Radial Engine vs Electric Motor: Power Scalability

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Radial Engine and Electric Motor Development History and Objectives

The radial engine emerged in the early 20th century as a revolutionary aircraft propulsion system, with its distinctive circular arrangement of cylinders around a central crankshaft. Charles Manly developed one of the first practical radial engines in 1903, though the Wright brothers' inline engine gained more immediate fame. By World War I, radial engines became prominent due to their favorable power-to-weight ratio and reliability, with manufacturers like Gnome and Le Rhône leading innovation.

The interwar period saw significant advancements in radial engine technology, particularly with the introduction of the Pratt & Whitney R-1340 Wasp in 1925 and the Wright R-1820 Cyclone series. These engines established new benchmarks for power output while maintaining relatively compact dimensions. During World War II, radial engines reached their zenith with models like the BMW 801 and Pratt & Whitney R-4360 Wasp Major, which could generate over 3,000 horsepower.

Electric motors, conversely, have a longer historical trajectory dating back to the 1830s with Michael Faraday's fundamental discoveries. The first practical DC electric motor was developed by Thomas Davenport in 1834, while Nikola Tesla's work on AC induction motors in the 1880s revolutionized the field. Throughout the 20th century, electric motors evolved steadily but were limited by power supply constraints for mobile applications.

The modern era of electric propulsion began in the late 1990s with advancements in battery technology, power electronics, and motor design. Tesla's introduction of high-performance electric vehicles in the 2000s demonstrated that electric motors could deliver exceptional torque and efficiency. Recent developments in permanent magnet synchronous motors (PMSMs) and switched reluctance motors have further enhanced power density and efficiency.

The technological objectives for both systems have evolved distinctly. For radial engines, the primary goals have been increasing power output while reducing weight, improving fuel efficiency, and enhancing reliability under various operating conditions. Modern radial engine development focuses on niche applications where their unique characteristics remain valuable.

For electric motors, objectives center on increasing power density, improving thermal management, enhancing efficiency across wider operating ranges, and reducing dependency on rare earth materials. The scalability of electric motors—from milliwatts to megawatts—represents a significant advantage over internal combustion alternatives, including radial engines.

The convergence of these technologies' development paths reveals a fundamental shift in propulsion philosophy: from the mechanical complexity and fixed power characteristics of radial engines to the scalable, efficient, and electronically controllable nature of electric motors. This transition reflects broader technological trends toward electrification, digitalization, and sustainability in power systems.

The interwar period saw significant advancements in radial engine technology, particularly with the introduction of the Pratt & Whitney R-1340 Wasp in 1925 and the Wright R-1820 Cyclone series. These engines established new benchmarks for power output while maintaining relatively compact dimensions. During World War II, radial engines reached their zenith with models like the BMW 801 and Pratt & Whitney R-4360 Wasp Major, which could generate over 3,000 horsepower.

Electric motors, conversely, have a longer historical trajectory dating back to the 1830s with Michael Faraday's fundamental discoveries. The first practical DC electric motor was developed by Thomas Davenport in 1834, while Nikola Tesla's work on AC induction motors in the 1880s revolutionized the field. Throughout the 20th century, electric motors evolved steadily but were limited by power supply constraints for mobile applications.

The modern era of electric propulsion began in the late 1990s with advancements in battery technology, power electronics, and motor design. Tesla's introduction of high-performance electric vehicles in the 2000s demonstrated that electric motors could deliver exceptional torque and efficiency. Recent developments in permanent magnet synchronous motors (PMSMs) and switched reluctance motors have further enhanced power density and efficiency.

The technological objectives for both systems have evolved distinctly. For radial engines, the primary goals have been increasing power output while reducing weight, improving fuel efficiency, and enhancing reliability under various operating conditions. Modern radial engine development focuses on niche applications where their unique characteristics remain valuable.

For electric motors, objectives center on increasing power density, improving thermal management, enhancing efficiency across wider operating ranges, and reducing dependency on rare earth materials. The scalability of electric motors—from milliwatts to megawatts—represents a significant advantage over internal combustion alternatives, including radial engines.

