Radial Engine vs Jet Engine: Efficiency in Transport

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propulsion Evolution and Performance Objectives

The evolution of aircraft propulsion systems has witnessed a remarkable transformation from the early days of aviation to the modern era. Radial engines, which dominated the skies during the first half of the 20th century, represented a significant advancement in aircraft propulsion technology. These engines featured cylinders arranged in a circular pattern around a central crankshaft, offering advantages in cooling efficiency and power-to-weight ratio compared to earlier inline engines.

By the 1940s, the emergence of jet engine technology marked a revolutionary shift in aviation propulsion. Sir Frank Whittle in the United Kingdom and Hans von Ohain in Germany independently developed the first practical jet engines, fundamentally changing the trajectory of aircraft design and performance capabilities. This transition from piston-driven propulsion to jet propulsion represents one of the most significant technological leaps in transportation history.

The performance objectives between these two propulsion systems differ substantially. Radial engines excel in reliability, operational simplicity, and effectiveness at lower altitudes and speeds. They provide excellent torque characteristics for propeller-driven aircraft and demonstrate remarkable durability under various operating conditions. However, they face inherent limitations in maximum speed and altitude performance due to propeller efficiency constraints.

Jet engines, conversely, were developed with fundamentally different performance objectives: achieving significantly higher speeds, operating efficiently at greater altitudes, and enabling longer-range flights. The absence of reciprocating components allows jet engines to operate more smoothly at high rotational speeds, dramatically reducing vibration while increasing potential thrust output.

The efficiency metrics for these propulsion systems vary considerably across different operational parameters. Radial engines typically demonstrate superior fuel efficiency at lower speeds and altitudes, making them economically advantageous for certain applications like regional transportation and specialized operations. Jet engines achieve optimal efficiency at high altitudes and speeds, transforming long-distance travel economics.

Current technological development continues to refine both systems, though with different emphases. Modern radial engine development focuses on reliability enhancements, emissions reduction, and integration with advanced materials. Meanwhile, jet engine evolution pursues improved fuel efficiency, noise reduction, emissions control, and enhanced power-to-weight ratios through advanced materials and computational design optimization.

The performance objectives driving propulsion technology today increasingly emphasize environmental sustainability alongside traditional metrics of speed, range, and payload capacity. This evolution reflects broader industry trends toward reducing aviation's environmental footprint while maintaining economic viability and meeting growing global transportation demands.

By the 1940s, the emergence of jet engine technology marked a revolutionary shift in aviation propulsion. Sir Frank Whittle in the United Kingdom and Hans von Ohain in Germany independently developed the first practical jet engines, fundamentally changing the trajectory of aircraft design and performance capabilities. This transition from piston-driven propulsion to jet propulsion represents one of the most significant technological leaps in transportation history.

The performance objectives between these two propulsion systems differ substantially. Radial engines excel in reliability, operational simplicity, and effectiveness at lower altitudes and speeds. They provide excellent torque characteristics for propeller-driven aircraft and demonstrate remarkable durability under various operating conditions. However, they face inherent limitations in maximum speed and altitude performance due to propeller efficiency constraints.

Jet engines, conversely, were developed with fundamentally different performance objectives: achieving significantly higher speeds, operating efficiently at greater altitudes, and enabling longer-range flights. The absence of reciprocating components allows jet engines to operate more smoothly at high rotational speeds, dramatically reducing vibration while increasing potential thrust output.

The efficiency metrics for these propulsion systems vary considerably across different operational parameters. Radial engines typically demonstrate superior fuel efficiency at lower speeds and altitudes, making them economically advantageous for certain applications like regional transportation and specialized operations. Jet engines achieve optimal efficiency at high altitudes and speeds, transforming long-distance travel economics.

Current technological development continues to refine both systems, though with different emphases. Modern radial engine development focuses on reliability enhancements, emissions reduction, and integration with advanced materials. Meanwhile, jet engine evolution pursues improved fuel efficiency, noise reduction, emissions control, and enhanced power-to-weight ratios through advanced materials and computational design optimization.

