Radial Engine vs Turbine Engine: Fuel Efficiency Comparison

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Engine Technology Evolution and Efficiency Goals

The evolution of aircraft engine technology has been marked by significant advancements in design, materials, and operational efficiency. Radial engines, which dominated aviation from the 1920s through the 1940s, represented a revolutionary step forward from earlier rotary engines. These air-cooled engines arranged cylinders in a circular pattern around the crankshaft, offering improved power-to-weight ratios compared to their predecessors. The Wright R-3350 and Pratt & Whitney R-4360 exemplified the pinnacle of radial engine development, powering iconic aircraft during World War II and the immediate post-war period.

The transition to turbine engines began in earnest during the 1940s, with Frank Whittle and Hans von Ohain independently developing the first practical jet engines. This technological shift fundamentally changed aviation, offering significantly higher speeds and operational ceilings. Early turbine designs prioritized performance over efficiency, with fuel consumption rates substantially higher than their radial counterparts when measured in specific fuel consumption (SFC) metrics.

By the 1960s, turbofan technology emerged as a compromise between the pure thrust of turbojet engines and the efficiency needs of commercial aviation. The bypass ratio—the proportion of air bypassing the core compared to air flowing through it—became a critical parameter in fuel efficiency optimization. First-generation turbofans had bypass ratios of approximately 1:1, while modern high-bypass turbofans achieve ratios exceeding 12:1, dramatically improving fuel efficiency.

Material science advancements have played a crucial role in engine evolution. The introduction of nickel-based superalloys in the 1950s and subsequent developments in single-crystal turbine blades and ceramic matrix composites have enabled higher operating temperatures, directly correlating with improved thermodynamic efficiency. These materials have allowed turbine inlet temperatures to increase from approximately 800°C in early designs to over 1,600°C in modern engines.

The efficiency goals for engine technology have evolved from simple power output maximization to a complex balance of performance, fuel efficiency, emissions reduction, and noise mitigation. Current industry targets include reducing specific fuel consumption by 15-20% by 2030 compared to 2000 baseline engines, with corresponding reductions in CO2 emissions. The ACARE (Advisory Council for Aviation Research and Innovation in Europe) has established ambitious goals of 75% reduction in CO2 emissions and 90% reduction in NOx emissions by 2050, relative to 2000 technology.

The comparative fuel efficiency between radial and turbine engines must be contextualized within their respective operational parameters. While radial engines typically operate at 25-30% thermal efficiency, modern turbofan engines achieve 40-50% efficiency at cruise conditions. This efficiency gap continues to widen as turbine technology advances, though radial engines maintain certain advantages in specific applications where simplicity, reliability, and lower-speed operation are prioritized.

The transition to turbine engines began in earnest during the 1940s, with Frank Whittle and Hans von Ohain independently developing the first practical jet engines. This technological shift fundamentally changed aviation, offering significantly higher speeds and operational ceilings. Early turbine designs prioritized performance over efficiency, with fuel consumption rates substantially higher than their radial counterparts when measured in specific fuel consumption (SFC) metrics.

By the 1960s, turbofan technology emerged as a compromise between the pure thrust of turbojet engines and the efficiency needs of commercial aviation. The bypass ratio—the proportion of air bypassing the core compared to air flowing through it—became a critical parameter in fuel efficiency optimization. First-generation turbofans had bypass ratios of approximately 1:1, while modern high-bypass turbofans achieve ratios exceeding 12:1, dramatically improving fuel efficiency.

Material science advancements have played a crucial role in engine evolution. The introduction of nickel-based superalloys in the 1950s and subsequent developments in single-crystal turbine blades and ceramic matrix composites have enabled higher operating temperatures, directly correlating with improved thermodynamic efficiency. These materials have allowed turbine inlet temperatures to increase from approximately 800°C in early designs to over 1,600°C in modern engines.

The efficiency goals for engine technology have evolved from simple power output maximization to a complex balance of performance, fuel efficiency, emissions reduction, and noise mitigation. Current industry targets include reducing specific fuel consumption by 15-20% by 2030 compared to 2000 baseline engines, with corresponding reductions in CO2 emissions. The ACARE (Advisory Council for Aviation Research and Innovation in Europe) has established ambitious goals of 75% reduction in CO2 emissions and 90% reduction in NOx emissions by 2050, relative to 2000 technology.