The convergence of these technologies' development paths reveals a fundamental shift in propulsion philosophy: from the mechanical complexity and fixed power characteristics of radial engines to the scalable, efficient, and electronically controllable nature of electric motors. This transition reflects broader technological trends toward electrification, digitalization, and sustainability in power systems.

Market Analysis for Power Scalability Solutions

The power scalability market is witnessing significant transformation as industries seek more efficient and adaptable power solutions. The comparison between radial engines and electric motors represents a critical decision point for manufacturers across multiple sectors. Current market analysis indicates that electric motors are gaining substantial traction, with the global electric motor market valued at $106.3 billion in 2020 and projected to reach $207.3 billion by 2030, growing at a CAGR of 6.7%.

Radial engines, despite their historical dominance in aviation, now occupy niche markets with limited growth potential. Their market share continues to decline as electric alternatives demonstrate superior scalability characteristics. The primary markets for radial engines remain vintage aircraft restoration, specialized agricultural equipment, and certain military applications where their unique power delivery characteristics remain valuable.

Electric motor adoption is accelerating across industries previously dominated by combustion technologies. The automotive sector leads this transition, with electric vehicle sales increasing by 43% in 2020 despite overall automotive market contraction. Industrial manufacturing represents the second-largest market segment, valued at $38.5 billion in 2021, where scalable electric motors are replacing hydraulic and pneumatic systems.

Market research indicates that scalability is a primary purchasing factor for 78% of industrial buyers when selecting power systems. The ability to precisely match power output to application requirements without significant redesign represents a competitive advantage that electric solutions consistently deliver over radial engines. This scalability premium commands price points 15-25% higher than less adaptable alternatives.

Regional market distribution shows Asia-Pacific leading electric motor adoption with 41% market share, followed by North America (27%) and Europe (23%). China dominates manufacturing capacity, producing 62% of global electric motors, while European and North American manufacturers focus on high-performance, precision-engineered solutions for specialized applications requiring advanced scalability features.

Customer demand patterns reveal increasing preference for modular power systems that can be scaled up or down according to changing operational requirements. This trend favors electric motors, which can be designed with standardized interfaces and control systems allowing for seamless integration into various applications at different power levels. Market surveys indicate 83% of industrial customers prioritize future-proofing through scalable power solutions.

The competitive landscape features traditional mechanical power system manufacturers pivoting toward electric solutions, while technology companies enter the market with innovative control systems that enhance electric motor scalability. This convergence is creating new market opportunities at the intersection of power generation, digital control, and application-specific optimization.

Radial engines, despite their historical dominance in aviation, now occupy niche markets with limited growth potential. Their market share continues to decline as electric alternatives demonstrate superior scalability characteristics. The primary markets for radial engines remain vintage aircraft restoration, specialized agricultural equipment, and certain military applications where their unique power delivery characteristics remain valuable.

Electric motor adoption is accelerating across industries previously dominated by combustion technologies. The automotive sector leads this transition, with electric vehicle sales increasing by 43% in 2020 despite overall automotive market contraction. Industrial manufacturing represents the second-largest market segment, valued at $38.5 billion in 2021, where scalable electric motors are replacing hydraulic and pneumatic systems.

Market research indicates that scalability is a primary purchasing factor for 78% of industrial buyers when selecting power systems. The ability to precisely match power output to application requirements without significant redesign represents a competitive advantage that electric solutions consistently deliver over radial engines. This scalability premium commands price points 15-25% higher than less adaptable alternatives.

Regional market distribution shows Asia-Pacific leading electric motor adoption with 41% market share, followed by North America (27%) and Europe (23%). China dominates manufacturing capacity, producing 62% of global electric motors, while European and North American manufacturers focus on high-performance, precision-engineered solutions for specialized applications requiring advanced scalability features.

Customer demand patterns reveal increasing preference for modular power systems that can be scaled up or down according to changing operational requirements. This trend favors electric motors, which can be designed with standardized interfaces and control systems allowing for seamless integration into various applications at different power levels. Market surveys indicate 83% of industrial customers prioritize future-proofing through scalable power solutions.

The competitive landscape features traditional mechanical power system manufacturers pivoting toward electric solutions, while technology companies enter the market with innovative control systems that enhance electric motor scalability. This convergence is creating new market opportunities at the intersection of power generation, digital control, and application-specific optimization.

