Ethyl Acetate and its Role in Circular Economy Models

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate Background and Objectives

Ethyl acetate, a versatile organic compound, has been a cornerstone in various industries for decades. Its journey from a simple chemical to a key player in circular economy models reflects the evolving landscape of sustainable industrial practices. The compound's history dates back to the early 19th century when it was first synthesized, but its significance has grown exponentially in recent years due to its potential in promoting sustainable production and consumption patterns.

The primary objective of researching ethyl acetate in the context of circular economy models is to explore its role in reducing waste, minimizing resource consumption, and enhancing overall sustainability across multiple sectors. This research aims to uncover innovative applications and processes that can leverage ethyl acetate's unique properties to create closed-loop systems, where materials are continuously recycled and reused.

As industries worldwide grapple with the challenges of environmental sustainability and resource scarcity, ethyl acetate has emerged as a promising solution due to its biodegradability and potential for recovery and reuse. The compound's ability to dissolve a wide range of substances makes it an excellent candidate for developing eco-friendly solvents and cleaning agents, which are crucial in transitioning towards more sustainable manufacturing processes.

The technological evolution of ethyl acetate production and utilization has seen significant advancements, particularly in the areas of green chemistry and biorefinery concepts. Recent trends indicate a shift towards bio-based production methods, utilizing renewable feedstocks instead of traditional petrochemical routes. This aligns with the circular economy principle of regenerative design, where biological materials are prioritized for their ability to be safely returned to the biosphere.

Furthermore, the research into ethyl acetate's role in circular economy models extends beyond its production and immediate applications. It encompasses the entire lifecycle of the compound, from sourcing raw materials to end-of-life management. This holistic approach aims to identify opportunities for creating value at every stage, minimizing waste, and reducing the environmental footprint of industrial processes.

As we delve deeper into the background and objectives of ethyl acetate research, it becomes evident that the compound's potential extends far beyond its traditional uses. The goal is to reimagine ethyl acetate not just as a chemical product, but as a key enabler of circular economy principles across diverse industries, from pharmaceuticals to agriculture, and from electronics to packaging.

The primary objective of researching ethyl acetate in the context of circular economy models is to explore its role in reducing waste, minimizing resource consumption, and enhancing overall sustainability across multiple sectors. This research aims to uncover innovative applications and processes that can leverage ethyl acetate's unique properties to create closed-loop systems, where materials are continuously recycled and reused.

As industries worldwide grapple with the challenges of environmental sustainability and resource scarcity, ethyl acetate has emerged as a promising solution due to its biodegradability and potential for recovery and reuse. The compound's ability to dissolve a wide range of substances makes it an excellent candidate for developing eco-friendly solvents and cleaning agents, which are crucial in transitioning towards more sustainable manufacturing processes.

The technological evolution of ethyl acetate production and utilization has seen significant advancements, particularly in the areas of green chemistry and biorefinery concepts. Recent trends indicate a shift towards bio-based production methods, utilizing renewable feedstocks instead of traditional petrochemical routes. This aligns with the circular economy principle of regenerative design, where biological materials are prioritized for their ability to be safely returned to the biosphere.

Furthermore, the research into ethyl acetate's role in circular economy models extends beyond its production and immediate applications. It encompasses the entire lifecycle of the compound, from sourcing raw materials to end-of-life management. This holistic approach aims to identify opportunities for creating value at every stage, minimizing waste, and reducing the environmental footprint of industrial processes.

As we delve deeper into the background and objectives of ethyl acetate research, it becomes evident that the compound's potential extends far beyond its traditional uses. The goal is to reimagine ethyl acetate not just as a chemical product, but as a key enabler of circular economy principles across diverse industries, from pharmaceuticals to agriculture, and from electronics to packaging.

Market Analysis for Ethyl Acetate in Circular Economy

The global market for ethyl acetate has been experiencing significant growth, driven by its versatile applications across various industries and its potential role in circular economy models. As a key component in sustainable production processes, ethyl acetate's market dynamics are closely tied to the increasing emphasis on environmentally friendly practices and resource efficiency.

In recent years, the ethyl acetate market has shown a steady upward trend, with a compound annual growth rate (CAGR) expected to remain strong in the coming years. This growth is primarily attributed to the rising demand from end-use industries such as paints and coatings, adhesives, pharmaceuticals, and food and beverages. The circular economy approach has further bolstered this growth by promoting the use of bio-based ethyl acetate and encouraging recycling and reuse practices.

