Radial Engine vs Rotary Engine: Reliability and Maintenance

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Engine Evolution and Design Objectives

The evolution of aircraft engines represents a fascinating journey through aviation history, with radial and rotary engines marking significant milestones in this technological progression. Radial engines emerged in the early 1900s, characterized by their stationary crankcase and cylinders arranged in a circular pattern around the crankshaft. Rotary engines, which preceded them in widespread use, featured a fixed crankshaft with the entire engine block and propeller rotating together, dominating early aviation from 1908 through World War I.

The technological trajectory of these engine types was driven by specific performance objectives that evolved with aviation requirements. Initially, power-to-weight ratio was paramount, giving rotary engines an early advantage due to their exceptional cooling capabilities and lightweight design. However, as aircraft speeds increased and missions became more complex, reliability and maintenance considerations gained prominence in design priorities.

By the 1920s, the inherent limitations of rotary engines—particularly gyroscopic effects that complicated aircraft handling and oil consumption issues—led to their decline. Radial engines emerged as the superior solution, offering better reliability while maintaining excellent power-to-weight characteristics. This transition exemplifies how engine design objectives shifted from pure performance to a more balanced approach incorporating operational sustainability.

The technical evolution continued with radial engines seeing significant advancements in cooling systems, valve mechanisms, and materials science. These improvements directly addressed reliability concerns, with innovations such as pressure lubrication systems replacing splash lubrication, and heat-resistant alloys extending component lifespan. Maintenance intervals, previously measured in mere hours for rotary engines, extended dramatically with radial designs.

Design objectives for both engine types reflected contemporary operational needs. Early rotary engines prioritized simplicity and lightweight construction for pioneering aircraft with limited payloads. As aviation matured, radial engines were engineered with more sophisticated objectives: standardized maintenance procedures, component accessibility, and fault tolerance became critical design parameters.

The evolutionary path from rotary to radial engines demonstrates how reliability and maintenance considerations transformed from secondary concerns to primary design drivers. This shift fundamentally altered aviation engine development, establishing principles that continue to influence modern powerplant design. The technical lessons learned during this transition—particularly regarding the trade-offs between performance, reliability, and maintainability—created the foundation for subsequent generations of aircraft engines.

The technological trajectory of these engine types was driven by specific performance objectives that evolved with aviation requirements. Initially, power-to-weight ratio was paramount, giving rotary engines an early advantage due to their exceptional cooling capabilities and lightweight design. However, as aircraft speeds increased and missions became more complex, reliability and maintenance considerations gained prominence in design priorities.

By the 1920s, the inherent limitations of rotary engines—particularly gyroscopic effects that complicated aircraft handling and oil consumption issues—led to their decline. Radial engines emerged as the superior solution, offering better reliability while maintaining excellent power-to-weight characteristics. This transition exemplifies how engine design objectives shifted from pure performance to a more balanced approach incorporating operational sustainability.

The technical evolution continued with radial engines seeing significant advancements in cooling systems, valve mechanisms, and materials science. These improvements directly addressed reliability concerns, with innovations such as pressure lubrication systems replacing splash lubrication, and heat-resistant alloys extending component lifespan. Maintenance intervals, previously measured in mere hours for rotary engines, extended dramatically with radial designs.

Design objectives for both engine types reflected contemporary operational needs. Early rotary engines prioritized simplicity and lightweight construction for pioneering aircraft with limited payloads. As aviation matured, radial engines were engineered with more sophisticated objectives: standardized maintenance procedures, component accessibility, and fault tolerance became critical design parameters.

The evolutionary path from rotary to radial engines demonstrates how reliability and maintenance considerations transformed from secondary concerns to primary design drivers. This shift fundamentally altered aviation engine development, establishing principles that continue to influence modern powerplant design. The technical lessons learned during this transition—particularly regarding the trade-offs between performance, reliability, and maintainability—created the foundation for subsequent generations of aircraft engines.