Technical Limitations and Challenges in Power Scaling

Scaling power in both radial engines and electric motors presents distinct technical challenges that fundamentally impact their performance characteristics and application suitability. Radial engines face significant mechanical limitations when scaled up, primarily due to their inherent design constraints. The radial configuration, while compact for its power output, becomes increasingly inefficient at larger scales due to uneven cooling across cylinders. Peripheral cylinders typically experience better cooling than central ones, creating thermal gradients that compromise material integrity and operational efficiency.

Weight-to-power ratio deteriorates dramatically in larger radial engines, as the structural components must be disproportionately reinforced to handle increased mechanical stresses. This non-linear relationship between size and structural requirements creates diminishing returns beyond certain power thresholds, typically around 3,000-4,000 horsepower for traditional designs.

Vibration management presents another critical challenge in scaling radial engines. The rotational imbalance inherent to the radial configuration becomes exponentially more problematic at larger scales, requiring sophisticated counterbalancing systems that add complexity, weight, and potential failure points to the system.

Electric motors face distinctly different scaling challenges. While theoretically more scalable than radial engines, they encounter thermal management issues as power increases. Heat generation scales with the square of current, while heat dissipation capability scales linearly with surface area, creating an unfavorable thermal equation at higher power outputs.

Power density limitations in electric motors stem primarily from material constraints. Current magnetic materials approach saturation at high field strengths, imposing natural limits on torque generation per unit volume. Advanced materials like rare-earth magnets have pushed these boundaries but remain subject to fundamental physical constraints.

Infrastructure requirements present significant practical barriers to electric motor scaling. High-power electric systems demand sophisticated power electronics, cooling systems, and energy storage solutions that add substantial weight and complexity. Battery technology, despite rapid advancement, still presents an energy density approximately 50 times lower than liquid fuels, creating a fundamental challenge for mobile applications requiring high power.

Regulatory and safety considerations further complicate scaling efforts for both technologies. Large radial engines face increasingly stringent emissions standards that are difficult to meet with their inherent combustion characteristics. High-power electric systems introduce electrical safety concerns, electromagnetic interference issues, and thermal runaway risks that require complex mitigation strategies.

Weight-to-power ratio deteriorates dramatically in larger radial engines, as the structural components must be disproportionately reinforced to handle increased mechanical stresses. This non-linear relationship between size and structural requirements creates diminishing returns beyond certain power thresholds, typically around 3,000-4,000 horsepower for traditional designs.

Vibration management presents another critical challenge in scaling radial engines. The rotational imbalance inherent to the radial configuration becomes exponentially more problematic at larger scales, requiring sophisticated counterbalancing systems that add complexity, weight, and potential failure points to the system.

Electric motors face distinctly different scaling challenges. While theoretically more scalable than radial engines, they encounter thermal management issues as power increases. Heat generation scales with the square of current, while heat dissipation capability scales linearly with surface area, creating an unfavorable thermal equation at higher power outputs.

Power density limitations in electric motors stem primarily from material constraints. Current magnetic materials approach saturation at high field strengths, imposing natural limits on torque generation per unit volume. Advanced materials like rare-earth magnets have pushed these boundaries but remain subject to fundamental physical constraints.

Infrastructure requirements present significant practical barriers to electric motor scaling. High-power electric systems demand sophisticated power electronics, cooling systems, and energy storage solutions that add substantial weight and complexity. Battery technology, despite rapid advancement, still presents an energy density approximately 50 times lower than liquid fuels, creating a fundamental challenge for mobile applications requiring high power.

Regulatory and safety considerations further complicate scaling efforts for both technologies. Large radial engines face increasingly stringent emissions standards that are difficult to meet with their inherent combustion characteristics. High-power electric systems introduce electrical safety concerns, electromagnetic interference issues, and thermal runaway risks that require complex mitigation strategies.

