Induction motors in advanced sensor integration applications

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Induction Motor Sensor Integration Background

Induction motors have been a cornerstone of industrial applications for over a century, providing reliable and efficient power for a wide range of machinery. In recent years, the integration of advanced sensors into these motors has opened up new possibilities for performance optimization, predictive maintenance, and energy efficiency. This technological convergence represents a significant leap forward in motor control and monitoring capabilities.

The evolution of sensor technology has been a key driver in this integration process. Traditional sensors, such as thermocouples and encoders, have been supplemented by more sophisticated devices, including vibration sensors, current sensors, and wireless communication modules. These advancements have enabled real-time monitoring of critical motor parameters, allowing for more precise control and early detection of potential issues.

The push towards Industry 4.0 and the Industrial Internet of Things (IIoT) has further accelerated the adoption of sensor-integrated induction motors. As factories and industrial processes become increasingly interconnected, the demand for smart, data-driven motor systems has grown exponentially. This trend has led to the development of motors that not only provide mechanical power but also serve as intelligent nodes in a larger industrial network.

One of the primary motivations behind sensor integration in induction motors is the pursuit of enhanced energy efficiency. With global energy consumption on the rise and increasing pressure to reduce carbon footprints, industries are seeking ways to optimize their power usage. Advanced sensors allow for fine-tuning of motor operations based on load conditions, ambient temperature, and other factors, resulting in significant energy savings over time.

Predictive maintenance is another critical area where sensor integration has made substantial impacts. By continuously monitoring parameters such as vibration, temperature, and current draw, it is possible to detect early signs of wear or impending failure. This proactive approach to maintenance can dramatically reduce downtime, extend motor lifespan, and lower overall operational costs.

The integration of sensors has also facilitated the development of more sophisticated control algorithms. Variable frequency drives (VFDs) can now utilize real-time data from integrated sensors to adjust motor speed and torque with unprecedented precision. This level of control not only improves process efficiency but also enables new applications in fields such as robotics and automation, where precise motor control is paramount.

As we look towards the future, the trajectory of induction motor sensor integration points towards even greater levels of sophistication and functionality. The miniaturization of sensor technology, coupled with advancements in wireless communication and edge computing, promises to deliver motors with ever-increasing intelligence and autonomy. These developments are set to redefine the role of induction motors in industrial applications, transforming them from simple power sources to key components in the smart factories of tomorrow.

The evolution of sensor technology has been a key driver in this integration process. Traditional sensors, such as thermocouples and encoders, have been supplemented by more sophisticated devices, including vibration sensors, current sensors, and wireless communication modules. These advancements have enabled real-time monitoring of critical motor parameters, allowing for more precise control and early detection of potential issues.

The push towards Industry 4.0 and the Industrial Internet of Things (IIoT) has further accelerated the adoption of sensor-integrated induction motors. As factories and industrial processes become increasingly interconnected, the demand for smart, data-driven motor systems has grown exponentially. This trend has led to the development of motors that not only provide mechanical power but also serve as intelligent nodes in a larger industrial network.

One of the primary motivations behind sensor integration in induction motors is the pursuit of enhanced energy efficiency. With global energy consumption on the rise and increasing pressure to reduce carbon footprints, industries are seeking ways to optimize their power usage. Advanced sensors allow for fine-tuning of motor operations based on load conditions, ambient temperature, and other factors, resulting in significant energy savings over time.

Predictive maintenance is another critical area where sensor integration has made substantial impacts. By continuously monitoring parameters such as vibration, temperature, and current draw, it is possible to detect early signs of wear or impending failure. This proactive approach to maintenance can dramatically reduce downtime, extend motor lifespan, and lower overall operational costs.

The integration of sensors has also facilitated the development of more sophisticated control algorithms. Variable frequency drives (VFDs) can now utilize real-time data from integrated sensors to adjust motor speed and torque with unprecedented precision. This level of control not only improves process efficiency but also enables new applications in fields such as robotics and automation, where precise motor control is paramount.

As we look towards the future, the trajectory of induction motor sensor integration points towards even greater levels of sophistication and functionality. The miniaturization of sensor technology, coupled with advancements in wireless communication and edge computing, promises to deliver motors with ever-increasing intelligence and autonomy. These developments are set to redefine the role of induction motors in industrial applications, transforming them from simple power sources to key components in the smart factories of tomorrow.