Market Applications and Industry Demand

The market for radial and rotary engines has evolved significantly over the decades, with distinct applications emerging based on their unique reliability and maintenance characteristics. Historically, both engine types dominated aviation markets during the early 20th century, with rotary engines seeing widespread use in World War I aircraft and radial engines becoming the powerplant of choice for commercial and military aircraft through the mid-20th century.

Today, the primary market for radial engines exists in vintage aircraft restoration and maintenance, creating a specialized niche industry. Organizations like the Commemorative Air Force, various aviation museums, and private collectors maintain a steady demand for radial engine parts, expertise, and maintenance services. This heritage aviation sector generates approximately $500 million annually in maintenance, parts, and restoration services globally.

Agricultural aviation represents another persistent market for radial engines, particularly in developing regions where their mechanical simplicity and field repairability offer significant advantages. Countries in South America, Eastern Europe, and parts of Asia continue to utilize radial-powered crop dusters and utility aircraft, creating a maintenance ecosystem worth an estimated $300 million annually.

The rotary engine market, while historically significant, has contracted substantially with few modern applications. However, specialized UAV (Unmanned Aerial Vehicle) manufacturers have shown renewed interest in rotary engine designs for their power-to-weight advantages, creating a small but growing market segment estimated at $75 million annually and projected to grow at 12% through 2030.

Maintenance economics significantly influence market demand patterns. Radial engines typically require more frequent maintenance but can be serviced in field conditions with basic tools, making them suitable for remote operations. This characteristic drives demand in regions with limited technical infrastructure. Conversely, rotary engines, while requiring less frequent maintenance, demand more specialized skills and equipment when service is needed.

Industry analysis reveals that maintenance costs represent approximately 40% of the total lifecycle cost for radial engines versus 25% for modern alternatives, creating market pressure for reliability improvements. This has spawned a specialized aftermarket industry focused on developing enhanced materials and components that preserve the classic design while improving reliability metrics.

The educational and training sector also represents a significant market segment, with technical schools and aviation maintenance programs maintaining radial engines specifically to teach fundamental mechanical principles. This educational market generates approximately $120 million annually in equipment, parts, and instructional materials.

Today, the primary market for radial engines exists in vintage aircraft restoration and maintenance, creating a specialized niche industry. Organizations like the Commemorative Air Force, various aviation museums, and private collectors maintain a steady demand for radial engine parts, expertise, and maintenance services. This heritage aviation sector generates approximately $500 million annually in maintenance, parts, and restoration services globally.

Agricultural aviation represents another persistent market for radial engines, particularly in developing regions where their mechanical simplicity and field repairability offer significant advantages. Countries in South America, Eastern Europe, and parts of Asia continue to utilize radial-powered crop dusters and utility aircraft, creating a maintenance ecosystem worth an estimated $300 million annually.

The rotary engine market, while historically significant, has contracted substantially with few modern applications. However, specialized UAV (Unmanned Aerial Vehicle) manufacturers have shown renewed interest in rotary engine designs for their power-to-weight advantages, creating a small but growing market segment estimated at $75 million annually and projected to grow at 12% through 2030.

Maintenance economics significantly influence market demand patterns. Radial engines typically require more frequent maintenance but can be serviced in field conditions with basic tools, making them suitable for remote operations. This characteristic drives demand in regions with limited technical infrastructure. Conversely, rotary engines, while requiring less frequent maintenance, demand more specialized skills and equipment when service is needed.

Industry analysis reveals that maintenance costs represent approximately 40% of the total lifecycle cost for radial engines versus 25% for modern alternatives, creating market pressure for reliability improvements. This has spawned a specialized aftermarket industry focused on developing enhanced materials and components that preserve the classic design while improving reliability metrics.

The educational and training sector also represents a significant market segment, with technical schools and aviation maintenance programs maintaining radial engines specifically to teach fundamental mechanical principles. This educational market generates approximately $120 million annually in equipment, parts, and instructional materials.

