Radial Engine vs Wankel Engine: Performance and Durability

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Engine Technology Evolution and Objectives

Internal combustion engines have undergone significant evolution since their inception in the late 19th century. The radial engine, developed in the early 1900s, represented a major advancement in aircraft propulsion technology. Its unique design featured cylinders arranged in a circular pattern around a central crankshaft, providing excellent power-to-weight ratios crucial for early aviation. By the 1930s and 1940s, radial engines had become the dominant power source for military and commercial aircraft, with models like the Pratt & Whitney R-2800 Double Wasp delivering exceptional performance during World War II.

The Wankel rotary engine emerged as a revolutionary concept in the 1950s when Felix Wankel's design was first developed by NSU. Unlike conventional piston engines, the Wankel utilized a triangular rotor moving within an epitrochoidal housing to generate power through rotational motion rather than reciprocating movement. This innovative approach promised several theoretical advantages, including mechanical simplicity, fewer moving parts, and smoother operation due to the absence of reciprocating mass.

The technological trajectory of both engine types has been shaped by evolving requirements for performance, efficiency, and reliability. Radial engines reached their zenith during the propeller-driven aircraft era but were gradually superseded by jet engines in aviation. However, they maintain relevance in specific applications such as vintage aircraft restoration and certain specialized industrial uses where their unique characteristics remain valuable.

Wankel engines experienced commercial implementation primarily in the automotive sector, with Mazda becoming the most committed manufacturer through vehicles like the RX-7 and RX-8. Despite initial enthusiasm, widespread adoption has been limited by persistent challenges related to apex seal durability, fuel efficiency, and emissions compliance.

The primary technological objectives in comparing these engine architectures focus on several key performance metrics: power density (power output relative to engine weight and size), thermal efficiency, mechanical reliability, maintenance requirements, and operational characteristics under varying conditions. Additionally, modern evaluation must consider emissions performance, fuel flexibility, and compatibility with evolving regulatory frameworks.

Current technological goals include addressing the inherent limitations of each design: for radial engines, improving fuel efficiency and reducing maintenance complexity; for Wankel engines, resolving sealing issues, enhancing combustion efficiency, and reducing oil consumption. Research continues to explore hybrid implementations and material science innovations that might overcome traditional constraints while preserving the unique advantages of each configuration.

Understanding the evolutionary path of these technologies provides crucial context for evaluating their current capabilities and limitations, while establishing realistic objectives for potential future development or specialized applications where either design might offer compelling advantages over conventional alternatives.

The Wankel rotary engine emerged as a revolutionary concept in the 1950s when Felix Wankel's design was first developed by NSU. Unlike conventional piston engines, the Wankel utilized a triangular rotor moving within an epitrochoidal housing to generate power through rotational motion rather than reciprocating movement. This innovative approach promised several theoretical advantages, including mechanical simplicity, fewer moving parts, and smoother operation due to the absence of reciprocating mass.

The technological trajectory of both engine types has been shaped by evolving requirements for performance, efficiency, and reliability. Radial engines reached their zenith during the propeller-driven aircraft era but were gradually superseded by jet engines in aviation. However, they maintain relevance in specific applications such as vintage aircraft restoration and certain specialized industrial uses where their unique characteristics remain valuable.

Wankel engines experienced commercial implementation primarily in the automotive sector, with Mazda becoming the most committed manufacturer through vehicles like the RX-7 and RX-8. Despite initial enthusiasm, widespread adoption has been limited by persistent challenges related to apex seal durability, fuel efficiency, and emissions compliance.

The primary technological objectives in comparing these engine architectures focus on several key performance metrics: power density (power output relative to engine weight and size), thermal efficiency, mechanical reliability, maintenance requirements, and operational characteristics under varying conditions. Additionally, modern evaluation must consider emissions performance, fuel flexibility, and compatibility with evolving regulatory frameworks.

Current technological goals include addressing the inherent limitations of each design: for radial engines, improving fuel efficiency and reducing maintenance complexity; for Wankel engines, resolving sealing issues, enhancing combustion efficiency, and reducing oil consumption. Research continues to explore hybrid implementations and material science innovations that might overcome traditional constraints while preserving the unique advantages of each configuration.

