Radial Engine vs Steam Turbine: Comparing Efficiency

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Radial Engine and Steam Turbine Historical Development

The radial engine emerged in the early 20th century as a revolutionary aircraft propulsion system. Developed from rotary engines, the first successful radial design was the Gnome engine, introduced in 1908. By the 1920s, radial engines had become dominant in aviation, with Charles Lawrance's J-1 engine and Pratt & Whitney's Wasp series establishing new standards for reliability and power-to-weight ratios. The interwar period saw significant advancements, culminating in the Wright R-3350 Duplex-Cyclone and Pratt & Whitney R-4360 Wasp Major, which represented the zenith of radial engine technology during World War II.

Steam turbine development followed a different trajectory, beginning with Sir Charles Parsons' invention in 1884. This revolutionary design converted thermal energy into rotational energy with unprecedented efficiency. By the early 1900s, steam turbines had begun replacing reciprocating steam engines in maritime applications and power generation. The Brown-Boveri company made significant contributions to turbine technology in the 1910s, while General Electric and Westinghouse led American developments.

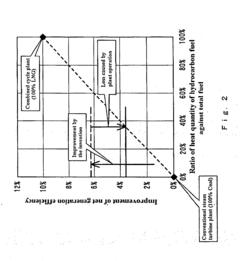

The efficiency comparison between these technologies reveals their distinct evolutionary paths. Radial engines achieved thermal efficiencies of 30-35% at their peak, with power-to-weight ratios that made them ideal for aviation. Their development focused on increasing reliability, reducing weight, and improving fuel consumption for aircraft applications.

Steam turbines, conversely, evolved toward much higher thermal efficiencies, eventually exceeding 40% in advanced designs. Their development prioritized scale economies, with larger units generally achieving better efficiency. Unlike radial engines, which reached their technological peak in the 1940s, steam turbine technology continued advancing significantly throughout the 20th century.

The divergent development paths reflect their different applications: radial engines optimized for mobile, lightweight applications where power density was paramount, while steam turbines excelled in stationary power generation where absolute efficiency and scalability were more critical than weight considerations.

By the 1950s, both technologies faced disruptive challenges. Radial engines were gradually supplanted by jet engines in aviation, while steam turbines faced competition from gas turbines and combined cycle systems in power generation. Nevertheless, the engineering principles established during their development continue to influence modern power systems design.

Steam turbine development followed a different trajectory, beginning with Sir Charles Parsons' invention in 1884. This revolutionary design converted thermal energy into rotational energy with unprecedented efficiency. By the early 1900s, steam turbines had begun replacing reciprocating steam engines in maritime applications and power generation. The Brown-Boveri company made significant contributions to turbine technology in the 1910s, while General Electric and Westinghouse led American developments.

The efficiency comparison between these technologies reveals their distinct evolutionary paths. Radial engines achieved thermal efficiencies of 30-35% at their peak, with power-to-weight ratios that made them ideal for aviation. Their development focused on increasing reliability, reducing weight, and improving fuel consumption for aircraft applications.

Steam turbines, conversely, evolved toward much higher thermal efficiencies, eventually exceeding 40% in advanced designs. Their development prioritized scale economies, with larger units generally achieving better efficiency. Unlike radial engines, which reached their technological peak in the 1940s, steam turbine technology continued advancing significantly throughout the 20th century.

The divergent development paths reflect their different applications: radial engines optimized for mobile, lightweight applications where power density was paramount, while steam turbines excelled in stationary power generation where absolute efficiency and scalability were more critical than weight considerations.

By the 1950s, both technologies faced disruptive challenges. Radial engines were gradually supplanted by jet engines in aviation, while steam turbines faced competition from gas turbines and combined cycle systems in power generation. Nevertheless, the engineering principles established during their development continue to influence modern power systems design.

Market Applications and Demand Analysis

The market landscape for both radial engines and steam turbines has evolved significantly over the decades, with each technology finding distinct application niches based on their efficiency profiles and operational characteristics. The aviation sector historically represented the primary market for radial engines, particularly during the golden age of piston-powered flight from the 1920s through the 1950s. Though largely replaced by jet engines in commercial aviation, radial engines maintain a specialized market in vintage aircraft restoration, aerobatic planes, and certain agricultural aircraft applications where their reliability and simplicity remain valued.