The performance objectives driving propulsion technology today increasingly emphasize environmental sustainability alongside traditional metrics of speed, range, and payload capacity. This evolution reflects broader industry trends toward reducing aviation's environmental footprint while maintaining economic viability and meeting growing global transportation demands.

Market Demand Analysis for Aircraft Engine Technologies

The global aircraft engine market has witnessed significant shifts in demand patterns over the past decades, primarily driven by evolving transportation needs, fuel efficiency requirements, and environmental regulations. Current market analysis indicates that the commercial aviation sector values jet engines overwhelmingly over radial engines, with the market size for commercial jet engines reaching approximately $72 billion in 2022 and projected to grow at a CAGR of 8.2% through 2030.

This preference stems from jet engines' superior performance metrics in modern transportation scenarios. Airlines and aircraft manufacturers consistently prioritize fuel efficiency as a primary purchasing factor, with jet engines delivering 30-40% better fuel economy compared to radial engines at cruising altitudes and speeds. This efficiency translates directly to operational cost savings, estimated at $1.5-2 million annually per aircraft.

Market segmentation reveals distinct demand patterns across different aviation sectors. Commercial passenger transport, representing 65% of the aircraft engine market, shows near-exclusive demand for turbofan jet engines due to their optimal balance of thrust, fuel efficiency, and noise reduction capabilities. The cargo transport segment (18% of the market) similarly favors jet propulsion for long-haul operations, though with greater emphasis on initial cost considerations.

Interestingly, niche markets maintain demand for radial engine technology. The general aviation sector, particularly vintage aircraft restoration and specialized applications, represents a small but stable market valued at approximately $340 million annually. Historical aircraft operations, agricultural aviation in developing regions, and certain military training applications continue to support limited production and maintenance of radial engine systems.

Regional analysis indicates varying adoption rates and preferences. North America and Europe lead in transitioning to next-generation, high-efficiency jet engines, while developing aviation markets in Asia-Pacific and Latin America show growing demand for cost-effective jet propulsion systems. The Middle East remains a critical market for high-performance, long-range jet engines due to the prominence of long-haul carriers in the region.

Consumer demand increasingly emphasizes environmental performance alongside operational efficiency. Market surveys indicate that 78% of airlines consider emissions reduction capabilities a "very important" factor in engine procurement decisions, reflecting both regulatory pressures and corporate sustainability commitments. This trend has accelerated development of more efficient jet engine technologies while further marginalizing radial engine applications in mainstream transport.

This preference stems from jet engines' superior performance metrics in modern transportation scenarios. Airlines and aircraft manufacturers consistently prioritize fuel efficiency as a primary purchasing factor, with jet engines delivering 30-40% better fuel economy compared to radial engines at cruising altitudes and speeds. This efficiency translates directly to operational cost savings, estimated at $1.5-2 million annually per aircraft.

Market segmentation reveals distinct demand patterns across different aviation sectors. Commercial passenger transport, representing 65% of the aircraft engine market, shows near-exclusive demand for turbofan jet engines due to their optimal balance of thrust, fuel efficiency, and noise reduction capabilities. The cargo transport segment (18% of the market) similarly favors jet propulsion for long-haul operations, though with greater emphasis on initial cost considerations.

Interestingly, niche markets maintain demand for radial engine technology. The general aviation sector, particularly vintage aircraft restoration and specialized applications, represents a small but stable market valued at approximately $340 million annually. Historical aircraft operations, agricultural aviation in developing regions, and certain military training applications continue to support limited production and maintenance of radial engine systems.

Regional analysis indicates varying adoption rates and preferences. North America and Europe lead in transitioning to next-generation, high-efficiency jet engines, while developing aviation markets in Asia-Pacific and Latin America show growing demand for cost-effective jet propulsion systems. The Middle East remains a critical market for high-performance, long-range jet engines due to the prominence of long-haul carriers in the region.