Market Analysis for Smart Induction Motors

The market for smart induction motors is experiencing significant growth, driven by the increasing demand for energy-efficient and intelligent industrial solutions. As industries worldwide focus on optimizing their operations and reducing energy consumption, smart induction motors have emerged as a key technology in advanced sensor integration applications. These motors, equipped with integrated sensors and advanced control systems, offer improved performance, reliability, and energy efficiency compared to traditional induction motors.

The global smart induction motor market is expected to expand at a compound annual growth rate (CAGR) of over 6% from 2021 to 2026. This growth is primarily attributed to the rising adoption of Industrial Internet of Things (IIoT) technologies and the increasing emphasis on predictive maintenance in manufacturing and process industries. The market size is projected to reach several billion dollars by 2026, with North America and Europe leading in terms of adoption and market share.

Key industries driving the demand for smart induction motors include automotive manufacturing, oil and gas, power generation, and water treatment. These sectors are increasingly recognizing the benefits of advanced sensor integration in motors, such as real-time monitoring of motor health, improved energy management, and enhanced operational efficiency. The automotive industry, in particular, is showing strong interest in smart induction motors for their potential to optimize production lines and reduce downtime.

The market is characterized by a growing trend towards customization and modular designs, allowing manufacturers to tailor smart induction motors to specific application requirements. This flexibility is particularly valuable in industries with diverse operational needs, such as chemical processing and food and beverage production. Additionally, the integration of artificial intelligence and machine learning algorithms in motor control systems is opening up new possibilities for predictive maintenance and adaptive performance optimization.

Despite the positive growth outlook, the market faces challenges such as high initial costs and the need for skilled personnel to operate and maintain these advanced systems. However, the long-term benefits of reduced energy consumption, improved reliability, and decreased maintenance costs are expected to outweigh these initial barriers. As a result, many industrial players are viewing the adoption of smart induction motors as a strategic investment in their operational future.

Geographically, while developed markets in North America and Europe currently lead in adoption, emerging economies in Asia-Pacific and Latin America are expected to show rapid growth in the coming years. This is driven by increasing industrialization, government initiatives promoting energy efficiency, and the modernization of manufacturing sectors in these regions. China, in particular, is poised to become a significant market for smart induction motors, supported by its ambitious industrial automation and smart manufacturing initiatives.

The global smart induction motor market is expected to expand at a compound annual growth rate (CAGR) of over 6% from 2021 to 2026. This growth is primarily attributed to the rising adoption of Industrial Internet of Things (IIoT) technologies and the increasing emphasis on predictive maintenance in manufacturing and process industries. The market size is projected to reach several billion dollars by 2026, with North America and Europe leading in terms of adoption and market share.

Key industries driving the demand for smart induction motors include automotive manufacturing, oil and gas, power generation, and water treatment. These sectors are increasingly recognizing the benefits of advanced sensor integration in motors, such as real-time monitoring of motor health, improved energy management, and enhanced operational efficiency. The automotive industry, in particular, is showing strong interest in smart induction motors for their potential to optimize production lines and reduce downtime.

The market is characterized by a growing trend towards customization and modular designs, allowing manufacturers to tailor smart induction motors to specific application requirements. This flexibility is particularly valuable in industries with diverse operational needs, such as chemical processing and food and beverage production. Additionally, the integration of artificial intelligence and machine learning algorithms in motor control systems is opening up new possibilities for predictive maintenance and adaptive performance optimization.

Despite the positive growth outlook, the market faces challenges such as high initial costs and the need for skilled personnel to operate and maintain these advanced systems. However, the long-term benefits of reduced energy consumption, improved reliability, and decreased maintenance costs are expected to outweigh these initial barriers. As a result, many industrial players are viewing the adoption of smart induction motors as a strategic investment in their operational future.

Geographically, while developed markets in North America and Europe currently lead in adoption, emerging economies in Asia-Pacific and Latin America are expected to show rapid growth in the coming years. This is driven by increasing industrialization, government initiatives promoting energy efficiency, and the modernization of manufacturing sectors in these regions. China, in particular, is poised to become a significant market for smart induction motors, supported by its ambitious industrial automation and smart manufacturing initiatives.

Current Challenges in Motor Sensor Integration

The integration of advanced sensors into induction motors presents several significant challenges that researchers and engineers are currently grappling with. One of the primary obstacles is the harsh operating environment within the motor, characterized by high temperatures, vibrations, and electromagnetic interference. These conditions can severely impact sensor performance and longevity, necessitating the development of robust and resilient sensing technologies.