The Asia-Pacific region dominates the global ethyl acetate market, accounting for a substantial share of the total consumption. This is largely due to the rapid industrialization and urbanization in countries like China and India, coupled with the growing manufacturing sector in the region. North America and Europe follow as significant markets, with increasing adoption of sustainable practices driving demand for eco-friendly ethyl acetate alternatives.

In the context of circular economy models, the market for ethyl acetate is witnessing a shift towards bio-based production methods. This trend is particularly evident in Europe and North America, where stringent environmental regulations and consumer preferences for sustainable products are driving innovation in the industry. Bio-based ethyl acetate, derived from renewable resources such as sugarcane or corn, is gaining traction as a more environmentally friendly alternative to traditional petroleum-based production.

The circular economy approach is also influencing the ethyl acetate market through increased focus on recycling and reuse. Many industries are exploring ways to recover and recycle ethyl acetate from their production processes, reducing waste and creating a more sustainable supply chain. This trend is expected to create new market opportunities for recycling technologies and services related to ethyl acetate recovery.

Despite the positive outlook, the ethyl acetate market faces challenges in terms of price volatility of raw materials and competition from alternative solvents. However, the growing emphasis on sustainability and the circular economy is expected to drive continued innovation and market growth in the coming years. As industries increasingly adopt circular economy principles, the demand for ethyl acetate in sustainable production processes is likely to expand, creating new opportunities for market players and fostering a more environmentally responsible approach to chemical production and use.

In recent years, the ethyl acetate market has shown a steady upward trend, with a compound annual growth rate (CAGR) expected to remain strong in the coming years. This growth is primarily attributed to the rising demand from end-use industries such as paints and coatings, adhesives, pharmaceuticals, and food and beverages. The circular economy approach has further bolstered this growth by promoting the use of bio-based ethyl acetate and encouraging recycling and reuse practices.

The Asia-Pacific region dominates the global ethyl acetate market, accounting for a substantial share of the total consumption. This is largely due to the rapid industrialization and urbanization in countries like China and India, coupled with the growing manufacturing sector in the region. North America and Europe follow as significant markets, with increasing adoption of sustainable practices driving demand for eco-friendly ethyl acetate alternatives.

In the context of circular economy models, the market for ethyl acetate is witnessing a shift towards bio-based production methods. This trend is particularly evident in Europe and North America, where stringent environmental regulations and consumer preferences for sustainable products are driving innovation in the industry. Bio-based ethyl acetate, derived from renewable resources such as sugarcane or corn, is gaining traction as a more environmentally friendly alternative to traditional petroleum-based production.

The circular economy approach is also influencing the ethyl acetate market through increased focus on recycling and reuse. Many industries are exploring ways to recover and recycle ethyl acetate from their production processes, reducing waste and creating a more sustainable supply chain. This trend is expected to create new market opportunities for recycling technologies and services related to ethyl acetate recovery.

Despite the positive outlook, the ethyl acetate market faces challenges in terms of price volatility of raw materials and competition from alternative solvents. However, the growing emphasis on sustainability and the circular economy is expected to drive continued innovation and market growth in the coming years. As industries increasingly adopt circular economy principles, the demand for ethyl acetate in sustainable production processes is likely to expand, creating new opportunities for market players and fostering a more environmentally responsible approach to chemical production and use.

Current Challenges in Ethyl Acetate Production

The production of ethyl acetate faces several significant challenges in the current industrial landscape. One of the primary issues is the reliance on non-renewable fossil fuel-based feedstocks, which raises concerns about sustainability and environmental impact. The traditional production methods, such as the esterification of ethanol with acetic acid or the Tishchenko reaction of acetaldehyde, often require high energy inputs and generate substantial waste streams.

Another challenge lies in the optimization of reaction conditions to improve yield and selectivity. The esterification process, for instance, is limited by equilibrium constraints, necessitating the use of excess reactants or the continuous removal of water to drive the reaction to completion. This not only increases production costs but also complicates the purification process.

The purification of ethyl acetate presents its own set of challenges. The formation of azeotropes with water and ethanol during distillation makes separation difficult and energy-intensive. Advanced separation techniques, such as extractive distillation or pressure-swing distillation, are often required, adding complexity and cost to the production process.