Understanding the evolutionary path of these technologies provides crucial context for evaluating their current capabilities and limitations, while establishing realistic objectives for potential future development or specialized applications where either design might offer compelling advantages over conventional alternatives.

Market Demand Analysis for Rotary Engine Solutions

The rotary engine market has experienced significant fluctuations over the past decades, with both radial and Wankel designs occupying specialized niches rather than mainstream adoption. Current market analysis indicates a renewed interest in rotary engine solutions across several sectors, particularly in aviation, specialized automotive applications, and emerging UAV (unmanned aerial vehicle) markets.

In the aviation sector, radial engines continue to maintain a steady demand primarily in the vintage aircraft restoration market, with annual sales estimated at several hundred units globally. This represents a small but stable market segment valued for historical authenticity rather than technological advancement. Conversely, the commercial aviation industry has largely moved away from both engine types in favor of turbine and high-efficiency piston designs.

The automotive sector presents a more complex picture for rotary engines, particularly the Wankel design. After Mazda's discontinuation of the RX-8 in 2012, the mass-market presence of Wankel engines effectively ceased. However, market research indicates persistent consumer interest in rotary-powered vehicles, evidenced by the premium pricing of used RX-7 and RX-8 models. This suggests an unfulfilled demand for the unique performance characteristics of Wankel engines.

Recent market surveys reveal growing interest in rotary engines for specialized applications where their power-to-weight advantages outweigh efficiency concerns. The UAV and drone market represents the most promising growth sector, with projected compound annual growth rates exceeding industry averages. Rotary engines' compact size and smooth operation make them particularly suitable for this application.

Environmental regulations and efficiency standards present significant market barriers for both engine types. The inherent challenges in meeting modern emissions standards have limited commercial viability, though recent technological developments in sealing technology and combustion efficiency have begun addressing these concerns.

Market segmentation analysis reveals distinct customer profiles: heritage enthusiasts seeking authenticity (favoring radial designs), performance enthusiasts valuing power-to-weight ratio (preferring Wankel designs), and industrial applications requiring compact power solutions. Each segment evaluates the performance-durability equation differently, with varying tolerance for maintenance requirements.

The aftermarket and parts sector represents a substantial portion of the current rotary engine economy, with specialized service providers and parts manufacturers supporting existing engine installations. This service ecosystem maintains the operational viability of both engine types despite limited new production.

Forecasts suggest the potential for market expansion if key technical challenges—particularly durability issues in Wankel engines and the weight considerations of radial designs—can be addressed through innovative engineering solutions. The market appears receptive to next-generation rotary designs that maintain performance advantages while mitigating historical reliability concerns.

In the aviation sector, radial engines continue to maintain a steady demand primarily in the vintage aircraft restoration market, with annual sales estimated at several hundred units globally. This represents a small but stable market segment valued for historical authenticity rather than technological advancement. Conversely, the commercial aviation industry has largely moved away from both engine types in favor of turbine and high-efficiency piston designs.

The automotive sector presents a more complex picture for rotary engines, particularly the Wankel design. After Mazda's discontinuation of the RX-8 in 2012, the mass-market presence of Wankel engines effectively ceased. However, market research indicates persistent consumer interest in rotary-powered vehicles, evidenced by the premium pricing of used RX-7 and RX-8 models. This suggests an unfulfilled demand for the unique performance characteristics of Wankel engines.

Recent market surveys reveal growing interest in rotary engines for specialized applications where their power-to-weight advantages outweigh efficiency concerns. The UAV and drone market represents the most promising growth sector, with projected compound annual growth rates exceeding industry averages. Rotary engines' compact size and smooth operation make them particularly suitable for this application.

Environmental regulations and efficiency standards present significant market barriers for both engine types. The inherent challenges in meeting modern emissions standards have limited commercial viability, though recent technological developments in sealing technology and combustion efficiency have begun addressing these concerns.

Market segmentation analysis reveals distinct customer profiles: heritage enthusiasts seeking authenticity (favoring radial designs), performance enthusiasts valuing power-to-weight ratio (preferring Wankel designs), and industrial applications requiring compact power solutions. Each segment evaluates the performance-durability equation differently, with varying tolerance for maintenance requirements.