Miniaturization of sensors while maintaining their accuracy and reliability is another critical challenge. As motor designs become more compact and efficient, the available space for sensor integration diminishes. This constraint requires innovative approaches to sensor design and placement, often involving the use of microelectromechanical systems (MEMS) technology or advanced packaging techniques.

The need for real-time, high-precision data acquisition and processing poses yet another hurdle. Modern motor control systems demand increasingly accurate and rapid feedback on various parameters such as temperature, vibration, and magnetic field strength. This requirement pushes the boundaries of sensor capabilities and data processing algorithms, often necessitating the implementation of edge computing solutions to reduce latency and improve response times.

Power management for integrated sensors is a significant concern, especially in applications where energy efficiency is paramount. Developing low-power sensors and energy harvesting techniques to power these devices without compromising motor performance is an ongoing area of research and development.

Electromagnetic compatibility (EMC) issues arise when integrating electronic sensors into the electrically noisy environment of an induction motor. Shielding and signal processing techniques must be employed to ensure accurate sensor readings and prevent interference with motor operation or other nearby electronic systems.

The cost-effectiveness of sensor integration is a persistent challenge, particularly for mass-produced motors. Balancing the added value of advanced sensing capabilities against the increased production costs requires careful consideration and often drives the search for innovative, low-cost sensing solutions.

Reliability and longevity of integrated sensors are crucial factors, as they must match or exceed the operational lifespan of the motor itself. This necessitates the development of sensors that can withstand prolonged exposure to harsh conditions without degradation or failure.

Lastly, the integration of sensors must not compromise the motor's performance or efficiency. This challenge requires careful design considerations to ensure that the presence of sensors does not introduce additional losses or mechanical imbalances that could affect motor operation.

Miniaturization of sensors while maintaining their accuracy and reliability is another critical challenge. As motor designs become more compact and efficient, the available space for sensor integration diminishes. This constraint requires innovative approaches to sensor design and placement, often involving the use of microelectromechanical systems (MEMS) technology or advanced packaging techniques.

The need for real-time, high-precision data acquisition and processing poses yet another hurdle. Modern motor control systems demand increasingly accurate and rapid feedback on various parameters such as temperature, vibration, and magnetic field strength. This requirement pushes the boundaries of sensor capabilities and data processing algorithms, often necessitating the implementation of edge computing solutions to reduce latency and improve response times.

Power management for integrated sensors is a significant concern, especially in applications where energy efficiency is paramount. Developing low-power sensors and energy harvesting techniques to power these devices without compromising motor performance is an ongoing area of research and development.

Electromagnetic compatibility (EMC) issues arise when integrating electronic sensors into the electrically noisy environment of an induction motor. Shielding and signal processing techniques must be employed to ensure accurate sensor readings and prevent interference with motor operation or other nearby electronic systems.

The cost-effectiveness of sensor integration is a persistent challenge, particularly for mass-produced motors. Balancing the added value of advanced sensing capabilities against the increased production costs requires careful consideration and often drives the search for innovative, low-cost sensing solutions.

Reliability and longevity of integrated sensors are crucial factors, as they must match or exceed the operational lifespan of the motor itself. This necessitates the development of sensors that can withstand prolonged exposure to harsh conditions without degradation or failure.

Lastly, the integration of sensors must not compromise the motor's performance or efficiency. This challenge requires careful design considerations to ensure that the presence of sensors does not introduce additional losses or mechanical imbalances that could affect motor operation.

Existing Sensor Integration Solutions

01 Design and construction of induction motors

This category covers the fundamental design principles and construction techniques for induction motors. It includes innovations in rotor and stator designs, winding configurations, and material selection to improve efficiency and performance.- Design and construction of induction motors: This category covers the fundamental design and construction aspects of induction motors, including rotor and stator configurations, winding arrangements, and core materials. Innovations in these areas aim to improve motor efficiency, power output, and overall performance.

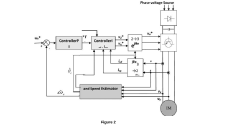

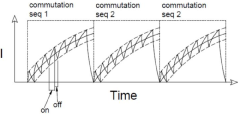

- Control systems for induction motors: Control systems play a crucial role in regulating the speed, torque, and efficiency of induction motors. This category encompasses various control strategies, including vector control, direct torque control, and sensorless control techniques, as well as the implementation of advanced microcontrollers and power electronics.

