Ethyl Acetate in Antimicrobial Film Production

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate in Antimicrobial Films: Background and Objectives

Ethyl acetate has emerged as a significant component in the development of antimicrobial films, marking a notable advancement in food packaging and preservation technologies. This organic compound, known for its versatility and low toxicity, has garnered increasing attention from researchers and industry professionals alike. The evolution of antimicrobial packaging solutions has been driven by the growing demand for extended shelf life and improved food safety, with ethyl acetate playing a crucial role in this progression.

The journey of antimicrobial film technology can be traced back to the early 2000s when the concept of active packaging began to gain traction. Initially, the focus was on incorporating antimicrobial agents directly into packaging materials. However, the introduction of ethyl acetate as a solvent and potential antimicrobial agent itself has opened up new avenues for research and development in this field.

Ethyl acetate's unique properties, including its ability to dissolve a wide range of substances and its inherent antimicrobial characteristics, have positioned it as a key player in the next generation of food packaging solutions. Its low boiling point and relatively mild odor make it an ideal candidate for incorporation into films without significantly altering the sensory properties of packaged foods.

The primary objective of research into ethyl acetate in antimicrobial film production is to develop more effective, sustainable, and cost-efficient packaging solutions. This involves exploring the compound's potential to enhance the antimicrobial properties of films, improve their mechanical and barrier properties, and ensure compatibility with a wide range of food products.

Current research trends focus on optimizing the concentration and dispersion of ethyl acetate within various polymer matrices to maximize its antimicrobial efficacy while maintaining film integrity. Additionally, there is growing interest in combining ethyl acetate with other natural antimicrobial agents to create synergistic effects and broaden the spectrum of antimicrobial activity.

The technological trajectory in this field is moving towards the development of smart packaging systems that not only prevent microbial growth but also actively respond to environmental changes. Ethyl acetate's role in these advanced systems is being investigated, particularly in terms of its controlled release mechanisms and its potential to act as a carrier for other active compounds.

As the global focus on reducing food waste and improving food safety intensifies, the importance of ethyl acetate in antimicrobial film production is expected to grow. Future research aims to address challenges such as scalability, regulatory compliance, and consumer acceptance, while continuing to explore novel applications and formulations that leverage the unique properties of ethyl acetate.

The journey of antimicrobial film technology can be traced back to the early 2000s when the concept of active packaging began to gain traction. Initially, the focus was on incorporating antimicrobial agents directly into packaging materials. However, the introduction of ethyl acetate as a solvent and potential antimicrobial agent itself has opened up new avenues for research and development in this field.

Ethyl acetate's unique properties, including its ability to dissolve a wide range of substances and its inherent antimicrobial characteristics, have positioned it as a key player in the next generation of food packaging solutions. Its low boiling point and relatively mild odor make it an ideal candidate for incorporation into films without significantly altering the sensory properties of packaged foods.

The primary objective of research into ethyl acetate in antimicrobial film production is to develop more effective, sustainable, and cost-efficient packaging solutions. This involves exploring the compound's potential to enhance the antimicrobial properties of films, improve their mechanical and barrier properties, and ensure compatibility with a wide range of food products.

Current research trends focus on optimizing the concentration and dispersion of ethyl acetate within various polymer matrices to maximize its antimicrobial efficacy while maintaining film integrity. Additionally, there is growing interest in combining ethyl acetate with other natural antimicrobial agents to create synergistic effects and broaden the spectrum of antimicrobial activity.

The technological trajectory in this field is moving towards the development of smart packaging systems that not only prevent microbial growth but also actively respond to environmental changes. Ethyl acetate's role in these advanced systems is being investigated, particularly in terms of its controlled release mechanisms and its potential to act as a carrier for other active compounds.

As the global focus on reducing food waste and improving food safety intensifies, the importance of ethyl acetate in antimicrobial film production is expected to grow. Future research aims to address challenges such as scalability, regulatory compliance, and consumer acceptance, while continuing to explore novel applications and formulations that leverage the unique properties of ethyl acetate.

