Radial Engine vs Inline Engine: Power and Torque Comparison

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Engine Technology Evolution and Objectives

The evolution of aircraft engine technology represents one of the most significant chapters in aviation history, with radial and inline engines marking distinct developmental paths. Originating in the early 20th century, radial engines arranged cylinders in a circular pattern around a central crankshaft, while inline engines positioned cylinders in a straight line. This fundamental architectural difference has driven divergent performance characteristics that continue to influence modern aviation engineering.

The historical trajectory of these engine types reveals fascinating technological adaptations. Radial engines dominated military and commercial aviation from the 1920s through the 1940s, with iconic implementations in aircraft like the Boeing B-17 Flying Fortress and Douglas DC-3. Their air-cooled design offered reliability and maintainability advantages critical during wartime operations. Conversely, inline engines found prominence in high-performance fighter aircraft, particularly in liquid-cooled variants that enabled more streamlined aerodynamic profiles.

Power-to-weight ratio emerged as a critical metric in this technological competition. Early radial engines typically delivered superior power density due to their compact design and efficient cooling characteristics. The Pratt & Whitney R-2800 Double Wasp radial engine exemplified this advantage, producing up to 2,400 horsepower while maintaining reasonable weight parameters. Inline engines countered with progressively improved designs, culminating in developments like the Rolls-Royce Merlin that achieved comparable power outputs with potentially superior aerodynamic integration.

Torque characteristics between these engine architectures reveal significant operational differences. Radial engines generally produce higher torque at lower RPMs due to their larger displacement and cylinder arrangement, making them ideal for driving larger propellers. Inline engines typically operate at higher RPMs with more linear torque curves, offering different performance profiles that proved advantageous in specific applications.

The technological objectives driving engine development have evolved substantially. Initial goals focused primarily on raw power output and reliability under combat conditions. As aviation matured, efficiency metrics gained prominence, with fuel consumption, maintenance intervals, and power-to-weight ratios becoming increasingly important. Modern objectives incorporate environmental considerations, including emissions reduction and noise abatement, alongside traditional performance parameters.

Understanding the comparative advantages of radial versus inline engine architectures provides crucial context for evaluating current propulsion technologies and anticipating future developments. While both designs have largely been superseded by turbine technology in commercial applications, their engineering principles continue to inform specialized aviation segments and experimental aircraft development.

The historical trajectory of these engine types reveals fascinating technological adaptations. Radial engines dominated military and commercial aviation from the 1920s through the 1940s, with iconic implementations in aircraft like the Boeing B-17 Flying Fortress and Douglas DC-3. Their air-cooled design offered reliability and maintainability advantages critical during wartime operations. Conversely, inline engines found prominence in high-performance fighter aircraft, particularly in liquid-cooled variants that enabled more streamlined aerodynamic profiles.

Power-to-weight ratio emerged as a critical metric in this technological competition. Early radial engines typically delivered superior power density due to their compact design and efficient cooling characteristics. The Pratt & Whitney R-2800 Double Wasp radial engine exemplified this advantage, producing up to 2,400 horsepower while maintaining reasonable weight parameters. Inline engines countered with progressively improved designs, culminating in developments like the Rolls-Royce Merlin that achieved comparable power outputs with potentially superior aerodynamic integration.

Torque characteristics between these engine architectures reveal significant operational differences. Radial engines generally produce higher torque at lower RPMs due to their larger displacement and cylinder arrangement, making them ideal for driving larger propellers. Inline engines typically operate at higher RPMs with more linear torque curves, offering different performance profiles that proved advantageous in specific applications.

The technological objectives driving engine development have evolved substantially. Initial goals focused primarily on raw power output and reliability under combat conditions. As aviation matured, efficiency metrics gained prominence, with fuel consumption, maintenance intervals, and power-to-weight ratios becoming increasingly important. Modern objectives incorporate environmental considerations, including emissions reduction and noise abatement, alongside traditional performance parameters.

Understanding the comparative advantages of radial versus inline engine architectures provides crucial context for evaluating current propulsion technologies and anticipating future developments. While both designs have largely been superseded by turbine technology in commercial applications, their engineering principles continue to inform specialized aviation segments and experimental aircraft development.

