Radial Engine vs Gas Turbine: Power-to-Weight Ratio

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aircraft Engine Evolution and Objectives

Aircraft propulsion technology has undergone remarkable evolution since the early 20th century, transitioning from simple piston engines to sophisticated gas turbines. The radial engine, developed in the 1920s-1930s, represented a significant advancement in aircraft propulsion, offering improved power output and reliability compared to earlier inline engines. These air-cooled engines arranged cylinders in a circular pattern around a central crankshaft, providing excellent cooling characteristics and structural integrity.

The mid-20th century witnessed a paradigm shift with the introduction of gas turbine technology. Frank Whittle in the UK and Hans von Ohain in Germany independently developed the first practical jet engines in the late 1930s, fundamentally changing aviation capabilities. This technological leap enabled aircraft to achieve previously impossible speeds and altitudes, marking the beginning of the jet age.

Power-to-weight ratio has consistently been a critical metric in aircraft engine development. Early radial engines typically delivered 0.5-0.7 horsepower per pound, while modern gas turbines can achieve 4-8 horsepower per pound—an order of magnitude improvement. This dramatic enhancement has enabled everything from supersonic flight to long-range commercial aviation.

The evolution trajectory shows clear technological inflection points: from wood and fabric aircraft with simple piston engines to all-metal designs with powerful radials, followed by early jets, high-bypass turbofans, and today's ultra-efficient engines with composite components and advanced electronic controls. Each generation has pushed the boundaries of the power-to-weight equation.

Current objectives in aircraft propulsion center on several key parameters: further improving power-to-weight ratios, enhancing fuel efficiency, reducing emissions, decreasing noise, and extending service intervals. The industry is targeting specific metrics such as 20% better fuel efficiency, 75% reduction in NOx emissions, and 10-15% improvement in power-to-weight ratios compared to previous generation engines.

Looking forward, emerging technologies like hybrid-electric propulsion, hydrogen fuel cells, and distributed propulsion architectures represent potential revolutionary advances. These technologies aim to address not only performance metrics but also sustainability concerns, with goals of carbon-neutral aviation by mid-century. The power-to-weight challenge remains central to these developments, with researchers exploring novel materials, combustion techniques, and system architectures to continue the upward trajectory of aircraft propulsion capability.

The mid-20th century witnessed a paradigm shift with the introduction of gas turbine technology. Frank Whittle in the UK and Hans von Ohain in Germany independently developed the first practical jet engines in the late 1930s, fundamentally changing aviation capabilities. This technological leap enabled aircraft to achieve previously impossible speeds and altitudes, marking the beginning of the jet age.

Power-to-weight ratio has consistently been a critical metric in aircraft engine development. Early radial engines typically delivered 0.5-0.7 horsepower per pound, while modern gas turbines can achieve 4-8 horsepower per pound—an order of magnitude improvement. This dramatic enhancement has enabled everything from supersonic flight to long-range commercial aviation.

The evolution trajectory shows clear technological inflection points: from wood and fabric aircraft with simple piston engines to all-metal designs with powerful radials, followed by early jets, high-bypass turbofans, and today's ultra-efficient engines with composite components and advanced electronic controls. Each generation has pushed the boundaries of the power-to-weight equation.

Current objectives in aircraft propulsion center on several key parameters: further improving power-to-weight ratios, enhancing fuel efficiency, reducing emissions, decreasing noise, and extending service intervals. The industry is targeting specific metrics such as 20% better fuel efficiency, 75% reduction in NOx emissions, and 10-15% improvement in power-to-weight ratios compared to previous generation engines.

Looking forward, emerging technologies like hybrid-electric propulsion, hydrogen fuel cells, and distributed propulsion architectures represent potential revolutionary advances. These technologies aim to address not only performance metrics but also sustainability concerns, with goals of carbon-neutral aviation by mid-century. The power-to-weight challenge remains central to these developments, with researchers exploring novel materials, combustion techniques, and system architectures to continue the upward trajectory of aircraft propulsion capability.

Market Analysis for Aviation Propulsion Systems

The aviation propulsion system market is experiencing significant transformation driven by technological advancements, environmental regulations, and changing operational requirements. Currently valued at approximately $42.5 billion globally, this market is projected to grow at a CAGR of 5.8% through 2030, with particular acceleration in more efficient propulsion technologies.