Market Analysis for Antimicrobial Packaging Solutions

The antimicrobial packaging market has experienced significant growth in recent years, driven by increasing consumer demand for food safety and extended shelf life of products. This trend is particularly evident in the food and beverage industry, where the need for effective packaging solutions to prevent microbial contamination and reduce food waste has become paramount.

The global antimicrobial packaging market is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain strong over the next five years. This growth is attributed to several factors, including the rising awareness of foodborne illnesses, stringent food safety regulations, and the growing preference for convenience foods with longer shelf lives.

North America and Europe currently dominate the antimicrobial packaging market, owing to their advanced food processing industries and stringent regulatory frameworks. However, the Asia-Pacific region is emerging as a lucrative market, driven by rapid urbanization, changing consumer lifestyles, and increasing disposable incomes.

The food and beverage sector remains the largest end-user of antimicrobial packaging solutions, accounting for a substantial share of the market. Within this sector, meat and poultry products, dairy items, and ready-to-eat meals are the primary applications driving demand for antimicrobial packaging.

In terms of materials, plastic-based antimicrobial packaging holds the largest market share due to its versatility, cost-effectiveness, and ease of incorporation with antimicrobial agents. However, there is a growing interest in sustainable and biodegradable antimicrobial packaging materials, aligning with the global push for environmentally friendly solutions.

The use of ethyl acetate in antimicrobial film production is gaining traction due to its effectiveness as a solvent for various antimicrobial agents. Its ability to enhance the dispersion of active compounds within the packaging material contributes to improved antimicrobial efficacy. This has led to increased research and development activities focused on optimizing ethyl acetate-based antimicrobial films for various food packaging applications.

Consumer preferences are shifting towards packaging solutions that not only extend product shelf life but also maintain the quality and freshness of food items. This trend has spurred innovation in active packaging technologies, including the development of novel antimicrobial agents and their incorporation into various packaging materials.

The COVID-19 pandemic has further accelerated the demand for antimicrobial packaging solutions, as consumers and businesses alike place greater emphasis on hygiene and safety. This has created new opportunities for market players to develop advanced antimicrobial packaging technologies that address both food safety concerns and the need for extended shelf life.

The global antimicrobial packaging market is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain strong over the next five years. This growth is attributed to several factors, including the rising awareness of foodborne illnesses, stringent food safety regulations, and the growing preference for convenience foods with longer shelf lives.

North America and Europe currently dominate the antimicrobial packaging market, owing to their advanced food processing industries and stringent regulatory frameworks. However, the Asia-Pacific region is emerging as a lucrative market, driven by rapid urbanization, changing consumer lifestyles, and increasing disposable incomes.

The food and beverage sector remains the largest end-user of antimicrobial packaging solutions, accounting for a substantial share of the market. Within this sector, meat and poultry products, dairy items, and ready-to-eat meals are the primary applications driving demand for antimicrobial packaging.

In terms of materials, plastic-based antimicrobial packaging holds the largest market share due to its versatility, cost-effectiveness, and ease of incorporation with antimicrobial agents. However, there is a growing interest in sustainable and biodegradable antimicrobial packaging materials, aligning with the global push for environmentally friendly solutions.

The use of ethyl acetate in antimicrobial film production is gaining traction due to its effectiveness as a solvent for various antimicrobial agents. Its ability to enhance the dispersion of active compounds within the packaging material contributes to improved antimicrobial efficacy. This has led to increased research and development activities focused on optimizing ethyl acetate-based antimicrobial films for various food packaging applications.

Consumer preferences are shifting towards packaging solutions that not only extend product shelf life but also maintain the quality and freshness of food items. This trend has spurred innovation in active packaging technologies, including the development of novel antimicrobial agents and their incorporation into various packaging materials.

The COVID-19 pandemic has further accelerated the demand for antimicrobial packaging solutions, as consumers and businesses alike place greater emphasis on hygiene and safety. This has created new opportunities for market players to develop advanced antimicrobial packaging technologies that address both food safety concerns and the need for extended shelf life.

