Soft Pneumatic Actuators for Automated Agricultural Technologies

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Soft Pneumatic Actuators Background and Objectives

Soft pneumatic actuators (SPAs) represent a revolutionary advancement in the field of robotics and automation, characterized by their flexibility, lightweight nature, and adaptability to various environments. The evolution of these actuators can be traced back to the early 2000s when researchers began exploring alternatives to rigid robotic systems. Over the past two decades, SPAs have undergone significant transformations, transitioning from simple proof-of-concept designs to sophisticated systems capable of complex movements and interactions.

The agricultural sector presents unique challenges that traditional rigid robotic systems struggle to address effectively. Crops and plants are delicate, varied in structure, and grow in unpredictable environments. This necessitates handling solutions that can adapt to these conditions without causing damage. SPAs, with their inherent compliance and gentle interaction capabilities, offer promising solutions to these challenges, making them particularly suitable for agricultural applications.

Current technological trends in SPA development focus on enhancing material properties, improving control systems, and optimizing pneumatic networks. Advancements in materials science have led to the development of more durable and responsive elastomers, while innovations in control algorithms have improved precision and reliability. Additionally, the integration of sensors and feedback mechanisms has enabled more intelligent and adaptive behavior in SPA systems.

The primary objective of this research is to explore and advance the application of soft pneumatic actuators in automated agricultural technologies. Specifically, we aim to develop SPAs that can effectively perform tasks such as harvesting delicate fruits, selective weeding, and plant monitoring without causing damage to crops or soil structures. This involves addressing key technical challenges including durability in harsh agricultural environments, precision control for varied tasks, and scalability for commercial implementation.

Furthermore, this research seeks to establish a comprehensive understanding of the design principles and operational parameters that govern SPA performance in agricultural settings. By systematically investigating factors such as material selection, pneumatic network design, and control strategies, we aim to create a foundation for future innovations in this field.

The long-term vision of this research extends beyond immediate applications to encompass broader implications for sustainable agriculture. By enabling more precise and gentle interactions with crops and soil, SPAs have the potential to reduce resource consumption, minimize environmental impact, and enhance crop yields. This aligns with global efforts to develop more sustainable and efficient agricultural practices in the face of growing food demands and environmental challenges.

The agricultural sector presents unique challenges that traditional rigid robotic systems struggle to address effectively. Crops and plants are delicate, varied in structure, and grow in unpredictable environments. This necessitates handling solutions that can adapt to these conditions without causing damage. SPAs, with their inherent compliance and gentle interaction capabilities, offer promising solutions to these challenges, making them particularly suitable for agricultural applications.

Current technological trends in SPA development focus on enhancing material properties, improving control systems, and optimizing pneumatic networks. Advancements in materials science have led to the development of more durable and responsive elastomers, while innovations in control algorithms have improved precision and reliability. Additionally, the integration of sensors and feedback mechanisms has enabled more intelligent and adaptive behavior in SPA systems.

The primary objective of this research is to explore and advance the application of soft pneumatic actuators in automated agricultural technologies. Specifically, we aim to develop SPAs that can effectively perform tasks such as harvesting delicate fruits, selective weeding, and plant monitoring without causing damage to crops or soil structures. This involves addressing key technical challenges including durability in harsh agricultural environments, precision control for varied tasks, and scalability for commercial implementation.

Furthermore, this research seeks to establish a comprehensive understanding of the design principles and operational parameters that govern SPA performance in agricultural settings. By systematically investigating factors such as material selection, pneumatic network design, and control strategies, we aim to create a foundation for future innovations in this field.

The long-term vision of this research extends beyond immediate applications to encompass broader implications for sustainable agriculture. By enabling more precise and gentle interactions with crops and soil, SPAs have the potential to reduce resource consumption, minimize environmental impact, and enhance crop yields. This aligns with global efforts to develop more sustainable and efficient agricultural practices in the face of growing food demands and environmental challenges.

Agricultural Automation Market Demand Analysis

The global agricultural automation market is experiencing significant growth, driven by increasing food demand, labor shortages, and the need for sustainable farming practices. According to recent market research, the agricultural automation market was valued at approximately $7 billion in 2021 and is projected to reach $16.5 billion by 2027, growing at a CAGR of 14.7% during the forecast period. This substantial growth reflects the urgent need for innovative solutions like soft pneumatic actuators in agricultural applications.