Gas turbine engines dominate the commercial aviation segment, accounting for over 85% of the market share due to their superior power-to-weight ratio and operational efficiency at high altitudes. The radial engine market, while historically significant, now represents less than 3% of new aviation propulsion installations, primarily limited to specialty applications such as vintage aircraft restoration, agricultural aviation, and certain light sport aircraft.

Regional analysis reveals distinct market patterns. North America leads with 38% market share, driven by major manufacturers like GE Aviation and Pratt & Whitney. Europe follows at 29%, with strong presence from Rolls-Royce and Safran. The Asia-Pacific region shows the fastest growth rate at 7.2% annually, particularly in China and India where aviation infrastructure expansion is creating substantial demand for new propulsion systems.

The power-to-weight ratio differential between gas turbines and radial engines represents a critical market driver. Modern turbofan engines achieve ratios of 5-8 kW/kg, while traditional radial engines typically deliver only 1-2 kW/kg. This performance gap has effectively segmented the market, with high-performance applications almost exclusively utilizing gas turbine technology.

Market forecasts indicate continued dominance of gas turbine technology, with particular growth in geared turbofan designs offering 15-20% better fuel efficiency than previous generations. The radial engine market is expected to remain stable but niche, with potential modest growth in specialized applications where simplicity, maintenance accessibility, and initial cost advantages outweigh power-to-weight considerations.

Customer demand analysis shows commercial airlines prioritizing fuel efficiency and reliability, with maintenance costs as a secondary consideration. General aviation customers demonstrate more diverse requirements, with segments valuing initial purchase cost and operational simplicity creating the remaining market space for radial engine technology.

Emerging market opportunities exist in hybrid propulsion systems that could potentially combine elements of both technologies, though these remain largely experimental. The sustainable aviation fuel compatibility of both engine types represents another evolving market factor, with gas turbines currently demonstrating greater adaptability to alternative fuel formulations.

Gas turbine engines dominate the commercial aviation segment, accounting for over 85% of the market share due to their superior power-to-weight ratio and operational efficiency at high altitudes. The radial engine market, while historically significant, now represents less than 3% of new aviation propulsion installations, primarily limited to specialty applications such as vintage aircraft restoration, agricultural aviation, and certain light sport aircraft.

Regional analysis reveals distinct market patterns. North America leads with 38% market share, driven by major manufacturers like GE Aviation and Pratt & Whitney. Europe follows at 29%, with strong presence from Rolls-Royce and Safran. The Asia-Pacific region shows the fastest growth rate at 7.2% annually, particularly in China and India where aviation infrastructure expansion is creating substantial demand for new propulsion systems.

The power-to-weight ratio differential between gas turbines and radial engines represents a critical market driver. Modern turbofan engines achieve ratios of 5-8 kW/kg, while traditional radial engines typically deliver only 1-2 kW/kg. This performance gap has effectively segmented the market, with high-performance applications almost exclusively utilizing gas turbine technology.

Market forecasts indicate continued dominance of gas turbine technology, with particular growth in geared turbofan designs offering 15-20% better fuel efficiency than previous generations. The radial engine market is expected to remain stable but niche, with potential modest growth in specialized applications where simplicity, maintenance accessibility, and initial cost advantages outweigh power-to-weight considerations.

Customer demand analysis shows commercial airlines prioritizing fuel efficiency and reliability, with maintenance costs as a secondary consideration. General aviation customers demonstrate more diverse requirements, with segments valuing initial purchase cost and operational simplicity creating the remaining market space for radial engine technology.

Emerging market opportunities exist in hybrid propulsion systems that could potentially combine elements of both technologies, though these remain largely experimental. The sustainable aviation fuel compatibility of both engine types represents another evolving market factor, with gas turbines currently demonstrating greater adaptability to alternative fuel formulations.

Current Technical Limitations of Radial and Turbine Engines

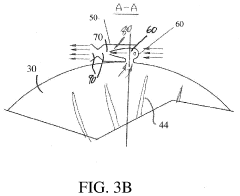

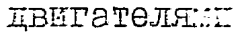

Radial engines, despite their historical significance in aviation, face several technical limitations in modern applications. Their power-to-weight ratio, while impressive for their era, has been surpassed by gas turbines. The radial configuration inherently creates significant drag due to its large frontal area, reducing aerodynamic efficiency. Additionally, the complex arrangement of cylinders around a central crankshaft leads to cooling challenges, as cylinders positioned at the bottom often receive inadequate airflow, resulting in uneven temperature distribution and potential thermal stress.