Steam turbines, conversely, have experienced sustained market growth across multiple sectors. The global steam turbine market was valued at approximately $24.1 billion in 2021 and is projected to reach $30.2 billion by 2027. Power generation represents the dominant application, with steam turbines powering roughly 80% of the world's electricity production. This market segment continues to expand in developing economies building new power infrastructure, particularly in Asia-Pacific regions where energy demand growth outpaces global averages.

Marine propulsion constitutes another significant market for steam turbines, especially for large vessels including LNG carriers and certain naval vessels. The industrial sector also maintains substantial demand for steam turbines in applications requiring process steam and mechanical drive capabilities, including petrochemical plants, paper mills, and steel manufacturing facilities.

Efficiency considerations heavily influence market dynamics for both technologies. Modern steam turbines achieve thermal efficiencies approaching 45% in combined cycle configurations, making them economically viable for large-scale power generation. Radial engines, with thermal efficiencies typically between 30-38%, face market constraints in applications where fuel efficiency is paramount.

Environmental regulations and sustainability initiatives are reshaping market demand patterns. Steam turbine manufacturers have responded with designs optimized for renewable energy applications, including geothermal power plants and concentrated solar thermal systems. This adaptation has opened new market segments as the energy transition accelerates. Radial engine applications, meanwhile, face increasing regulatory pressure regarding emissions, though niche markets persist where their unique power-to-weight characteristics outweigh efficiency considerations.

Customer requirements regarding maintenance intervals and operational flexibility also influence market segmentation. Radial engines offer advantages in remote operations where simplicity of maintenance is valued, while steam turbines excel in continuous operation scenarios where minimal downtime is essential.

Steam turbines, conversely, have experienced sustained market growth across multiple sectors. The global steam turbine market was valued at approximately $24.1 billion in 2021 and is projected to reach $30.2 billion by 2027. Power generation represents the dominant application, with steam turbines powering roughly 80% of the world's electricity production. This market segment continues to expand in developing economies building new power infrastructure, particularly in Asia-Pacific regions where energy demand growth outpaces global averages.

Marine propulsion constitutes another significant market for steam turbines, especially for large vessels including LNG carriers and certain naval vessels. The industrial sector also maintains substantial demand for steam turbines in applications requiring process steam and mechanical drive capabilities, including petrochemical plants, paper mills, and steel manufacturing facilities.

Efficiency considerations heavily influence market dynamics for both technologies. Modern steam turbines achieve thermal efficiencies approaching 45% in combined cycle configurations, making them economically viable for large-scale power generation. Radial engines, with thermal efficiencies typically between 30-38%, face market constraints in applications where fuel efficiency is paramount.

Environmental regulations and sustainability initiatives are reshaping market demand patterns. Steam turbine manufacturers have responded with designs optimized for renewable energy applications, including geothermal power plants and concentrated solar thermal systems. This adaptation has opened new market segments as the energy transition accelerates. Radial engine applications, meanwhile, face increasing regulatory pressure regarding emissions, though niche markets persist where their unique power-to-weight characteristics outweigh efficiency considerations.

Customer requirements regarding maintenance intervals and operational flexibility also influence market segmentation. Radial engines offer advantages in remote operations where simplicity of maintenance is valued, while steam turbines excel in continuous operation scenarios where minimal downtime is essential.

Technical Specifications and Performance Limitations

Radial engines and steam turbines represent two distinct power generation technologies with fundamentally different operating principles and performance characteristics. The radial engine, a type of internal combustion engine, arranges cylinders in a circular pattern around a central crankshaft, creating a compact design particularly favored in aircraft applications during the early to mid-20th century. These engines typically operate at rotational speeds between 2,000-2,800 RPM, generating power outputs ranging from 100 to 3,500 horsepower depending on configuration and displacement.