Labor scarcity represents one of the most pressing challenges facing modern agriculture. In developed countries, the agricultural workforce has been steadily declining, with farm labor decreasing by 20-30% in the past decade across North America and Europe. This shortage has created a strong demand for automation technologies that can perform repetitive tasks such as harvesting, pruning, and crop maintenance with minimal human intervention.

The precision agriculture segment, which includes technologies for targeted crop management, is expected to dominate the market with a share of approximately 35%. Soft pneumatic actuators are particularly well-positioned within this segment due to their gentle handling capabilities, which are essential for delicate crops like fruits, vegetables, and ornamental plants that require careful manipulation during harvesting and processing.

Regional analysis indicates that North America currently leads the agricultural automation market with a 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 16.8% during the forecast period, driven by rapid modernization of agricultural practices in countries like China and India, where there is increasing adoption of advanced technologies to improve productivity.

End-user segmentation reveals that large-scale commercial farms currently account for 65% of the market demand for agricultural automation technologies. However, there is growing interest from small and medium-sized farms, which are increasingly adopting affordable automation solutions to remain competitive. This trend presents significant opportunities for soft pneumatic actuator technologies that can be scaled and adapted to various farm sizes and operational requirements.

Consumer preferences are also driving market demand, with increasing concerns about food safety, quality, and sustainability. The market for organic produce has grown by 12.4% annually over the past five years, creating demand for gentle handling technologies that maintain product integrity without chemical treatments. Soft pneumatic actuators offer advantages in this context due to their compliant nature and ability to handle delicate organic produce without causing damage.

Government initiatives and subsidies for agricultural modernization are further accelerating market growth. Countries across the globe have implemented policies to support smart farming practices, with the European Union allocating €10 billion for agricultural technology development in its latest budget framework, and similar initiatives emerging in the United States, China, and Japan.

Labor scarcity represents one of the most pressing challenges facing modern agriculture. In developed countries, the agricultural workforce has been steadily declining, with farm labor decreasing by 20-30% in the past decade across North America and Europe. This shortage has created a strong demand for automation technologies that can perform repetitive tasks such as harvesting, pruning, and crop maintenance with minimal human intervention.

The precision agriculture segment, which includes technologies for targeted crop management, is expected to dominate the market with a share of approximately 35%. Soft pneumatic actuators are particularly well-positioned within this segment due to their gentle handling capabilities, which are essential for delicate crops like fruits, vegetables, and ornamental plants that require careful manipulation during harvesting and processing.

Regional analysis indicates that North America currently leads the agricultural automation market with a 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 16.8% during the forecast period, driven by rapid modernization of agricultural practices in countries like China and India, where there is increasing adoption of advanced technologies to improve productivity.

End-user segmentation reveals that large-scale commercial farms currently account for 65% of the market demand for agricultural automation technologies. However, there is growing interest from small and medium-sized farms, which are increasingly adopting affordable automation solutions to remain competitive. This trend presents significant opportunities for soft pneumatic actuator technologies that can be scaled and adapted to various farm sizes and operational requirements.

Consumer preferences are also driving market demand, with increasing concerns about food safety, quality, and sustainability. The market for organic produce has grown by 12.4% annually over the past five years, creating demand for gentle handling technologies that maintain product integrity without chemical treatments. Soft pneumatic actuators offer advantages in this context due to their compliant nature and ability to handle delicate organic produce without causing damage.

Government initiatives and subsidies for agricultural modernization are further accelerating market growth. Countries across the globe have implemented policies to support smart farming practices, with the European Union allocating €10 billion for agricultural technology development in its latest budget framework, and similar initiatives emerging in the United States, China, and Japan.

Current State and Challenges in Soft Robotics for Agriculture

Soft robotics represents a paradigm shift in agricultural automation, offering compliant and adaptable solutions for delicate crop handling. Currently, the field is experiencing rapid growth with significant advancements in materials science and control systems. Research institutions worldwide, including Harvard's Biodesign Lab and ETH Zurich, have developed prototype soft pneumatic actuators specifically designed for agricultural applications, demonstrating capabilities in selective harvesting and plant manipulation.