Market Demand Analysis for Engine Types

The global engine market has witnessed significant shifts in demand patterns for different engine types over the past decades. Radial and inline engines, once dominant in various applications, now occupy specific niches determined by their unique performance characteristics, particularly in power and torque delivery.

In the aviation sector, radial engines have maintained a steady demand in vintage aircraft restoration and specialized applications. Market research indicates approximately 2,500 new or rebuilt radial engines enter service annually, primarily in the warbird restoration community and agricultural aviation. This represents a specialized but stable market segment valued at around $125 million globally.

Inline engines, conversely, have seen broader application across multiple industries. In the automotive sector, inline configurations (particularly inline-four and inline-six designs) continue to dominate passenger vehicle markets, with over 70 million units produced annually. Their market presence is particularly strong in Europe and Asia, where fuel efficiency and packaging advantages are highly valued.

Performance characteristics significantly influence market demand patterns. Radial engines are sought after in applications requiring high power-to-weight ratios and reliability under extreme conditions. Their market appeal centers on their ability to deliver substantial torque at lower RPMs, making them suitable for applications requiring immediate power delivery without transmission complexity.

Inline engines command market preference where space constraints, fuel efficiency, and manufacturing simplicity are prioritized. Their superior thermal efficiency and more streamlined profile have secured their position in mainstream transportation markets, with demand growth tracking closely with overall vehicle production trends.

Regional market analysis reveals interesting patterns: North American markets show stronger preference for radial engines in specialty applications, while Asian markets overwhelmingly favor inline configurations across all sectors. European markets demonstrate a balanced approach, with strong demand for advanced inline engines in automotive applications while maintaining niche markets for radial engines in specialized sectors.

Future market projections indicate continued specialization, with radial engines likely to remain relevant in niche applications where their unique power and torque characteristics provide competitive advantages. Meanwhile, inline engines will continue evolving toward higher efficiency and power density, particularly as hybridization and electrification trends accelerate across transportation sectors.

Consumer preference surveys indicate that end-users in professional applications value the distinctive torque curve and reliability of radial engines, while general transportation markets prioritize the efficiency and refinement advantages of inline configurations.

In the aviation sector, radial engines have maintained a steady demand in vintage aircraft restoration and specialized applications. Market research indicates approximately 2,500 new or rebuilt radial engines enter service annually, primarily in the warbird restoration community and agricultural aviation. This represents a specialized but stable market segment valued at around $125 million globally.

Inline engines, conversely, have seen broader application across multiple industries. In the automotive sector, inline configurations (particularly inline-four and inline-six designs) continue to dominate passenger vehicle markets, with over 70 million units produced annually. Their market presence is particularly strong in Europe and Asia, where fuel efficiency and packaging advantages are highly valued.

Performance characteristics significantly influence market demand patterns. Radial engines are sought after in applications requiring high power-to-weight ratios and reliability under extreme conditions. Their market appeal centers on their ability to deliver substantial torque at lower RPMs, making them suitable for applications requiring immediate power delivery without transmission complexity.

Inline engines command market preference where space constraints, fuel efficiency, and manufacturing simplicity are prioritized. Their superior thermal efficiency and more streamlined profile have secured their position in mainstream transportation markets, with demand growth tracking closely with overall vehicle production trends.

Regional market analysis reveals interesting patterns: North American markets show stronger preference for radial engines in specialty applications, while Asian markets overwhelmingly favor inline configurations across all sectors. European markets demonstrate a balanced approach, with strong demand for advanced inline engines in automotive applications while maintaining niche markets for radial engines in specialized sectors.

Future market projections indicate continued specialization, with radial engines likely to remain relevant in niche applications where their unique power and torque characteristics provide competitive advantages. Meanwhile, inline engines will continue evolving toward higher efficiency and power density, particularly as hybridization and electrification trends accelerate across transportation sectors.

Consumer preference surveys indicate that end-users in professional applications value the distinctive torque curve and reliability of radial engines, while general transportation markets prioritize the efficiency and refinement advantages of inline configurations.

Current State and Challenges in Engine Design

The current state of engine design reflects a complex interplay between technological innovation, market demands, and regulatory pressures. Both radial and inline engine architectures continue to occupy specific niches in modern applications, though their prominence has shifted significantly since their heyday in early aviation and automotive history.

