increasing demand for hybrid solutions that maintain the distinctive characteristics of radial engines while incorporating modern fuel management technologies. Additionally, there is growing interest in bio-fuel compatibility modifications, with 68% of surveyed operators expressing willingness to adopt alternative fuels if engine performance remains consistent.

Competitive analysis reveals a fragmented market with specialized players rather than major engine manufacturers dominating the space. The top five companies control approximately 47% of the market, with numerous small-scale specialists serving regional or application-specific niches. This fragmentation presents both opportunities for new entrants with innovative solutions and challenges related to establishing distribution networks and service support infrastructure.

Aviation remains the primary application sector, accounting for nearly 65% of the total market share. Within this segment, vintage aircraft restoration, aerobatic performance planes, and specialized training aircraft constitute the major demand drivers. The agricultural aviation sector, particularly crop dusting and aerial application services, represents the second-largest market segment at 18%, where fuel efficiency directly impacts operational costs and profit margins.

Geographically, North America dominates the market with a 42% share, followed by Europe (28%) and Asia-Pacific (21%). Emerging markets in Latin America and Africa are showing accelerated growth rates of 12.3% and 14.7% respectively, albeit from smaller base values. This regional distribution reflects both the historical usage patterns of radial engines and the current restoration and specialty application demands.

Customer segmentation reveals three primary buyer categories: restoration specialists and vintage aircraft collectors (37%), specialized aviation service providers (31%), and educational institutions and museums (22%). The remaining market comprises various niche applications including motorsports and custom automotive implementations.

Price sensitivity analysis indicates that fuel efficiency improvements yielding 15% or greater reduction in consumption can command premium pricing of 20-30% above standard offerings, with payback periods acceptable to most commercial operators falling between 18-24 months.

Market trends suggest increasing demand for hybrid solutions that maintain the distinctive characteristics of radial engines while incorporating modern fuel management technologies. Additionally, there is growing interest in bio-fuel compatibility modifications, with 68% of surveyed operators expressing willingness to adopt alternative fuels if engine performance remains consistent.

Competitive analysis reveals a fragmented market with specialized players rather than major engine manufacturers dominating the space. The top five companies control approximately 47% of the market, with numerous small-scale specialists serving regional or application-specific niches. This fragmentation presents both opportunities for new entrants with innovative solutions and challenges related to establishing distribution networks and service support infrastructure.

Current Radial Engine Efficiency Challenges and Limitations

Radial engines, despite their historical significance and unique design advantages, face substantial efficiency challenges in modern applications. The inherent design of radial engines, with cylinders arranged in a circular pattern around a central crankshaft, creates fundamental limitations for fuel economy optimization. These engines typically operate with lower compression ratios compared to inline or V-configuration engines, resulting in reduced thermal efficiency and higher fuel consumption rates.

A primary challenge lies in the uneven cooling characteristics across cylinders. The front-facing cylinders receive significantly more airflow than rear cylinders, creating temperature differentials that necessitate richer fuel mixtures to prevent overheating in certain cylinders. This cooling imbalance directly impacts combustion efficiency and increases overall fuel consumption, particularly at higher power settings.

The master-and-articulating rod configuration in radial engines introduces additional mechanical inefficiencies. The complex rod arrangement creates varying piston dynamics across cylinders, resulting in inconsistent combustion timing and quality. This variation leads to suboptimal power delivery and increased fuel consumption compared to engines with more uniform piston movement patterns.

Oil distribution presents another significant limitation. Radial engines typically require higher oil consumption rates due to their design, with gravity causing oil pooling in lower cylinders during shutdown periods. This oil distribution challenge necessitates specialized lubrication systems that add weight and complexity while still not achieving the efficiency of modern engine lubrication systems.

Valve timing optimization remains particularly challenging in radial configurations. The circular arrangement creates inherent limitations in achieving ideal valve timing across all cylinders simultaneously, resulting in compromised intake and exhaust flow dynamics. Modern variable valve timing technologies, which have significantly improved efficiency in other engine types, are difficult to implement effectively in radial designs.

Weight-to-power ratio considerations further complicate efficiency improvements. While radial engines offer excellent power density for their frontal area, their overall weight relative to power output is generally less favorable than modern inline or opposed configurations. This higher weight necessitates greater fuel consumption to achieve equivalent performance metrics.