- Energy efficiency improvements in induction motors: This category focuses on innovations aimed at enhancing the energy efficiency of induction motors. It includes advancements in motor design, materials, and manufacturing processes to reduce losses and improve overall performance, as well as the development of high-efficiency motor standards and regulations.

- Specialized applications of induction motors: Induction motors are used in a wide range of specialized applications, each with unique requirements. This category covers adaptations and modifications of induction motors for specific industries or operating conditions, such as high-speed motors, submersible motors, or motors for hazardous environments.

- Diagnostics and condition monitoring of induction motors: This category encompasses techniques and technologies for monitoring the health and performance of induction motors. It includes methods for fault detection, predictive maintenance, and real-time monitoring of motor parameters to ensure optimal operation and prevent unexpected failures.

02 Control systems for induction motors

This point focuses on the development of control systems and methods for induction motors. It includes advancements in speed control, torque regulation, and power factor correction to enhance motor performance and efficiency in various applications.Expand Specific Solutions03 Efficiency improvements in induction motors

This category encompasses innovations aimed at improving the overall efficiency of induction motors. It includes techniques for reducing energy losses, optimizing magnetic circuits, and enhancing thermal management to increase motor efficiency across different operating conditions.Expand Specific Solutions04 Specialized applications of induction motors

This point covers the adaptation and optimization of induction motors for specific applications. It includes designs tailored for industrial machinery, electric vehicles, renewable energy systems, and other specialized uses requiring unique motor characteristics.Expand Specific Solutions05 Manufacturing and assembly techniques for induction motors

This category focuses on innovative manufacturing processes and assembly techniques for induction motors. It includes advancements in production methods, automation, quality control, and cost-effective manufacturing to improve motor reliability and reduce production costs.Expand Specific Solutions

Key Players in Motor Sensor Integration

The research on induction motors in advanced sensor integration applications is in a mature stage of development, with a significant market size and established technological foundations. The competitive landscape is characterized by a mix of major automotive manufacturers, industrial automation companies, and specialized electronics firms. Companies like Hyundai Motor Co., Kia Corp., and GM Global Technology Operations are leveraging this technology to enhance their vehicle performance and efficiency. Simultaneously, industrial players such as Rockwell Automation Technologies and Mitsubishi Electric Corp. are integrating advanced sensors into their motor systems for improved control and monitoring. The market is further diversified by the presence of specialized firms like Regal Beloit America and Visteon Global Technologies, focusing on niche applications and innovations in sensor-integrated induction motor technology.

GM Global Technology Operations LLC

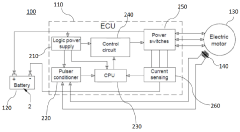

Technical Solution: GM has developed advanced sensor integration systems for induction motors in electric vehicles. Their technology utilizes a combination of Hall effect sensors and resolver-based position sensing to accurately monitor motor performance and control[1]. The system integrates temperature sensors to prevent overheating and optimize efficiency. GM's solution also incorporates current sensors for precise torque control and fault detection. The integrated sensor package communicates with the motor control unit via a high-speed CAN bus, enabling real-time adjustments and diagnostics[3]. This comprehensive approach allows for improved motor efficiency, extended range, and enhanced reliability in GM's electric vehicle lineup.

Strengths: Comprehensive sensor integration, real-time monitoring and control, improved efficiency and reliability. Weaknesses: Potentially higher cost due to multiple sensor types, complexity in calibration and maintenance.

Rockwell Automation Technologies, Inc.

Technical Solution: Rockwell Automation has developed a sophisticated sensor integration system for induction motors in industrial applications. Their solution combines smart sensors with advanced analytics to provide predictive maintenance capabilities[2]. The system utilizes vibration sensors, temperature monitors, and current sensors to create a comprehensive picture of motor health. Data from these sensors is processed using edge computing devices, which apply machine learning algorithms to detect anomalies and predict potential failures[4]. The integrated system communicates with Rockwell's FactoryTalk analytics platform, allowing for centralized monitoring and control of multiple motors across a facility. This approach enables proactive maintenance scheduling, reducing downtime and extending motor life.

Strengths: Predictive maintenance capabilities, scalable across multiple motors, integration with existing industrial control systems. Weaknesses: May require significant initial investment, potential for data overload in large-scale implementations.