Current Challenges in Ethyl Acetate-based Antimicrobial Films

The development of ethyl acetate-based antimicrobial films faces several significant challenges that hinder their widespread adoption and effectiveness. One of the primary obstacles is the volatility of ethyl acetate, which can lead to rapid evaporation during the film formation process. This volatility not only affects the stability of the antimicrobial properties but also poses difficulties in maintaining consistent film thickness and uniformity.

Another challenge lies in the compatibility of ethyl acetate with various polymer matrices used in film production. The solvent properties of ethyl acetate can sometimes cause undesirable interactions with certain polymers, leading to structural changes or degradation of the film. This compatibility issue limits the range of materials that can be effectively used in conjunction with ethyl acetate for antimicrobial film production.

The controlled release of antimicrobial agents from ethyl acetate-based films presents a complex challenge. Achieving a sustained and effective release profile over an extended period is crucial for maintaining long-term antimicrobial activity. However, the rapid evaporation of ethyl acetate can lead to an initial burst release of antimicrobial agents, followed by a significant drop in efficacy over time.

Environmental and health concerns associated with ethyl acetate usage also pose challenges. While ethyl acetate is generally considered less toxic compared to other solvents, its use in large-scale production still raises questions about worker exposure and environmental impact. Regulatory compliance and safety measures need to be carefully addressed to ensure the responsible use of ethyl acetate in antimicrobial film production.

The scalability of ethyl acetate-based antimicrobial film production processes presents another hurdle. Transitioning from laboratory-scale experiments to industrial-scale manufacturing while maintaining consistent quality and antimicrobial efficacy requires significant engineering and process optimization. Factors such as drying conditions, solvent recovery, and quality control become increasingly complex at larger scales.

Furthermore, the cost-effectiveness of ethyl acetate-based antimicrobial films compared to alternative technologies remains a challenge. While ethyl acetate itself is relatively inexpensive, the overall production costs, including specialized equipment and safety measures, can impact the economic viability of these films in certain applications.

Lastly, the long-term stability and shelf life of ethyl acetate-based antimicrobial films under various environmental conditions need further investigation. Factors such as temperature, humidity, and exposure to light can potentially affect the antimicrobial properties and structural integrity of the films over time, limiting their practical applications in diverse settings.

Another challenge lies in the compatibility of ethyl acetate with various polymer matrices used in film production. The solvent properties of ethyl acetate can sometimes cause undesirable interactions with certain polymers, leading to structural changes or degradation of the film. This compatibility issue limits the range of materials that can be effectively used in conjunction with ethyl acetate for antimicrobial film production.

The controlled release of antimicrobial agents from ethyl acetate-based films presents a complex challenge. Achieving a sustained and effective release profile over an extended period is crucial for maintaining long-term antimicrobial activity. However, the rapid evaporation of ethyl acetate can lead to an initial burst release of antimicrobial agents, followed by a significant drop in efficacy over time.

Environmental and health concerns associated with ethyl acetate usage also pose challenges. While ethyl acetate is generally considered less toxic compared to other solvents, its use in large-scale production still raises questions about worker exposure and environmental impact. Regulatory compliance and safety measures need to be carefully addressed to ensure the responsible use of ethyl acetate in antimicrobial film production.

The scalability of ethyl acetate-based antimicrobial film production processes presents another hurdle. Transitioning from laboratory-scale experiments to industrial-scale manufacturing while maintaining consistent quality and antimicrobial efficacy requires significant engineering and process optimization. Factors such as drying conditions, solvent recovery, and quality control become increasingly complex at larger scales.

Furthermore, the cost-effectiveness of ethyl acetate-based antimicrobial films compared to alternative technologies remains a challenge. While ethyl acetate itself is relatively inexpensive, the overall production costs, including specialized equipment and safety measures, can impact the economic viability of these films in certain applications.