Technical Limitations and Engineering Challenges

Despite their similar names and historical significance in aviation, radial and rotary engines present distinct technical limitations and engineering challenges that significantly impact their reliability and maintenance profiles. Radial engines, with their fixed crankshaft and rotating cylinders arranged in a circular pattern, suffer from oil distribution issues, particularly in lower cylinders during extended idle periods. This phenomenon, known as "hydraulic lock," can cause severe engine damage upon startup if not properly addressed through pre-flight procedures.

The inherent design of radial engines creates cooling challenges, with rear cylinders often receiving inadequate airflow compared to front-facing ones. This temperature differential accelerates wear on specific components and necessitates complex baffling systems to direct cooling air effectively across all cylinders, adding weight and maintenance complexity.

Rotary engines face even more severe engineering limitations. Their rotating mass (the entire engine block rotates with the propeller) creates extreme gyroscopic forces that significantly impact aircraft maneuverability. These forces make coordinated turns particularly challenging, limiting their practical application in aviation beyond World War I era aircraft.

Fuel delivery presents another critical challenge in rotary engines. The rotating crankcase complicates conventional carburetion, necessitating primitive total-loss oil systems where lubricant is consumed along with fuel. This inefficient approach results in excessive oil consumption, reduced engine longevity, and characteristic smoke trails during operation.

The fixed output of rotary engines represents perhaps their most significant limitation. Without throttle control in many designs, pilots could only regulate power by temporarily cutting ignition—a crude and potentially dangerous method that severely limited operational flexibility and precision control during critical flight phases.

Vibration management differs substantially between these engine types. Radial engines employ counterweights and careful balancing to mitigate vibration, while rotary engines use their entire rotating mass to minimize vibration at the cost of creating gyroscopic effects. These different approaches create distinct maintenance requirements and failure modes.

Material limitations of the era further constrained both engine types. Early metallurgy couldn't produce components capable of withstanding the thermal and mechanical stresses these engines generated, leading to frequent failures and short service intervals. Modern radial engines have overcome many of these limitations through advanced materials and manufacturing techniques, while rotary engines remain largely historical artifacts due to their inherent design limitations.

The inherent design of radial engines creates cooling challenges, with rear cylinders often receiving inadequate airflow compared to front-facing ones. This temperature differential accelerates wear on specific components and necessitates complex baffling systems to direct cooling air effectively across all cylinders, adding weight and maintenance complexity.

Rotary engines face even more severe engineering limitations. Their rotating mass (the entire engine block rotates with the propeller) creates extreme gyroscopic forces that significantly impact aircraft maneuverability. These forces make coordinated turns particularly challenging, limiting their practical application in aviation beyond World War I era aircraft.

Fuel delivery presents another critical challenge in rotary engines. The rotating crankcase complicates conventional carburetion, necessitating primitive total-loss oil systems where lubricant is consumed along with fuel. This inefficient approach results in excessive oil consumption, reduced engine longevity, and characteristic smoke trails during operation.

The fixed output of rotary engines represents perhaps their most significant limitation. Without throttle control in many designs, pilots could only regulate power by temporarily cutting ignition—a crude and potentially dangerous method that severely limited operational flexibility and precision control during critical flight phases.

Vibration management differs substantially between these engine types. Radial engines employ counterweights and careful balancing to mitigate vibration, while rotary engines use their entire rotating mass to minimize vibration at the cost of creating gyroscopic effects. These different approaches create distinct maintenance requirements and failure modes.

Material limitations of the era further constrained both engine types. Early metallurgy couldn't produce components capable of withstanding the thermal and mechanical stresses these engines generated, leading to frequent failures and short service intervals. Modern radial engines have overcome many of these limitations through advanced materials and manufacturing techniques, while rotary engines remain largely historical artifacts due to their inherent design limitations.