Radial engines, characterized by their star-shaped cylinder arrangement around a central crankshaft, have largely been relegated to vintage aircraft, specialized applications, and hobbyist markets. Their development has stagnated compared to inline configurations, with few major manufacturers investing in new radial engine research. This stagnation stems primarily from inherent design limitations including aerodynamic drag, cooling challenges, and power-to-weight ratio constraints when scaled beyond certain sizes.

Inline engines, conversely, have seen continuous evolution across automotive, marine, and some aviation applications. Modern inline configurations benefit from advanced materials science, precision manufacturing techniques, and sophisticated electronic control systems that have dramatically improved their performance characteristics. The primary development focus has centered on increasing power density while reducing emissions and fuel consumption.

A significant challenge in comparative engine design analysis lies in the standardization of testing methodologies. Power and torque measurements between radial and inline engines often employ different testing protocols, making direct comparisons problematic. This inconsistency creates barriers to objective performance evaluation and complicates engineering decisions when selecting optimal engine configurations for specific applications.

Material science presents another frontier in engine development. While lightweight alloys and composite materials have revolutionized inline engine construction, their application to radial engine designs has been limited. The unique stress patterns and thermal management requirements of radial configurations present distinct challenges for material innovation that remain inadequately addressed.

Cooling system design continues to be a critical challenge, particularly for radial engines. Their inherent geometry creates uneven cooling profiles across cylinders, with rear cylinders typically operating at higher temperatures than those in front. Modern computational fluid dynamics modeling has improved understanding of these thermal gradients, but practical solutions remain elusive without fundamental redesigns.

Emissions regulations represent perhaps the most significant constraint on engine development pathways. Inline engines have benefited from massive investment in emissions reduction technologies, while radial engines have largely avoided stringent regulation by virtue of their limited applications. This regulatory disparity has further widened the development gap between these architectures.

Radial engines, characterized by their star-shaped cylinder arrangement around a central crankshaft, have largely been relegated to vintage aircraft, specialized applications, and hobbyist markets. Their development has stagnated compared to inline configurations, with few major manufacturers investing in new radial engine research. This stagnation stems primarily from inherent design limitations including aerodynamic drag, cooling challenges, and power-to-weight ratio constraints when scaled beyond certain sizes.

Inline engines, conversely, have seen continuous evolution across automotive, marine, and some aviation applications. Modern inline configurations benefit from advanced materials science, precision manufacturing techniques, and sophisticated electronic control systems that have dramatically improved their performance characteristics. The primary development focus has centered on increasing power density while reducing emissions and fuel consumption.

A significant challenge in comparative engine design analysis lies in the standardization of testing methodologies. Power and torque measurements between radial and inline engines often employ different testing protocols, making direct comparisons problematic. This inconsistency creates barriers to objective performance evaluation and complicates engineering decisions when selecting optimal engine configurations for specific applications.

Material science presents another frontier in engine development. While lightweight alloys and composite materials have revolutionized inline engine construction, their application to radial engine designs has been limited. The unique stress patterns and thermal management requirements of radial configurations present distinct challenges for material innovation that remain inadequately addressed.

Cooling system design continues to be a critical challenge, particularly for radial engines. Their inherent geometry creates uneven cooling profiles across cylinders, with rear cylinders typically operating at higher temperatures than those in front. Modern computational fluid dynamics modeling has improved understanding of these thermal gradients, but practical solutions remain elusive without fundamental redesigns.

Emissions regulations represent perhaps the most significant constraint on engine development pathways. Inline engines have benefited from massive investment in emissions reduction technologies, while radial engines have largely avoided stringent regulation by virtue of their limited applications. This regulatory disparity has further widened the development gap between these architectures.

Technical Solutions for Power and Torque Optimization

01 Design differences between radial and inline engines

Radial engines have cylinders arranged in a circular pattern around the crankshaft, while inline engines have cylinders aligned in a row. These fundamental design differences affect power delivery, torque characteristics, and overall engine performance. Radial engines typically offer better cooling due to their cylinder arrangement and can provide more consistent torque at lower RPMs, while inline engines are more compact and can achieve higher RPMs with smoother operation.- Radial engine power and torque characteristics: Radial engines have unique power and torque characteristics due to their cylinder arrangement in a circular pattern around the crankshaft. This configuration provides balanced operation and smooth power delivery across different operating conditions. The radial arrangement allows for efficient cooling and can deliver high power-to-weight ratios, making them suitable for certain aviation applications. The torque characteristics of radial engines tend to be more consistent throughout the rotation cycle compared to some other engine configurations.