Lastly, the long-term stability and shelf life of ethyl acetate-based antimicrobial films under various environmental conditions need further investigation. Factors such as temperature, humidity, and exposure to light can potentially affect the antimicrobial properties and structural integrity of the films over time, limiting their practical applications in diverse settings.

Existing Ethyl Acetate Incorporation Methods

01 Antimicrobial compositions containing ethyl acetate

Ethyl acetate is used as a component in various antimicrobial compositions. These formulations may include additional active ingredients to enhance the overall antimicrobial efficacy. The compositions can be applied in different forms such as solutions, sprays, or coatings to provide protection against a range of microorganisms.- Antimicrobial compositions containing ethyl acetate: Ethyl acetate is used as a component in various antimicrobial compositions. These formulations may include additional active ingredients to enhance the overall antimicrobial efficacy. The compositions can be applied in different forms such as solutions, sprays, or coatings to provide protection against a wide range of microorganisms.

- Ethyl acetate as a solvent for antimicrobial agents: Ethyl acetate serves as an effective solvent for dissolving and delivering antimicrobial agents. Its ability to dissolve both polar and non-polar substances makes it useful for creating stable formulations with various active ingredients. This property enhances the distribution and efficacy of antimicrobial compounds in the final product.

- Synergistic effects of ethyl acetate with other antimicrobials: When combined with other antimicrobial agents, ethyl acetate can exhibit synergistic effects, enhancing the overall antimicrobial activity of the formulation. This synergy allows for the development of more potent antimicrobial products with potentially lower concentrations of individual active ingredients.

- Ethyl acetate in natural and plant-based antimicrobial formulations: Ethyl acetate is used in the extraction and formulation of natural and plant-based antimicrobial compounds. It can effectively extract bioactive components from plants, which are then incorporated into antimicrobial products. This approach is particularly relevant for developing eco-friendly and sustainable antimicrobial solutions.

- Applications of ethyl acetate-based antimicrobial products: Antimicrobial products containing ethyl acetate find applications in various fields, including healthcare, food preservation, and industrial settings. These products can be used for surface disinfection, personal care, and as preservatives in different formulations, demonstrating the versatility of ethyl acetate in antimicrobial applications.

02 Ethyl acetate as a solvent for antimicrobial agents

Ethyl acetate serves as an effective solvent for dissolving and delivering antimicrobial agents. Its ability to dissolve various compounds makes it useful in formulating stable and effective antimicrobial solutions. This property is particularly valuable in creating products that require uniform distribution of active ingredients.Expand Specific Solutions03 Synergistic effects of ethyl acetate with other antimicrobials

When combined with other antimicrobial agents, ethyl acetate can exhibit synergistic effects, enhancing the overall antimicrobial activity. These combinations may result in broader spectrum activity or increased potency against specific microorganisms. Such synergistic formulations can be particularly useful in applications requiring robust antimicrobial protection.Expand Specific Solutions04 Ethyl acetate in food preservation and packaging

Ethyl acetate's antimicrobial properties make it valuable in food preservation and packaging applications. It can be incorporated into food packaging materials or used as a treatment for food products to extend shelf life and maintain food safety. Its use in this context helps prevent spoilage and reduce the risk of foodborne illnesses.Expand Specific Solutions05 Environmental and safety considerations of ethyl acetate as an antimicrobial

While ethyl acetate demonstrates antimicrobial properties, its use must be balanced with environmental and safety considerations. Research focuses on optimizing its application to ensure efficacy while minimizing potential risks. This includes studying its biodegradability, potential for residue formation, and effects on non-target organisms to develop safe and sustainable antimicrobial solutions.Expand Specific Solutions

Key Players in Antimicrobial Packaging Industry

The research on the use of Ethyl Acetate in Antimicrobial Film Production is in a developing stage, with growing market potential due to increasing demand for food safety and packaging innovations. The global antimicrobial packaging market is expanding, driven by consumer awareness and stringent regulations. Technologically, the field is advancing rapidly, with companies like Ecolab USA, Inc., 3M Innovative Properties Co., and DuPont de Nemours, Inc. leading the way in research and development. These firms are investing in novel formulations and application methods to enhance the efficacy and sustainability of antimicrobial films. The involvement of academic institutions such as Technical University of Denmark and Clemson University indicates a collaborative approach between industry and academia, fostering innovation in this sector.