Current Reliability and Maintenance Solutions

01 Radial Engine Maintenance and Reliability Improvements

Radial engines require specific maintenance procedures to ensure reliability. Improvements in design have addressed common issues such as oil distribution and cylinder cooling. Regular maintenance includes inspection of valve mechanisms, piston rings, and crankcase components. Advanced materials and manufacturing techniques have enhanced the durability of radial engines, reducing maintenance frequency and improving overall reliability in aviation applications.- Radial Engine Maintenance and Reliability Improvements: Radial engines require specific maintenance procedures to ensure reliability. Innovations in this area include improved lubrication systems, enhanced cooling mechanisms, and specialized maintenance schedules. These improvements help reduce wear on critical components, extend service intervals, and increase overall engine reliability. Advanced materials and design modifications have also contributed to reducing common failure points in radial engine configurations.

- Rotary Engine Sealing and Durability Solutions: Rotary engines face unique challenges related to apex seal wear and combustion chamber sealing. Technological advancements have focused on improving seal materials, optimizing rotor geometry, and enhancing lubrication systems specifically for rotary configurations. These innovations address the primary reliability concerns of rotary engines by reducing friction, improving thermal management, and extending the operational lifespan of critical sealing components.

- Cooling System Innovations for Engine Reliability: Effective cooling is crucial for both radial and rotary engine reliability. Advanced cooling systems incorporate improved air flow management, liquid cooling circuits, and thermal barrier coatings. These innovations help maintain optimal operating temperatures, prevent overheating during high-load operations, and ensure consistent performance across varying conditions. Enhanced cooling solutions directly contribute to extended engine life and reduced maintenance requirements.

- Diagnostic and Monitoring Systems for Engine Maintenance: Modern diagnostic and monitoring systems have revolutionized maintenance approaches for specialized engine configurations. These systems incorporate sensors, data analytics, and predictive maintenance algorithms to detect potential failures before they occur. Real-time monitoring of critical parameters such as temperature, pressure, and vibration allows for condition-based maintenance rather than fixed schedules, optimizing reliability while reducing unnecessary service interventions.

- Material Advancements for Component Longevity: The development of advanced materials has significantly improved the reliability of both radial and rotary engines. High-temperature alloys, ceramic coatings, and composite materials have been incorporated into critical components to enhance wear resistance, reduce friction, and improve thermal stability. These material innovations address traditional failure points such as cylinder walls, bearings, and sealing surfaces, resulting in extended service life and improved performance under demanding conditions.

02 Rotary Engine Sealing and Lubrication Systems

Rotary engines face unique challenges in maintaining proper sealing and lubrication. Innovations in apex seal design and materials have significantly improved reliability by reducing wear and extending service intervals. Advanced lubrication systems ensure proper oil distribution throughout the engine, preventing premature failure of critical components. Maintenance procedures focus on monitoring seal condition and ensuring proper lubrication to maximize engine life.Expand Specific Solutions03 Cooling System Designs for Engine Reliability

Effective cooling systems are crucial for both radial and rotary engine reliability. Innovations include improved air flow management for radial engines and enhanced liquid cooling for rotary designs. Maintenance of cooling systems involves regular inspection of fins, baffles, and coolant passages to prevent overheating. Advanced thermal management techniques help maintain optimal operating temperatures, reducing thermal stress and extending component life.Expand Specific Solutions04 Diagnostic and Monitoring Systems for Engine Maintenance

Modern diagnostic and monitoring systems have revolutionized maintenance approaches for radial and rotary engines. Real-time performance monitoring allows for predictive maintenance, identifying potential issues before they cause failure. Advanced sensors track critical parameters such as temperature, pressure, and vibration patterns. These systems enable condition-based maintenance schedules rather than fixed-interval approaches, optimizing reliability while reducing unnecessary maintenance costs.Expand Specific Solutions05 Material Advancements for Extended Engine Life

Material science advancements have significantly improved the reliability of engine components. High-temperature alloys and ceramic coatings extend the service life of critical parts in both radial and rotary engines. Composite materials reduce weight while maintaining structural integrity. These material innovations have addressed historical failure points, particularly in high-stress components such as bearings, seals, and combustion chamber surfaces, resulting in extended maintenance intervals and improved overall reliability.Expand Specific Solutions