Consumer demand increasingly emphasizes environmental performance alongside operational efficiency. Market surveys indicate that 78% of airlines consider emissions reduction capabilities a "very important" factor in engine procurement decisions, reflecting both regulatory pressures and corporate sustainability commitments. This trend has accelerated development of more efficient jet engine technologies while further marginalizing radial engine applications in mainstream transport.

Technical Limitations and Engineering Challenges

Despite their historical significance, radial engines face substantial technical limitations in modern transport applications. The inherent design of radial engines creates significant aerodynamic drag due to their large frontal area, severely limiting aircraft speed potential. This fundamental constraint becomes increasingly problematic as transportation demands shift toward higher speeds and greater efficiency. Additionally, radial engines exhibit lower power-to-weight ratios compared to jet engines, resulting in reduced performance capabilities, especially at higher altitudes where air density decreases.

Thermal efficiency represents another critical limitation of radial engines. With typical thermal efficiency ratings between 30-38%, radial engines convert a smaller proportion of fuel energy into useful work compared to modern jet engines that can achieve 40-50% thermal efficiency. This efficiency gap translates directly into higher operational costs and reduced range capabilities for radial-powered aircraft.

Maintenance complexity presents significant engineering challenges for radial engines. Their exposed cylinder arrangement, while beneficial for cooling, makes them vulnerable to environmental factors and increases maintenance frequency. The numerous moving parts—including multiple cylinders, pistons, and valve assemblies—create numerous potential failure points requiring regular inspection and replacement.

Jet engines, while superior in many aspects, face their own set of engineering challenges. Material science limitations remain significant, particularly regarding turbine blade materials that must withstand extreme temperatures exceeding 1,400°C while maintaining structural integrity under immense rotational forces. Advanced cooling systems and exotic materials like single-crystal superalloys partially address these issues but add complexity and cost.

Fuel efficiency at varying operational conditions presents ongoing challenges for jet engine designers. While jets excel at high-altitude cruise conditions, they demonstrate lower efficiency during takeoff, landing, and low-speed operations—precisely where radial engines maintain relatively consistent performance profiles. This operational efficiency variance necessitates complex engine management systems to optimize performance across flight regimes.

Noise pollution and emissions represent significant engineering challenges for jet engines. The high-velocity exhaust gases create substantial noise footprints around airports, requiring complex sound suppression systems that often compromise performance. Similarly, emissions control technologies must balance environmental regulations against performance requirements, creating engineering trade-offs that impact overall system efficiency.

Manufacturing precision requirements for jet engines far exceed those of radial engines, with turbine blade tolerances measured in micrometers. This precision manufacturing necessity drives production costs significantly higher and creates supply chain vulnerabilities for specialized components and materials.

Thermal efficiency represents another critical limitation of radial engines. With typical thermal efficiency ratings between 30-38%, radial engines convert a smaller proportion of fuel energy into useful work compared to modern jet engines that can achieve 40-50% thermal efficiency. This efficiency gap translates directly into higher operational costs and reduced range capabilities for radial-powered aircraft.

Maintenance complexity presents significant engineering challenges for radial engines. Their exposed cylinder arrangement, while beneficial for cooling, makes them vulnerable to environmental factors and increases maintenance frequency. The numerous moving parts—including multiple cylinders, pistons, and valve assemblies—create numerous potential failure points requiring regular inspection and replacement.

Jet engines, while superior in many aspects, face their own set of engineering challenges. Material science limitations remain significant, particularly regarding turbine blade materials that must withstand extreme temperatures exceeding 1,400°C while maintaining structural integrity under immense rotational forces. Advanced cooling systems and exotic materials like single-crystal superalloys partially address these issues but add complexity and cost.

Fuel efficiency at varying operational conditions presents ongoing challenges for jet engine designers. While jets excel at high-altitude cruise conditions, they demonstrate lower efficiency during takeoff, landing, and low-speed operations—precisely where radial engines maintain relatively consistent performance profiles. This operational efficiency variance necessitates complex engine management systems to optimize performance across flight regimes.