Ecolab USA, Inc.

Technical Solution: Ecolab has developed an innovative antimicrobial film production process utilizing ethyl acetate as a key component. Their approach involves incorporating ethyl acetate into a polymer matrix, which serves as a carrier for antimicrobial agents. The ethyl acetate acts as both a solvent and a plasticizer, enhancing the film's flexibility and durability[1]. The company's proprietary blend includes natural antimicrobial compounds that are slowly released from the film, providing long-lasting protection against a broad spectrum of microorganisms[2]. Ecolab's films are designed for use in food packaging, healthcare settings, and industrial applications, offering a sustainable solution to reduce microbial contamination and extend product shelf life[3].

Strengths: Versatile application across multiple industries, environmentally friendly formulation, and extended antimicrobial efficacy. Weaknesses: Potential for higher production costs due to specialized formulation and possible limitations in extreme temperature conditions.

3M Innovative Properties Co.

Technical Solution: 3M has pioneered a novel approach to antimicrobial film production using ethyl acetate as a crucial element in their manufacturing process. Their technology involves a multi-layer film structure where ethyl acetate is used to create a microporous layer that encapsulates antimicrobial agents[4]. This structure allows for controlled release of the active ingredients, ensuring long-term effectiveness. The company has also developed a proprietary coating technique that utilizes ethyl acetate to enhance the adhesion of antimicrobial compounds to various substrate materials[5]. 3M's films are engineered to maintain their antimicrobial properties even after repeated cleaning cycles, making them ideal for high-touch surfaces in healthcare and public spaces[6].

Strengths: Advanced multi-layer technology, durable antimicrobial performance, and wide range of substrate compatibility. Weaknesses: Complex manufacturing process may lead to higher production costs and potential limitations in biodegradability.

Innovations in Ethyl Acetate-based Antimicrobial Agents

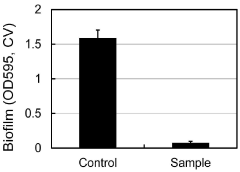

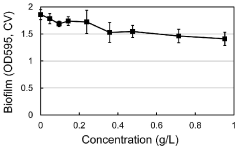

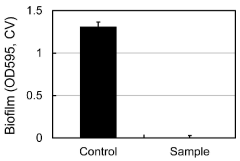

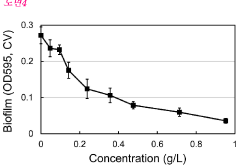

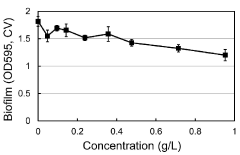

Microbe biofilm formation inhibitor using ethyl acetate solvent fractions in methanol extracts from angelica gigas

PatentActiveKR1020140044049A

Innovation

- A microbial biofilm formation inhibitor using a solvent fraction from the methanol extract of Angelica gigas, specifically extracted with ethyl acetate, is developed to inhibit biofilm formation.

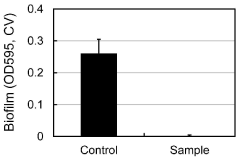

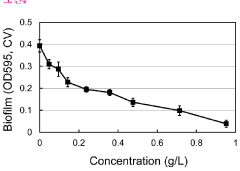

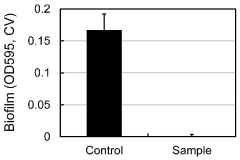

Microbe biofilm formation inhibitor using ethyl acetate solvent fractions in methanol extracts from myristica fragrans

PatentActiveKR1020140044068A

Innovation

- A microbial biofilm formation inhibitor using a solvent fraction obtained from nutmeg extract, specifically extracted with methanol and fractionated with ethyl acetate, is used to inhibit biofilm formation.