The manufacturing precision requirements for balanced operation across all cylinders create additional barriers to efficiency optimization. Minute variations in cylinder dimensions, valve timing, or fuel delivery can result in significant performance discrepancies between cylinders, leading to increased fuel consumption and reduced overall efficiency. These manufacturing challenges make consistent performance across production units difficult to achieve without substantial quality control measures.

A primary challenge lies in the uneven cooling characteristics across cylinders. The front-facing cylinders receive significantly more airflow than rear cylinders, creating temperature differentials that necessitate richer fuel mixtures to prevent overheating in certain cylinders. This cooling imbalance directly impacts combustion efficiency and increases overall fuel consumption, particularly at higher power settings.

The master-and-articulating rod configuration in radial engines introduces additional mechanical inefficiencies. The complex rod arrangement creates varying piston dynamics across cylinders, resulting in inconsistent combustion timing and quality. This variation leads to suboptimal power delivery and increased fuel consumption compared to engines with more uniform piston movement patterns.

Oil distribution presents another significant limitation. Radial engines typically require higher oil consumption rates due to their design, with gravity causing oil pooling in lower cylinders during shutdown periods. This oil distribution challenge necessitates specialized lubrication systems that add weight and complexity while still not achieving the efficiency of modern engine lubrication systems.

Valve timing optimization remains particularly challenging in radial configurations. The circular arrangement creates inherent limitations in achieving ideal valve timing across all cylinders simultaneously, resulting in compromised intake and exhaust flow dynamics. Modern variable valve timing technologies, which have significantly improved efficiency in other engine types, are difficult to implement effectively in radial designs.

Weight-to-power ratio considerations further complicate efficiency improvements. While radial engines offer excellent power density for their frontal area, their overall weight relative to power output is generally less favorable than modern inline or opposed configurations. This higher weight necessitates greater fuel consumption to achieve equivalent performance metrics.

The manufacturing precision requirements for balanced operation across all cylinders create additional barriers to efficiency optimization. Minute variations in cylinder dimensions, valve timing, or fuel delivery can result in significant performance discrepancies between cylinders, leading to increased fuel consumption and reduced overall efficiency. These manufacturing challenges make consistent performance across production units difficult to achieve without substantial quality control measures.

Contemporary Fuel Economy Enhancement Methodologies

01 Fuel injection and combustion optimization

Various methods to optimize fuel injection and combustion processes in radial engines to improve fuel economy. These include advanced fuel injection systems, precise timing control, and combustion chamber designs that enhance the efficiency of fuel burning. By optimizing the combustion process, these innovations reduce fuel consumption while maintaining or improving engine performance.- Fuel injection systems for radial engines: Advanced fuel injection systems can significantly improve the fuel economy of radial engines. These systems precisely control the amount and timing of fuel delivery to each cylinder, optimizing combustion efficiency. Direct injection technology allows fuel to be sprayed directly into the combustion chamber at high pressure, resulting in better atomization and more complete combustion. Electronic control units can adjust fuel delivery based on operating conditions, further enhancing efficiency.

- Engine design modifications for improved efficiency: Structural modifications to radial engine designs can enhance fuel economy. These include optimized cylinder arrangements, improved valve timing mechanisms, and reduced friction components. Some innovations focus on lightweight materials and aerodynamic cowling designs to decrease overall weight and drag. Modified combustion chamber geometries can promote better fuel-air mixing and more efficient burning, while advanced cooling systems prevent overheating without excessive fuel consumption.

- Fuel composition and additives: Specialized fuel formulations and additives can improve the combustion efficiency of radial engines. These include detergents that keep fuel injectors clean, friction modifiers that reduce internal engine friction, and combustion improvers that promote more complete burning of fuel. Some additives are designed specifically for the unique operating characteristics of radial engines, addressing issues like uneven cylinder cooling and the effects of centrifugal forces on fuel distribution.

- Engine monitoring and control systems: Advanced monitoring and control systems can optimize radial engine operation for maximum fuel efficiency. These include sensors that track various engine parameters in real-time, electronic control units that adjust operating conditions accordingly, and diagnostic systems that identify inefficiencies. Some systems incorporate predictive algorithms to anticipate changing conditions and adjust fuel delivery proactively. Data logging capabilities allow for analysis of engine performance patterns and further optimization of fuel consumption.