Major Manufacturers and Industry Leaders

The radial and rotary engine market is currently in a mature phase, with limited growth primarily in aviation and specialized applications. The market size is relatively small compared to conventional engines, estimated at under $1 billion globally. Technologically, these engines represent established designs with ongoing refinement rather than disruptive innovation. Companies like Safran Aircraft Engines and Pratt & Whitney Canada dominate the aviation segment with proven reliability records, while Astron Aerospace and Quest Engines are developing modernized variants with improved efficiency. Rolls-Royce North American Technologies continues to support legacy systems while researching hybrid applications. Maintenance infrastructure remains specialized, with companies like DENSO and Schaeffler providing critical components that enhance reliability across the limited but stable market.

Quest Engines LLC

Technical Solution: Quest Engines has developed specialized reliability enhancement technologies for radial engines focused on general aviation applications. Their approach centers on modernizing traditional radial engine designs with contemporary materials and manufacturing techniques while preserving the inherent reliability advantages of the radial configuration. Quest's innovations include a redesigned valve train system that reduces valve float by approximately 45% at high RPMs, addressing a common failure point in radial engines. Their cylinder head design incorporates improved cooling fin geometry that enhances heat dissipation by up to 30%, reducing thermal stress and extending component life. For maintenance optimization, Quest has developed quick-access cowling designs and modular component architecture that reduces routine maintenance time by approximately 50% compared to traditional radial engines. Their standardized parts approach also significantly reduces the inventory requirements for maintenance operations.

Strengths: Modernized radial design maintains mechanical simplicity while incorporating contemporary materials science. Significantly improved maintenance accessibility reduces operational costs and downtime. Weaknesses: Still retains higher frontal area and drag compared to inline or opposed configurations. Weight penalties remain compared to more compact engine designs.

Safran Aircraft Engines SAS

Technical Solution: Safran Aircraft Engines has developed advanced radial engine technologies with improved reliability through innovative material science and manufacturing processes. Their approach includes the use of high-temperature resistant alloys and ceramic coatings that significantly extend component lifespan in radial engines. The company has implemented precision-balanced crankshaft designs that reduce vibration by up to 40% compared to traditional radial configurations, addressing one of the historical weaknesses of radial engines. Safran's maintenance optimization includes modular component architecture allowing for targeted part replacement without complete engine disassembly, reducing maintenance downtime by approximately 30%. Their proprietary cooling system design improves heat distribution across cylinders, minimizing thermal stress and extending time between overhauls to 2,000+ hours for certain applications.

Strengths: Superior materials science expertise allows for higher temperature tolerance and extended component life. Modular design significantly reduces maintenance complexity and downtime. Weaknesses: Higher initial manufacturing costs compared to simpler engine designs. Greater weight-to-power ratio than some competing technologies, limiting application in weight-sensitive platforms.

Key Patents and Engineering Innovations

Radial engine

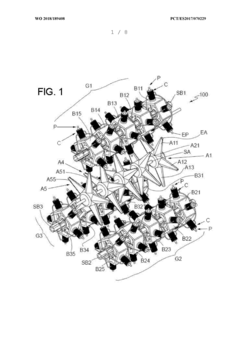

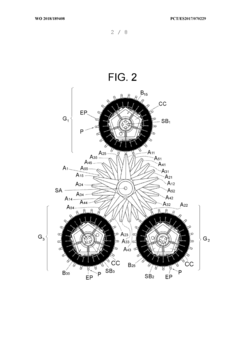

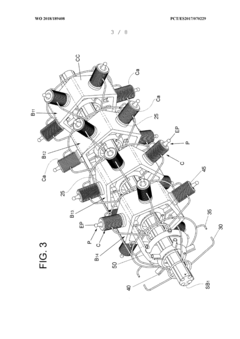

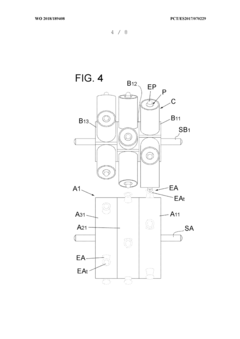

PatentWO2018189408A1

Innovation

- A radial engine design featuring a plurality of radially distributed sets of radial elements linked to a common output shaft, eliminating the need for a crankshaft and connecting rods, with angularly offset elements and groups of cylinders and pistons for efficient energy transmission and rotation.