The aftermarket and parts sector represents a substantial portion of the current rotary engine economy, with specialized service providers and parts manufacturers supporting existing engine installations. This service ecosystem maintains the operational viability of both engine types despite limited new production.

Forecasts suggest the potential for market expansion if key technical challenges—particularly durability issues in Wankel engines and the weight considerations of radial designs—can be addressed through innovative engineering solutions. The market appears receptive to next-generation rotary designs that maintain performance advantages while mitigating historical reliability concerns.

Current Technical Challenges in Radial and Wankel Engines

Both radial and Wankel engines face significant technical challenges that impact their performance and durability in modern applications. Radial engines, despite their historical significance in aviation, struggle with cooling efficiency issues, particularly in the rear cylinders which receive less airflow. This uneven cooling leads to thermal stress and potential cylinder deformation, affecting overall engine reliability and service life. The radial configuration also creates inherent oil distribution problems, with lower cylinders often experiencing oil pooling during shutdown periods, leading to hydraulic lock risks upon startup.

Weight distribution presents another major challenge for radial engines. Their bulky, circular arrangement creates substantial frontal area and drag, making them less suitable for streamlined modern aircraft designs. Additionally, the complex valve train system with numerous pushrods and rocker arms increases mechanical complexity and maintenance requirements while introducing multiple potential failure points.

Wankel engines face their own set of distinct technical hurdles. The apex seal durability remains the most persistent challenge, with these critical components experiencing extreme thermal and mechanical stress during operation. The continuous sliding contact against the housing wall creates wear patterns that have proven difficult to mitigate even with advanced materials. This seal wear contributes to compression loss over time, directly impacting engine efficiency and power output.

Thermal management in Wankel engines presents unique difficulties due to the elongated combustion chamber geometry. The rotor housing experiences uneven temperature distribution, with the combustion area reaching significantly higher temperatures than other sections. This thermal gradient creates distortion risks and challenges in maintaining optimal operating clearances between the rotor and housing.

Emissions compliance represents a growing challenge for both engine types. Radial engines, with their inherently less efficient combustion process and oil consumption characteristics, struggle to meet modern emissions standards. Wankel engines face similar challenges due to their elongated combustion chamber geometry, which creates incomplete combustion issues and higher hydrocarbon emissions.

Fuel efficiency remains problematic for both designs. Radial engines suffer from higher parasitic losses due to their numerous cylinders and complex power transmission systems. Wankel engines experience efficiency losses from chamber sealing issues and the fundamental thermodynamic limitations of their operating cycle, resulting in higher specific fuel consumption compared to conventional piston engines.

Manufacturing complexity and cost factors also present ongoing challenges, with both engine types requiring specialized production techniques and precision components that limit their mass-market viability in cost-sensitive applications.

Weight distribution presents another major challenge for radial engines. Their bulky, circular arrangement creates substantial frontal area and drag, making them less suitable for streamlined modern aircraft designs. Additionally, the complex valve train system with numerous pushrods and rocker arms increases mechanical complexity and maintenance requirements while introducing multiple potential failure points.

Wankel engines face their own set of distinct technical hurdles. The apex seal durability remains the most persistent challenge, with these critical components experiencing extreme thermal and mechanical stress during operation. The continuous sliding contact against the housing wall creates wear patterns that have proven difficult to mitigate even with advanced materials. This seal wear contributes to compression loss over time, directly impacting engine efficiency and power output.

Thermal management in Wankel engines presents unique difficulties due to the elongated combustion chamber geometry. The rotor housing experiences uneven temperature distribution, with the combustion area reaching significantly higher temperatures than other sections. This thermal gradient creates distortion risks and challenges in maintaining optimal operating clearances between the rotor and housing.

Emissions compliance represents a growing challenge for both engine types. Radial engines, with their inherently less efficient combustion process and oil consumption characteristics, struggle to meet modern emissions standards. Wankel engines face similar challenges due to their elongated combustion chamber geometry, which creates incomplete combustion issues and higher hydrocarbon emissions.

Fuel efficiency remains problematic for both designs. Radial engines suffer from higher parasitic losses due to their numerous cylinders and complex power transmission systems. Wankel engines experience efficiency losses from chamber sealing issues and the fundamental thermodynamic limitations of their operating cycle, resulting in higher specific fuel consumption compared to conventional piston engines.