Noise pollution and emissions represent significant engineering challenges for jet engines. The high-velocity exhaust gases create substantial noise footprints around airports, requiring complex sound suppression systems that often compromise performance. Similarly, emissions control technologies must balance environmental regulations against performance requirements, creating engineering trade-offs that impact overall system efficiency.

Manufacturing precision requirements for jet engines far exceed those of radial engines, with turbine blade tolerances measured in micrometers. This precision manufacturing necessity drives production costs significantly higher and creates supply chain vulnerabilities for specialized components and materials.

Current Propulsion Solutions Comparison

01 Radial engine efficiency improvements

Radial engines can be optimized for better efficiency through various design modifications. These include improved cylinder cooling arrangements, enhanced valve timing mechanisms, and optimized fuel delivery systems. The radial configuration offers advantages in terms of power-to-weight ratio and mechanical simplicity, but requires specific engineering solutions to maximize efficiency and performance in aviation applications.- Radial engine efficiency improvements: Radial engines have been improved through various design modifications to enhance their efficiency. These improvements include optimized cylinder arrangements, better cooling systems, and advanced valve timing mechanisms. The radial configuration offers advantages in terms of power-to-weight ratio and reliability for certain applications, though they generally have lower thermal efficiency compared to inline configurations. Modern materials and manufacturing techniques have helped address some traditional limitations of radial engines.

- Jet engine thermal and propulsive efficiency enhancements: Jet engines have undergone significant developments to improve both thermal and propulsive efficiency. These include advanced combustion chamber designs, improved compressor and turbine aerodynamics, and optimized fuel injection systems. Higher bypass ratios in turbofan engines have substantially increased propulsive efficiency by accelerating a larger mass of air at lower velocity. Thermal efficiency improvements have been achieved through higher pressure ratios and operating temperatures, enabled by advanced materials and cooling technologies.

- Hybrid propulsion systems combining different engine types: Hybrid propulsion systems that combine elements of different engine types have been developed to leverage the advantages of each. These systems may integrate radial engine components with jet engine technologies, or combine conventional engines with electric propulsion. Such hybrid approaches can optimize efficiency across different flight regimes, providing better fuel economy during cruise while maintaining high power availability for takeoff and climb. These systems often incorporate advanced control algorithms to manage the transition between different propulsion modes.

- Advanced materials and manufacturing for engine efficiency: The development and application of advanced materials and manufacturing techniques have significantly contributed to engine efficiency improvements. Lightweight alloys, ceramic composites, and single-crystal turbine blades allow engines to operate at higher temperatures and pressures while reducing weight. Additive manufacturing enables the production of complex geometries that optimize fluid flow and heat transfer. Surface treatments and coatings reduce friction and improve durability, further enhancing efficiency through reduced mechanical losses and extended maintenance intervals.

- Fuel and combustion optimization technologies: Innovations in fuel delivery systems and combustion processes have led to significant efficiency gains in both radial and jet engines. Advanced fuel injection technologies provide precise control over fuel-air mixtures, while staged combustion approaches optimize the burning process across different operating conditions. Lean-burn technologies reduce fuel consumption while maintaining performance, and alternative fuel compatibility expands operational flexibility. Computational fluid dynamics and real-time combustion monitoring systems enable further refinements to the combustion process, maximizing energy extraction while minimizing emissions.