Despite these advances, the integration of soft robotics in agriculture faces substantial technical challenges. Material durability remains a critical concern, as agricultural environments expose actuators to harsh conditions including UV radiation, temperature fluctuations, moisture, and chemical exposure from pesticides and fertilizers. Most current soft materials degrade rapidly under these conditions, limiting their practical deployment in field settings.

Control precision presents another significant hurdle. While soft actuators excel in compliance and adaptability, they often lack the positional accuracy required for precise agricultural tasks such as targeted pruning or selective harvesting. The non-linear behavior of soft materials complicates the development of accurate control algorithms, resulting in unpredictable movements that can damage delicate crops.

Power efficiency and portability constraints further limit widespread adoption. Current pneumatic systems require bulky compressors and air delivery systems, making them impractical for mobile agricultural platforms. The energy requirements for maintaining pressure in pneumatic networks exceed what is feasible for battery-powered field operations, restricting their application to stationary or tethered systems.

Scalability challenges persist as most successful demonstrations remain at laboratory scale. The transition to commercial-scale agricultural operations requires manufacturing processes that can produce consistent, reliable soft actuators at volume and reasonable cost. Current fabrication methods are largely artisanal, involving manual molding and assembly processes that resist standardization.

Sensing integration represents another frontier challenge. Effective agricultural robotics requires real-time feedback about environmental conditions and interaction forces. However, embedding sensors within soft structures without compromising their mechanical properties remains technically difficult. The lack of proprioceptive and tactile sensing limits the ability of soft actuators to respond appropriately to varying crop conditions.

Regulatory and standardization frameworks for agricultural soft robotics remain underdeveloped. Unlike traditional rigid robotics, soft systems lack established safety protocols and performance metrics, creating uncertainty for commercial adoption. This regulatory gap, combined with the technical challenges, has resulted in limited field validation of soft pneumatic actuators in real agricultural settings.

Despite these advances, the integration of soft robotics in agriculture faces substantial technical challenges. Material durability remains a critical concern, as agricultural environments expose actuators to harsh conditions including UV radiation, temperature fluctuations, moisture, and chemical exposure from pesticides and fertilizers. Most current soft materials degrade rapidly under these conditions, limiting their practical deployment in field settings.

Control precision presents another significant hurdle. While soft actuators excel in compliance and adaptability, they often lack the positional accuracy required for precise agricultural tasks such as targeted pruning or selective harvesting. The non-linear behavior of soft materials complicates the development of accurate control algorithms, resulting in unpredictable movements that can damage delicate crops.

Power efficiency and portability constraints further limit widespread adoption. Current pneumatic systems require bulky compressors and air delivery systems, making them impractical for mobile agricultural platforms. The energy requirements for maintaining pressure in pneumatic networks exceed what is feasible for battery-powered field operations, restricting their application to stationary or tethered systems.

Scalability challenges persist as most successful demonstrations remain at laboratory scale. The transition to commercial-scale agricultural operations requires manufacturing processes that can produce consistent, reliable soft actuators at volume and reasonable cost. Current fabrication methods are largely artisanal, involving manual molding and assembly processes that resist standardization.

Sensing integration represents another frontier challenge. Effective agricultural robotics requires real-time feedback about environmental conditions and interaction forces. However, embedding sensors within soft structures without compromising their mechanical properties remains technically difficult. The lack of proprioceptive and tactile sensing limits the ability of soft actuators to respond appropriately to varying crop conditions.

Regulatory and standardization frameworks for agricultural soft robotics remain underdeveloped. Unlike traditional rigid robotics, soft systems lack established safety protocols and performance metrics, creating uncertainty for commercial adoption. This regulatory gap, combined with the technical challenges, has resulted in limited field validation of soft pneumatic actuators in real agricultural settings.

Current Soft Pneumatic Solutions for Agricultural Applications

01 Design and fabrication of soft pneumatic actuators

Soft pneumatic actuators are designed and fabricated using flexible materials that can deform when pressurized with air or fluid. These actuators typically consist of chambers or channels embedded within elastomeric materials that expand or contract when pressure is applied. The fabrication methods include molding, 3D printing, and layered manufacturing techniques to create the internal channels and chambers necessary for actuation. These design approaches enable the development of lightweight, compliant actuators suitable for various applications.- Design and structure of soft pneumatic actuators: Soft pneumatic actuators are designed with flexible materials that can deform when pressurized with air or other fluids. These actuators typically consist of chambers or channels embedded within elastomeric materials that expand or contract in specific ways when pressurized. The structural design determines the motion pattern, such as bending, twisting, or extending. Various geometries and material combinations are employed to achieve different movement capabilities and force outputs while maintaining the inherent compliance and safety advantages of soft robotics.