The comparative fuel efficiency between radial and turbine engines must be contextualized within their respective operational parameters. While radial engines typically operate at 25-30% thermal efficiency, modern turbofan engines achieve 40-50% efficiency at cruise conditions. This efficiency gap continues to widen as turbine technology advances, though radial engines maintain certain advantages in specific applications where simplicity, reliability, and lower-speed operation are prioritized.

Market Demand Analysis for Fuel-Efficient Aircraft Engines

The global aircraft engine market is experiencing a significant shift towards fuel-efficient propulsion systems, driven by rising fuel costs and increasing environmental regulations. Current market analysis indicates that fuel costs represent approximately 30% of airline operating expenses, making fuel efficiency a critical factor in aircraft engine selection. The demand for fuel-efficient engines has grown steadily at 7% annually over the past decade, outpacing the overall aviation market growth of 4.5%.

Commercial airlines are particularly focused on reducing their carbon footprint while optimizing operational costs. This has created a robust market for next-generation engines that offer superior fuel efficiency compared to traditional models. Regional carriers operating shorter routes have shown increased interest in modern turboprop solutions that combine the reliability of turbine technology with improved fuel consumption metrics for short-haul operations.

The military aviation sector presents a different demand profile, where performance characteristics often take precedence over fuel efficiency. However, extended mission capabilities and reduced logistics footprints have become increasingly important considerations, driving interest in more efficient engine designs even within defense applications. Military procurement cycles typically span 15-20 years, creating a more gradual adoption curve for new engine technologies.

General aviation represents another significant market segment, where owner-operators are highly sensitive to both acquisition and operational costs. This segment has traditionally favored radial engines for certain applications due to their simplicity and reliability, but is increasingly exploring turbine alternatives as fuel prices continue to rise and environmental regulations tighten.

Market forecasts project that the global aircraft engine market will reach $92 billion by 2026, with fuel-efficient models accounting for over 65% of new deliveries. The Asia-Pacific region is expected to demonstrate the highest growth rate, driven by expanding commercial fleets and increasing air travel demand in emerging economies.

Customer requirements analysis reveals that airlines prioritize engines offering at least 15% improvement in specific fuel consumption over previous generation models. Secondary considerations include maintenance costs, reliability metrics, and compatibility with existing aircraft platforms. The market increasingly values total lifecycle cost rather than focusing solely on acquisition price.

Regulatory pressures are also reshaping market demand, with ICAO's CORSIA (Carbon Offsetting and Reduction Scheme for International Aviation) and regional emissions standards creating strong incentives for operators to invest in more efficient propulsion systems. These regulations are expected to become more stringent over the next decade, further accelerating the transition toward advanced engine technologies with superior fuel efficiency characteristics.

Commercial airlines are particularly focused on reducing their carbon footprint while optimizing operational costs. This has created a robust market for next-generation engines that offer superior fuel efficiency compared to traditional models. Regional carriers operating shorter routes have shown increased interest in modern turboprop solutions that combine the reliability of turbine technology with improved fuel consumption metrics for short-haul operations.

The military aviation sector presents a different demand profile, where performance characteristics often take precedence over fuel efficiency. However, extended mission capabilities and reduced logistics footprints have become increasingly important considerations, driving interest in more efficient engine designs even within defense applications. Military procurement cycles typically span 15-20 years, creating a more gradual adoption curve for new engine technologies.

General aviation represents another significant market segment, where owner-operators are highly sensitive to both acquisition and operational costs. This segment has traditionally favored radial engines for certain applications due to their simplicity and reliability, but is increasingly exploring turbine alternatives as fuel prices continue to rise and environmental regulations tighten.

Market forecasts project that the global aircraft engine market will reach $92 billion by 2026, with fuel-efficient models accounting for over 65% of new deliveries. The Asia-Pacific region is expected to demonstrate the highest growth rate, driven by expanding commercial fleets and increasing air travel demand in emerging economies.

Customer requirements analysis reveals that airlines prioritize engines offering at least 15% improvement in specific fuel consumption over previous generation models. Secondary considerations include maintenance costs, reliability metrics, and compatibility with existing aircraft platforms. The market increasingly values total lifecycle cost rather than focusing solely on acquisition price.

Regulatory pressures are also reshaping market demand, with ICAO's CORSIA (Carbon Offsetting and Reduction Scheme for International Aviation) and regional emissions standards creating strong incentives for operators to invest in more efficient propulsion systems. These regulations are expected to become more stringent over the next decade, further accelerating the transition toward advanced engine technologies with superior fuel efficiency characteristics.