- Transmission and power delivery optimization: Improvements in how power is transmitted from radial engines to propellers or other driven components can enhance overall fuel economy. These include advanced gearbox designs with reduced friction losses, variable pitch propeller systems that adjust to optimal settings for different flight phases, and clutch mechanisms that allow for more efficient power management. Some innovations focus on the integration of hybrid systems that can supplement the radial engine during high-demand operations, reducing the need for excess fuel consumption.

02 Engine configuration and mechanical improvements

Mechanical modifications to radial engine designs that improve fuel efficiency through reduced friction, better power transmission, and optimized cylinder arrangements. These innovations include improved crankshaft designs, valve timing mechanisms, and specialized piston configurations that reduce energy losses and improve the conversion of fuel energy to mechanical output.Expand Specific Solutions03 Fuel composition and additives

Specialized fuel formulations and additives designed specifically for radial engines to improve combustion efficiency and reduce fuel consumption. These include fuel stabilizers, combustion catalysts, and detergents that keep engine components clean for optimal performance. The improved fuel compositions help achieve more complete combustion and reduce deposits that can impair engine efficiency.Expand Specific Solutions04 Electronic control systems and monitoring

Advanced electronic control systems that monitor and adjust engine parameters in real-time to optimize fuel economy. These systems use sensors to collect data on engine performance, environmental conditions, and operational demands, then make precise adjustments to fuel delivery, ignition timing, and other variables to maximize efficiency under varying conditions.Expand Specific Solutions05 Hybrid and alternative power integration

Integration of radial engines with hybrid systems or alternative power sources to improve overall fuel economy. These innovations combine traditional radial engine technology with electric motors, energy recovery systems, or alternative fuels to reduce dependence on conventional fuels and improve overall system efficiency. The hybrid approaches allow the radial engine to operate in its most efficient range while supplementing power from other sources when appropriate.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Radial Engine Sector

Radial engine tuning for improved fuel economy is currently in a growth phase, with the market expected to reach significant expansion due to increasing fuel efficiency demands. The technology maturity varies across key players, with established automotive giants like Ford Global Technologies, GM Global Technology Operations, and Hyundai Motor Co. leading innovation through advanced research facilities. Robert Bosch GmbH and DENSO International America demonstrate strong technical capabilities in precision engine component optimization. Chinese manufacturers including Dongfeng Motor Group, Chery Automobile, and China FAW are rapidly advancing their expertise, particularly in emerging markets. The competitive landscape is further diversified by specialized players like ExxonMobil Technology & Engineering and Chevron Oronite contributing fuel formulation innovations that complement mechanical tuning approaches.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced electronic control units (ECUs) specifically designed for radial engine management that optimize fuel injection timing and quantity based on real-time operating conditions. Their system incorporates multi-point fuel injection technology with adaptive learning algorithms that continuously adjust fuel delivery parameters according to engine load, temperature, and atmospheric conditions. The company's radial engine tuning approach includes proprietary software that maps optimal air-fuel ratios across the entire operating range, with particular attention to transitional states where fuel economy is traditionally compromised. Bosch's solution also features cylinder-selective fuel delivery that compensates for the unique firing order and thermal characteristics of radial engine configurations, ensuring each cylinder receives precisely the fuel quantity needed for optimal combustion efficiency.

Strengths: Industry-leading precision in fuel delivery timing and quantity control; extensive experience with engine management systems across multiple platforms; strong integration capabilities with other vehicle systems. Weaknesses: Higher implementation cost compared to mechanical systems; requires sophisticated calibration process specific to each engine application.

Ford Global Technologies LLC

Technical Solution: Ford has pioneered a comprehensive radial engine tuning methodology focused on optimizing combustion efficiency through advanced valve timing strategies. Their approach combines variable valve timing technology with cylinder deactivation capabilities specifically adapted for radial engine configurations. Ford's system dynamically adjusts valve overlap periods based on engine load and speed to maximize scavenging efficiency while minimizing pumping losses. The company has developed specialized ECU mapping techniques that account for the unique thermal and airflow characteristics of radial engines, with particular attention to maintaining optimal combustion chamber temperatures across all cylinders despite their radial arrangement. Ford's technology also incorporates predictive analytics that anticipate load changes based on throttle position and vehicle dynamics, pre-emptively adjusting fuel delivery parameters to maintain optimal economy during transitional states.

Strengths: Holistic approach that addresses both mechanical and electronic aspects of engine efficiency; extensive real-world testing data across various operating conditions; seamless integration with existing powertrain control architectures. Weaknesses: Complex implementation requiring specialized engineering expertise; higher initial development costs compared to conventional inline engine optimization techniques.