Core Innovations in Motor Sensing

Cutting-edge sensor less speed regulation in induction motor

PatentPendingIN202441004199A

Innovation

- A sensorless speed regulation system utilizing advanced algorithms and machine learning for real-time feedback and dynamic adjustments, eliminating the need for external sensors and enhancing adaptability to load changes.

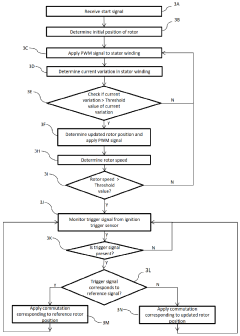

Method and system for controlling an integrated starter-generator

PatentUndeterminedIN201621004628A

Innovation

- A method and system for controlling an integrated starter-generator using an ignition trigger sensor to determine the rotor position and apply pulse-width-modulated signals to the stator windings, eliminating the need for hall-effect sensors and reducing reliance on internal engine casing components.

Energy Efficiency Implications

The integration of advanced sensors in induction motors has significant implications for energy efficiency in various industrial applications. By providing real-time data on motor performance, these sensors enable more precise control and optimization of motor operation, leading to substantial energy savings.

One of the primary ways sensor integration improves energy efficiency is through enhanced motor condition monitoring. Advanced sensors can detect early signs of motor degradation, such as bearing wear or insulation breakdown, allowing for timely maintenance interventions. This proactive approach prevents efficiency losses associated with deteriorating motor components and extends the overall lifespan of the motor, reducing energy consumption over time.

Furthermore, sensor integration facilitates dynamic load matching, allowing induction motors to operate at their optimal efficiency points across varying load conditions. By continuously monitoring parameters such as speed, torque, and power factor, the motor control system can adjust operating parameters in real-time to maintain peak efficiency. This adaptive control strategy is particularly beneficial in applications with fluctuating load demands, such as in manufacturing processes or HVAC systems.

The incorporation of temperature sensors in critical motor components enables more effective thermal management. By monitoring winding and bearing temperatures, the control system can optimize cooling strategies and prevent overheating, which is a significant source of energy loss in electric motors. This thermal optimization not only improves energy efficiency but also enhances motor reliability and longevity.

Advanced sensor integration also supports the implementation of sophisticated energy management systems at the plant or facility level. By providing detailed data on motor performance and energy consumption, these systems can identify opportunities for load shifting, peak demand reduction, and overall energy optimization across multiple motor-driven processes.

Moreover, the data collected from integrated sensors enables the development of more accurate motor models and digital twins. These virtual representations of physical motors allow for simulation and optimization of motor performance under various operating conditions, leading to improved design and control strategies that further enhance energy efficiency.

In the context of variable frequency drives (VFDs), sensor integration enables more precise speed control and flux optimization. By accurately measuring rotor speed and position, VFDs can minimize slip and optimize the air gap flux, resulting in reduced losses and improved overall system efficiency.

As industrial processes become increasingly automated and interconnected, the role of sensor-integrated induction motors in energy efficiency strategies is expected to grow. The ability to seamlessly integrate motor performance data into broader industrial IoT ecosystems will facilitate more comprehensive energy management approaches, potentially leading to significant reductions in industrial energy consumption and associated carbon emissions.

One of the primary ways sensor integration improves energy efficiency is through enhanced motor condition monitoring. Advanced sensors can detect early signs of motor degradation, such as bearing wear or insulation breakdown, allowing for timely maintenance interventions. This proactive approach prevents efficiency losses associated with deteriorating motor components and extends the overall lifespan of the motor, reducing energy consumption over time.

Furthermore, sensor integration facilitates dynamic load matching, allowing induction motors to operate at their optimal efficiency points across varying load conditions. By continuously monitoring parameters such as speed, torque, and power factor, the motor control system can adjust operating parameters in real-time to maintain peak efficiency. This adaptive control strategy is particularly beneficial in applications with fluctuating load demands, such as in manufacturing processes or HVAC systems.

The incorporation of temperature sensors in critical motor components enables more effective thermal management. By monitoring winding and bearing temperatures, the control system can optimize cooling strategies and prevent overheating, which is a significant source of energy loss in electric motors. This thermal optimization not only improves energy efficiency but also enhances motor reliability and longevity.

Advanced sensor integration also supports the implementation of sophisticated energy management systems at the plant or facility level. By providing detailed data on motor performance and energy consumption, these systems can identify opportunities for load shifting, peak demand reduction, and overall energy optimization across multiple motor-driven processes.