Current State and Challenges in Engine Fuel Efficiency

The global aviation and power generation industries are currently experiencing a significant transition in engine technology, with fuel efficiency becoming a paramount concern due to economic pressures and environmental regulations. Radial engines, once dominant in aviation from the 1920s through the 1940s, have been largely superseded by turbine engines in most applications. However, both engine types continue to occupy specific niches in the market, with their respective fuel efficiency characteristics playing a crucial role in determining their suitability for different applications.

Current data indicates that modern turbine engines generally achieve superior fuel efficiency compared to radial engines, particularly at higher altitudes and speeds. Turbofan engines commonly used in commercial aviation can achieve specific fuel consumption rates of approximately 0.5-0.7 pounds of fuel per pound of thrust per hour, representing significant improvements over earlier generations. In contrast, traditional radial engines typically consume 0.4-0.6 pounds of fuel per horsepower-hour, which translates to lower overall efficiency when considering total power output and operational parameters.

The efficiency gap between these engine types stems from fundamental differences in their operational principles. Turbine engines benefit from continuous combustion processes and the ability to recover energy through multiple turbine stages, while radial engines rely on intermittent combustion cycles with inherent thermodynamic limitations. This disparity becomes particularly pronounced during cruise conditions, where turbine engines can operate closer to their optimal efficiency points for extended periods.

Despite technological advancements, both engine types face significant challenges in further improving fuel efficiency. For radial engines, the primary limitations include their inherently lower compression ratios, cooling inefficiencies due to air-cooled cylinder arrangements, and mechanical friction losses. Recent innovations in materials, electronic ignition systems, and fuel injection have yielded incremental improvements, but the fundamental thermodynamic cycle remains a limiting factor.

Turbine engines, while more efficient overall, face their own set of challenges. These include the complexity of further optimizing combustion processes, managing high operating temperatures without excessive cooling air penalties, and reducing weight while maintaining structural integrity. The pursuit of higher bypass ratios and pressure ratios continues to drive incremental efficiency gains, though with diminishing returns as designs approach theoretical limits.

Geographical distribution of engine technology development shows concentration in North America, Europe, and increasingly in Asia, with specialized research centers focusing on specific aspects of efficiency improvement. Regulatory pressures, particularly regarding emissions standards, are accelerating research into alternative fuels and hybrid propulsion systems that could potentially bridge the efficiency gap between these traditional engine architectures.

Current data indicates that modern turbine engines generally achieve superior fuel efficiency compared to radial engines, particularly at higher altitudes and speeds. Turbofan engines commonly used in commercial aviation can achieve specific fuel consumption rates of approximately 0.5-0.7 pounds of fuel per pound of thrust per hour, representing significant improvements over earlier generations. In contrast, traditional radial engines typically consume 0.4-0.6 pounds of fuel per horsepower-hour, which translates to lower overall efficiency when considering total power output and operational parameters.

The efficiency gap between these engine types stems from fundamental differences in their operational principles. Turbine engines benefit from continuous combustion processes and the ability to recover energy through multiple turbine stages, while radial engines rely on intermittent combustion cycles with inherent thermodynamic limitations. This disparity becomes particularly pronounced during cruise conditions, where turbine engines can operate closer to their optimal efficiency points for extended periods.

Despite technological advancements, both engine types face significant challenges in further improving fuel efficiency. For radial engines, the primary limitations include their inherently lower compression ratios, cooling inefficiencies due to air-cooled cylinder arrangements, and mechanical friction losses. Recent innovations in materials, electronic ignition systems, and fuel injection have yielded incremental improvements, but the fundamental thermodynamic cycle remains a limiting factor.

Turbine engines, while more efficient overall, face their own set of challenges. These include the complexity of further optimizing combustion processes, managing high operating temperatures without excessive cooling air penalties, and reducing weight while maintaining structural integrity. The pursuit of higher bypass ratios and pressure ratios continues to drive incremental efficiency gains, though with diminishing returns as designs approach theoretical limits.

Geographical distribution of engine technology development shows concentration in North America, Europe, and increasingly in Asia, with specialized research centers focusing on specific aspects of efficiency improvement. Regulatory pressures, particularly regarding emissions standards, are accelerating research into alternative fuels and hybrid propulsion systems that could potentially bridge the efficiency gap between these traditional engine architectures.