Environmental Impact of Ethyl Acetate in Packaging

The environmental impact of ethyl acetate in packaging, particularly in antimicrobial film production, is a crucial consideration for sustainable manufacturing practices. Ethyl acetate, while effective as a solvent in film production, poses several environmental challenges that must be addressed.

One of the primary concerns is the volatile organic compound (VOC) emissions associated with ethyl acetate use. During the production and application of antimicrobial films, ethyl acetate can evaporate and contribute to air pollution. These emissions can lead to the formation of ground-level ozone and smog, potentially impacting air quality and human health in surrounding areas.

Water pollution is another significant issue. If not properly managed, ethyl acetate can contaminate water sources through industrial runoff or improper disposal. This contamination can harm aquatic ecosystems and potentially affect drinking water supplies. The biodegradability of ethyl acetate in water is relatively slow, which means it can persist in the environment for extended periods.

The production of ethyl acetate itself has environmental implications. It is typically synthesized from ethanol and acetic acid, both of which are derived from petrochemical sources. This reliance on fossil fuels contributes to carbon emissions and resource depletion. However, it's worth noting that bio-based alternatives for ethyl acetate production are being explored, which could potentially reduce its carbon footprint.

In the context of packaging, the use of ethyl acetate in antimicrobial films raises concerns about the recyclability and biodegradability of the final product. While the films themselves may offer benefits in terms of food preservation and shelf-life extension, they may complicate recycling processes or contribute to plastic pollution if not properly disposed of.

To mitigate these environmental impacts, several strategies are being explored in the packaging industry. These include the development of water-based alternatives to ethyl acetate, the implementation of closed-loop systems to capture and recycle solvent emissions, and the exploration of bio-based sources for ethyl acetate production.

Additionally, life cycle assessments are being conducted to evaluate the overall environmental impact of ethyl acetate use in antimicrobial packaging compared to alternative solutions. These assessments consider factors such as energy consumption, greenhouse gas emissions, and waste generation throughout the entire product lifecycle.

As regulations around VOC emissions and environmental protection become more stringent, the packaging industry is increasingly focused on finding more sustainable solutions. This includes not only addressing the environmental impact of ethyl acetate but also developing entirely new packaging materials and technologies that offer antimicrobial properties without the associated environmental concerns.

One of the primary concerns is the volatile organic compound (VOC) emissions associated with ethyl acetate use. During the production and application of antimicrobial films, ethyl acetate can evaporate and contribute to air pollution. These emissions can lead to the formation of ground-level ozone and smog, potentially impacting air quality and human health in surrounding areas.

Water pollution is another significant issue. If not properly managed, ethyl acetate can contaminate water sources through industrial runoff or improper disposal. This contamination can harm aquatic ecosystems and potentially affect drinking water supplies. The biodegradability of ethyl acetate in water is relatively slow, which means it can persist in the environment for extended periods.

The production of ethyl acetate itself has environmental implications. It is typically synthesized from ethanol and acetic acid, both of which are derived from petrochemical sources. This reliance on fossil fuels contributes to carbon emissions and resource depletion. However, it's worth noting that bio-based alternatives for ethyl acetate production are being explored, which could potentially reduce its carbon footprint.

In the context of packaging, the use of ethyl acetate in antimicrobial films raises concerns about the recyclability and biodegradability of the final product. While the films themselves may offer benefits in terms of food preservation and shelf-life extension, they may complicate recycling processes or contribute to plastic pollution if not properly disposed of.

To mitigate these environmental impacts, several strategies are being explored in the packaging industry. These include the development of water-based alternatives to ethyl acetate, the implementation of closed-loop systems to capture and recycle solvent emissions, and the exploration of bio-based sources for ethyl acetate production.

Additionally, life cycle assessments are being conducted to evaluate the overall environmental impact of ethyl acetate use in antimicrobial packaging compared to alternative solutions. These assessments consider factors such as energy consumption, greenhouse gas emissions, and waste generation throughout the entire product lifecycle.