02 Jet engine thermal efficiency enhancements

Thermal efficiency in jet engines can be significantly improved through advanced combustion chamber designs, heat recovery systems, and optimized turbine blade configurations. These enhancements allow for better utilization of fuel energy, reduced heat losses, and improved overall engine performance. Higher thermal efficiency translates directly to reduced fuel consumption and increased thrust-to-weight ratios in modern jet propulsion systems.Expand Specific Solutions03 Hybrid propulsion systems combining radial and jet technologies

Innovative hybrid propulsion systems that integrate elements of both radial engine design and jet engine technology can achieve unique efficiency benefits. These systems may utilize the mechanical reliability of radial configurations while incorporating jet propulsion principles for higher speed operation. Such hybrid approaches can be particularly valuable in specialized aviation applications where the strengths of both engine types are advantageous.Expand Specific Solutions04 Advanced materials and manufacturing for engine efficiency

The application of advanced materials and manufacturing techniques significantly impacts both radial and jet engine efficiency. Lightweight alloys, ceramic composites, and precision-engineered components reduce weight while improving thermal properties and structural integrity. Modern manufacturing methods enable more complex geometries that optimize airflow, reduce friction losses, and enhance overall engine performance across different operating conditions.Expand Specific Solutions05 Fuel system optimizations for improved engine efficiency

Sophisticated fuel delivery and management systems play a crucial role in maximizing efficiency in both radial and jet engines. Advanced fuel injection technologies, electronic control systems, and alternative fuel compatibility features allow for precise combustion control across varying operational parameters. These optimizations result in more complete fuel burning, reduced emissions, and improved specific fuel consumption in aviation propulsion systems.Expand Specific Solutions

Major Manufacturers and Industry Landscape

The radial engine versus jet engine efficiency debate in transport reflects an industry in transition. The market for aircraft propulsion systems is mature but evolving, with an estimated global value exceeding $50 billion annually. While radial engines dominated early aviation, jet engines now represent technological maturity in commercial transport. Companies like Pratt & Whitney Canada, GE, and Mitsubishi Heavy Industries lead jet engine innovation with high bypass turbofans offering superior fuel efficiency at high altitudes and speeds. Meanwhile, niche applications for radial engines persist in specialized sectors. Research institutions including Harbin Engineering University and Zhejiang University collaborate with aerospace manufacturers to advance propulsion efficiency, focusing on sustainable aviation fuels and hybrid-electric systems to address environmental concerns while maintaining performance requirements.

Pratt & Whitney Canada Corp.

Technical Solution: Pratt & Whitney Canada has developed advanced turbofan and turboprop engines that represent significant improvements over radial engines in transport efficiency. Their PT6 turboprop engine family combines elements of both technologies, offering jet-like performance with propeller efficiency. Their latest generation engines employ advanced aerodynamics, innovative cooling systems, and proprietary alloys that allow operation at higher temperatures for improved thermodynamic efficiency. The company has implemented a dual-spool architecture that optimizes performance across different flight regimes, achieving 15-20% better fuel efficiency compared to equivalent radial engines. Their TALON (Technology for Advanced Low NOx) combustor technology reduces emissions while maintaining high performance. Pratt & Whitney's geared turbofan technology decouples fan and turbine speeds, allowing each component to operate at optimal efficiency points, resulting in 16% lower fuel consumption compared to conventional jet engines.

Strengths: Superior power-to-weight ratio compared to radial engines; significantly better fuel efficiency at high altitudes and speeds; lower maintenance requirements with longer time between overhauls. Weaknesses: Higher initial acquisition costs; more complex systems requiring specialized maintenance; less efficient at very low speeds compared to some radial engine implementations.

General Electric Company

Technical Solution: General Electric has pioneered jet engine technology with their advanced turbofan designs that dramatically outperform radial engines in transport applications. Their LEAP (Leading Edge Aviation Propulsion) engine incorporates 3D-woven carbon fiber composite fan blades and case, ceramic matrix composite components in the hot section, and advanced cooling technologies that enable higher operating temperatures and pressures. This results in approximately 15% better fuel efficiency compared to previous generation engines. GE's additive manufacturing techniques allow for complex geometries that optimize airflow and reduce weight, contributing to a 5:1 bypass ratio that significantly improves propulsive efficiency. Their digital twin technology enables predictive maintenance and performance optimization throughout the engine lifecycle. GE has also developed hybrid electric propulsion systems that combine jet engine efficiency with electric motor benefits for specific flight phases, potentially offering 25% fuel savings in next-generation aircraft.