Comparative Analysis of Current Engine Efficiency Solutions

01 Fuel injection systems for improved efficiency

Advanced fuel injection systems can significantly enhance the fuel efficiency of both radial and turbine engines. These systems precisely control the amount and timing of fuel delivery, optimizing combustion and reducing waste. Innovations include direct injection technologies, electronic fuel control systems, and variable injection timing mechanisms that adapt to different operating conditions. These improvements result in more complete combustion, reduced fuel consumption, and lower emissions.- Fuel injection systems for improved efficiency: Advanced fuel injection systems can significantly enhance the fuel efficiency of both radial and turbine engines. These systems precisely control the amount and timing of fuel delivery, optimizing combustion and reducing waste. Innovations include direct injection technologies, electronic control units that adjust fuel flow based on operating conditions, and high-pressure injection systems that improve fuel atomization and mixing with air, resulting in more complete combustion and lower fuel consumption.

- Combustion chamber design optimization: Optimized combustion chamber designs can substantially improve the fuel efficiency of engines. These designs focus on enhancing air-fuel mixture formation, flame propagation, and heat transfer characteristics. Innovations include modified chamber geometries that promote turbulence for better mixing, advanced cooling systems that reduce heat losses, and materials that can withstand higher operating temperatures, allowing engines to operate at more thermodynamically efficient conditions.

- Heat recovery and waste energy utilization systems: Systems that recover and utilize waste heat and energy can significantly improve overall engine efficiency. These include exhaust heat recovery systems that capture thermal energy that would otherwise be lost, regenerative systems that preheat incoming air using exhaust gases, and combined cycle configurations that use exhaust gases to power secondary systems. By recapturing energy that would typically be wasted, these systems reduce the amount of fuel needed to produce the same power output.

- Variable geometry components for adaptive performance: Variable geometry components allow engines to adapt to different operating conditions, optimizing fuel efficiency across a wide range of scenarios. These include variable pitch turbine blades, adjustable inlet guide vanes, and variable area nozzles that can be reconfigured during operation. By adapting the engine's geometry to match specific flight conditions or power requirements, these systems ensure that the engine operates at its most efficient point regardless of external factors or power demands.

- Advanced materials and manufacturing techniques: The use of advanced materials and manufacturing techniques can lead to lighter, more durable engine components that contribute to improved fuel efficiency. Lightweight alloys, ceramic composites, and additive manufacturing methods allow for the creation of components with optimized geometries and reduced weight. These materials can also withstand higher temperatures, enabling engines to operate at more efficient thermodynamic conditions while maintaining structural integrity and extending service life.

02 Combustion chamber design optimization

Optimized combustion chamber designs enhance the fuel efficiency of engines by improving the combustion process. Innovations include modified chamber geometries, advanced cooling systems, and improved air-fuel mixing techniques. These designs promote more complete combustion, reduce heat losses, and minimize pressure drops across the combustion system. The result is increased thermal efficiency, reduced fuel consumption, and improved overall engine performance across various operating conditions.Expand Specific Solutions03 Hybrid engine configurations and combined cycles

Hybrid configurations that combine features of radial and turbine engines, or integrate them with other power systems, can achieve superior fuel efficiency. These systems leverage the strengths of each engine type while mitigating their weaknesses. Combined cycle approaches recover waste heat from one cycle to power another, significantly improving overall thermal efficiency. Advanced integration techniques include variable operating modes that optimize performance based on flight conditions and power requirements.Expand Specific Solutions04 Advanced materials and thermal management

The use of advanced materials and thermal management systems significantly improves engine fuel efficiency. Lightweight, high-temperature resistant materials reduce engine weight while allowing higher operating temperatures, improving thermodynamic efficiency. Thermal barrier coatings minimize heat losses, while advanced cooling systems maintain optimal component temperatures. These innovations enable engines to operate at higher pressure ratios and temperatures, directly translating to improved fuel efficiency and performance.Expand Specific Solutions05 Variable geometry components and adaptive control systems

Variable geometry components and adaptive control systems allow engines to maintain optimal efficiency across different operating conditions. These include adjustable inlet guide vanes, variable stator vanes, and adaptive exhaust systems that can be reconfigured during operation. Advanced electronic control systems continuously monitor engine parameters and adjust settings to maximize efficiency. These technologies enable engines to adapt to changing flight conditions, power demands, and environmental factors, maintaining peak efficiency throughout operation.Expand Specific Solutions