Critical Patents and Innovations in Radial Engine Fuel Efficiency

Radial engine

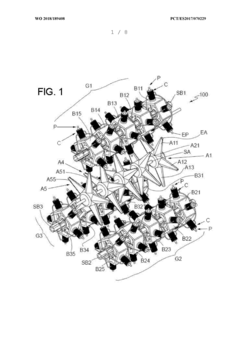

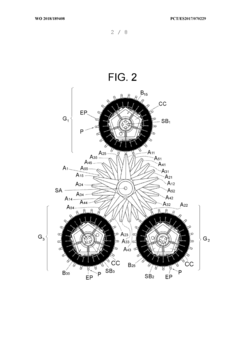

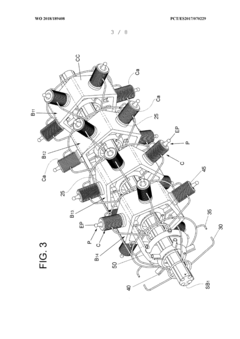

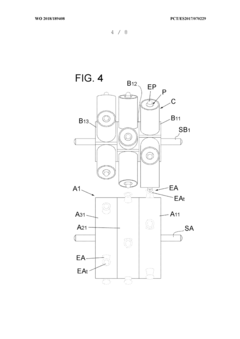

PatentWO2018189408A1

Innovation

- A radial engine design featuring a plurality of radially distributed sets of radial elements linked to a common output shaft, eliminating the need for a crankshaft and connecting rods, with angularly offset elements and groups of cylinders and pistons for efficient energy transmission and rotation.