Environmental concerns also pose significant challenges. The use of sulfuric acid as a catalyst in traditional processes leads to corrosion issues and the generation of acidic waste streams that require neutralization and disposal. Moreover, the volatile organic compound (VOC) emissions associated with ethyl acetate production and use necessitate stringent control measures to comply with increasingly strict environmental regulations.

The circular economy model presents both opportunities and challenges for ethyl acetate production. While it offers potential pathways for sustainable production, such as the use of bio-based feedstocks or recycled waste streams, implementing these approaches at an industrial scale remains challenging. The development of efficient bioprocesses for ethyl acetate production, for example, is hindered by low yields and the need for extensive purification steps.

Economic factors further complicate the landscape. The fluctuating prices of raw materials, particularly ethanol and acetic acid, impact production costs and market competitiveness. Additionally, the capital-intensive nature of retrofitting existing plants or building new facilities for more sustainable production methods poses financial barriers for many manufacturers.

Lastly, the development of alternative solvents and the push towards solvent-free processes in various industries threaten the long-term demand for ethyl acetate. This necessitates continuous innovation in both production technologies and application areas to maintain the relevance of ethyl acetate in a rapidly evolving industrial ecosystem.

Another challenge lies in the optimization of reaction conditions to improve yield and selectivity. The esterification process, for instance, is limited by equilibrium constraints, necessitating the use of excess reactants or the continuous removal of water to drive the reaction to completion. This not only increases production costs but also complicates the purification process.

The purification of ethyl acetate presents its own set of challenges. The formation of azeotropes with water and ethanol during distillation makes separation difficult and energy-intensive. Advanced separation techniques, such as extractive distillation or pressure-swing distillation, are often required, adding complexity and cost to the production process.

Environmental concerns also pose significant challenges. The use of sulfuric acid as a catalyst in traditional processes leads to corrosion issues and the generation of acidic waste streams that require neutralization and disposal. Moreover, the volatile organic compound (VOC) emissions associated with ethyl acetate production and use necessitate stringent control measures to comply with increasingly strict environmental regulations.

The circular economy model presents both opportunities and challenges for ethyl acetate production. While it offers potential pathways for sustainable production, such as the use of bio-based feedstocks or recycled waste streams, implementing these approaches at an industrial scale remains challenging. The development of efficient bioprocesses for ethyl acetate production, for example, is hindered by low yields and the need for extensive purification steps.

Economic factors further complicate the landscape. The fluctuating prices of raw materials, particularly ethanol and acetic acid, impact production costs and market competitiveness. Additionally, the capital-intensive nature of retrofitting existing plants or building new facilities for more sustainable production methods poses financial barriers for many manufacturers.

Lastly, the development of alternative solvents and the push towards solvent-free processes in various industries threaten the long-term demand for ethyl acetate. This necessitates continuous innovation in both production technologies and application areas to maintain the relevance of ethyl acetate in a rapidly evolving industrial ecosystem.

Circular Economy Solutions for Ethyl Acetate

01 Production and purification of ethyl acetate

Various methods for producing and purifying ethyl acetate are described, including esterification processes, distillation techniques, and separation methods. These processes aim to improve the yield and purity of ethyl acetate for industrial applications.- Production and purification of ethyl acetate: Various methods for producing and purifying ethyl acetate are described, including esterification processes, distillation techniques, and the use of catalysts. These methods aim to improve the yield and purity of ethyl acetate, which is an important industrial solvent and chemical intermediate.

- Applications of ethyl acetate in chemical processes: Ethyl acetate is utilized in diverse chemical processes, such as extraction, separation, and as a reaction medium. It is particularly useful in the production of pharmaceuticals, polymers, and other specialty chemicals due to its solvent properties and relatively low toxicity.

- Ethyl acetate in coating and adhesive formulations: Ethyl acetate is a key component in many coating and adhesive formulations. It is used as a solvent in paints, varnishes, and adhesives due to its fast evaporation rate and ability to dissolve a wide range of polymers and resins.

- Recovery and recycling of ethyl acetate: Methods for recovering and recycling ethyl acetate from industrial processes are described. These techniques aim to reduce waste, lower production costs, and minimize environmental impact by reusing the solvent in various applications.