The mechanical complexity of radial engines presents another limitation. Their master-and-articulating rod assembly introduces additional weight and potential failure points. Oil management remains problematic, with lower cylinders prone to oil pooling during shutdown, potentially causing hydraulic lock during startup if not properly drained. Furthermore, radial engines typically operate at lower RPMs compared to other engine types, limiting their maximum power output relative to their size and weight.

Gas turbine engines, while offering superior power-to-weight ratios, face their own set of technical challenges. Their efficiency is highly dependent on operating conditions, with optimal performance typically achieved only at high altitudes and speeds. At lower altitudes and during idle operations, turbines suffer from relatively poor fuel efficiency compared to reciprocating engines. The high operating temperatures of turbines (often exceeding 1,500°C in the combustion chamber) necessitate advanced materials and cooling systems, significantly increasing manufacturing complexity and cost.

Turbine engines exhibit poor transient response characteristics, with noticeable lag during rapid power changes—a critical limitation in applications requiring immediate thrust adjustments. Their high-speed operation (often 20,000+ RPM) necessitates reduction gearing for propeller applications, adding weight and complexity. Additionally, turbines are particularly sensitive to foreign object damage, with even small debris potentially causing catastrophic failure due to the high-speed rotating components.

From a maintenance perspective, both engine types present distinct challenges. Radial engines require frequent valve adjustments and cylinder inspections due to their complex mechanical nature. Gas turbines, while having fewer moving parts, demand specialized maintenance procedures and expensive component replacements, with hot section inspections and overhauls representing significant operational costs. Their sophisticated electronic control systems also introduce potential failure points that require specialized diagnostic equipment and expertise.

The manufacturing precision requirements for both engine types are stringent but differ in nature. Radial engines demand precise machining of numerous mechanical components, while turbines require advanced metallurgy and manufacturing techniques to produce components capable of withstanding extreme thermal and mechanical stresses.

The mechanical complexity of radial engines presents another limitation. Their master-and-articulating rod assembly introduces additional weight and potential failure points. Oil management remains problematic, with lower cylinders prone to oil pooling during shutdown, potentially causing hydraulic lock during startup if not properly drained. Furthermore, radial engines typically operate at lower RPMs compared to other engine types, limiting their maximum power output relative to their size and weight.

Gas turbine engines, while offering superior power-to-weight ratios, face their own set of technical challenges. Their efficiency is highly dependent on operating conditions, with optimal performance typically achieved only at high altitudes and speeds. At lower altitudes and during idle operations, turbines suffer from relatively poor fuel efficiency compared to reciprocating engines. The high operating temperatures of turbines (often exceeding 1,500°C in the combustion chamber) necessitate advanced materials and cooling systems, significantly increasing manufacturing complexity and cost.

Turbine engines exhibit poor transient response characteristics, with noticeable lag during rapid power changes—a critical limitation in applications requiring immediate thrust adjustments. Their high-speed operation (often 20,000+ RPM) necessitates reduction gearing for propeller applications, adding weight and complexity. Additionally, turbines are particularly sensitive to foreign object damage, with even small debris potentially causing catastrophic failure due to the high-speed rotating components.

From a maintenance perspective, both engine types present distinct challenges. Radial engines require frequent valve adjustments and cylinder inspections due to their complex mechanical nature. Gas turbines, while having fewer moving parts, demand specialized maintenance procedures and expensive component replacements, with hot section inspections and overhauls representing significant operational costs. Their sophisticated electronic control systems also introduce potential failure points that require specialized diagnostic equipment and expertise.

The manufacturing precision requirements for both engine types are stringent but differ in nature. Radial engines demand precise machining of numerous mechanical components, while turbines require advanced metallurgy and manufacturing techniques to produce components capable of withstanding extreme thermal and mechanical stresses.