Thermal efficiency for radial engines generally falls between 25-38%, with larger models achieving higher efficiency ratings. Their power-to-weight ratio typically ranges from 0.4 to 0.7 horsepower per pound, making them relatively lightweight for their output capacity. However, radial engines face inherent limitations including significant aerodynamic drag due to their large frontal area, complex cooling requirements, and relatively high fuel consumption rates of 0.4-0.6 pounds per horsepower-hour.

In contrast, steam turbines operate on the Rankine cycle, converting thermal energy from pressurized steam into mechanical energy through multiple stages of rotating blades. Modern steam turbines achieve rotational speeds between 1,800-3,600 RPM for power generation applications, with industrial units producing outputs from several megawatts to over 1,500 megawatts in large power plants.

Steam turbines demonstrate superior thermal efficiency, typically ranging from 35-45% for standard configurations and reaching up to 60% in advanced combined cycle systems. Their power density significantly exceeds that of radial engines, with large units producing over 1,000 MW while occupying relatively compact footprints. The heat rate for modern steam turbines ranges from 7,500-9,000 BTU/kWh, representing a substantial efficiency advantage over internal combustion alternatives.

Key limitations of steam turbines include their substantial startup time requirements (30 minutes to several hours), significant initial capital investment, and complex auxiliary systems including condensers, feedwater heaters, and cooling towers. Additionally, steam turbines exhibit reduced efficiency at partial loads, typically losing 10-15% efficiency when operating at 50% capacity.

From a materials perspective, radial engines primarily utilize aluminum alloys for cylinders and magnesium or steel alloys for crankcase components, with operational temperature limits around 300°C at cylinder heads. Steam turbines employ specialized high-temperature alloys including chrome-molybdenum steels and nickel-based superalloys capable of withstanding steam temperatures up to 620°C in advanced ultra-supercritical designs, enabling their superior thermodynamic performance.

Thermal efficiency for radial engines generally falls between 25-38%, with larger models achieving higher efficiency ratings. Their power-to-weight ratio typically ranges from 0.4 to 0.7 horsepower per pound, making them relatively lightweight for their output capacity. However, radial engines face inherent limitations including significant aerodynamic drag due to their large frontal area, complex cooling requirements, and relatively high fuel consumption rates of 0.4-0.6 pounds per horsepower-hour.

In contrast, steam turbines operate on the Rankine cycle, converting thermal energy from pressurized steam into mechanical energy through multiple stages of rotating blades. Modern steam turbines achieve rotational speeds between 1,800-3,600 RPM for power generation applications, with industrial units producing outputs from several megawatts to over 1,500 megawatts in large power plants.

Steam turbines demonstrate superior thermal efficiency, typically ranging from 35-45% for standard configurations and reaching up to 60% in advanced combined cycle systems. Their power density significantly exceeds that of radial engines, with large units producing over 1,000 MW while occupying relatively compact footprints. The heat rate for modern steam turbines ranges from 7,500-9,000 BTU/kWh, representing a substantial efficiency advantage over internal combustion alternatives.

Key limitations of steam turbines include their substantial startup time requirements (30 minutes to several hours), significant initial capital investment, and complex auxiliary systems including condensers, feedwater heaters, and cooling towers. Additionally, steam turbines exhibit reduced efficiency at partial loads, typically losing 10-15% efficiency when operating at 50% capacity.

From a materials perspective, radial engines primarily utilize aluminum alloys for cylinders and magnesium or steel alloys for crankcase components, with operational temperature limits around 300°C at cylinder heads. Steam turbines employ specialized high-temperature alloys including chrome-molybdenum steels and nickel-based superalloys capable of withstanding steam temperatures up to 620°C in advanced ultra-supercritical designs, enabling their superior thermodynamic performance.

Current Efficiency Comparison Methodologies

01 Radial engine design improvements for efficiency

Various design improvements in radial engines can enhance their operational efficiency. These include optimized cylinder arrangements, improved cooling systems, and advanced valve timing mechanisms. By reducing friction losses and enhancing combustion efficiency, these design modifications can significantly improve the power output and fuel consumption of radial engines. Modern materials and manufacturing techniques have also contributed to making radial engines more efficient and reliable for various applications.- Radial engine design improvements for efficiency: Various design improvements in radial engines can enhance their operational efficiency. These include optimized cylinder arrangements, improved cooling systems, and advanced valve timing mechanisms. By reducing friction losses and enhancing combustion efficiency, these design modifications can significantly improve the power output and fuel consumption of radial engines, making them more competitive with other engine types in specific applications.