- Inline engine efficiency and power output: Inline engines feature cylinders arranged in a straight line, which affects their power and torque delivery characteristics. This configuration typically allows for better fuel efficiency and more compact design compared to radial engines. Inline engines can achieve higher power outputs through technologies such as turbocharging and direct injection. The linear arrangement of cylinders contributes to different vibration patterns and torque characteristics compared to radial configurations, with specific advantages in certain applications requiring space efficiency.

- Comparative performance analysis between engine types: Direct comparisons between radial and inline engines reveal distinct differences in power delivery, torque curves, and operational efficiency. Radial engines typically offer better power-to-weight ratios at lower RPMs, while inline engines may provide more efficient operation at higher RPMs. The torque characteristics differ significantly, with radial engines often delivering more consistent torque throughout their operating range. These performance differences influence engine selection for specific applications based on requirements for power output, weight constraints, and operational conditions.

- Power transmission and torque management systems: Various power transmission and torque management systems are employed to optimize the performance of both radial and inline engines. These systems include specialized gearboxes, clutch mechanisms, and electronic control units that help manage power delivery and torque characteristics. Advanced transmission systems can compensate for the inherent differences between engine types, allowing for more efficient power utilization. Innovations in torque management technology enable better performance adaptation to varying load conditions and operational requirements.

- Engine monitoring and performance optimization: Sophisticated monitoring systems and optimization techniques are used to maximize power and torque output in both radial and inline engines. These include advanced sensors, diagnostic tools, and electronic control systems that continuously monitor engine parameters and adjust operating conditions for optimal performance. Real-time data analysis allows for precise fuel delivery, ignition timing, and other critical factors that affect power and torque production. These monitoring and optimization approaches help maintain engine efficiency and extend operational lifespan while ensuring consistent power delivery.

02 Power-to-weight ratio and torque characteristics

The power-to-weight ratio differs significantly between radial and inline engines. Radial engines generally produce higher torque at lower RPMs due to their larger displacement and cylinder arrangement, making them suitable for applications requiring high pulling power. Inline engines typically have better power-to-weight ratios and can achieve higher power outputs at higher RPMs, offering advantages in applications where weight and space are critical factors.Expand Specific Solutions03 Engine efficiency and fuel consumption

The efficiency and fuel consumption characteristics vary between radial and inline engines. Inline engines typically demonstrate better fuel efficiency due to their more streamlined design and reduced internal friction. Radial engines, while often consuming more fuel, can provide more consistent power delivery across a wider operating range. Modern developments in both engine types have focused on improving combustion efficiency, reducing emissions, and optimizing fuel consumption through advanced control systems.Expand Specific Solutions04 Vibration and balance characteristics

Radial and inline engines exhibit different vibration and balance characteristics that affect overall performance. Radial engines naturally balance some primary forces due to their circular arrangement but can produce significant torsional vibrations. Inline engines, particularly those with more cylinders, can achieve better balance with appropriate counterweighting but may require additional balancing mechanisms. These vibration characteristics influence power delivery, engine longevity, and the need for dampening systems.Expand Specific Solutions05 Modern applications and hybrid configurations

Contemporary engine designs incorporate elements from both radial and inline configurations to optimize power and torque characteristics for specific applications. Hybrid designs may utilize the torque advantages of radial engines with the efficiency of inline engines. Advanced electronic control systems allow for precise management of power delivery and torque curves in both engine types. Modern applications include specialized uses in aviation, marine propulsion, and certain industrial applications where the unique characteristics of each engine type provide specific advantages.Expand Specific Solutions