- Manufacturing techniques for soft pneumatic actuators: Manufacturing of soft pneumatic actuators involves several specialized techniques including molding, 3D printing, and layered fabrication. Silicone casting in multi-part molds is a common method, allowing for complex internal channel structures. Advanced manufacturing approaches incorporate embedded sensors, variable material stiffness, and multi-material printing to enhance functionality. These fabrication methods enable customization of actuator properties such as compliance, response time, and force generation capabilities while maintaining the soft, flexible nature essential for safe human interaction.

- Control systems and sensing for soft pneumatic actuators: Control systems for soft pneumatic actuators incorporate pressure regulation, valve control, and feedback mechanisms to achieve precise movements. These systems often utilize embedded or external sensors to monitor actuator state, position, and interaction forces. Machine learning algorithms and adaptive control strategies are implemented to compensate for the nonlinear behavior inherent in soft materials. Integration of sensing elements such as strain sensors, pressure transducers, and vision systems enables closed-loop control and responsive behavior in dynamic environments.

- Applications of soft pneumatic actuators in robotics and biomedicine: Soft pneumatic actuators find diverse applications in fields requiring safe human interaction, adaptable gripping, and biomimetic movement. In robotics, they enable compliant grippers capable of handling delicate or irregularly shaped objects without complex control systems. Biomedical applications include assistive devices, rehabilitation equipment, and minimally invasive surgical tools that can navigate through confined spaces while minimizing tissue damage. Wearable technologies incorporate these actuators for ergonomic support, motion assistance, and haptic feedback systems that conform to the human body.

- Material innovations for enhanced soft pneumatic actuator performance: Material innovations are crucial for advancing soft pneumatic actuator capabilities. Research focuses on developing elastomers with improved durability, response time, and environmental resistance. Smart materials that change properties in response to stimuli enable programmable stiffness and adaptive behavior. Fiber reinforcement techniques and composite structures enhance force output while maintaining flexibility. Biodegradable and biocompatible materials expand applications in medical and environmental fields, while self-healing compounds increase longevity and reliability in demanding operational conditions.

02 Applications in robotics and automation

Soft pneumatic actuators are increasingly used in robotics and automation systems where traditional rigid actuators are unsuitable. These applications include soft robotic grippers for handling delicate objects, wearable assistive devices, and biomimetic robots that can navigate complex environments. The inherent compliance of soft actuators makes them ideal for human-robot interaction scenarios, providing safer operation compared to conventional rigid systems. They can conform to irregular shapes and operate in unstructured environments while minimizing the risk of damage to objects or injury to humans.Expand Specific Solutions03 Control systems and sensing integration

Advanced control systems are essential for precise operation of soft pneumatic actuators. These systems often incorporate pressure sensors, position feedback mechanisms, and machine learning algorithms to achieve accurate movement and force control. Integration of sensing elements directly into the soft structure enables closed-loop control and adaptive behavior. Some designs feature embedded sensors that can detect deformation, contact forces, or environmental conditions, allowing the actuator to respond intelligently to changing situations.Expand Specific Solutions04 Novel materials and composite structures

Research in soft pneumatic actuators focuses on developing novel materials and composite structures to enhance performance characteristics. These include fiber-reinforced elastomers that can direct deformation in specific ways, multi-material designs that combine rigid and soft components, and stimuli-responsive materials that change properties under different conditions. Advanced manufacturing techniques allow for the creation of anisotropic structures that exhibit different mechanical behaviors in different directions, enabling complex motions from simple pressure inputs.Expand Specific Solutions05 Energy efficiency and portable power systems

Improving energy efficiency is a critical aspect of soft pneumatic actuator development. Innovations include optimized channel geometries to reduce pressure requirements, valve systems that minimize air consumption, and energy recovery mechanisms. For portable applications, compact air supply systems, miniature pumps, and integrated pressure reservoirs are being developed. Some designs incorporate passive elements like springs or bistable mechanisms to reduce the energy needed for actuation or to maintain positions without continuous pressure input.Expand Specific Solutions