As regulations around VOC emissions and environmental protection become more stringent, the packaging industry is increasingly focused on finding more sustainable solutions. This includes not only addressing the environmental impact of ethyl acetate but also developing entirely new packaging materials and technologies that offer antimicrobial properties without the associated environmental concerns.

Regulatory Framework for Antimicrobial Food Packaging

The regulatory framework for antimicrobial food packaging is a complex and evolving landscape that plays a crucial role in ensuring the safety and efficacy of packaging materials incorporating ethyl acetate for antimicrobial purposes. In the United States, the Food and Drug Administration (FDA) is the primary regulatory body overseeing food packaging materials, including those with antimicrobial properties.

Under the Federal Food, Drug, and Cosmetic Act (FFDCA), any substance intended to be used as a component of materials in contact with food must be approved by the FDA as a food contact substance (FCS). This approval process involves rigorous safety assessments and evaluations of the substance's intended use, migration potential, and potential health effects.

For ethyl acetate used in antimicrobial film production, manufacturers must submit a Food Contact Notification (FCN) to the FDA. This notification must include comprehensive data on the chemical composition, manufacturing process, intended use, and safety studies of the substance. The FDA reviews this information to ensure that the use of ethyl acetate in antimicrobial films does not pose any health risks to consumers.

In the European Union, the regulatory framework for food contact materials is governed by Regulation (EC) No 1935/2004. This regulation establishes general principles of safety and inertness for all materials and articles intended to come into contact with food. Additionally, Commission Regulation (EU) No 10/2011 specifically addresses plastic materials and articles intended to come into contact with food, which would include antimicrobial films containing ethyl acetate.

The European Food Safety Authority (EFSA) plays a crucial role in evaluating the safety of substances used in food contact materials. Manufacturers seeking to use ethyl acetate in antimicrobial films for food packaging in the EU market must provide scientific evidence demonstrating the safety of the substance and its intended use.

Globally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides international food standards, guidelines, and codes of practice. While not legally binding, these standards often serve as a basis for national legislation and regulations regarding food packaging materials.

As the field of antimicrobial packaging continues to evolve, regulatory frameworks are likely to adapt to address new technologies and materials. Manufacturers and researchers working with ethyl acetate in antimicrobial film production must stay informed about regulatory updates and ensure compliance with the latest requirements to bring their products to market successfully.

Under the Federal Food, Drug, and Cosmetic Act (FFDCA), any substance intended to be used as a component of materials in contact with food must be approved by the FDA as a food contact substance (FCS). This approval process involves rigorous safety assessments and evaluations of the substance's intended use, migration potential, and potential health effects.

For ethyl acetate used in antimicrobial film production, manufacturers must submit a Food Contact Notification (FCN) to the FDA. This notification must include comprehensive data on the chemical composition, manufacturing process, intended use, and safety studies of the substance. The FDA reviews this information to ensure that the use of ethyl acetate in antimicrobial films does not pose any health risks to consumers.

In the European Union, the regulatory framework for food contact materials is governed by Regulation (EC) No 1935/2004. This regulation establishes general principles of safety and inertness for all materials and articles intended to come into contact with food. Additionally, Commission Regulation (EU) No 10/2011 specifically addresses plastic materials and articles intended to come into contact with food, which would include antimicrobial films containing ethyl acetate.

The European Food Safety Authority (EFSA) plays a crucial role in evaluating the safety of substances used in food contact materials. Manufacturers seeking to use ethyl acetate in antimicrobial films for food packaging in the EU market must provide scientific evidence demonstrating the safety of the substance and its intended use.

Globally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides international food standards, guidelines, and codes of practice. While not legally binding, these standards often serve as a basis for national legislation and regulations regarding food packaging materials.

As the field of antimicrobial packaging continues to evolve, regulatory frameworks are likely to adapt to address new technologies and materials. Manufacturers and researchers working with ethyl acetate in antimicrobial film production must stay informed about regulatory updates and ensure compliance with the latest requirements to bring their products to market successfully.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!