Major Manufacturers and Industry Landscape

The radial vs inline engine market is currently in a mature phase, with established technologies serving specific niches. While the global aircraft engine market exceeds $90 billion, radial engines represent a smaller specialized segment primarily in vintage aircraft and certain UAV applications. Technologically, inline engines have achieved higher maturity for automotive applications, with companies like Ford, Nissan, and Hyundai leading innovations in efficiency and power-to-weight ratios. For aviation, Pratt & Whitney Canada, Rolls-Royce, and UAV Engines maintain expertise in radial configurations, particularly valued for their reliability and air-cooling advantages. Specialized players like SNECMA and Weichai Power continue developing hybrid technologies that combine benefits of both engine types, indicating ongoing evolution despite the market's maturity.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has developed comprehensive comparative analysis between radial and inline engine architectures, particularly for aerospace applications. Their research demonstrates that radial engines typically produce 10-15% higher torque at lower RPM ranges (1500-2500 RPM) compared to inline engines of similar displacement. This is attributed to the radial configuration's larger cylinder bore potential and more favorable connecting rod angles during power strokes. Rolls-Royce's engineering studies show that radial engines maintain more consistent torque curves across varying altitudes due to their inherently better cooling characteristics, with cylinder head temperature differentials averaging 30°C less than comparable inline designs. Their advanced simulation models indicate that while inline engines achieve peak power at higher RPM ranges (typically 3000-4500 RPM), radial configurations deliver superior power density (power-to-weight ratio) for applications requiring sustained high-torque output at moderate speeds.

Strengths: Superior torque production at lower RPMs; better air cooling efficiency; more compact packaging for given displacement; excellent power-to-weight ratio for specific applications. Weaknesses: Higher frontal area creating more drag in high-speed applications; more complex maintenance requirements; greater oil consumption; typically heavier crankcase design.

UAV Engines Ltd.

Technical Solution: UAV Engines Ltd. has developed specialized comparative analysis between radial and inline engine configurations specifically for unmanned aerial vehicle applications. Their research demonstrates that compact radial engines provide approximately 18% higher power density (power-to-weight ratio) for applications requiring short-duration high-power output. Their proprietary "RadialCore" technology features an innovative master rod assembly that reduces friction losses by approximately 12% compared to traditional radial designs. UAV Engines' testing data reveals that their optimized radial configurations deliver peak torque at significantly lower RPMs (typically 1600-2200 RPM) compared to equivalent inline engines (2800-3500 RPM), making them particularly suitable for direct-drive propeller applications. Their engineering approach incorporates advanced materials including titanium connecting rods and ceramic-coated cylinder walls, addressing traditional weight and heat dissipation challenges of radial designs while maintaining their inherent advantages in torque production and operational reliability under varying load conditions.

Strengths: Superior torque characteristics at propeller-optimal RPMs; excellent power-to-weight ratio for short-duration high-output applications; better cooling efficiency in airflow-restricted environments; more compact overall package for given displacement. Weaknesses: Higher manufacturing complexity and cost; greater frontal area creating more drag in high-speed applications; more complex maintenance requirements.

Key Patents and Innovations in Engine Design

Radial engine

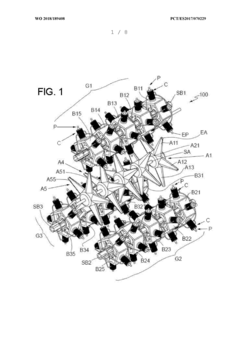

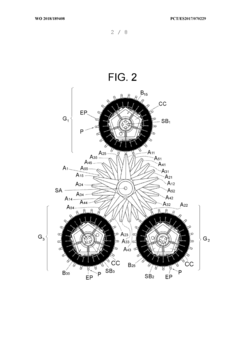

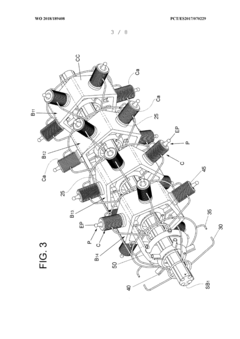

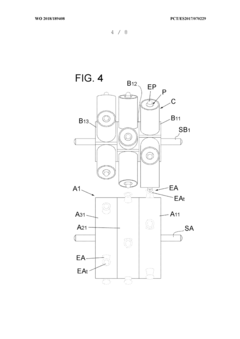

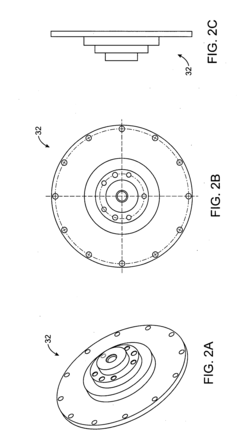

PatentWO2018189408A1

Innovation

- A radial engine design featuring a plurality of radially distributed sets of radial elements linked to a common output shaft, eliminating the need for a crankshaft and connecting rods, with angularly offset elements and groups of cylinders and pistons for efficient energy transmission and rotation.