Comparative Analysis of Power-to-Weight Ratio Solutions

01 Gas turbine design improvements for higher power-to-weight ratio

Various design improvements in gas turbines have led to significant increases in power-to-weight ratios. These include advanced lightweight materials, improved aerodynamics, and optimized combustion systems. Modern gas turbines incorporate multi-stage compressors and turbines with enhanced efficiency, resulting in more power output from smaller, lighter engines. These innovations have made gas turbines particularly advantageous in aviation and power generation applications where weight considerations are critical.- Gas turbine design improvements for higher power-to-weight ratio: Various design improvements in gas turbines have led to significant increases in power-to-weight ratios. These include advanced aerodynamic designs, lightweight materials, improved cooling systems, and optimized combustion chambers. Modern gas turbines incorporate composite materials, advanced alloys, and innovative component designs that reduce overall weight while maintaining or increasing power output, resulting in superior power-to-weight ratios compared to traditional radial engines.

- Radial engine configurations for improved performance: Radial engines have undergone various modifications to enhance their power-to-weight ratio. These include optimized cylinder arrangements, improved valve timing mechanisms, enhanced cooling systems, and lightweight component designs. Some innovations involve hybrid configurations that combine radial engine characteristics with other engine types to maximize power output while minimizing weight, addressing the traditionally lower power-to-weight ratio of radial engines compared to gas turbines.

- Hybrid propulsion systems combining radial engines and gas turbines: Hybrid propulsion systems that integrate both radial engine and gas turbine technologies have been developed to leverage the advantages of each. These systems can provide improved power-to-weight ratios by utilizing the high power density of gas turbines while incorporating the reliability and operational characteristics of radial engines. Such hybrid configurations often employ sophisticated control systems to optimize performance across different operating conditions.

- Lightweight materials and manufacturing techniques: The application of advanced lightweight materials and modern manufacturing techniques has significantly improved the power-to-weight ratios of both radial engines and gas turbines. Ceramic composites, titanium alloys, carbon fiber components, and additive manufacturing processes have enabled the production of lighter yet stronger engine components. These innovations have particularly benefited gas turbines, allowing them to achieve substantially higher power-to-weight ratios than traditional radial engines.

- Cooling and efficiency enhancements affecting power-to-weight ratio: Advanced cooling systems and efficiency enhancements have played a crucial role in improving the power-to-weight ratios of both engine types. For gas turbines, sophisticated blade cooling technologies, improved thermal management, and optimized airflow designs have allowed higher operating temperatures and increased power output without proportional weight increases. In radial engines, enhanced cooling fin designs, improved oil circulation systems, and optimized air cooling have addressed traditional thermal limitations, allowing for better performance relative to weight.

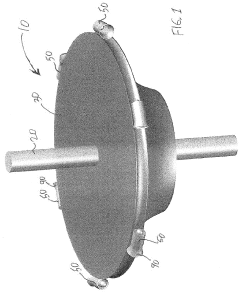

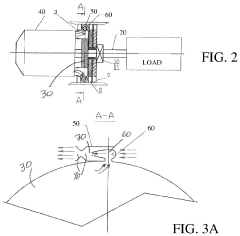

02 Radial engine configuration and power density characteristics

Radial engines feature a unique configuration where cylinders are arranged radially around a central crankshaft, resembling a star pattern. This design provides certain advantages in power density for specific applications. While heavier than inline configurations per horsepower, radial engines offer excellent air cooling capabilities and mechanical simplicity. Their compact frontal area made them particularly suitable for aircraft applications in earlier aviation eras, though their power-to-weight ratio is generally lower than modern gas turbines.Expand Specific Solutions03 Hybrid propulsion systems combining different engine types

Hybrid propulsion systems that combine different engine types can optimize power-to-weight ratios for specific operational profiles. These systems may integrate radial engines with gas turbines or other power sources to leverage the advantages of each technology. Such combinations allow for improved fuel efficiency during different flight phases or operating conditions. The integration often includes sophisticated control systems that determine the optimal power source based on altitude, speed, and mission requirements.Expand Specific Solutions04 Advanced materials and manufacturing techniques for engine weight reduction

The development of advanced materials and manufacturing techniques has significantly contributed to improving power-to-weight ratios in both radial engines and gas turbines. Lightweight alloys, composite materials, and ceramic components have replaced traditional heavier materials. Additive manufacturing and precision machining allow for optimized component designs with reduced weight while maintaining structural integrity. These advancements have enabled thinner walls, integrated components, and more efficient cooling systems that contribute to overall weight reduction.Expand Specific Solutions05 Comparative analysis of engine efficiency across different operational conditions