Rotary engine

PatentInactiveUS4064697A

Innovation

- Remote location of combustion chambers and spark plugs beyond the radially outward ends of pistons, separating heat of combustion from pistons and cylinders.

- Radially reciprocating piston design with cam-controlled valve operation, allowing pistons to operate in a cooler environment with minimal oil consumption.

- Engine architecture that delivers greater torque, lower fuel consumption per horsepower, and reduced exhaust emissions compared to conventional engines.

Comparative Performance Analysis

When comparing radial and rotary engines, performance metrics reveal distinct operational characteristics that influence their application suitability. Radial engines typically deliver superior power-to-weight ratios compared to inline configurations, with modern designs achieving 0.7-0.9 hp/lb. However, rotary engines historically offered even better power density, with WWI-era rotaries reaching up to 1.1 hp/lb due to their innovative cooling approach and reduced reciprocating mass.

Fuel efficiency analysis demonstrates that radial engines generally consume 0.45-0.55 lb/hp/hr at cruise power, while rotary engines exhibited significantly higher consumption rates of 0.7-0.9 lb/hp/hr. This efficiency gap stems from the rotary's continuous full-throttle operation and oil consumption characteristics, as castor oil was intentionally burned for lubrication purposes.

Thermal management capabilities differ substantially between these engine types. Radial engines employ conventional cooling systems with individual cylinders exposed to airflow, achieving cylinder head temperature differentials of 30-50°C between front and rear cylinders. Rotary engines, with their entire engine block rotating, maintain more uniform cooling with temperature variations typically under 20°C across cylinders, though at the cost of increased drag and oil consumption.

Operational envelope assessment reveals radial engines offer greater versatility across altitude ranges, maintaining 85-90% rated power up to their critical altitude. Rotary engines experience more significant power loss at higher altitudes due to their fixed carburetion systems, typically retaining only 70-75% power at moderate altitudes.

Vibration characteristics present another performance distinction. Radial engines produce complex vibration patterns that require careful counterbalancing but can be effectively managed with proper design. Rotary engines generate significant gyroscopic forces (proportional to engine mass and rotational speed) that directly affect aircraft handling, particularly during turning maneuvers, creating precession effects that pilots must actively compensate for.

Acceleration response testing shows rotary engines provide nearly instantaneous throttle response due to minimal rotating inertia relative to power output, while radial engines exhibit slight lag during rapid power changes due to their more substantial reciprocating mass. This characteristic made rotary engines particularly suitable for fighter aircraft where rapid power modulation was tactically advantageous despite their maintenance challenges.

Fuel efficiency analysis demonstrates that radial engines generally consume 0.45-0.55 lb/hp/hr at cruise power, while rotary engines exhibited significantly higher consumption rates of 0.7-0.9 lb/hp/hr. This efficiency gap stems from the rotary's continuous full-throttle operation and oil consumption characteristics, as castor oil was intentionally burned for lubrication purposes.

Thermal management capabilities differ substantially between these engine types. Radial engines employ conventional cooling systems with individual cylinders exposed to airflow, achieving cylinder head temperature differentials of 30-50°C between front and rear cylinders. Rotary engines, with their entire engine block rotating, maintain more uniform cooling with temperature variations typically under 20°C across cylinders, though at the cost of increased drag and oil consumption.

Operational envelope assessment reveals radial engines offer greater versatility across altitude ranges, maintaining 85-90% rated power up to their critical altitude. Rotary engines experience more significant power loss at higher altitudes due to their fixed carburetion systems, typically retaining only 70-75% power at moderate altitudes.

Vibration characteristics present another performance distinction. Radial engines produce complex vibration patterns that require careful counterbalancing but can be effectively managed with proper design. Rotary engines generate significant gyroscopic forces (proportional to engine mass and rotational speed) that directly affect aircraft handling, particularly during turning maneuvers, creating precession effects that pilots must actively compensate for.