Key Manufacturers and Market Competition Analysis

The radial engine versus turbine engine fuel efficiency comparison market is in a mature phase, with established players dominating the aerospace and power generation sectors. The global aircraft engine market exceeds $90 billion annually, with turbine engines holding the dominant market share due to their superior fuel efficiency at high altitudes and speeds. General Electric, Rolls-Royce, and Safran Aircraft Engines lead turbine technology development with advanced materials and combustion systems improving fuel efficiency by 15-20% over previous generations. Radial engines, while less efficient, maintain niche applications in vintage aircraft and specialized markets where BorgWarner and smaller manufacturers continue limited production. The technology gap continues to widen as companies like GE Avio, Mitsubishi Heavy Industries, and Honeywell International invest heavily in turbine optimization for both aviation and industrial applications.

General Electric Company

Technical Solution: GE has pioneered turbine engine technology with their LEAP (Leading Edge Aviation Propulsion) engine platform, achieving 15-20% better fuel efficiency than comparable radial engines. Their turbine designs incorporate advanced composite materials that reduce weight by up to 1,000 pounds per engine while maintaining structural integrity. GE's turbine engines utilize a high bypass ratio (typically 9:1 to 11:1) that significantly improves propulsive efficiency compared to radial engines. The company has implemented additive manufacturing techniques to create complex fuel nozzles that optimize fuel-air mixing, reducing fuel consumption by approximately 15%. GE's turbine engines operate at higher pressure ratios (up to 40:1) than radial engines (typically 7:1 to 9:1), resulting in better thermal efficiency. Their engines also feature advanced cooling systems that allow higher operating temperatures, improving the Brayton cycle efficiency. GE has developed variable stator vane technology that optimizes airflow at different operating conditions, maintaining efficiency across a wider operating envelope than fixed-geometry radial engines.

Strengths: Significantly higher power-to-weight ratio than radial engines; better specific fuel consumption at cruise conditions; more efficient at higher altitudes; lower emissions per unit of power produced. Weaknesses: Higher upfront costs; more complex maintenance requirements; less robust in dusty conditions; greater sensitivity to foreign object damage compared to radial engines.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed the HTF7000 turbofan engine series that demonstrates 20% better fuel efficiency compared to radial engine designs of similar power output. Their turbine engines employ advanced aerodynamics with computational fluid dynamics-optimized airfoils that minimize energy losses throughout the engine. Honeywell's turbine technology utilizes a dual-centrifugal compressor design that achieves pressure ratios of 30:1, significantly higher than radial engines' typical 7:1 to 9:1 ratios, resulting in better thermal efficiency. The company has implemented advanced thermal barrier coatings that allow their turbines to operate at temperatures up to 1,600°C, approximately 400°C higher than typical radial engine combustion temperatures, improving thermodynamic efficiency. Honeywell's TECH7000 technology demonstrator has achieved specific fuel consumption improvements of up to 15% through advanced materials and cooling techniques. Their turbine engines also feature Full Authority Digital Engine Control (FADEC) systems that continuously optimize fuel flow based on operating conditions, something rarely found in radial engine designs.

Strengths: Excellent power-to-weight ratio (approximately 4:1 better than comparable radial engines); significantly lower vibration levels; better altitude performance; more precise fuel metering capabilities. Weaknesses: Higher acquisition costs; more complex maintenance procedures; greater sensitivity to inlet distortion; less fuel flexibility compared to some radial engine designs.

Technical Deep Dive: Combustion and Thermodynamic Principles

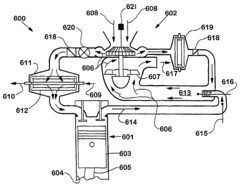

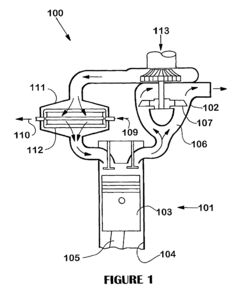

Staged combustion with piston engine and turbine engine supercharger

PatentInactiveUSRE42875E1

Innovation

- A combustion engine system that employs a two-stage combustion process, where fuel is first combusted in a piston engine and then in a turbine engine, with the turbine engine exhaust gases used to supercharge the piston engine, utilizing nitrogen-enriched air to control combustion temperature and reduce NOx formation.