Comparative analyses of radial engines and gas turbines reveal different efficiency profiles across various operational conditions. Gas turbines generally offer superior power-to-weight ratios at high altitudes and speeds, while radial engines may provide advantages at lower altitudes and speeds. Factors affecting these comparisons include fuel consumption rates, maintenance requirements, reliability, and operational flexibility. Modern computational fluid dynamics and simulation techniques have enabled more precise optimization of engine designs for specific operational envelopes.Expand Specific Solutions

Leading Manufacturers in Aircraft Engine Industry

The radial engine vs gas turbine power-to-weight ratio competition landscape is currently in a mature phase, with gas turbines dominating modern aviation applications due to superior power-to-weight ratios. The market size exceeds $25 billion annually, driven by commercial aviation, military applications, and industrial power generation. Leading players like Rolls-Royce, GE, RTX (formerly United Technologies), and Honeywell have established technological dominance in gas turbines through decades of R&D investment. Military entities such as the US Air Force continue pushing performance boundaries, while research institutions like Northwestern Polytechnical University contribute to fundamental advancements. Despite gas turbines' prevalence, radial engines maintain niche applications where simplicity and reliability outweigh power density considerations.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has pioneered significant advancements in gas turbine technology, focusing on optimizing power-to-weight ratios through innovative materials and design. Their Trent series turbofans achieve power-to-weight ratios exceeding 10:1, substantially outperforming radial engines. The company employs single-crystal turbine blades and advanced ceramic matrix composites that can withstand temperatures up to 1,600°C, allowing higher combustion temperatures and improved thermodynamic efficiency. Their latest gas turbine designs incorporate additive manufacturing techniques to reduce component weight by up to 30% while maintaining structural integrity. Rolls-Royce's UltraFan technology demonstrates a 25% fuel efficiency improvement over first-generation Trent engines, with corresponding improvements in power density. Their comprehensive approach includes advanced cooling systems that enable higher operating temperatures without compromising component lifespan.

Strengths: Industry-leading materials science capabilities allow operation at higher temperatures, improving thermodynamic efficiency. Extensive experience in aerospace applications provides deep understanding of weight optimization. Weaknesses: Higher manufacturing costs compared to traditional radial engines. Greater system complexity requires more sophisticated maintenance protocols and specialized technician training.

General Electric Company

Technical Solution: GE has developed a comprehensive approach to gas turbine power-to-weight optimization through their advanced turbine technology portfolio. Their latest aviation gas turbines achieve power-to-weight ratios of approximately 8-10:1, significantly outperforming traditional radial engines which typically reach only 1-2:1. GE utilizes proprietary nickel-based superalloys and thermal barrier coatings that enable operation at temperatures exceeding 1,500°C, dramatically improving thermodynamic efficiency. Their advanced aerodynamic designs incorporate 3D-printed fuel nozzles that are 25% lighter and five times more durable than conventional manufacturing methods. GE's turbine blade cooling technology employs sophisticated internal cooling passages that allow higher operating temperatures without compromising structural integrity. The company has also pioneered ceramic matrix composite (CMC) components that reduce weight by approximately 30% compared to metal equivalents while withstanding higher temperatures, directly enhancing power-to-weight performance.

Strengths: Extensive research capabilities and manufacturing infrastructure allow rapid implementation of innovations. Vertical integration provides control over the entire development process from materials to final assembly. Weaknesses: High development costs for new technologies must be amortized across production volumes. Complex supply chain management required for specialized materials and components.

Critical Patents in Engine Efficiency Enhancement

Gas turbine engine having bladeless first stage and ejectors

PatentActiveUS20200355125A1

Innovation

- A gas turbine engine design featuring a central power shaft, rotatable turbine impeller, compressor, ejectors with combustion chambers, mixing chambers, and convergent-divergent nozzles that accelerate mixed flows to create reaction thrust, using relatively inexpensive materials and avoiding the need for cooling, with a compression ratio of six or less and a gas expansion ratio exceeding the compressor ratio by hundreds or thousands.

Gas-turbine device

PatentWO1993019290A1

Innovation

- A gas turbine device with two groups of closed channels arranged radially, featuring a multi-stage compressor connected kinematically to the rotor, allowing for the sequential compression and interaction of combustible mixtures through channels, enhancing the degree of compression and energy conversion efficiency.