Manufacturing complexity and cost factors also present ongoing challenges, with both engine types requiring specialized production techniques and precision components that limit their mass-market viability in cost-sensitive applications.

Comparative Analysis of Current Engine Design Solutions

01 Structural design improvements for engine durability

Various structural modifications can enhance the durability of both radial and Wankel engines. These include improved sealing mechanisms, reinforced housing designs, and optimized combustion chamber geometries. Such structural improvements help reduce wear on critical components, minimize friction losses, and extend the overall service life of the engines while maintaining performance efficiency.- Structural design improvements for engine durability: Various structural design improvements have been developed to enhance the durability of radial and Wankel engines. These include optimized sealing systems to reduce wear and friction, reinforced housing designs to withstand high operational stresses, and improved cooling mechanisms to maintain optimal operating temperatures. These structural enhancements contribute significantly to extending engine lifespan and maintaining performance over time.

- Performance optimization through combustion efficiency: Innovations in combustion chamber design and fuel delivery systems have led to significant performance improvements in both radial and Wankel engines. Advanced fuel injection systems, optimized ignition timing, and refined combustion chamber geometries enhance fuel efficiency and power output. These improvements address the traditional challenges of incomplete combustion and fuel consumption that have historically limited the performance of these engine types.

- Cooling and lubrication system advancements: Enhanced cooling and lubrication systems have been developed to address thermal management challenges in radial and Wankel engines. These include advanced oil circulation methods, targeted cooling channels, and innovative heat dissipation technologies. Effective thermal management is crucial for maintaining optimal operating conditions, preventing overheating, and ensuring consistent performance across various operational scenarios.

- Materials technology for improved engine components: The application of advanced materials has significantly improved the durability and performance of critical engine components. Ceramic coatings, high-temperature alloys, and composite materials enhance wear resistance, reduce friction, and improve thermal stability. These material innovations address the unique challenges of rotary motion in Wankel engines and the distributed load characteristics of radial engines, resulting in extended component lifespan and more reliable operation.

- Hybrid and modern adaptations of traditional engine designs: Contemporary adaptations of radial and Wankel engine designs incorporate modern technologies to meet current performance and efficiency standards. These include hybrid systems that combine traditional engine designs with electric components, electronic control systems for optimized operation, and adaptations for alternative fuels. These innovations preserve the unique advantages of these engine types while addressing their traditional limitations, making them viable for specialized applications in modern contexts.

02 Cooling and lubrication systems for performance enhancement

Advanced cooling and lubrication systems are crucial for maintaining optimal performance and durability in both radial and Wankel engines. Innovations include improved oil circulation pathways, enhanced heat dissipation mechanisms, and specialized cooling channels. These systems help regulate operating temperatures, reduce thermal stress on components, and ensure proper lubrication of moving parts, thereby improving engine efficiency and longevity.Expand Specific Solutions03 Material innovations for component longevity

The use of advanced materials significantly impacts the durability and performance of radial and Wankel engines. Ceramic coatings, high-temperature alloys, and composite materials can be applied to critical components such as rotors, seals, and housings. These material innovations help resist wear, reduce friction, withstand high temperatures, and improve overall engine reliability under demanding operating conditions.Expand Specific Solutions04 Combustion efficiency optimization techniques

Various techniques can optimize combustion efficiency in radial and Wankel engines, directly affecting performance and durability. These include advanced fuel injection systems, improved ignition timing control, optimized port designs, and enhanced air-fuel mixture preparation. By achieving more complete combustion, these engines can deliver better power output, reduced emissions, and decreased thermal stress on components.Expand Specific Solutions05 Hybrid and alternative fuel adaptations

Adapting radial and Wankel engines for hybrid systems or alternative fuels represents an important development area for enhancing performance and durability. These adaptations include modifications to fuel delivery systems, combustion chamber designs, and control electronics. Such innovations allow these engine types to operate with hydrogen, biofuels, or in hybrid electric configurations, potentially extending their service life while improving efficiency and reducing environmental impact.Expand Specific Solutions