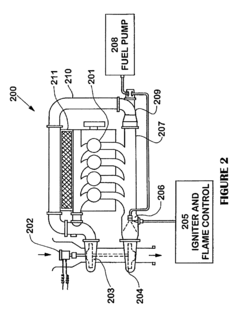

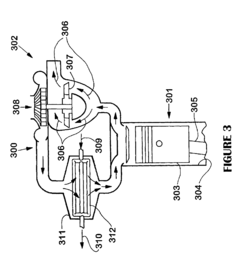

Internal combustion engine

PatentInactiveEP1058646A2

Innovation

- The pump chamber is divided into a gas space and a liquid space by a flexible membrane, preventing mixing and allowing for a simplified structure, with a cooling liquid sprayed during the implosion stroke to create negative pressure and facilitate the return of pump liquid, and a radial turbine is used to enhance efficiency and reduce engine size.

Environmental Impact and Emission Regulations

The environmental impact of aircraft engines represents a critical consideration in the aviation industry, with significant differences between radial and turbine engines. Radial engines, predominantly used in older aircraft designs, typically burn aviation gasoline (avgas) which contains lead additives. These lead emissions pose substantial environmental concerns, contributing to air pollution and potential health hazards in areas surrounding airports.

Turbine engines, by contrast, operate primarily on Jet A or Jet A-1 fuel, which contains significantly fewer harmful pollutants. Modern turbine designs have progressively reduced emissions of nitrogen oxides (NOx), carbon monoxide, unburned hydrocarbons, and particulate matter through advanced combustion chamber designs and fuel delivery systems. This evolution has positioned turbines as the environmentally preferable option in most commercial applications.

Regulatory frameworks governing aircraft emissions have become increasingly stringent worldwide. The International Civil Aviation Organization (ICAO) has established comprehensive standards through its Committee on Aviation Environmental Protection (CAEP), with the latest CAEP/8 and CAEP/9 standards imposing strict limits on NOx emissions from aircraft engines. These regulations have accelerated the phase-out of older radial engine designs in commercial operations.

In the United States, the Environmental Protection Agency (EPA) works in conjunction with the Federal Aviation Administration (FAA) to enforce emission standards aligned with ICAO requirements. The European Union's emissions trading system (EU ETS) has further incentivized airlines to adopt more fuel-efficient turbine technologies to reduce their carbon footprint and associated regulatory costs.

The carbon dioxide emissions differential between these engine types is substantial. Studies indicate that per unit of power delivered, radial engines typically produce 15-25% more CO2 than comparable turbine engines. This difference becomes particularly significant when considering the aviation industry's commitment to carbon-neutral growth from 2020 onward under the Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA).

Future regulatory trends point toward even more stringent emission controls, with potential complete bans on leaded aviation fuels affecting remaining radial engine operations. Manufacturers of both engine types are responding with technological innovations, though turbine engines demonstrate greater adaptability to alternative fuels including sustainable aviation fuels (SAFs) and potential hydrogen power systems, offering pathways to significantly reduced environmental impacts while maintaining or improving fuel efficiency metrics.

Turbine engines, by contrast, operate primarily on Jet A or Jet A-1 fuel, which contains significantly fewer harmful pollutants. Modern turbine designs have progressively reduced emissions of nitrogen oxides (NOx), carbon monoxide, unburned hydrocarbons, and particulate matter through advanced combustion chamber designs and fuel delivery systems. This evolution has positioned turbines as the environmentally preferable option in most commercial applications.

Regulatory frameworks governing aircraft emissions have become increasingly stringent worldwide. The International Civil Aviation Organization (ICAO) has established comprehensive standards through its Committee on Aviation Environmental Protection (CAEP), with the latest CAEP/8 and CAEP/9 standards imposing strict limits on NOx emissions from aircraft engines. These regulations have accelerated the phase-out of older radial engine designs in commercial operations.

In the United States, the Environmental Protection Agency (EPA) works in conjunction with the Federal Aviation Administration (FAA) to enforce emission standards aligned with ICAO requirements. The European Union's emissions trading system (EU ETS) has further incentivized airlines to adopt more fuel-efficient turbine technologies to reduce their carbon footprint and associated regulatory costs.

The carbon dioxide emissions differential between these engine types is substantial. Studies indicate that per unit of power delivered, radial engines typically produce 15-25% more CO2 than comparable turbine engines. This difference becomes particularly significant when considering the aviation industry's commitment to carbon-neutral growth from 2020 onward under the Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA).