Fuel Efficiency and Environmental Impact Assessment

When comparing radial engines and gas turbines, fuel efficiency and environmental impact are critical factors that significantly influence their practical applications and future viability. Radial engines, despite their historical prominence, generally exhibit lower fuel efficiency compared to modern gas turbines. The typical radial engine operates at a thermal efficiency of approximately 30-35%, with fuel consumption rates ranging from 0.4 to 0.6 pounds per horsepower-hour depending on the specific model and operational conditions.

Gas turbines, by contrast, demonstrate superior fuel efficiency, particularly in larger applications and at optimal operating conditions. Modern aviation gas turbines achieve thermal efficiencies of 40-50%, with advanced combined-cycle industrial turbines reaching up to 60% efficiency. This translates to significantly lower specific fuel consumption rates, typically between 0.3 and 0.5 pounds per horsepower-hour for aviation applications.

The environmental impact profile of these engine types differs substantially. Radial engines produce higher levels of unburned hydrocarbons and carbon monoxide due to their less complete combustion processes. They also generate significant particulate matter emissions, especially during startup and low-power operations. The noise pollution from radial engines is characterized by distinctive low-frequency sound patterns that can propagate over considerable distances.

Gas turbines produce lower levels of carbon monoxide and unburned hydrocarbons but generate higher nitrogen oxide (NOx) emissions due to their higher combustion temperatures. However, modern gas turbine designs incorporate low-NOx combustors that have substantially reduced these emissions. The noise signature of gas turbines is dominated by high-frequency components that attenuate more rapidly with distance.

Carbon dioxide emissions correlate directly with fuel efficiency, giving gas turbines an environmental advantage in terms of greenhouse gas production per unit of power output. A typical radial engine emits approximately 20-30% more CO2 per unit of power compared to an equivalent gas turbine in similar applications.

Recent regulatory frameworks have placed increasing pressure on engine manufacturers to reduce emissions. While radial engines face challenges meeting stringent modern environmental standards without significant modifications, gas turbines have demonstrated greater adaptability to environmental regulations through technological innovations such as lean premixed combustion systems and selective catalytic reduction.

The lifecycle environmental assessment further favors gas turbines, which typically offer longer service intervals and operational lifespans, reducing the environmental impact associated with manufacturing replacement components and complete engine overhauls. This advantage is partially offset by the more complex materials and manufacturing processes required for gas turbines, which may involve rare earth elements and energy-intensive production methods.

Gas turbines, by contrast, demonstrate superior fuel efficiency, particularly in larger applications and at optimal operating conditions. Modern aviation gas turbines achieve thermal efficiencies of 40-50%, with advanced combined-cycle industrial turbines reaching up to 60% efficiency. This translates to significantly lower specific fuel consumption rates, typically between 0.3 and 0.5 pounds per horsepower-hour for aviation applications.

The environmental impact profile of these engine types differs substantially. Radial engines produce higher levels of unburned hydrocarbons and carbon monoxide due to their less complete combustion processes. They also generate significant particulate matter emissions, especially during startup and low-power operations. The noise pollution from radial engines is characterized by distinctive low-frequency sound patterns that can propagate over considerable distances.

Gas turbines produce lower levels of carbon monoxide and unburned hydrocarbons but generate higher nitrogen oxide (NOx) emissions due to their higher combustion temperatures. However, modern gas turbine designs incorporate low-NOx combustors that have substantially reduced these emissions. The noise signature of gas turbines is dominated by high-frequency components that attenuate more rapidly with distance.

Carbon dioxide emissions correlate directly with fuel efficiency, giving gas turbines an environmental advantage in terms of greenhouse gas production per unit of power output. A typical radial engine emits approximately 20-30% more CO2 per unit of power compared to an equivalent gas turbine in similar applications.

Recent regulatory frameworks have placed increasing pressure on engine manufacturers to reduce emissions. While radial engines face challenges meeting stringent modern environmental standards without significant modifications, gas turbines have demonstrated greater adaptability to environmental regulations through technological innovations such as lean premixed combustion systems and selective catalytic reduction.

The lifecycle environmental assessment further favors gas turbines, which typically offer longer service intervals and operational lifespans, reducing the environmental impact associated with manufacturing replacement components and complete engine overhauls. This advantage is partially offset by the more complex materials and manufacturing processes required for gas turbines, which may involve rare earth elements and energy-intensive production methods.