Strengths: Industry-leading thermal efficiency; exceptional reliability with 99.98% dispatch reliability; advanced materials enabling higher thrust-to-weight ratios; comprehensive digital monitoring capabilities. Weaknesses: Higher complexity and initial cost compared to radial engines; requires more sophisticated maintenance infrastructure; less fuel-flexible than some radial engine designs.

Core Technologies in Modern Engine Design

Radial engine

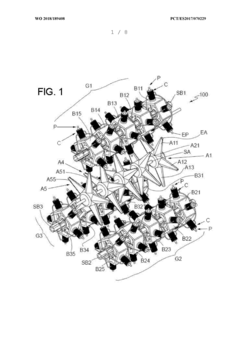

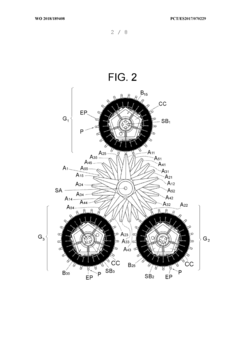

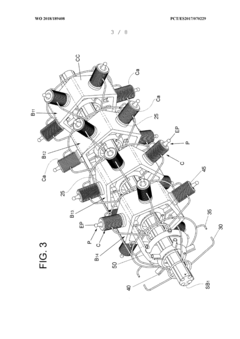

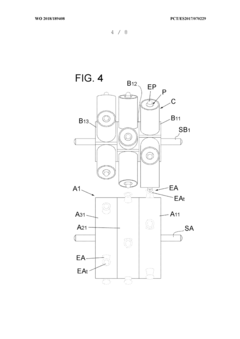

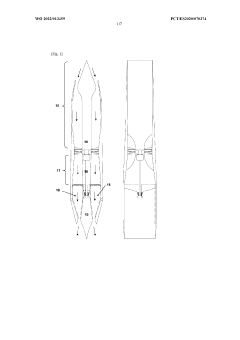

PatentWO2018189408A1

Innovation

- A radial engine design featuring a plurality of radially distributed sets of radial elements linked to a common output shaft, eliminating the need for a crankshaft and connecting rods, with angularly offset elements and groups of cylinders and pistons for efficient energy transmission and rotation.

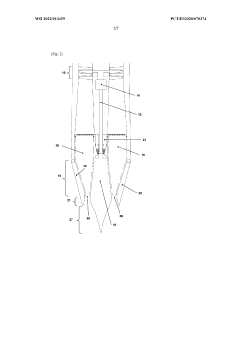

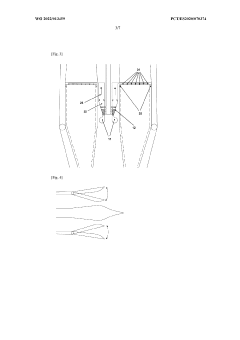

Jet engine for aircraft

PatentWO2022013459A1

Innovation

- A turbomachine jet engine design using a gas generator with a liquid fuel and oxidant injected in a fuel-rich ratio to generate high-pressure gas, featuring a turbine-driven high-speed shaft, adjustable intake, axial compressor, rectangular combustion chambers, and converging/divergent nozzles with dual fuel types and operational modes, including electric mode for reduced thrust.

Environmental Impact Assessment

The environmental impact of aircraft engines represents a critical consideration in modern transportation systems, with radial and jet engines exhibiting markedly different ecological footprints throughout their operational lifecycles.

Radial engines, predominantly used in earlier aviation history, produce emissions primarily consisting of carbon dioxide, carbon monoxide, unburned hydrocarbons, and particulate matter. Their relatively lower operational temperatures result in reduced nitrogen oxide emissions compared to jet engines. However, their fuel efficiency limitations translate to higher carbon emissions per passenger-mile when compared to modern propulsion systems.