Key Industry Players in Agricultural Soft Robotics

The soft pneumatic actuator market for agricultural automation is in an early growth phase, characterized by significant research activity but limited commercial deployment. The market is projected to expand as agriculture increasingly adopts automation technologies to address labor shortages and sustainability challenges. Leading academic institutions including Harvard College, MIT, Cornell University, and Zhejiang University are driving fundamental research, while companies like Artimus Robotics, Oxipital AI, and Parker-Hannifin are beginning to commercialize applications. The technology remains in development with varying maturity levels - basic research is well-established, but commercial-ready systems are still emerging. Collaboration between research institutions and industry partners is accelerating advancement toward practical agricultural implementations that combine soft robotics with sensing and control technologies.

President & Fellows of Harvard College

Technical Solution: Harvard's Wyss Institute has pioneered soft pneumatic actuators through their groundbreaking work on soft robotics. Their technology utilizes elastomeric materials with embedded pneumatic networks that deform in programmable ways when pressurized with air. The Harvard team has developed a comprehensive platform including fabrication techniques like multi-material 3D printing and molding processes that enable complex actuator geometries. Their agricultural applications focus on delicate crop handling, with pneumatic grippers designed specifically for harvesting fragile fruits and vegetables without damage. The actuators incorporate embedded sensing capabilities through conductive materials that change resistance during deformation, providing real-time feedback on actuator state and environmental interactions. Harvard has also developed control algorithms that account for the non-linear behavior of soft materials, enabling precise movement despite the inherent compliance of these systems.

Strengths: Superior material science expertise, particularly in silicone-based elastomers; extensive intellectual property portfolio; established fabrication methods for complex geometries. Weaknesses: Higher production costs compared to traditional rigid systems; challenges in scaling manufacturing processes for commercial agricultural deployment; potential durability concerns in harsh field conditions.

Artimus Robotics, Inc.

Technical Solution: Artimus Robotics has developed HASEL (Hydraulically Amplified Self-healing Electrostatic) actuators, representing a significant innovation in soft pneumatic technology for agricultural applications. Their proprietary actuators use electrostatic forces to displace a liquid dielectric, creating hydraulic pressure that drives shape change in flexible structures. This approach combines the programmable control of electrostatic actuators with the versatility and power of hydraulic systems. For agricultural automation, Artimus has adapted their technology to create modular actuator units that can be configured into various end-effectors for tasks like selective harvesting, precision weeding, and delicate seedling transplantation. Their systems operate at lower pressures than traditional pneumatics, reducing infrastructure requirements while maintaining force output. The company has also developed specialized coatings for their actuators that enhance durability in agricultural environments, protecting against UV exposure, chemical exposure from fertilizers, and abrasion from soil particles.

Strengths: Proprietary HASEL technology offers faster response times than conventional pneumatics; lower energy consumption during sustained positioning tasks; self-sensing capabilities reduce system complexity. Weaknesses: Limited field-testing history compared to established technologies; higher initial cost than conventional systems; requires specialized control electronics that may complicate integration with existing farm equipment.

Core Patents and Technical Literature in Soft Pneumatic Actuation

Soft robotic assistive device

PatentWO2025190946A1

Innovation

- The use of a piezoelectric resonant acoustic gas pump to minimize distortion of pressure waveforms in soft pneumatic actuators, allowing for accurate tracking of body part position and strength through pressure measurement, and precise control of actuation.

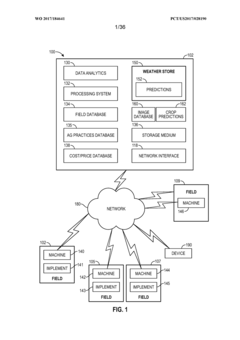

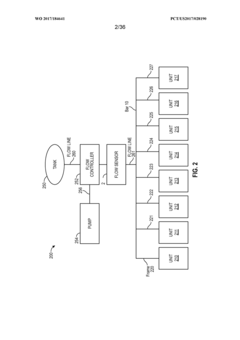

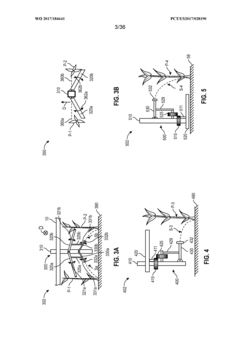

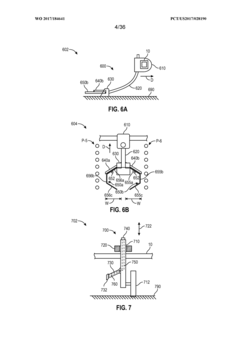

Implements and application units having at least one flexible or pivoting application member for placement of applications with respect to agricultural plants of agricultural fields