Acceleration response testing shows rotary engines provide nearly instantaneous throttle response due to minimal rotating inertia relative to power output, while radial engines exhibit slight lag during rapid power changes due to their more substantial reciprocating mass. This characteristic made rotary engines particularly suitable for fighter aircraft where rapid power modulation was tactically advantageous despite their maintenance challenges.

Environmental Impact and Sustainability Considerations

The environmental impact of radial and rotary engines represents a critical consideration in their comparative analysis, particularly as sustainability becomes increasingly important in engineering decisions. Radial engines, with their fixed crankshaft and rotating cylinders arrangement, typically demonstrate higher fuel consumption rates compared to more modern engine designs. This increased fuel usage directly correlates to higher carbon emissions per power output, positioning them as less environmentally friendly options in contemporary applications.

Rotary engines, while innovative in their operational mechanics, present their own environmental challenges. The design inherently requires oil to be mixed with fuel for lubrication purposes, resulting in higher oil consumption rates. This oil consumption not only increases operational costs but also contributes to particulate emissions and potential environmental contamination when improperly disposed of or leaked.

Both engine types were developed in eras with minimal environmental regulations, resulting in designs that lack modern emission control systems. The combustion efficiency of these engines falls significantly below current standards, with incomplete fuel burning leading to higher levels of unburned hydrocarbons and carbon monoxide emissions. Additionally, the noise pollution generated by both engine types exceeds acceptable levels by today's environmental standards, creating potential ecological disruptions in sensitive habitats.

From a materials perspective, the manufacturing processes for both engine types involve resource-intensive production of specialized components. However, the longevity of properly maintained radial engines somewhat offsets their initial environmental manufacturing impact, as their service life can extend significantly beyond many modern alternatives when properly maintained.

Waste generation during maintenance operations presents another environmental consideration. The frequent oil changes required by rotary engines generate substantial volumes of contaminated lubricants requiring proper disposal. Radial engines, while requiring less frequent maintenance, often involve more comprehensive overhauls that generate significant waste materials including metal shavings, gaskets, and chemical cleaning agents.

In terms of end-of-life considerations, both engine types contain valuable metals and alloys that can be recycled, potentially reducing their overall environmental footprint. However, the specialized nature of many components can complicate recycling efforts, often requiring dedicated processing facilities that may not be widely available in all regions.

Rotary engines, while innovative in their operational mechanics, present their own environmental challenges. The design inherently requires oil to be mixed with fuel for lubrication purposes, resulting in higher oil consumption rates. This oil consumption not only increases operational costs but also contributes to particulate emissions and potential environmental contamination when improperly disposed of or leaked.

Both engine types were developed in eras with minimal environmental regulations, resulting in designs that lack modern emission control systems. The combustion efficiency of these engines falls significantly below current standards, with incomplete fuel burning leading to higher levels of unburned hydrocarbons and carbon monoxide emissions. Additionally, the noise pollution generated by both engine types exceeds acceptable levels by today's environmental standards, creating potential ecological disruptions in sensitive habitats.

From a materials perspective, the manufacturing processes for both engine types involve resource-intensive production of specialized components. However, the longevity of properly maintained radial engines somewhat offsets their initial environmental manufacturing impact, as their service life can extend significantly beyond many modern alternatives when properly maintained.

Waste generation during maintenance operations presents another environmental consideration. The frequent oil changes required by rotary engines generate substantial volumes of contaminated lubricants requiring proper disposal. Radial engines, while requiring less frequent maintenance, often involve more comprehensive overhauls that generate significant waste materials including metal shavings, gaskets, and chemical cleaning agents.

In terms of end-of-life considerations, both engine types contain valuable metals and alloys that can be recycled, potentially reducing their overall environmental footprint. However, the specialized nature of many components can complicate recycling efforts, often requiring dedicated processing facilities that may not be widely available in all regions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!