- Ethyl acetate as a green solvent alternative: Ethyl acetate is explored as a more environmentally friendly alternative to traditional solvents in various industrial processes. Its relatively low toxicity, biodegradability, and renewable sourcing potential make it an attractive option for sustainable chemical manufacturing.

02 Applications of ethyl acetate in chemical processes

Ethyl acetate is utilized in diverse chemical processes, such as solvent extraction, as a reaction medium, and in the production of other chemicals. Its properties make it suitable for various industrial applications, including pharmaceuticals and polymer synthesis.Expand Specific Solutions03 Ethyl acetate in coating and adhesive formulations

Ethyl acetate is employed in the formulation of coatings, adhesives, and related products. Its solvent properties and compatibility with various resins make it valuable in these applications, contributing to improved performance and drying characteristics.Expand Specific Solutions04 Recycling and recovery of ethyl acetate

Methods for recycling and recovering ethyl acetate from industrial processes are described. These techniques aim to reduce waste, improve efficiency, and minimize environmental impact by reusing the solvent in various applications.Expand Specific Solutions05 Ethyl acetate in biofuel and renewable chemical production

The use of ethyl acetate in the production of biofuels and renewable chemicals is explored. This includes its role as an intermediate or solvent in biorefinery processes, contributing to the development of more sustainable chemical production methods.Expand Specific Solutions

Key Players in Ethyl Acetate Industry

The research on Ethyl Acetate and its role in circular economy models is gaining traction as industries seek sustainable solutions. The market is in a growth phase, with increasing demand for eco-friendly solvents driving expansion. The global ethyl acetate market size is projected to reach significant figures in the coming years. Technologically, the field is advancing, with companies like Celanese International Corp., Wacker Chemie AG, and Eastman Chemical Co. leading innovations in production processes and applications. Academic institutions such as the University of Florida and Nanjing Normal University are contributing to research advancements. The involvement of both established chemical companies and emerging biotechnology firms indicates a maturing technology landscape with potential for further developments in circular economy applications.

Celanese International Corp.

Technical Solution: Celanese has developed an innovative process for ethyl acetate production that aligns with circular economy principles. Their method utilizes bioethanol derived from renewable sources as a key raw material, reducing reliance on fossil-based feedstocks[1]. The process employs a highly efficient catalytic system that enables direct esterification of ethanol with acetic acid, achieving conversion rates of up to 99%[2]. Additionally, Celanese has implemented advanced separation techniques, including membrane technology, to purify the ethyl acetate product while minimizing energy consumption and waste generation[3]. The company has also integrated a closed-loop recycling system that recovers and reuses unreacted raw materials, further enhancing the sustainability of the production process[4].

Strengths: High conversion rates, use of renewable feedstocks, and efficient recycling system. Weaknesses: Potential higher production costs compared to traditional methods and dependence on bioethanol availability.

Eastman Chemical Co.

Technical Solution: Eastman Chemical has developed a circular economy approach for ethyl acetate production through their innovative carbon renewal technology. This process breaks down waste plastic materials into molecular building blocks, which are then used as feedstock for manufacturing new materials, including ethyl acetate[1]. The company's method can process a wide variety of waste plastics, including those that are traditionally difficult to recycle[2]. Eastman's circular recycling process reduces greenhouse gas emissions by up to 20-50% compared to traditional production methods[3]. Furthermore, the company has implemented a closed-loop system that captures and reuses process solvents, minimizing waste and improving overall efficiency[4]. Eastman has also invested in advanced purification technologies to ensure the high quality of the ethyl acetate produced from recycled materials[5].

Strengths: Addresses plastic waste issues, significant reduction in greenhouse gas emissions, and versatility in feedstock. Weaknesses: Potential challenges in scaling up the technology and ensuring consistent quality of recycled feedstock.

Innovations in Sustainable Ethyl Acetate Production

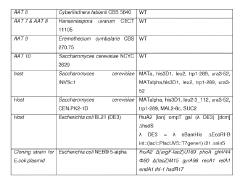

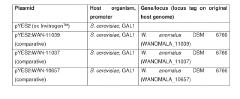

Alcohol acetyl transferases for ethyl acetate production

PatentWO2018100097A1

Innovation

- Identification and utilization of novel polypeptides with alcohol acetyl transferase activity, specifically those with an alpha-beta hydrolase fold and a serine-histidine or serine-aspartic acid-histidine triad, for microbial production of ethyl acetate from ethanol and acetyl coenzyme A, using recombinant expression vectors in suitable host cells like E. coli and yeast species.