PatentWO2017184641A1

Innovation

- The development of systems with flexible or pivoting application members that adjust their position based on contact with plants, ensuring fluid outlets are oriented correctly to apply inputs directly to the rhizosphere or base regions of plants, using mechanisms like feelers, linkage members, and biasing elements to maintain equidistance from plant rows.

Environmental Impact and Sustainability Considerations

The integration of Soft Pneumatic Actuators (SPAs) in agricultural automation presents significant environmental and sustainability implications that warrant careful consideration. These flexible, air-driven mechanisms offer several environmental advantages compared to traditional rigid actuators, particularly in their material composition and operational characteristics.

SPAs typically utilize elastomeric materials such as silicone rubber, which require less energy-intensive manufacturing processes than metal components in conventional actuators. The production of these materials generally results in lower carbon emissions and reduced extraction of finite metal resources. Additionally, many elastomers used in SPAs can be formulated from bio-based sources, further decreasing their environmental footprint.

Energy efficiency represents another critical sustainability aspect of SPA implementation in agricultural settings. These actuators operate at lower pressures compared to traditional hydraulic or rigid pneumatic systems, resulting in reduced energy consumption during operation. When powered by renewable energy sources such as solar or wind, SPA-based agricultural systems can achieve near-carbon-neutral operation, aligning with global sustainability goals.

The lightweight and compliant nature of SPAs contributes to soil preservation by minimizing compaction issues commonly associated with heavier agricultural machinery. This characteristic helps maintain soil structure and health, promoting better water infiltration and reducing erosion risks. Furthermore, the precise and gentle manipulation capabilities of SPAs enable more targeted application of agricultural inputs, potentially reducing chemical usage by 15-30% according to recent field studies.

End-of-life considerations also favor SPAs from a sustainability perspective. Many elastomeric materials can be recycled or repurposed, and their simpler construction facilitates easier disassembly compared to complex mechanical actuators. However, challenges remain regarding the complete biodegradability of certain elastomers and the potential for microplastic generation as these materials degrade in agricultural environments.

Water conservation represents another sustainability benefit, as SPA-based precision agriculture systems can reduce water usage through more accurate irrigation targeting. Field trials have demonstrated water savings of up to 25% when using SPA-controlled precision irrigation compared to conventional methods, a critical advantage in water-stressed agricultural regions.

As agricultural systems increasingly face climate change pressures, the adaptability and resilience of SPA-based technologies offer sustainability advantages. Their inherent flexibility allows for operation across varying environmental conditions, potentially extending growing seasons and enabling agriculture in previously unsuitable locations, thereby contributing to food security goals while minimizing additional resource requirements.

SPAs typically utilize elastomeric materials such as silicone rubber, which require less energy-intensive manufacturing processes than metal components in conventional actuators. The production of these materials generally results in lower carbon emissions and reduced extraction of finite metal resources. Additionally, many elastomers used in SPAs can be formulated from bio-based sources, further decreasing their environmental footprint.

Energy efficiency represents another critical sustainability aspect of SPA implementation in agricultural settings. These actuators operate at lower pressures compared to traditional hydraulic or rigid pneumatic systems, resulting in reduced energy consumption during operation. When powered by renewable energy sources such as solar or wind, SPA-based agricultural systems can achieve near-carbon-neutral operation, aligning with global sustainability goals.

The lightweight and compliant nature of SPAs contributes to soil preservation by minimizing compaction issues commonly associated with heavier agricultural machinery. This characteristic helps maintain soil structure and health, promoting better water infiltration and reducing erosion risks. Furthermore, the precise and gentle manipulation capabilities of SPAs enable more targeted application of agricultural inputs, potentially reducing chemical usage by 15-30% according to recent field studies.

End-of-life considerations also favor SPAs from a sustainability perspective. Many elastomeric materials can be recycled or repurposed, and their simpler construction facilitates easier disassembly compared to complex mechanical actuators. However, challenges remain regarding the complete biodegradability of certain elastomers and the potential for microplastic generation as these materials degrade in agricultural environments.