- Steam turbine efficiency enhancement techniques: Steam turbine efficiency can be enhanced through various techniques including improved blade designs, advanced sealing systems, and optimized steam flow paths. These enhancements reduce energy losses and increase the conversion of thermal energy to mechanical power. Additional improvements include multi-stage designs with reheat cycles and the use of advanced materials that can withstand higher temperatures and pressures, resulting in higher thermal efficiency.

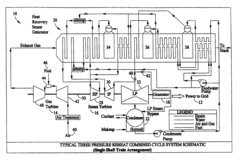

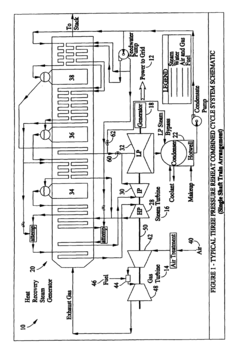

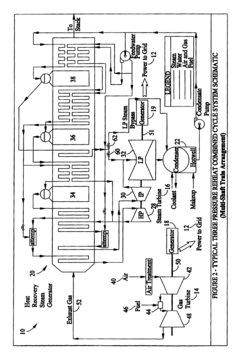

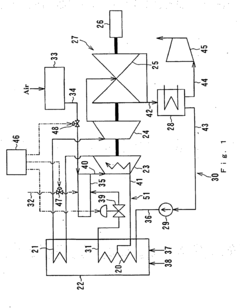

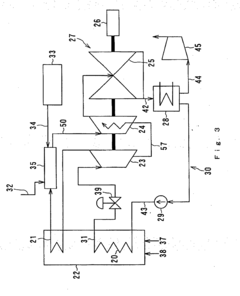

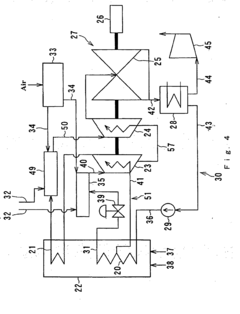

- Combined cycle systems integrating steam turbines: Combined cycle systems that integrate steam turbines with other power generation technologies can achieve higher overall efficiency. These systems typically recover waste heat from primary power sources to generate steam for turbines, significantly improving the total energy utilization. Examples include gas turbine-steam turbine combined cycles and integrated gasification combined cycle systems, which can achieve thermal efficiencies substantially higher than standalone conventional power plants.

- Monitoring and control systems for performance optimization: Advanced monitoring and control systems can optimize the performance of both radial engines and steam turbines. These systems use sensors and computational algorithms to continuously monitor operating parameters and adjust settings for optimal efficiency. Real-time analysis of performance data allows for predictive maintenance, early detection of efficiency losses, and automated adjustments to maintain peak performance under varying load conditions and environmental factors.

- Novel materials and manufacturing techniques: The use of advanced materials and modern manufacturing techniques can significantly improve the efficiency of both radial engines and steam turbines. Lightweight alloys, ceramic components, and composite materials can reduce weight, improve thermal properties, and enhance durability. Additionally, precision manufacturing methods like 3D printing and advanced machining enable more complex geometries that optimize fluid flow and reduce energy losses, resulting in higher operational efficiency and extended service life.

02 Steam turbine efficiency enhancement techniques

Steam turbine efficiency can be enhanced through various techniques including improved blade designs, advanced sealing systems, and optimized steam flow paths. These enhancements reduce energy losses and increase the conversion of thermal energy to mechanical power. Additional efficiency gains can be achieved through proper heat management, condensate recovery systems, and the use of multiple pressure stages. Modern computational fluid dynamics has enabled more precise design of turbine components to maximize efficiency across different operating conditions.Expand Specific Solutions03 Combined cycle systems integrating radial engines and steam turbines