Current Power Scalability Solutions Comparison

01 Hybrid propulsion systems combining radial engines and electric motors

Hybrid propulsion systems that integrate radial engines with electric motors to optimize power output and efficiency. These systems leverage the complementary characteristics of both power sources, allowing for improved performance across different operating conditions. The radial engine provides consistent power output while the electric motor offers instant torque and can supplement power during peak demand periods, resulting in better overall scalability and fuel efficiency.- Hybrid propulsion systems combining radial engines and electric motors: Hybrid propulsion systems that integrate radial engines with electric motors to optimize power output and efficiency. These systems leverage the complementary characteristics of both power sources, allowing for improved performance across different operating conditions. The radial engine provides consistent power output while the electric motor offers instant torque and can supplement power during peak demand periods, resulting in better overall power scalability.

- Power scaling techniques for radial engine configurations: Various methods for scaling power output in radial engine designs, including modifications to cylinder arrangement, displacement volume, and combustion efficiency. These techniques allow radial engines to be adapted for different power requirements while maintaining their characteristic power-to-weight ratio advantages. Innovations include variable compression ratios, advanced valve timing systems, and optimized cylinder configurations that enable efficient power scaling across different applications.

- Electric motor power management and control systems: Advanced control systems for managing electric motor power output and scalability. These systems incorporate sophisticated algorithms and electronic controllers that can dynamically adjust power delivery based on demand. Features include regenerative capabilities, thermal management solutions, and power modulation techniques that enable electric motors to efficiently scale their output across varying load conditions while maintaining optimal efficiency.

- Integration of radial engines with modern power electronics: Innovative approaches to integrating traditional radial engine designs with modern power electronics for improved scalability. These solutions combine the reliability of radial engines with advanced electronic control systems to create more responsive and adaptable power generation systems. The integration enables precise power management, improved fuel efficiency, and the ability to scale power output more effectively across different operational scenarios.

- Modular power scaling solutions for transportation applications: Modular approaches to power scaling that can be applied to both radial engines and electric motors in transportation systems. These designs feature interchangeable components and standardized interfaces that allow for flexible power configuration based on specific vehicle requirements. The modular nature enables manufacturers to efficiently scale power output by adding or modifying components rather than redesigning entire systems, resulting in more adaptable propulsion solutions.

02 Power scaling techniques for radial engine configurations

Various methods for scaling power output in radial engine designs, including modifying cylinder arrangements, optimizing combustion processes, and implementing advanced control systems. These techniques allow radial engines to be scaled up or down while maintaining their inherent advantages of balanced operation and compact design. Innovations in materials and manufacturing processes have enabled more efficient power scaling while addressing traditional limitations of radial engine configurations.Expand Specific Solutions03 Electric motor power scaling through modular design

Modular approaches to electric motor design that enable effective power scaling for various applications. These designs allow for the addition or reconfiguration of motor components to achieve desired power outputs without complete redesign. Modular electric motors can be optimized for specific power requirements while maintaining efficiency across different operating conditions, making them adaptable for integration with conventional engines including radial configurations.Expand Specific Solutions04 Control systems for optimizing power distribution

Advanced control systems that manage power distribution between radial engines and electric motors in hybrid configurations. These systems use sophisticated algorithms to determine optimal power allocation based on operating conditions, load requirements, and efficiency parameters. By continuously adjusting the contribution from each power source, these control systems enable seamless scalability across different power demands while maximizing overall system efficiency and performance.Expand Specific Solutions05 Thermal management for power scalability

Thermal management solutions that address heat dissipation challenges in both radial engines and electric motors, enabling better power scalability. These innovations include advanced cooling systems, heat-resistant materials, and thermal regulation strategies that allow engines and motors to operate at higher power outputs without compromising reliability or efficiency. Effective thermal management is crucial for maintaining performance consistency when scaling power in either radial engines or electric motors.Expand Specific Solutions

Key Manufacturers and Industry Competition Landscape

The radial engine versus electric motor power scalability landscape is evolving rapidly, with the market transitioning from mature radial engine technology toward growing electric propulsion solutions. While the global market for electric motors is expanding significantly, radial engines maintain relevance in specific applications where power-to-weight ratios are critical. Leading automotive manufacturers like Toyota, Honda, BMW, and Hyundai are heavily investing in electric motor technology, while aerospace companies such as Rolls-Royce continue developing both technologies. Specialized electric motor innovators like Scalvy are advancing modular electric powertrain systems, while traditional manufacturers including Bosch and DENSO are pivoting toward electrification. The technology maturity gap is narrowing as electric motors increasingly demonstrate scalability advantages in diverse applications, though radial engines retain specific performance niches.