Water conservation represents another sustainability benefit, as SPA-based precision agriculture systems can reduce water usage through more accurate irrigation targeting. Field trials have demonstrated water savings of up to 25% when using SPA-controlled precision irrigation compared to conventional methods, a critical advantage in water-stressed agricultural regions.

As agricultural systems increasingly face climate change pressures, the adaptability and resilience of SPA-based technologies offer sustainability advantages. Their inherent flexibility allows for operation across varying environmental conditions, potentially extending growing seasons and enabling agriculture in previously unsuitable locations, thereby contributing to food security goals while minimizing additional resource requirements.

Field Testing and Implementation Strategies

Field testing of soft pneumatic actuators (SPAs) in agricultural environments requires systematic protocols to evaluate performance under real-world conditions. Initial testing should occur in controlled agricultural settings, gradually transitioning to commercial farms with varying soil types, crop densities, and weather conditions. Data collection must focus on actuator durability, response time, precision of movement, and energy efficiency across multiple growing seasons to establish reliability benchmarks.

Implementation strategies for SPAs in agriculture necessitate modular design approaches that allow for easy integration with existing farm equipment. Standardized pneumatic interfaces and control systems facilitate adoption by reducing the technical barriers for farmers. Scalability considerations are paramount—systems must function effectively from small-scale precision applications to large-field operations without significant reconfiguration.

Cost-benefit analyses reveal that while initial implementation costs for SPA systems exceed traditional mechanical solutions, operational savings emerge through reduced maintenance requirements and lower energy consumption. The non-rigid nature of SPAs minimizes crop damage during operation, potentially increasing yield by 8-12% compared to conventional rigid systems according to preliminary field studies.

Environmental adaptation protocols must address temperature fluctuations, humidity variations, and exposure to agricultural chemicals. Testing indicates that silicone-based SPAs maintain operational integrity between -5°C and 45°C, though performance optimization requires material selection specific to deployment regions. Protective coatings have demonstrated 300% improvement in resistance to UV degradation and chemical exposure.

Farmer training programs represent a critical implementation component, as the transition from hydraulic or purely mechanical systems to pneumatic soft robotics requires new maintenance routines and operational knowledge. Successful implementation cases have utilized phased deployment strategies, beginning with simple applications like selective harvesting before advancing to complex tasks such as precision pruning or pollination assistance.

Regulatory compliance testing must verify that SPA systems meet safety standards for agricultural equipment while addressing concerns about pneumatic system failures. Redundancy systems and fail-safe mechanisms that default to non-damaging positions upon pressure loss have proven essential for certification and farmer acceptance.

Implementation strategies for SPAs in agriculture necessitate modular design approaches that allow for easy integration with existing farm equipment. Standardized pneumatic interfaces and control systems facilitate adoption by reducing the technical barriers for farmers. Scalability considerations are paramount—systems must function effectively from small-scale precision applications to large-field operations without significant reconfiguration.

Cost-benefit analyses reveal that while initial implementation costs for SPA systems exceed traditional mechanical solutions, operational savings emerge through reduced maintenance requirements and lower energy consumption. The non-rigid nature of SPAs minimizes crop damage during operation, potentially increasing yield by 8-12% compared to conventional rigid systems according to preliminary field studies.

Environmental adaptation protocols must address temperature fluctuations, humidity variations, and exposure to agricultural chemicals. Testing indicates that silicone-based SPAs maintain operational integrity between -5°C and 45°C, though performance optimization requires material selection specific to deployment regions. Protective coatings have demonstrated 300% improvement in resistance to UV degradation and chemical exposure.

Farmer training programs represent a critical implementation component, as the transition from hydraulic or purely mechanical systems to pneumatic soft robotics requires new maintenance routines and operational knowledge. Successful implementation cases have utilized phased deployment strategies, beginning with simple applications like selective harvesting before advancing to complex tasks such as precision pruning or pollination assistance.

Regulatory compliance testing must verify that SPA systems meet safety standards for agricultural equipment while addressing concerns about pneumatic system failures. Redundancy systems and fail-safe mechanisms that default to non-damaging positions upon pressure loss have proven essential for certification and farmer acceptance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!