Jet engines, while more fuel-efficient in terms of passenger-miles per gallon, especially at high altitudes and speeds, generate significant nitrogen oxide emissions due to their high-temperature combustion processes. These emissions contribute substantially to the formation of tropospheric ozone, a potent greenhouse gas. Additionally, jet engines produce contrails at high altitudes, which can develop into cirrus clouds that trap heat in the atmosphere, potentially contributing to global warming effects.

Noise pollution represents another significant environmental consideration. Radial engines typically generate lower-frequency noise that dissipates more rapidly than the high-pitched, far-reaching noise signature of jet engines. This difference becomes particularly relevant when considering airport proximity to residential areas and wildlife habitats.

The manufacturing and maintenance processes for both engine types also present distinct environmental challenges. Jet engines require specialized alloys and materials that often involve energy-intensive extraction and processing methods. Conversely, radial engines utilize more conventional materials but may require more frequent maintenance interventions, resulting in additional resource consumption over their operational lifespan.

End-of-life considerations reveal that radial engines, with their simpler construction and fewer exotic materials, potentially offer more straightforward recycling pathways. Jet engines, while containing valuable recoverable metals, present more complex disassembly and material separation challenges.

Recent regulatory frameworks have increasingly focused on aviation emissions, with particular emphasis on carbon dioxide and nitrogen oxides. These regulations have spurred technological innovations in both engine categories, though jet engine development has received significantly greater investment due to its dominance in commercial aviation.

The environmental calculus between these engine types ultimately depends on specific operational contexts, including flight distance, altitude, passenger capacity, and frequency of service. This multifaceted assessment must consider not only direct emissions but also the broader lifecycle impacts from manufacturing through decommissioning.

Radial engines, predominantly used in earlier aviation history, produce emissions primarily consisting of carbon dioxide, carbon monoxide, unburned hydrocarbons, and particulate matter. Their relatively lower operational temperatures result in reduced nitrogen oxide emissions compared to jet engines. However, their fuel efficiency limitations translate to higher carbon emissions per passenger-mile when compared to modern propulsion systems.

Jet engines, while more fuel-efficient in terms of passenger-miles per gallon, especially at high altitudes and speeds, generate significant nitrogen oxide emissions due to their high-temperature combustion processes. These emissions contribute substantially to the formation of tropospheric ozone, a potent greenhouse gas. Additionally, jet engines produce contrails at high altitudes, which can develop into cirrus clouds that trap heat in the atmosphere, potentially contributing to global warming effects.

Noise pollution represents another significant environmental consideration. Radial engines typically generate lower-frequency noise that dissipates more rapidly than the high-pitched, far-reaching noise signature of jet engines. This difference becomes particularly relevant when considering airport proximity to residential areas and wildlife habitats.

The manufacturing and maintenance processes for both engine types also present distinct environmental challenges. Jet engines require specialized alloys and materials that often involve energy-intensive extraction and processing methods. Conversely, radial engines utilize more conventional materials but may require more frequent maintenance interventions, resulting in additional resource consumption over their operational lifespan.

End-of-life considerations reveal that radial engines, with their simpler construction and fewer exotic materials, potentially offer more straightforward recycling pathways. Jet engines, while containing valuable recoverable metals, present more complex disassembly and material separation challenges.

Recent regulatory frameworks have increasingly focused on aviation emissions, with particular emphasis on carbon dioxide and nitrogen oxides. These regulations have spurred technological innovations in both engine categories, though jet engine development has received significantly greater investment due to its dominance in commercial aviation.

The environmental calculus between these engine types ultimately depends on specific operational contexts, including flight distance, altitude, passenger capacity, and frequency of service. This multifaceted assessment must consider not only direct emissions but also the broader lifecycle impacts from manufacturing through decommissioning.

Fuel Efficiency and Operating Economics

When comparing radial engines and jet engines from a fuel efficiency and economic perspective, several critical factors emerge that significantly impact their viability in different transport applications. Radial engines typically demonstrate lower specific fuel consumption at lower speeds and altitudes, making them economically advantageous for short-haul operations where aircraft spend minimal time at cruising altitude.