Materials Science Advancements for Engine Weight Reduction

The evolution of materials science has played a pivotal role in enhancing the power-to-weight ratio of both radial engines and gas turbines. Advanced materials have consistently pushed the boundaries of engine performance while reducing overall weight, a critical factor in aviation applications.

Aluminum alloys represented the first significant breakthrough, with their implementation in engine components reducing weight by up to 60% compared to traditional steel parts. The 1940s saw the introduction of heat-treated aluminum alloys specifically designed for radial engines, improving their power-to-weight ratio from approximately 0.5 hp/lb to 0.7 hp/lb.

Titanium alloys emerged in the 1950s as game-changers for gas turbine development. These materials offer exceptional strength-to-weight ratios and heat resistance, enabling gas turbines to operate at higher temperatures and pressures. Modern titanium alloys used in compressor sections have reduced component weight by approximately 40% while maintaining structural integrity at operational temperatures exceeding 600°C.

Composite materials represent the most recent advancement, with carbon fiber reinforced polymers (CFRPs) and ceramic matrix composites (CMCs) finding applications in both engine types. CFRPs provide weight reductions of 25-30% compared to aluminum components in non-critical radial engine parts. For gas turbines, CMCs allow operation at temperatures up to 1300°C without the cooling requirements of metal components, significantly improving thermodynamic efficiency.

Superalloys, particularly nickel-based variants, have revolutionized turbine blade design. These materials maintain structural integrity at temperatures approaching 90% of their melting point, enabling higher combustion temperatures and improved thermal efficiency. Modern single-crystal superalloys have increased the temperature capability of turbine blades by approximately 200°C since their introduction.

Additive manufacturing has further accelerated materials innovation by enabling complex geometries previously impossible with traditional manufacturing methods. 3D-printed components can incorporate internal cooling channels and optimized structures that reduce weight while maintaining or improving performance characteristics.

The cumulative effect of these materials advancements has been transformative. Modern gas turbines achieve power-to-weight ratios exceeding 5.0 hp/lb, while advanced radial engines have improved to approximately 1.2 hp/lb. This disparity highlights why gas turbines have largely supplanted radial engines in most high-performance aviation applications where power-to-weight ratio is a critical design consideration.

Aluminum alloys represented the first significant breakthrough, with their implementation in engine components reducing weight by up to 60% compared to traditional steel parts. The 1940s saw the introduction of heat-treated aluminum alloys specifically designed for radial engines, improving their power-to-weight ratio from approximately 0.5 hp/lb to 0.7 hp/lb.

Titanium alloys emerged in the 1950s as game-changers for gas turbine development. These materials offer exceptional strength-to-weight ratios and heat resistance, enabling gas turbines to operate at higher temperatures and pressures. Modern titanium alloys used in compressor sections have reduced component weight by approximately 40% while maintaining structural integrity at operational temperatures exceeding 600°C.

Composite materials represent the most recent advancement, with carbon fiber reinforced polymers (CFRPs) and ceramic matrix composites (CMCs) finding applications in both engine types. CFRPs provide weight reductions of 25-30% compared to aluminum components in non-critical radial engine parts. For gas turbines, CMCs allow operation at temperatures up to 1300°C without the cooling requirements of metal components, significantly improving thermodynamic efficiency.

Superalloys, particularly nickel-based variants, have revolutionized turbine blade design. These materials maintain structural integrity at temperatures approaching 90% of their melting point, enabling higher combustion temperatures and improved thermal efficiency. Modern single-crystal superalloys have increased the temperature capability of turbine blades by approximately 200°C since their introduction.

Additive manufacturing has further accelerated materials innovation by enabling complex geometries previously impossible with traditional manufacturing methods. 3D-printed components can incorporate internal cooling channels and optimized structures that reduce weight while maintaining or improving performance characteristics.

The cumulative effect of these materials advancements has been transformative. Modern gas turbines achieve power-to-weight ratios exceeding 5.0 hp/lb, while advanced radial engines have improved to approximately 1.2 hp/lb. This disparity highlights why gas turbines have largely supplanted radial engines in most high-performance aviation applications where power-to-weight ratio is a critical design consideration.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!