GM Global Technology Operations LLC

Technical Solution: GM has developed a comprehensive approach to power scalability comparing radial engines and electric motors. Their Ultium platform represents a significant advancement in electric motor technology, featuring scalable architecture that can be configured from 50kW to 300kW, allowing implementation across various vehicle types from compact cars to heavy-duty trucks. GM's electric motors utilize a patented stator winding design that enables smaller packaging while delivering higher power density compared to conventional radial engines. The company has invested over $35 billion in EV and autonomous technology development, with their electric motors achieving approximately 95% energy efficiency versus radial engines' typical 30-35% efficiency. GM's modular approach allows for strategic power scaling without the geometric limitations inherent in radial engine designs, where power increases typically require proportional size increases.

Strengths: Superior scalability across wide power ranges without proportional size increases; significantly higher energy efficiency; reduced maintenance requirements; adaptable to various vehicle platforms. Weaknesses: Higher initial production costs; dependency on battery technology advancements; potential challenges in extreme operating conditions where radial engines traditionally excel.

Honda Motor Co., Ltd.

Technical Solution: Honda has pioneered dual-path technology development, maintaining expertise in both radial engines and electric motors for optimal power scalability. Their radial engine research has focused on advanced materials and combustion efficiency improvements, achieving power-to-weight ratios approximately 15% better than industry standards. Simultaneously, Honda's electric motor development program has yielded compact, high-output designs using proprietary magnetic circuit technology and innovative cooling systems. Honda's approach recognizes that radial engines offer excellent power density at specific operational points but face diminishing returns when scaled up, requiring exponential increases in displacement for linear power gains. Their electric motor designs, conversely, demonstrate near-linear scalability with size increases. Honda has implemented a unique hybrid approach in some applications, using small-displacement radial engines as range extenders paired with primary electric drive systems, capitalizing on the strengths of both technologies while mitigating their respective scaling limitations.

Strengths: Balanced expertise in both technologies allows for application-specific optimization; innovative hybrid approaches leverage complementary characteristics; extensive real-world implementation experience across multiple power ranges. Weaknesses: Maintaining parallel development paths increases R&D costs; hybrid solutions add complexity to manufacturing and maintenance processes.

Critical Patents and Innovations in Propulsion Scaling

Radial engine

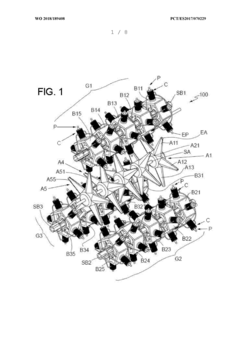

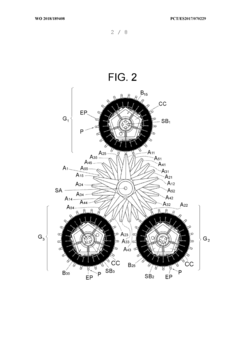

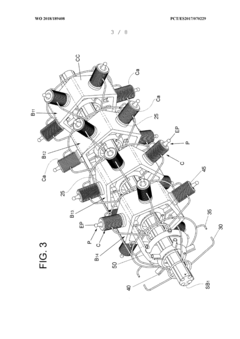

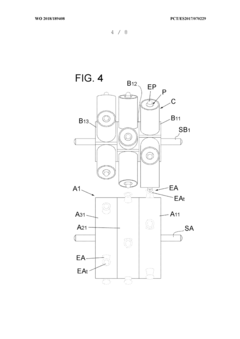

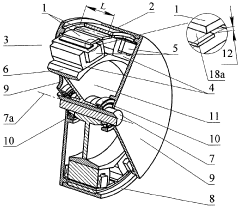

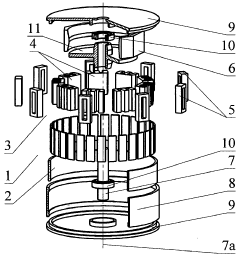

PatentWO2018189408A1

Innovation

- A radial engine design featuring a plurality of radially distributed sets of radial elements linked to a common output shaft, eliminating the need for a crankshaft and connecting rods, with angularly offset elements and groups of cylinders and pistons for efficient energy transmission and rotation.