Moreover, the data collected from integrated sensors enables the development of more accurate motor models and digital twins. These virtual representations of physical motors allow for simulation and optimization of motor performance under various operating conditions, leading to improved design and control strategies that further enhance energy efficiency.

In the context of variable frequency drives (VFDs), sensor integration enables more precise speed control and flux optimization. By accurately measuring rotor speed and position, VFDs can minimize slip and optimize the air gap flux, resulting in reduced losses and improved overall system efficiency.

As industrial processes become increasingly automated and interconnected, the role of sensor-integrated induction motors in energy efficiency strategies is expected to grow. The ability to seamlessly integrate motor performance data into broader industrial IoT ecosystems will facilitate more comprehensive energy management approaches, potentially leading to significant reductions in industrial energy consumption and associated carbon emissions.

Industrial IoT Integration Prospects

The integration of induction motors with advanced sensor technologies presents significant opportunities for Industrial IoT applications. As manufacturing processes become increasingly automated and interconnected, the demand for smart, sensor-equipped motors is expected to grow substantially. These advanced motors can provide real-time data on performance, energy consumption, and potential maintenance issues, enabling predictive maintenance strategies and optimizing overall system efficiency.

In the context of Industrial IoT, induction motors equipped with integrated sensors can serve as crucial data collection points within a larger network of interconnected devices. This integration allows for seamless communication between motors and other industrial equipment, facilitating more comprehensive monitoring and control of entire production lines. The data gathered from these smart motors can be analyzed using advanced analytics and machine learning algorithms to identify patterns, predict failures, and optimize operational parameters.

The prospects for Industrial IoT integration extend beyond individual motor performance. By incorporating induction motors with advanced sensors into a broader IoT ecosystem, manufacturers can achieve greater visibility across their entire production process. This holistic approach enables more efficient resource allocation, improved quality control, and enhanced decision-making capabilities. For instance, data from multiple motors can be aggregated and analyzed to identify bottlenecks in production or opportunities for energy savings across the entire facility.

Furthermore, the integration of induction motors with Industrial IoT systems opens up new possibilities for remote monitoring and control. Operators can access real-time motor performance data from anywhere, allowing for quick responses to potential issues and reducing downtime. This capability is particularly valuable for large-scale industrial operations or geographically dispersed facilities, where on-site monitoring may be challenging or cost-prohibitive.

As the Industrial IoT landscape continues to evolve, the role of induction motors with advanced sensor integration is likely to become increasingly central to smart manufacturing strategies. The data generated by these motors will contribute to the development of more sophisticated digital twins, enabling accurate simulations of industrial processes and facilitating continuous improvement. Additionally, the integration of these smart motors with emerging technologies such as 5G networks and edge computing will further enhance their capabilities, enabling faster data processing and more responsive control systems.

In the context of Industrial IoT, induction motors equipped with integrated sensors can serve as crucial data collection points within a larger network of interconnected devices. This integration allows for seamless communication between motors and other industrial equipment, facilitating more comprehensive monitoring and control of entire production lines. The data gathered from these smart motors can be analyzed using advanced analytics and machine learning algorithms to identify patterns, predict failures, and optimize operational parameters.

The prospects for Industrial IoT integration extend beyond individual motor performance. By incorporating induction motors with advanced sensors into a broader IoT ecosystem, manufacturers can achieve greater visibility across their entire production process. This holistic approach enables more efficient resource allocation, improved quality control, and enhanced decision-making capabilities. For instance, data from multiple motors can be aggregated and analyzed to identify bottlenecks in production or opportunities for energy savings across the entire facility.

Furthermore, the integration of induction motors with Industrial IoT systems opens up new possibilities for remote monitoring and control. Operators can access real-time motor performance data from anywhere, allowing for quick responses to potential issues and reducing downtime. This capability is particularly valuable for large-scale industrial operations or geographically dispersed facilities, where on-site monitoring may be challenging or cost-prohibitive.

As the Industrial IoT landscape continues to evolve, the role of induction motors with advanced sensor integration is likely to become increasingly central to smart manufacturing strategies. The data generated by these motors will contribute to the development of more sophisticated digital twins, enabling accurate simulations of industrial processes and facilitating continuous improvement. Additionally, the integration of these smart motors with emerging technologies such as 5G networks and edge computing will further enhance their capabilities, enabling faster data processing and more responsive control systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!