Combined cycle systems that integrate radial engines with steam turbines can achieve higher overall efficiency by utilizing waste heat recovery. The exhaust heat from radial engines can be captured to generate steam for turbines, creating a more efficient power generation system. These integrated systems can significantly improve fuel utilization and reduce emissions compared to standalone engines or turbines. The synergistic operation allows for better load management and operational flexibility across various industrial applications.Expand Specific Solutions04 Monitoring and control systems for efficiency optimization

Advanced monitoring and control systems play a crucial role in optimizing the efficiency of both radial engines and steam turbines. These systems use sensors and algorithms to continuously monitor operating parameters and make real-time adjustments to maintain peak efficiency. Predictive maintenance capabilities can identify potential issues before they affect performance, while automated control systems can optimize combustion, steam flow, and other critical parameters. Digital twin technology enables simulation-based optimization of operational parameters under various conditions.Expand Specific Solutions05 Novel materials and manufacturing techniques for efficiency improvement

The development of advanced materials and manufacturing techniques has significantly contributed to efficiency improvements in both radial engines and steam turbines. High-temperature alloys, ceramic coatings, and composite materials enable components to withstand higher operating temperatures and pressures, directly improving thermodynamic efficiency. Additive manufacturing allows for complex geometries that optimize fluid flow and heat transfer. Surface treatments and precision manufacturing reduce friction losses and improve sealing, further enhancing the overall efficiency of these power systems.Expand Specific Solutions

Leading Manufacturers and Industry Landscape

The radial engine vs steam turbine efficiency comparison market is in a mature phase, with established players dominating different application segments. The global market size for these power generation technologies exceeds $100 billion, with steam turbines holding a larger share due to their industrial and utility applications. Technologically, steam turbines have reached higher maturity levels, with companies like General Electric, Siemens AG, and Mitsubishi Power leading innovation in efficiency improvements and emissions reduction. Radial engine technology, while more niche, maintains relevance in specific applications with Isuzu Motors, DENSO Corp, and MAN Truck & Bus developing more efficient variants. The competitive landscape shows a clear division between large conglomerates focusing on steam turbine advancements and specialized manufacturers improving radial engine performance for targeted applications.

General Electric Company

Technical Solution: General Electric has developed advanced steam turbine technologies that significantly improve efficiency compared to radial engines. Their H-class steam turbines achieve thermal efficiencies exceeding 45% in combined cycle applications, with some configurations reaching up to 64% efficiency. GE's steam turbines incorporate advanced 3D aerodynamic designs, optimized blade profiles, and improved sealing systems that minimize leakage losses. Their turbines feature variable stator vanes and advanced cooling technologies that allow operation at higher temperatures (up to 1600°C), substantially increasing the Rankine cycle efficiency. GE has also implemented digital twin technology for predictive maintenance and performance optimization, reducing downtime and extending turbine lifespan compared to mechanical radial engines.

Strengths: Superior thermal efficiency (45-64% vs 30-35% for radial engines), higher power-to-weight ratio, lower emissions, and better scalability for large power applications. Weaknesses: Higher initial capital costs, more complex installation requirements, and less suitable for small-scale or mobile applications where radial engines might offer advantages.

Mitsubishi Heavy Industries, Ltd.

Technical Solution: Mitsubishi Heavy Industries has developed proprietary steam turbine technologies that significantly outperform radial engines in efficiency metrics. Their advanced steam turbine designs incorporate 48-inch titanium blades in the low-pressure sections, allowing for optimal steam expansion and energy capture. MHI's J-series steam turbines achieve thermal efficiencies of up to 63% in combined cycle configurations, utilizing advanced materials that withstand temperatures exceeding 1,600°C. Their turbines feature variable pressure operation capabilities, allowing for efficiency optimization across different load profiles - a significant advantage over the more rigid operational parameters of radial engines. MHI has implemented advanced sealing technologies including brush seals and abradable coatings that reduce leakage losses by approximately 30% compared to conventional designs, directly improving overall efficiency.

Strengths: Exceptional thermal efficiency (up to 63%), superior power density, excellent part-load performance, and significantly lower emissions per kWh. Weaknesses: Higher complexity requiring specialized maintenance personnel, substantial initial investment costs, and longer startup times compared to radial engines which can reach operational status more quickly.