Future regulatory trends point toward even more stringent emission controls, with potential complete bans on leaded aviation fuels affecting remaining radial engine operations. Manufacturers of both engine types are responding with technological innovations, though turbine engines demonstrate greater adaptability to alternative fuels including sustainable aviation fuels (SAFs) and potential hydrogen power systems, offering pathways to significantly reduced environmental impacts while maintaining or improving fuel efficiency metrics.

Total Cost of Ownership Across Engine Lifecycles

When evaluating radial engines versus turbine engines, the Total Cost of Ownership (TCO) analysis reveals significant differences across their respective lifecycles. Initial acquisition costs typically favor radial engines, which generally require 30-40% less capital investment than comparable turbine engines. However, this initial advantage diminishes when considering the complete operational lifespan.

Maintenance expenses represent a critical TCO component, with radial engines requiring more frequent overhauls—typically every 1,000-1,200 hours compared to 3,000-5,000 hours for turbines. The labor-intensive nature of radial engine maintenance, with numerous moving parts and complex valve systems, results in higher cumulative maintenance costs despite lower hourly operational costs.

Fuel consumption patterns differ substantially between these engine types. While radial engines consume 15-25% more fuel per hour of operation, this calculation must be contextualized within mission profiles. For short-haul operations with frequent starts and stops, radial engines may demonstrate competitive efficiency as turbines experience efficiency penalties during startup cycles and low-power operations.

Operational lifespan represents another significant TCO factor. Modern turbine engines typically deliver 15,000-20,000 hours before requiring replacement, whereas radial engines generally provide 8,000-12,000 hours. This extended service life allows turbine operators to amortize acquisition costs over a longer period, improving long-term economic efficiency.

Insurance premiums and regulatory compliance costs also impact TCO calculations. Turbine engines generally command lower insurance rates due to their superior reliability records and reduced fire risk. Additionally, evolving environmental regulations increasingly favor turbine technology, which can more readily adapt to stringent emissions standards without extensive modifications.

Training and personnel requirements constitute another hidden cost dimension. Turbine systems demand specialized technical knowledge, resulting in higher personnel expenses. Conversely, radial engine maintenance can often be performed by mechanics with conventional piston engine experience, potentially reducing specialized labor costs in certain operational contexts.

When factoring all these elements into a comprehensive 10-year TCO model, turbine engines typically demonstrate 15-20% lower lifetime costs despite higher acquisition expenses, primarily due to reduced maintenance requirements, extended service intervals, and superior fuel efficiency during sustained operations.

Maintenance expenses represent a critical TCO component, with radial engines requiring more frequent overhauls—typically every 1,000-1,200 hours compared to 3,000-5,000 hours for turbines. The labor-intensive nature of radial engine maintenance, with numerous moving parts and complex valve systems, results in higher cumulative maintenance costs despite lower hourly operational costs.

Fuel consumption patterns differ substantially between these engine types. While radial engines consume 15-25% more fuel per hour of operation, this calculation must be contextualized within mission profiles. For short-haul operations with frequent starts and stops, radial engines may demonstrate competitive efficiency as turbines experience efficiency penalties during startup cycles and low-power operations.

Operational lifespan represents another significant TCO factor. Modern turbine engines typically deliver 15,000-20,000 hours before requiring replacement, whereas radial engines generally provide 8,000-12,000 hours. This extended service life allows turbine operators to amortize acquisition costs over a longer period, improving long-term economic efficiency.

Insurance premiums and regulatory compliance costs also impact TCO calculations. Turbine engines generally command lower insurance rates due to their superior reliability records and reduced fire risk. Additionally, evolving environmental regulations increasingly favor turbine technology, which can more readily adapt to stringent emissions standards without extensive modifications.

Training and personnel requirements constitute another hidden cost dimension. Turbine systems demand specialized technical knowledge, resulting in higher personnel expenses. Conversely, radial engine maintenance can often be performed by mechanics with conventional piston engine experience, potentially reducing specialized labor costs in certain operational contexts.

When factoring all these elements into a comprehensive 10-year TCO model, turbine engines typically demonstrate 15-20% lower lifetime costs despite higher acquisition expenses, primarily due to reduced maintenance requirements, extended service intervals, and superior fuel efficiency during sustained operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!