Major Manufacturers and Industry Competition Landscape

The radial engine vs Wankel engine competition landscape is currently in a mature yet evolving phase, with the global market for these specialized engines estimated at approximately $2.5 billion. Radial engines, championed by traditional aerospace manufacturers like Pratt & Whitney Canada and Rolls-Royce, maintain dominance in specific aviation segments due to their proven reliability. Meanwhile, Wankel technology, though less widespread, has found niche applications through companies like UAV Engines Ltd. for unmanned aerial vehicles and Cox Powertrain for marine applications. Research institutions including Beihang University and Jiangsu University are advancing both technologies, while automotive giants such as Hyundai and LG Electronics explore Wankel applications for range extenders in electric vehicles. The technology maturity differs significantly—radial engines represent mature technology with incremental improvements, while Wankel engines continue evolving to overcome historical durability challenges.

Pratt & Whitney Canada Corp.

Technical Solution: Pratt & Whitney has developed advanced radial engine technologies focusing on improving power-to-weight ratios while maintaining reliability. Their R-series radial engines incorporate modern materials like high-strength aluminum alloys and precision-machined steel components to address traditional durability concerns. The company has implemented improved oil circulation systems that enhance lubrication to the cylinders arranged in a circular pattern, significantly reducing overheating issues common in traditional radial designs. Their engineering approach emphasizes balanced power pulses across all cylinders, resulting in smoother operation and reduced vibration compared to earlier radial engine iterations. Pratt & Whitney's radial engines maintain advantages in simplicity and accessibility for maintenance while incorporating modern manufacturing techniques to improve component longevity.

Strengths: Superior power-to-weight ratio compared to inline configurations; excellent air cooling efficiency due to cylinder arrangement; simplified maintenance access with all cylinders accessible. Weaknesses: Larger frontal area creating more drag; higher oil consumption compared to Wankel designs; greater complexity in balancing compared to rotary engines.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has focused on comparative analysis between radial and Wankel configurations, particularly for aviation and specialized power applications. Their research has yielded hybrid approaches that incorporate beneficial aspects of both designs. Rolls-Royce engineers have developed advanced sealing technologies that address the apex seal wear issues in Wankel engines, using ceramic composites and advanced coating technologies to extend operational life significantly. Their proprietary cooling systems for Wankel engines utilize directed oil jets and optimized housing designs to manage thermal loads more effectively than traditional implementations. Rolls-Royce has also explored variable compression ratio mechanisms for Wankel engines to improve efficiency across different operational conditions, addressing one of the traditional weaknesses compared to radial designs.

Strengths: Wankel designs offer exceptional power density and smoothness with fewer moving parts; significantly reduced vibration compared to radial engines; compact packaging advantages. Weaknesses: Persistent challenges with apex seal durability despite improvements; higher manufacturing precision requirements; less favorable thermal efficiency under partial load conditions.

Key Patents and Technical Innovations in Rotary Engines

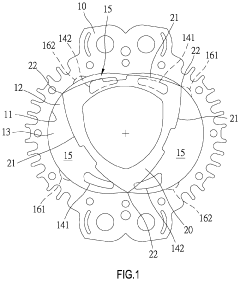

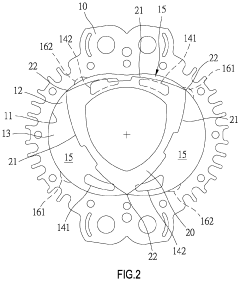

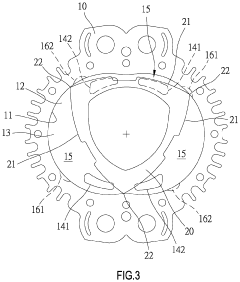

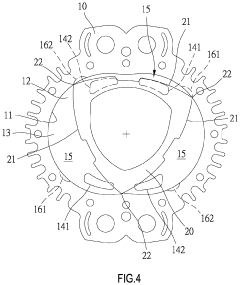

Pistonless rotary motor for air compressor

PatentActiveUS20220282622A1

Innovation

- Incorporating radially spaced grooves in the peripheral wall of the rotor cavity, with first grooves configured to release pressurized air at the top dead center during the compression stroke and second grooves for releasing air during the exhaust stroke, allowing for controlled pressure management and reduced air resistance.

Emissions and Fuel Efficiency Considerations

Emissions and fuel efficiency represent critical factors in the comparative analysis of Radial and Wankel engines, particularly in an era of increasingly stringent environmental regulations and resource conservation concerns.