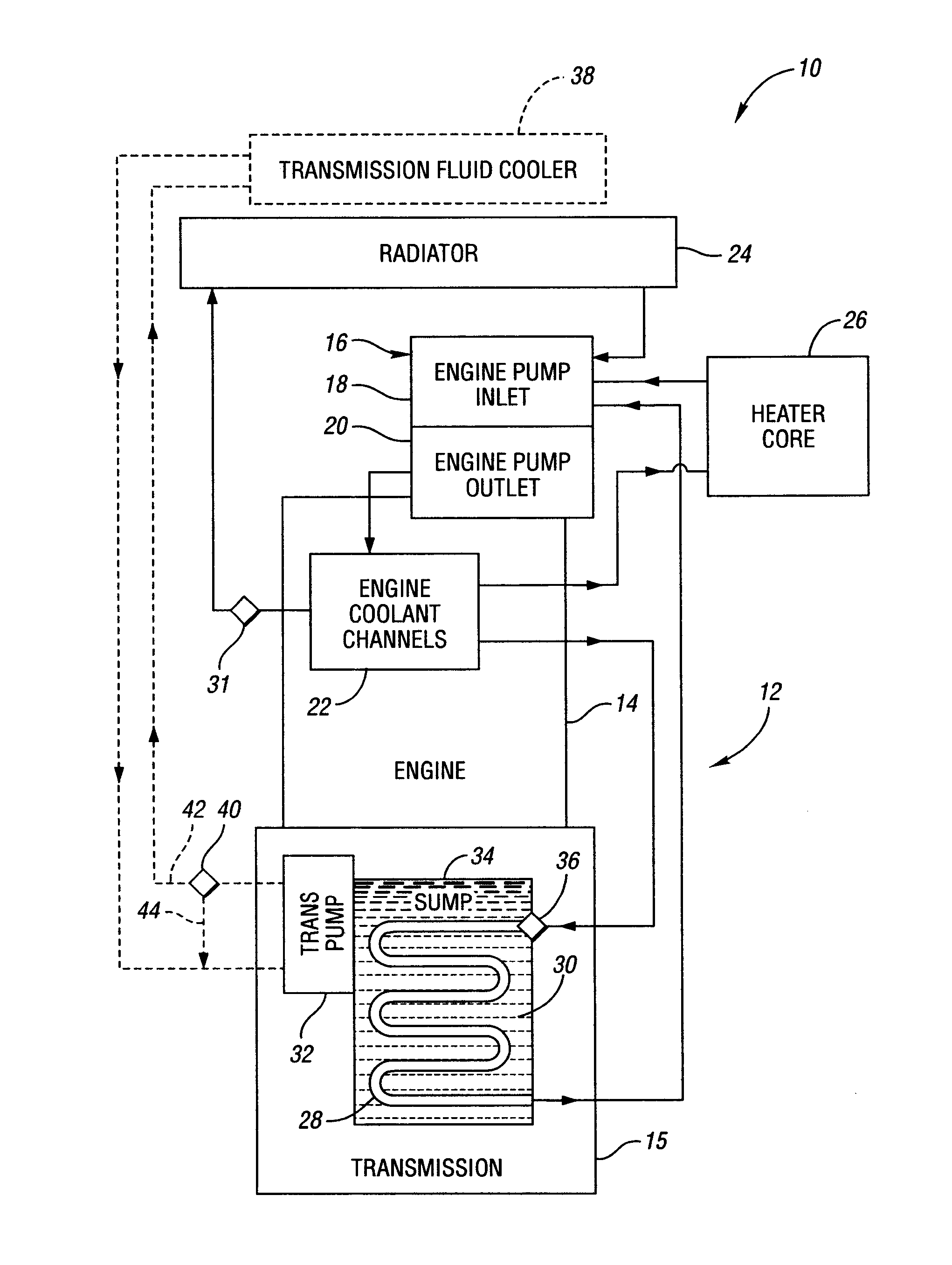

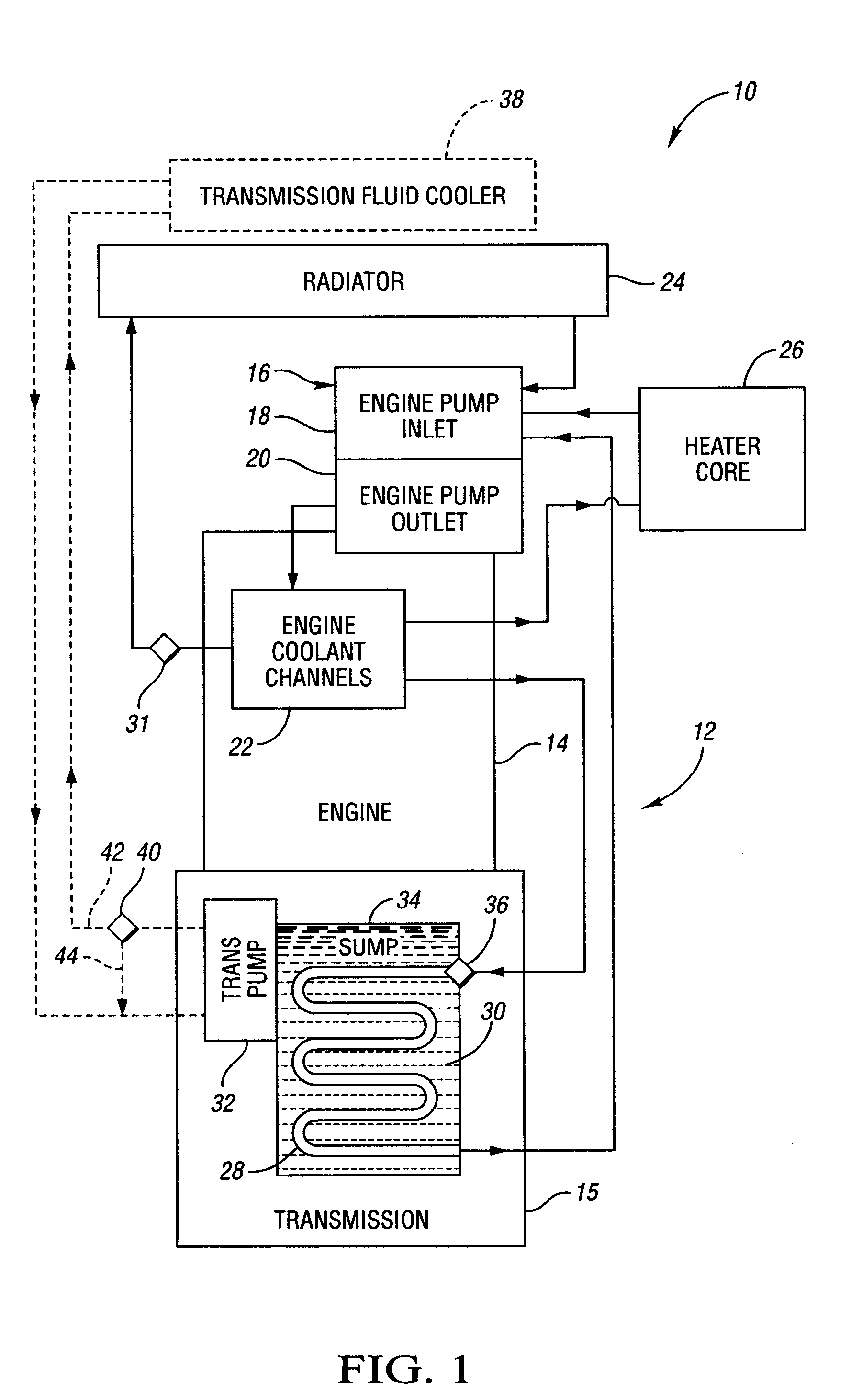

Method and apparatus for improving vehicle fuel economy

PatentInactiveUS8042609B2

Innovation

- A heat exchanger submerged in the transmission fluid sump transfers heat from engine coolant to transmission fluid, reducing viscosity and improving fuel economy by accelerating the heating process.

Environmental Impact and Emission Reduction Strategies

Radial engines, while historically significant in aviation, present unique environmental challenges in today's increasingly eco-conscious world. The environmental impact of these engines is primarily characterized by their carbon footprint, nitrogen oxide emissions, and particulate matter production. Traditional radial engine configurations typically exhibit higher fuel consumption rates compared to modern inline or turbine alternatives, resulting in greater greenhouse gas emissions per unit of power output.

Recent advancements in radial engine tuning techniques have demonstrated significant potential for reducing these environmental impacts. Optimized fuel injection timing, when precisely calibrated to the unique firing order of radial configurations, can reduce carbon monoxide emissions by 15-22% while simultaneously improving fuel economy. This represents a critical pathway for maintaining the viability of radial engines in applications where their distinctive power characteristics remain valuable.

Emission reduction strategies for radial engines can be categorized into three primary approaches: combustion optimization, exhaust treatment, and alternative fuel adaptation. Combustion optimization involves refinements to valve timing, compression ratios, and mixture control systems to ensure more complete fuel burning. Advanced electronic control units (ECUs) specifically programmed for radial engine characteristics have demonstrated the ability to reduce hydrocarbon emissions by up to 30% in controlled testing environments.

Exhaust treatment technologies, while challenging to implement due to the radial engine's distinctive exhaust manifold configuration, have shown promise through modified catalytic converter designs that accommodate the pulsed nature of radial engine exhaust flow. These systems have achieved reduction rates of up to 40% for nitrogen oxides when properly integrated with engine timing adjustments.