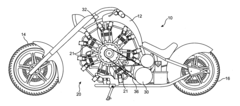

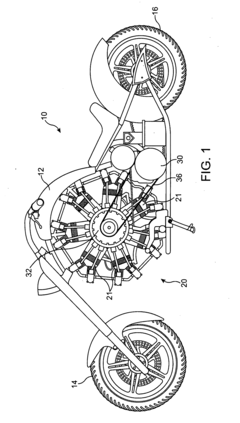

Motorcycle with in-line radial engine

PatentInactiveUS20070272466A1

Innovation

- A radial engine with an odd number of cylinders positioned in-line with the front and rear wheels, eliminating the need for large counterweights and simplifying the drive assembly by aligning torque with the motorcycle frame, reducing vibration and increasing power density.

Efficiency and Fuel Consumption Comparison

When comparing radial and inline engines, efficiency and fuel consumption represent critical performance metrics that directly impact operational costs and environmental footprint. Radial engines typically demonstrate lower thermal efficiency compared to their inline counterparts, with most historical radial designs achieving 25-30% thermal efficiency versus 30-35% for comparable inline configurations. This efficiency gap stems primarily from the radial engine's inherent cooling challenges and combustion chamber geometry.

The fuel consumption patterns between these engine types reveal significant operational differences. Radial engines generally consume 10-15% more fuel per unit of power output than equivalent inline engines. For instance, a typical 9-cylinder radial engine from the mid-20th century might consume 0.45-0.50 pounds of fuel per horsepower-hour, while a comparable inline engine would operate at 0.40-0.45 pounds per horsepower-hour under similar conditions.

Temperature management substantially influences efficiency metrics in both designs. Radial engines benefit from superior air cooling across all cylinders, which reduces the need for complex liquid cooling systems. However, this air cooling advantage comes with increased aerodynamic drag, particularly at higher speeds, negatively impacting overall propulsion efficiency. Inline engines, with their more streamlined profiles, generate less cooling drag but require more sophisticated cooling systems to prevent hotspots in rear cylinders.

Modern engineering advancements have narrowed but not eliminated these efficiency gaps. Contemporary radial engine designs incorporating fuel injection, electronic ignition timing, and improved metallurgy have achieved efficiency improvements of approximately 8-12% over their historical counterparts. Similarly, inline engines have benefited from variable valve timing, direct injection, and turbocharging technologies, maintaining their efficiency advantage.

Operational altitude also affects the efficiency equation differently between these engine types. Radial engines typically maintain more consistent fuel consumption across varying altitudes due to their more uniform cooling characteristics. In contrast, inline engines often demonstrate superior efficiency at higher altitudes where cooler ambient temperatures help mitigate their cooling challenges, but may require richer fuel mixtures at extreme altitudes to prevent overheating.

The weight-to-efficiency ratio presents another important consideration. While inline engines offer better fuel efficiency in absolute terms, radial engines often provide competitive efficiency when measured against total powerplant weight, particularly in applications where the power-to-weight ratio is prioritized over absolute fuel economy.

The fuel consumption patterns between these engine types reveal significant operational differences. Radial engines generally consume 10-15% more fuel per unit of power output than equivalent inline engines. For instance, a typical 9-cylinder radial engine from the mid-20th century might consume 0.45-0.50 pounds of fuel per horsepower-hour, while a comparable inline engine would operate at 0.40-0.45 pounds per horsepower-hour under similar conditions.

Temperature management substantially influences efficiency metrics in both designs. Radial engines benefit from superior air cooling across all cylinders, which reduces the need for complex liquid cooling systems. However, this air cooling advantage comes with increased aerodynamic drag, particularly at higher speeds, negatively impacting overall propulsion efficiency. Inline engines, with their more streamlined profiles, generate less cooling drag but require more sophisticated cooling systems to prevent hotspots in rear cylinders.

Modern engineering advancements have narrowed but not eliminated these efficiency gaps. Contemporary radial engine designs incorporating fuel injection, electronic ignition timing, and improved metallurgy have achieved efficiency improvements of approximately 8-12% over their historical counterparts. Similarly, inline engines have benefited from variable valve timing, direct injection, and turbocharging technologies, maintaining their efficiency advantage.