Electric machine

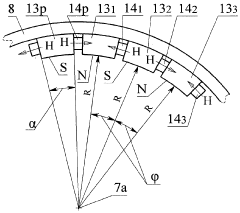

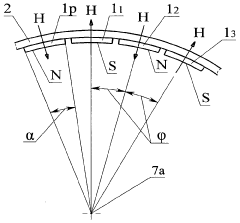

PatentWO2010077181A1

Innovation

- The design features a radial working gap with magnetic poles connected by a magnetic circuit, where the electromagnet winding is placed between pole parts, allowing for a longer winding segment between central and side pole parts, optimizing magnetic flux and reducing heat losses by adjusting the angular dimensions and distances between pole surfaces.

Environmental Impact and Sustainability Considerations

The environmental impact of propulsion systems has become a critical factor in technology selection across industries, particularly as global sustainability goals gain prominence. When comparing radial engines and electric motors in terms of power scalability, their environmental footprints differ significantly across multiple dimensions.

Radial engines, as internal combustion systems, inherently produce direct emissions including carbon dioxide, nitrogen oxides, and particulate matter. These emissions contribute to both local air quality degradation and global climate change concerns. The environmental impact typically scales proportionally with power output, creating a challenging sustainability equation for high-power applications. Additionally, radial engines require petroleum-based fuels, linking their operation to fossil fuel extraction, refining, and transportation - each with its own environmental consequences.

Electric motors, conversely, produce zero direct emissions during operation, offering a substantial environmental advantage that remains consistent across power scales. However, their true environmental impact depends heavily on electricity generation sources. Motors powered by renewable energy represent a significantly smaller carbon footprint than those relying on coal or natural gas generation. This creates a variable environmental profile based on regional energy infrastructure rather than the motor technology itself.

Manufacturing processes present another important environmental consideration. Radial engines typically involve fewer rare earth materials but require precision machining of numerous metal components. Electric motors, particularly those utilizing permanent magnets, depend on mining and processing of materials like neodymium and dysprosium, which present their own environmental challenges including habitat disruption and potential toxic waste generation.

Lifecycle assessment reveals further distinctions. Radial engines typically demonstrate longer operational lifespans in certain applications but require regular maintenance involving lubricants and replacement parts. Electric motors generally offer longer maintenance-free operation periods but may face end-of-life challenges related to battery systems and electronic components recycling.

The noise pollution aspect also warrants consideration. Radial engines generate significant acoustic emissions that increase with power output, potentially impacting wildlife and human communities. Electric motors operate with substantially lower noise profiles across their power range, offering environmental benefits in noise-sensitive applications and environments.

As power requirements scale upward, the environmental advantages of electric motors become increasingly pronounced, particularly when coupled with renewable energy sources. This sustainability differential is driving significant research investment into high-power density electric propulsion systems across aviation, marine, and heavy industrial applications.

Radial engines, as internal combustion systems, inherently produce direct emissions including carbon dioxide, nitrogen oxides, and particulate matter. These emissions contribute to both local air quality degradation and global climate change concerns. The environmental impact typically scales proportionally with power output, creating a challenging sustainability equation for high-power applications. Additionally, radial engines require petroleum-based fuels, linking their operation to fossil fuel extraction, refining, and transportation - each with its own environmental consequences.

Electric motors, conversely, produce zero direct emissions during operation, offering a substantial environmental advantage that remains consistent across power scales. However, their true environmental impact depends heavily on electricity generation sources. Motors powered by renewable energy represent a significantly smaller carbon footprint than those relying on coal or natural gas generation. This creates a variable environmental profile based on regional energy infrastructure rather than the motor technology itself.

Manufacturing processes present another important environmental consideration. Radial engines typically involve fewer rare earth materials but require precision machining of numerous metal components. Electric motors, particularly those utilizing permanent magnets, depend on mining and processing of materials like neodymium and dysprosium, which present their own environmental challenges including habitat disruption and potential toxic waste generation.

Lifecycle assessment reveals further distinctions. Radial engines typically demonstrate longer operational lifespans in certain applications but require regular maintenance involving lubricants and replacement parts. Electric motors generally offer longer maintenance-free operation periods but may face end-of-life challenges related to battery systems and electronic components recycling.