The operational economics of radial engines benefit from their relatively simple mechanical design, which translates to lower maintenance costs and longer time between overhauls (TBO) compared to early jet engines. Historical data indicates maintenance costs for radial engines averaging 30-40% less per flight hour than first-generation jet engines, though this gap has narrowed with modern turbofan technology.

Jet engines, conversely, exhibit superior fuel efficiency at higher altitudes and speeds, particularly above 25,000 feet and 300 knots. Modern high-bypass turbofan engines achieve specific fuel consumption rates as low as 0.5 lb/lbf-hr, representing a 60-70% improvement over radial engine configurations in comparable thrust categories. This efficiency differential becomes particularly pronounced on longer routes where the cruise segment constitutes a larger portion of the flight profile.

The economic crossover point between these technologies occurs approximately at the 300-500 nautical mile range threshold. Below this range, the lower acquisition costs and maintenance simplicity of radial engines may offset their higher fuel consumption. Beyond this threshold, the superior fuel economics of jet propulsion typically dominate the cost equation despite higher initial capital expenditure.

Lifecycle cost analysis reveals that while radial engines present lower upfront investment (typically 40-60% less than comparable jet powerplants), their operational economics deteriorate with increasing utilization rates. For operators with annual utilization exceeding 1,500 flight hours, jet engines generally deliver superior total cost of ownership despite higher acquisition and specialized maintenance requirements.

Environmental considerations further impact the economic equation, with jet engines producing fewer emissions per passenger-mile when operated at optimal altitudes and speeds. This translates to reduced environmental compliance costs in regulatory frameworks that incorporate carbon pricing mechanisms, providing an additional economic advantage for jet propulsion in markets with stringent emissions regulations.

The scalability economics also favor jet engines for larger transport applications, as their power-to-weight ratio improves more favorably with increasing size compared to radial configurations, creating a virtuous economic cycle for larger aircraft that radial technology cannot match.

The operational economics of radial engines benefit from their relatively simple mechanical design, which translates to lower maintenance costs and longer time between overhauls (TBO) compared to early jet engines. Historical data indicates maintenance costs for radial engines averaging 30-40% less per flight hour than first-generation jet engines, though this gap has narrowed with modern turbofan technology.

Jet engines, conversely, exhibit superior fuel efficiency at higher altitudes and speeds, particularly above 25,000 feet and 300 knots. Modern high-bypass turbofan engines achieve specific fuel consumption rates as low as 0.5 lb/lbf-hr, representing a 60-70% improvement over radial engine configurations in comparable thrust categories. This efficiency differential becomes particularly pronounced on longer routes where the cruise segment constitutes a larger portion of the flight profile.

The economic crossover point between these technologies occurs approximately at the 300-500 nautical mile range threshold. Below this range, the lower acquisition costs and maintenance simplicity of radial engines may offset their higher fuel consumption. Beyond this threshold, the superior fuel economics of jet propulsion typically dominate the cost equation despite higher initial capital expenditure.

Lifecycle cost analysis reveals that while radial engines present lower upfront investment (typically 40-60% less than comparable jet powerplants), their operational economics deteriorate with increasing utilization rates. For operators with annual utilization exceeding 1,500 flight hours, jet engines generally deliver superior total cost of ownership despite higher acquisition and specialized maintenance requirements.

Environmental considerations further impact the economic equation, with jet engines producing fewer emissions per passenger-mile when operated at optimal altitudes and speeds. This translates to reduced environmental compliance costs in regulatory frameworks that incorporate carbon pricing mechanisms, providing an additional economic advantage for jet propulsion in markets with stringent emissions regulations.

The scalability economics also favor jet engines for larger transport applications, as their power-to-weight ratio improves more favorably with increasing size compared to radial configurations, creating a virtuous economic cycle for larger aircraft that radial technology cannot match.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!