Core Engineering Principles and Design Innovations

Methods of measuring steam turbine efficiency

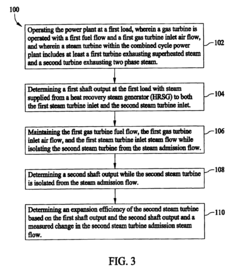

PatentInactiveUS6901348B2

Innovation

- A method involving operating a combined cycle power plant at specific loads, isolating the low-pressure steam turbine, and determining shaft outputs with and without steam admission, while maintaining constant gas turbine fuel and air flows, to calculate the expansion efficiency based on measured changes in steam flow and shaft outputs.

Steam turbine plant

PatentInactiveEP1580483B1

Innovation

- A steam turbine plant design incorporating a superheating combustor that uses hydrocarbon fuel and oxygen to generate super high temperature steam up to 900 degrees centigrade, which is then used to drive the steam turbines, while also utilizing a controller to adjust flow rates and maintain optimal temperatures and pressures, improving heat efficiency.

Environmental Impact and Sustainability Considerations

The environmental footprint of radial engines and steam turbines represents a critical dimension in their comparative analysis. Radial engines, with their direct combustion of fossil fuels, produce significant carbon dioxide emissions alongside nitrogen oxides and particulate matter. These emissions contribute substantially to both local air pollution and global climate change concerns, particularly when operated at high frequencies or in densely populated areas.

Steam turbines present a more complex environmental profile. While they can operate using various heat sources, including renewable options like geothermal or concentrated solar power, many industrial applications still rely on fossil fuel combustion for steam generation. However, the centralized nature of steam production facilities allows for more effective implementation of emission control technologies compared to distributed radial engine systems.

Water consumption emerges as another significant environmental factor. Steam turbines require substantial water resources for cooling and condensation processes, potentially straining local water supplies in water-scarce regions. This water dependency creates additional environmental vulnerabilities that radial engines largely avoid, though the latter require petroleum-based lubricants that pose contamination risks.

From a lifecycle perspective, steam turbines generally demonstrate superior longevity, with operational lifespans often exceeding 30 years with proper maintenance. This extended service life reduces the environmental impact associated with manufacturing replacement components. Radial engines typically require more frequent overhauls and component replacements, increasing their embodied carbon footprint over time.

Noise pollution represents another environmental consideration. Radial engines generate significant acoustic emissions during operation, potentially requiring additional noise abatement measures in sensitive environments. Steam turbines, particularly in larger installations, can be more effectively sound-insulated, reducing their acoustic environmental impact.

Recent sustainability innovations have improved both technologies' environmental profiles. Advanced combustion control systems and biofuel compatibility have enhanced radial engine sustainability, while steam turbine efficiency improvements and integration with combined heat and power systems have reduced their resource intensity. These developments suggest that environmental performance will continue to be a dynamic factor in the comparative assessment of these technologies.

Steam turbines present a more complex environmental profile. While they can operate using various heat sources, including renewable options like geothermal or concentrated solar power, many industrial applications still rely on fossil fuel combustion for steam generation. However, the centralized nature of steam production facilities allows for more effective implementation of emission control technologies compared to distributed radial engine systems.

Water consumption emerges as another significant environmental factor. Steam turbines require substantial water resources for cooling and condensation processes, potentially straining local water supplies in water-scarce regions. This water dependency creates additional environmental vulnerabilities that radial engines largely avoid, though the latter require petroleum-based lubricants that pose contamination risks.

From a lifecycle perspective, steam turbines generally demonstrate superior longevity, with operational lifespans often exceeding 30 years with proper maintenance. This extended service life reduces the environmental impact associated with manufacturing replacement components. Radial engines typically require more frequent overhauls and component replacements, increasing their embodied carbon footprint over time.

Noise pollution represents another environmental consideration. Radial engines generate significant acoustic emissions during operation, potentially requiring additional noise abatement measures in sensitive environments. Steam turbines, particularly in larger installations, can be more effectively sound-insulated, reducing their acoustic environmental impact.