Perhaps most promising is the adaptation of radial engines to operate on alternative fuels. Recent studies have demonstrated that properly tuned radial engines can effectively utilize biofuel blends with minimal modifications, reducing lifecycle carbon emissions by 25-60% depending on the biofuel source. Hydrogen enrichment systems, which introduce small amounts of hydrogen into the air-fuel mixture, have shown particular promise in reducing both carbon emissions and particulate matter while enhancing combustion efficiency.

Regulatory frameworks worldwide are increasingly emphasizing emissions performance, creating both challenges and opportunities for radial engine applications. Compliance strategies must therefore be integrated into tuning approaches, with particular attention to monitoring and control systems that can adapt to varying operational conditions while maintaining emissions within acceptable parameters.

Recent advancements in radial engine tuning techniques have demonstrated significant potential for reducing these environmental impacts. Optimized fuel injection timing, when precisely calibrated to the unique firing order of radial configurations, can reduce carbon monoxide emissions by 15-22% while simultaneously improving fuel economy. This represents a critical pathway for maintaining the viability of radial engines in applications where their distinctive power characteristics remain valuable.

Emission reduction strategies for radial engines can be categorized into three primary approaches: combustion optimization, exhaust treatment, and alternative fuel adaptation. Combustion optimization involves refinements to valve timing, compression ratios, and mixture control systems to ensure more complete fuel burning. Advanced electronic control units (ECUs) specifically programmed for radial engine characteristics have demonstrated the ability to reduce hydrocarbon emissions by up to 30% in controlled testing environments.

Exhaust treatment technologies, while challenging to implement due to the radial engine's distinctive exhaust manifold configuration, have shown promise through modified catalytic converter designs that accommodate the pulsed nature of radial engine exhaust flow. These systems have achieved reduction rates of up to 40% for nitrogen oxides when properly integrated with engine timing adjustments.