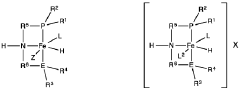

Homogeneous iron catalysts for the conversion of ethanol to ethyl acetate and hydrogen

PatentWO2019027965A1

Innovation

- A process utilizing a homogeneous iron catalyst with a tridentate pincer ligand for dehydrogenative coupling of ethanol at moderate temperatures, producing ethyl acetate efficiently and selectively, with iron loadings as low as 0.001 mol%, allowing for continuous operation and easy separation of ethyl acetate from the catalyst.

Environmental Impact Assessment

The environmental impact assessment of ethyl acetate production and its role in circular economy models reveals both challenges and opportunities. Traditional production methods of ethyl acetate, primarily through the esterification of ethanol and acetic acid, have been associated with significant environmental concerns. These include high energy consumption, greenhouse gas emissions, and the generation of hazardous waste byproducts.

However, recent advancements in green chemistry and sustainable manufacturing processes have led to more environmentally friendly production methods. Bio-based ethyl acetate, derived from renewable resources such as biomass, has shown promise in reducing the carbon footprint of production. Life cycle assessments indicate that bio-based ethyl acetate can potentially reduce greenhouse gas emissions by up to 50% compared to conventional petrochemical-based production.

Water consumption and wastewater generation are critical environmental factors in ethyl acetate production. Traditional methods often require substantial amounts of water for cooling and separation processes. Innovative technologies, such as reactive distillation and membrane separation, have demonstrated significant reductions in water usage and wastewater generation, contributing to more sustainable production practices.

In the context of circular economy models, ethyl acetate presents opportunities for closed-loop systems. The solvent properties of ethyl acetate make it suitable for various industrial applications, including paints, coatings, and pharmaceuticals. Implementing efficient recycling and recovery systems can significantly reduce the environmental impact of ethyl acetate use. Advanced distillation techniques and solvent recovery units have shown recovery rates of up to 95%, minimizing waste and reducing the need for virgin material production.

The biodegradability of ethyl acetate is another crucial aspect of its environmental profile. While it is considered readily biodegradable in both aerobic and anaerobic conditions, proper handling and disposal practices are essential to prevent soil and water contamination. Implementing best practices in storage, transportation, and end-of-life management can mitigate potential environmental risks associated with ethyl acetate use.

Integrating ethyl acetate into circular economy models also involves considering its potential for upcycling and repurposing. Research has shown promising results in using recovered ethyl acetate as a feedstock for other chemical processes, further extending its lifecycle and reducing overall environmental impact. This approach aligns with the principles of industrial symbiosis, where waste streams from one process become valuable inputs for another.

However, recent advancements in green chemistry and sustainable manufacturing processes have led to more environmentally friendly production methods. Bio-based ethyl acetate, derived from renewable resources such as biomass, has shown promise in reducing the carbon footprint of production. Life cycle assessments indicate that bio-based ethyl acetate can potentially reduce greenhouse gas emissions by up to 50% compared to conventional petrochemical-based production.

Water consumption and wastewater generation are critical environmental factors in ethyl acetate production. Traditional methods often require substantial amounts of water for cooling and separation processes. Innovative technologies, such as reactive distillation and membrane separation, have demonstrated significant reductions in water usage and wastewater generation, contributing to more sustainable production practices.

In the context of circular economy models, ethyl acetate presents opportunities for closed-loop systems. The solvent properties of ethyl acetate make it suitable for various industrial applications, including paints, coatings, and pharmaceuticals. Implementing efficient recycling and recovery systems can significantly reduce the environmental impact of ethyl acetate use. Advanced distillation techniques and solvent recovery units have shown recovery rates of up to 95%, minimizing waste and reducing the need for virgin material production.

The biodegradability of ethyl acetate is another crucial aspect of its environmental profile. While it is considered readily biodegradable in both aerobic and anaerobic conditions, proper handling and disposal practices are essential to prevent soil and water contamination. Implementing best practices in storage, transportation, and end-of-life management can mitigate potential environmental risks associated with ethyl acetate use.