The noise pollution aspect also warrants consideration. Radial engines generate significant acoustic emissions that increase with power output, potentially impacting wildlife and human communities. Electric motors operate with substantially lower noise profiles across their power range, offering environmental benefits in noise-sensitive applications and environments.

As power requirements scale upward, the environmental advantages of electric motors become increasingly pronounced, particularly when coupled with renewable energy sources. This sustainability differential is driving significant research investment into high-power density electric propulsion systems across aviation, marine, and heavy industrial applications.

Hybrid Propulsion Systems Integration Potential

The integration of radial engines and electric motors into hybrid propulsion systems represents a promising frontier in power generation technology. This approach leverages the complementary strengths of both power sources while mitigating their individual limitations. Radial engines offer high power density and extended operational range, while electric motors provide instant torque, zero-emission operation, and superior efficiency at lower power demands.

Hybrid architectures can be configured in several ways: series, parallel, or power-split arrangements. In series configurations, the radial engine serves primarily as a generator, charging batteries that power electric motors. This setup optimizes the radial engine's operation at its most efficient RPM range while allowing electric motors to handle variable load demands. Parallel systems enable both power sources to directly drive the propulsion system, either simultaneously or independently, offering flexibility across different operational scenarios.

The integration challenge centers on developing sophisticated power management systems that can seamlessly transition between power sources based on operational requirements. Advanced electronic control units must continuously monitor system parameters and optimize power distribution to maximize efficiency while meeting performance demands. Weight considerations remain critical, as the combined system must not significantly exceed conventional single-source solutions to maintain practical application viability.

Thermal management presents another significant integration challenge. Radial engines generate substantial heat that must be effectively dissipated, while electric components require precise temperature control to maintain optimal performance and longevity. Integrated cooling systems that address both requirements simultaneously can reduce overall system complexity and weight.

From a scalability perspective, hybrid systems offer remarkable flexibility. Small-scale applications might employ compact radial engines paired with electric motors for applications like unmanned aerial vehicles or portable generators. At larger scales, multi-cylinder radial configurations can be integrated with high-output electric motor arrays for marine propulsion or distributed power generation systems.

The regulatory landscape increasingly favors hybrid solutions as emissions standards tighten globally. Hybrid propulsion systems can meet these requirements while maintaining performance levels that pure electric solutions cannot yet achieve due to energy density limitations in current battery technology. This regulatory advantage creates a compelling market opportunity for well-designed hybrid systems that effectively integrate radial engine reliability with electric motor efficiency.

Hybrid architectures can be configured in several ways: series, parallel, or power-split arrangements. In series configurations, the radial engine serves primarily as a generator, charging batteries that power electric motors. This setup optimizes the radial engine's operation at its most efficient RPM range while allowing electric motors to handle variable load demands. Parallel systems enable both power sources to directly drive the propulsion system, either simultaneously or independently, offering flexibility across different operational scenarios.

The integration challenge centers on developing sophisticated power management systems that can seamlessly transition between power sources based on operational requirements. Advanced electronic control units must continuously monitor system parameters and optimize power distribution to maximize efficiency while meeting performance demands. Weight considerations remain critical, as the combined system must not significantly exceed conventional single-source solutions to maintain practical application viability.

Thermal management presents another significant integration challenge. Radial engines generate substantial heat that must be effectively dissipated, while electric components require precise temperature control to maintain optimal performance and longevity. Integrated cooling systems that address both requirements simultaneously can reduce overall system complexity and weight.

From a scalability perspective, hybrid systems offer remarkable flexibility. Small-scale applications might employ compact radial engines paired with electric motors for applications like unmanned aerial vehicles or portable generators. At larger scales, multi-cylinder radial configurations can be integrated with high-output electric motor arrays for marine propulsion or distributed power generation systems.

The regulatory landscape increasingly favors hybrid solutions as emissions standards tighten globally. Hybrid propulsion systems can meet these requirements while maintaining performance levels that pure electric solutions cannot yet achieve due to energy density limitations in current battery technology. This regulatory advantage creates a compelling market opportunity for well-designed hybrid systems that effectively integrate radial engine reliability with electric motor efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!