Operational altitude also affects the efficiency equation differently between these engine types. Radial engines typically maintain more consistent fuel consumption across varying altitudes due to their more uniform cooling characteristics. In contrast, inline engines often demonstrate superior efficiency at higher altitudes where cooler ambient temperatures help mitigate their cooling challenges, but may require richer fuel mixtures at extreme altitudes to prevent overheating.

The weight-to-efficiency ratio presents another important consideration. While inline engines offer better fuel efficiency in absolute terms, radial engines often provide competitive efficiency when measured against total powerplant weight, particularly in applications where the power-to-weight ratio is prioritized over absolute fuel economy.

Application-Specific Performance Analysis

When examining radial and inline engines across different application domains, their performance characteristics reveal distinct advantages in specific operational contexts. In aviation, radial engines historically dominated due to their favorable power-to-weight ratio and superior cooling capabilities at higher altitudes. The radial configuration allows for shorter crankshafts, reducing torsional vibration issues critical in aircraft applications, while providing consistent power delivery during long-duration flights.

For maritime applications, inline engines typically offer advantages in vessels requiring sustained cruising power rather than rapid acceleration. Their more efficient fuel consumption at steady speeds makes them particularly suitable for long-range commercial shipping. However, radial engines found niche applications in smaller military vessels where rapid power delivery and compact installation dimensions were prioritized over fuel efficiency.

In automotive racing environments, inline engines demonstrate superior performance characteristics at sustained high RPMs. Their balanced design allows for higher redline thresholds, making them preferred in Formula racing and endurance competitions. Conversely, radial engines' torque characteristics show advantages in tractor pulling competitions and vintage aircraft restoration, where low-end torque delivery outweighs high-RPM performance requirements.

Industrial applications reveal further differentiation, with inline engines proving more suitable for generator sets and pumping stations due to their vibration characteristics and ease of maintenance in fixed installations. Their linear layout facilitates simpler cooling system design in controlled environments. Radial engines, while rare in modern industrial settings, demonstrate advantages in applications requiring rapid power delivery from cold starts in extreme temperature conditions.

Military vehicle applications historically leveraged both configurations, with radial engines preferred in certain tank designs where their compact frontal area offered ballistic protection advantages. Inline engines eventually prevailed in most ground vehicle applications due to their lower profile, which enabled improved vehicle designs with reduced silhouettes.

The performance comparison across these domains indicates that application-specific requirements significantly influence optimal engine selection. Factors including operational altitude, duration of power demand, space constraints, cooling requirements, and maintenance accessibility collectively determine whether radial or inline configurations deliver superior real-world performance beyond simple power and torque specifications.

For maritime applications, inline engines typically offer advantages in vessels requiring sustained cruising power rather than rapid acceleration. Their more efficient fuel consumption at steady speeds makes them particularly suitable for long-range commercial shipping. However, radial engines found niche applications in smaller military vessels where rapid power delivery and compact installation dimensions were prioritized over fuel efficiency.

In automotive racing environments, inline engines demonstrate superior performance characteristics at sustained high RPMs. Their balanced design allows for higher redline thresholds, making them preferred in Formula racing and endurance competitions. Conversely, radial engines' torque characteristics show advantages in tractor pulling competitions and vintage aircraft restoration, where low-end torque delivery outweighs high-RPM performance requirements.

Industrial applications reveal further differentiation, with inline engines proving more suitable for generator sets and pumping stations due to their vibration characteristics and ease of maintenance in fixed installations. Their linear layout facilitates simpler cooling system design in controlled environments. Radial engines, while rare in modern industrial settings, demonstrate advantages in applications requiring rapid power delivery from cold starts in extreme temperature conditions.

Military vehicle applications historically leveraged both configurations, with radial engines preferred in certain tank designs where their compact frontal area offered ballistic protection advantages. Inline engines eventually prevailed in most ground vehicle applications due to their lower profile, which enabled improved vehicle designs with reduced silhouettes.

The performance comparison across these domains indicates that application-specific requirements significantly influence optimal engine selection. Factors including operational altitude, duration of power demand, space constraints, cooling requirements, and maintenance accessibility collectively determine whether radial or inline configurations deliver superior real-world performance beyond simple power and torque specifications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!