Recent sustainability innovations have improved both technologies' environmental profiles. Advanced combustion control systems and biofuel compatibility have enhanced radial engine sustainability, while steam turbine efficiency improvements and integration with combined heat and power systems have reduced their resource intensity. These developments suggest that environmental performance will continue to be a dynamic factor in the comparative assessment of these technologies.

Maintenance Requirements and Operational Costs

Maintenance of radial engines requires regular inspection and servicing of multiple cylinders arranged in a circular pattern. Each cylinder contains numerous moving parts that experience significant wear due to the reciprocating motion and high operating temperatures. The maintenance schedule typically demands inspection every 25-50 operating hours, with major overhauls required after 1,000-1,500 hours of operation. These overhauls involve disassembling the engine, inspecting all components, replacing worn parts, and reassembling with precise tolerances—a labor-intensive process requiring specialized skills.

Operational costs for radial engines are considerably higher than modern alternatives due to their fuel consumption rates of 0.4-0.6 pounds per horsepower-hour. Additionally, their oil consumption is substantial, typically 1-2% of fuel consumption, as these engines rely on oil not only for lubrication but also for cooling and sealing. The complexity of the radial configuration also results in higher parts replacement costs throughout the lifecycle.

Steam turbines, by contrast, present a different maintenance profile characterized by longer intervals between major services. Routine maintenance typically occurs at 8,000-10,000 operating hours, with major overhauls scheduled at 30,000-50,000 hours. While these overhauls are complex engineering operations requiring specialized equipment and expertise, the frequency is significantly lower than for radial engines.

The operational cost advantage of steam turbines becomes apparent in long-term deployment scenarios. Modern steam turbines achieve thermal efficiencies of 35-45% (compared to radial engines' 25-30%), translating to lower fuel costs per unit of power generated. However, this efficiency comes with higher initial installation costs and the requirement for supporting systems such as boilers, condensers, and water treatment facilities.

Lifecycle cost analysis reveals that radial engines typically have lower acquisition costs but higher lifetime maintenance expenses. A typical radial engine might cost $50,000-$150,000 initially, with lifetime maintenance potentially exceeding 200% of the purchase price. Steam turbines require initial investments of $200,000-$2,000,000 (depending on capacity), but maintenance costs over their 25-30 year operational life may represent only 100-150% of the purchase price.

Personnel requirements also differ significantly. Radial engines can often be maintained by skilled mechanics with appropriate training, while steam turbine maintenance typically requires specialized engineers and technicians with advanced qualifications in thermodynamics, materials science, and control systems.

Operational costs for radial engines are considerably higher than modern alternatives due to their fuel consumption rates of 0.4-0.6 pounds per horsepower-hour. Additionally, their oil consumption is substantial, typically 1-2% of fuel consumption, as these engines rely on oil not only for lubrication but also for cooling and sealing. The complexity of the radial configuration also results in higher parts replacement costs throughout the lifecycle.

Steam turbines, by contrast, present a different maintenance profile characterized by longer intervals between major services. Routine maintenance typically occurs at 8,000-10,000 operating hours, with major overhauls scheduled at 30,000-50,000 hours. While these overhauls are complex engineering operations requiring specialized equipment and expertise, the frequency is significantly lower than for radial engines.

The operational cost advantage of steam turbines becomes apparent in long-term deployment scenarios. Modern steam turbines achieve thermal efficiencies of 35-45% (compared to radial engines' 25-30%), translating to lower fuel costs per unit of power generated. However, this efficiency comes with higher initial installation costs and the requirement for supporting systems such as boilers, condensers, and water treatment facilities.

Lifecycle cost analysis reveals that radial engines typically have lower acquisition costs but higher lifetime maintenance expenses. A typical radial engine might cost $50,000-$150,000 initially, with lifetime maintenance potentially exceeding 200% of the purchase price. Steam turbines require initial investments of $200,000-$2,000,000 (depending on capacity), but maintenance costs over their 25-30 year operational life may represent only 100-150% of the purchase price.

Personnel requirements also differ significantly. Radial engines can often be maintained by skilled mechanics with appropriate training, while steam turbine maintenance typically requires specialized engineers and technicians with advanced qualifications in thermodynamics, materials science, and control systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!