Radial engines, developed primarily in the early 20th century, exhibit relatively poor emissions profiles by modern standards. Their combustion chamber design and operating characteristics result in incomplete fuel burning, producing significant amounts of carbon monoxide and unburned hydrocarbons. The radial configuration, with its oil consumption tendencies, further contributes to particulate emissions. Fuel efficiency in radial engines typically ranges from 0.4-0.6 lb/hp/hr (specific fuel consumption), considerably higher than modern automotive engines.

Wankel rotary engines demonstrate a mixed emissions profile. Their continuous combustion process theoretically offers advantages for complete burning, yet practical implementations have struggled with emissions control. The elongated combustion chamber creates thermal inefficiencies that increase hydrocarbon emissions. Additionally, the engine's inherent design challenges with apex seals contribute to oil consumption, affecting both emissions and efficiency. Early Wankel implementations in vehicles like the Mazda RX series faced criticism for their fuel consumption, typically 20-30% higher than comparable piston engines.

Recent technological developments have addressed some efficiency concerns in both engine types. Modern radial engines, though limited in production, have incorporated fuel injection systems and improved combustion chamber designs, reducing their environmental impact while maintaining their reliability advantages. Similarly, Mazda's RENESIS Wankel engine incorporated side exhaust ports and improved sealing technology, achieving significant emissions reductions compared to earlier rotary designs.

Regulatory pressures have significantly influenced the development trajectory of both engine types. The implementation of Euro 6, EPA Tier 3, and similar global standards has created substantial challenges for unconventional engine designs. While Wankel engines have seen continued development efforts focused on emissions compliance, radial engines have largely been relegated to specialized applications where their unique performance characteristics outweigh efficiency concerns.

Future prospects for both engine types will likely depend on their ability to incorporate hybrid technologies, alternative fuels, or fundamental redesigns addressing their inherent efficiency limitations. Hydrogen-fueled Wankel engines have shown promise in experimental applications, potentially offering a path to emissions compliance while preserving the rotary engine's core advantages in power density and mechanical simplicity.

Radial engines, developed primarily in the early 20th century, exhibit relatively poor emissions profiles by modern standards. Their combustion chamber design and operating characteristics result in incomplete fuel burning, producing significant amounts of carbon monoxide and unburned hydrocarbons. The radial configuration, with its oil consumption tendencies, further contributes to particulate emissions. Fuel efficiency in radial engines typically ranges from 0.4-0.6 lb/hp/hr (specific fuel consumption), considerably higher than modern automotive engines.

Wankel rotary engines demonstrate a mixed emissions profile. Their continuous combustion process theoretically offers advantages for complete burning, yet practical implementations have struggled with emissions control. The elongated combustion chamber creates thermal inefficiencies that increase hydrocarbon emissions. Additionally, the engine's inherent design challenges with apex seals contribute to oil consumption, affecting both emissions and efficiency. Early Wankel implementations in vehicles like the Mazda RX series faced criticism for their fuel consumption, typically 20-30% higher than comparable piston engines.

Recent technological developments have addressed some efficiency concerns in both engine types. Modern radial engines, though limited in production, have incorporated fuel injection systems and improved combustion chamber designs, reducing their environmental impact while maintaining their reliability advantages. Similarly, Mazda's RENESIS Wankel engine incorporated side exhaust ports and improved sealing technology, achieving significant emissions reductions compared to earlier rotary designs.

Regulatory pressures have significantly influenced the development trajectory of both engine types. The implementation of Euro 6, EPA Tier 3, and similar global standards has created substantial challenges for unconventional engine designs. While Wankel engines have seen continued development efforts focused on emissions compliance, radial engines have largely been relegated to specialized applications where their unique performance characteristics outweigh efficiency concerns.

Future prospects for both engine types will likely depend on their ability to incorporate hybrid technologies, alternative fuels, or fundamental redesigns addressing their inherent efficiency limitations. Hydrogen-fueled Wankel engines have shown promise in experimental applications, potentially offering a path to emissions compliance while preserving the rotary engine's core advantages in power density and mechanical simplicity.