Integrating ethyl acetate into circular economy models also involves considering its potential for upcycling and repurposing. Research has shown promising results in using recovered ethyl acetate as a feedstock for other chemical processes, further extending its lifecycle and reducing overall environmental impact. This approach aligns with the principles of industrial symbiosis, where waste streams from one process become valuable inputs for another.

Regulatory Framework for Circular Chemical Industry

The regulatory framework for the circular chemical industry plays a crucial role in promoting the sustainable use of ethyl acetate and other chemicals within circular economy models. As governments and international organizations increasingly recognize the importance of transitioning to a circular economy, new regulations and policies are being developed to support this shift.

At the European Union level, the Circular Economy Action Plan, adopted in 2020, sets out a comprehensive framework for promoting circularity across various sectors, including the chemical industry. This plan includes measures to incentivize the design of sustainable chemical products, enhance recycling processes, and reduce waste generation. Specifically for ethyl acetate, regulations such as the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) ensure its safe use and proper handling throughout its lifecycle.

In the United States, the Environmental Protection Agency (EPA) has implemented the Sustainable Materials Management (SMM) program, which aims to promote the circular use of materials, including chemicals like ethyl acetate. The program encourages manufacturers to consider the entire lifecycle of their products and to implement strategies for reducing waste and increasing recycling rates.

Many countries have also introduced Extended Producer Responsibility (EPR) schemes, which hold manufacturers accountable for the entire lifecycle of their products, including disposal and recycling. These regulations incentivize companies to design products with circularity in mind, potentially leading to increased use of recyclable solvents like ethyl acetate.

The chemical industry itself has taken proactive steps to align with circular economy principles. Initiatives such as the European Chemical Industry Council's (Cefic) Circular Economy Action Plan outline strategies for increasing the circularity of chemical products, including the development of new recycling technologies and the promotion of bio-based feedstocks.

International standards organizations, such as the International Organization for Standardization (ISO), have developed guidelines for implementing circular economy practices. ISO/TC 323 focuses on circular economy standards, providing a framework for organizations to assess and improve their circularity, which can be applied to the production and use of ethyl acetate.

As the regulatory landscape continues to evolve, it is likely that more stringent requirements for chemical circularity will be implemented. This may include mandatory recycling targets, restrictions on single-use chemicals, and incentives for the development of more sustainable chemical processes. For ethyl acetate and similar solvents, this could lead to increased focus on recovery and reuse technologies, as well as the development of bio-based alternatives.

At the European Union level, the Circular Economy Action Plan, adopted in 2020, sets out a comprehensive framework for promoting circularity across various sectors, including the chemical industry. This plan includes measures to incentivize the design of sustainable chemical products, enhance recycling processes, and reduce waste generation. Specifically for ethyl acetate, regulations such as the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) ensure its safe use and proper handling throughout its lifecycle.

In the United States, the Environmental Protection Agency (EPA) has implemented the Sustainable Materials Management (SMM) program, which aims to promote the circular use of materials, including chemicals like ethyl acetate. The program encourages manufacturers to consider the entire lifecycle of their products and to implement strategies for reducing waste and increasing recycling rates.

Many countries have also introduced Extended Producer Responsibility (EPR) schemes, which hold manufacturers accountable for the entire lifecycle of their products, including disposal and recycling. These regulations incentivize companies to design products with circularity in mind, potentially leading to increased use of recyclable solvents like ethyl acetate.

The chemical industry itself has taken proactive steps to align with circular economy principles. Initiatives such as the European Chemical Industry Council's (Cefic) Circular Economy Action Plan outline strategies for increasing the circularity of chemical products, including the development of new recycling technologies and the promotion of bio-based feedstocks.

International standards organizations, such as the International Organization for Standardization (ISO), have developed guidelines for implementing circular economy practices. ISO/TC 323 focuses on circular economy standards, providing a framework for organizations to assess and improve their circularity, which can be applied to the production and use of ethyl acetate.

As the regulatory landscape continues to evolve, it is likely that more stringent requirements for chemical circularity will be implemented. This may include mandatory recycling targets, restrictions on single-use chemicals, and incentives for the development of more sustainable chemical processes. For ethyl acetate and similar solvents, this could lead to increased focus on recovery and reuse technologies, as well as the development of bio-based alternatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!