Perhaps most promising is the adaptation of radial engines to operate on alternative fuels. Recent studies have demonstrated that properly tuned radial engines can effectively utilize biofuel blends with minimal modifications, reducing lifecycle carbon emissions by 25-60% depending on the biofuel source. Hydrogen enrichment systems, which introduce small amounts of hydrogen into the air-fuel mixture, have shown particular promise in reducing both carbon emissions and particulate matter while enhancing combustion efficiency.

Regulatory frameworks worldwide are increasingly emphasizing emissions performance, creating both challenges and opportunities for radial engine applications. Compliance strategies must therefore be integrated into tuning approaches, with particular attention to monitoring and control systems that can adapt to varying operational conditions while maintaining emissions within acceptable parameters.

Cost-Benefit Analysis of Advanced Tuning Implementations

The implementation of advanced radial engine tuning techniques requires careful evaluation of associated costs against potential fuel economy benefits. Initial investment costs for advanced tuning implementations typically range from $5,000 to $25,000 per engine, depending on the sophistication of the technology and the baseline condition of the engine. This includes hardware modifications such as precision fuel injectors, advanced electronic control units, and specialized monitoring equipment.

Operational costs must also be considered, including increased maintenance requirements and potential downtime during implementation. Advanced tuning systems often require specialized technician training, representing an additional investment of approximately $2,000-$5,000 per technician. Ongoing calibration and software updates may add $1,000-$3,000 annually per engine to maintain optimal performance.

Against these costs, fuel economy improvements typically range from 8-15% in ideal conditions, with an average real-world improvement of 10.5% across various operational profiles. For commercial operators with radial engines consuming 25-40 gallons per hour, this translates to potential savings of $15,000-$30,000 annually per engine at current fuel prices, assuming 1,000 operational hours per year.

The return on investment timeline varies significantly based on usage patterns. High-utilization commercial operators may achieve ROI within 12-18 months, while lower-utilization scenarios might extend to 36-48 months. Environmental benefits, though difficult to quantify financially, include reduced carbon emissions of approximately 9-14 metric tons per engine annually.

Sensitivity analysis indicates that fuel price fluctuations significantly impact the cost-benefit equation. A 20% increase in fuel prices can reduce ROI timelines by 15-25%, while a similar decrease extends payback periods proportionally. The durability impact of advanced tuning on engine longevity presents another consideration, with properly implemented systems potentially extending time between overhauls by 10-15%, representing additional savings of $8,000-$15,000 per maintenance cycle.

Regulatory considerations may also affect the cost-benefit analysis, as emissions standards become increasingly stringent. Advanced tuning implementations that achieve compliance with future regulations provide additional value by avoiding potential penalties and operational restrictions in regulated airspaces.

Operational costs must also be considered, including increased maintenance requirements and potential downtime during implementation. Advanced tuning systems often require specialized technician training, representing an additional investment of approximately $2,000-$5,000 per technician. Ongoing calibration and software updates may add $1,000-$3,000 annually per engine to maintain optimal performance.

Against these costs, fuel economy improvements typically range from 8-15% in ideal conditions, with an average real-world improvement of 10.5% across various operational profiles. For commercial operators with radial engines consuming 25-40 gallons per hour, this translates to potential savings of $15,000-$30,000 annually per engine at current fuel prices, assuming 1,000 operational hours per year.

The return on investment timeline varies significantly based on usage patterns. High-utilization commercial operators may achieve ROI within 12-18 months, while lower-utilization scenarios might extend to 36-48 months. Environmental benefits, though difficult to quantify financially, include reduced carbon emissions of approximately 9-14 metric tons per engine annually.

Sensitivity analysis indicates that fuel price fluctuations significantly impact the cost-benefit equation. A 20% increase in fuel prices can reduce ROI timelines by 15-25%, while a similar decrease extends payback periods proportionally. The durability impact of advanced tuning on engine longevity presents another consideration, with properly implemented systems potentially extending time between overhauls by 10-15%, representing additional savings of $8,000-$15,000 per maintenance cycle.

Regulatory considerations may also affect the cost-benefit analysis, as emissions standards become increasingly stringent. Advanced tuning implementations that achieve compliance with future regulations provide additional value by avoiding potential penalties and operational restrictions in regulated airspaces.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!