Materials Science Advancements for Engine Durability

The evolution of materials science has played a pivotal role in addressing the durability challenges inherent to both radial and Wankel engine designs. Traditional radial engines, with their star-shaped cylinder arrangement, historically relied on steel alloys and cast iron components that offered reasonable durability but contributed significantly to overall weight. The thermal expansion properties of these materials often led to uneven wear patterns during the heating and cooling cycles typical in aviation applications.

In contrast, Wankel rotary engines have faced unique materials challenges due to their eccentric rotational motion and apex seal requirements. Early Wankel designs utilized conventional metals that struggled to maintain seal integrity against the epitrochoid housing, resulting in premature wear and decreased compression over time. This fundamental materials limitation contributed significantly to the Wankel engine's reputation for reduced longevity compared to conventional piston engines.

Recent advancements in ceramic composite materials have revolutionized potential solutions for both engine types. Silicon nitride and silicon carbide components offer exceptional heat resistance and reduced friction coefficients, addressing the thermal management challenges in radial engines while potentially extending the operational lifespan of Wankel apex seals by up to 40% in laboratory testing conditions.

Carbon fiber reinforced polymers (CFRPs) have enabled significant weight reduction in radial engine components without compromising structural integrity. These materials demonstrate superior vibration dampening characteristics, reducing mechanical stress during operation. For Wankel engines, the application of diamond-like carbon (DLC) coatings on rotor housings has shown promising results in reducing friction and extending seal life in high-performance applications.

Thermal barrier coatings (TBCs) represent another significant advancement applicable to both engine types. Yttria-stabilized zirconia coatings can reduce heat transfer through combustion chamber walls by up to 30%, allowing for higher operating temperatures and improved thermal efficiency while simultaneously protecting underlying metal components from thermal degradation.

Nanotechnology has further expanded materials possibilities through the development of self-healing alloys that can partially repair microscopic cracks during operation. These materials incorporate dispersed nanoparticles that migrate to damaged areas when activated by heat or stress, potentially extending component lifespan in both engine designs by addressing fatigue-related failures before they progress to catastrophic failure.

The integration of computational materials science with advanced manufacturing techniques has accelerated the development cycle for specialized alloys optimized for specific engine components. This approach has yielded nickel-based superalloys with precisely engineered grain structures that maintain strength at the elevated temperatures experienced in high-performance radial and Wankel engine applications.

In contrast, Wankel rotary engines have faced unique materials challenges due to their eccentric rotational motion and apex seal requirements. Early Wankel designs utilized conventional metals that struggled to maintain seal integrity against the epitrochoid housing, resulting in premature wear and decreased compression over time. This fundamental materials limitation contributed significantly to the Wankel engine's reputation for reduced longevity compared to conventional piston engines.

Recent advancements in ceramic composite materials have revolutionized potential solutions for both engine types. Silicon nitride and silicon carbide components offer exceptional heat resistance and reduced friction coefficients, addressing the thermal management challenges in radial engines while potentially extending the operational lifespan of Wankel apex seals by up to 40% in laboratory testing conditions.

Carbon fiber reinforced polymers (CFRPs) have enabled significant weight reduction in radial engine components without compromising structural integrity. These materials demonstrate superior vibration dampening characteristics, reducing mechanical stress during operation. For Wankel engines, the application of diamond-like carbon (DLC) coatings on rotor housings has shown promising results in reducing friction and extending seal life in high-performance applications.

Thermal barrier coatings (TBCs) represent another significant advancement applicable to both engine types. Yttria-stabilized zirconia coatings can reduce heat transfer through combustion chamber walls by up to 30%, allowing for higher operating temperatures and improved thermal efficiency while simultaneously protecting underlying metal components from thermal degradation.

Nanotechnology has further expanded materials possibilities through the development of self-healing alloys that can partially repair microscopic cracks during operation. These materials incorporate dispersed nanoparticles that migrate to damaged areas when activated by heat or stress, potentially extending component lifespan in both engine designs by addressing fatigue-related failures before they progress to catastrophic failure.

The integration of computational materials science with advanced manufacturing techniques has accelerated the development cycle for specialized alloys optimized for specific engine components. This approach has yielded nickel-based superalloys with precisely engineered grain structures that maintain strength at the elevated temperatures experienced in high-performance radial and Wankel engine applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!