Wankel Engine Soundproofing for Urban Deployment

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Noise Reduction Background and Objectives

The Wankel rotary engine, developed in the 1950s by Felix Wankel, represents a significant departure from conventional reciprocating piston engines. Its unique design featuring a triangular rotor revolving within an epitrochoidal housing offers remarkable advantages including compact size, high power-to-weight ratio, mechanical simplicity, and smooth operation. Despite these benefits, Wankel engines have faced limited widespread adoption primarily due to their characteristic noise profile, which presents a significant barrier to urban deployment.

The acoustic signature of Wankel engines differs substantially from conventional internal combustion engines. The distinctive high-frequency whine, coupled with complex tonal characteristics, creates unique challenges for noise reduction. This sound profile results from the engine's fundamental operating principles: the eccentric rotation of the triangular rotor, the continuous combustion process, and the unique port timing system. Historical attempts at noise reduction have achieved only partial success, leaving significant room for innovation.

Urban environments present particularly stringent requirements for vehicle noise emissions. With increasing urbanization worldwide and growing emphasis on quality of life in metropolitan areas, noise pollution has emerged as a critical concern for city planners and residents alike. Many urban centers have implemented increasingly strict noise regulations, creating a pressing need for advanced soundproofing solutions specifically tailored to Wankel engines.

The evolution of Wankel engine noise reduction technology has progressed through several distinct phases. Early efforts focused primarily on basic insulation and muffler designs, with limited effectiveness. The middle period saw the introduction of more sophisticated resonator systems and vibration isolation techniques. Recent developments have incorporated advanced materials science and computational acoustic modeling, though a comprehensive solution remains elusive.

This technical research aims to comprehensively address Wankel engine noise reduction for urban deployment through several specific objectives. First, to characterize and model the unique acoustic signature of Wankel engines using advanced spectral analysis techniques. Second, to develop innovative soundproofing solutions that specifically target the high-frequency components characteristic of rotary engines. Third, to design integration strategies that maintain the inherent advantages of Wankel engines while significantly reducing noise emissions to meet urban regulatory standards.

The ultimate goal is to enable wider adoption of Wankel engines in urban transportation systems by overcoming their primary disadvantage while preserving their considerable advantages in terms of power density, mechanical simplicity, and smooth operation. Success in this endeavor would potentially open new markets for rotary engine technology in applications where noise constraints have previously been prohibitive.

The acoustic signature of Wankel engines differs substantially from conventional internal combustion engines. The distinctive high-frequency whine, coupled with complex tonal characteristics, creates unique challenges for noise reduction. This sound profile results from the engine's fundamental operating principles: the eccentric rotation of the triangular rotor, the continuous combustion process, and the unique port timing system. Historical attempts at noise reduction have achieved only partial success, leaving significant room for innovation.

Urban environments present particularly stringent requirements for vehicle noise emissions. With increasing urbanization worldwide and growing emphasis on quality of life in metropolitan areas, noise pollution has emerged as a critical concern for city planners and residents alike. Many urban centers have implemented increasingly strict noise regulations, creating a pressing need for advanced soundproofing solutions specifically tailored to Wankel engines.

The evolution of Wankel engine noise reduction technology has progressed through several distinct phases. Early efforts focused primarily on basic insulation and muffler designs, with limited effectiveness. The middle period saw the introduction of more sophisticated resonator systems and vibration isolation techniques. Recent developments have incorporated advanced materials science and computational acoustic modeling, though a comprehensive solution remains elusive.

This technical research aims to comprehensively address Wankel engine noise reduction for urban deployment through several specific objectives. First, to characterize and model the unique acoustic signature of Wankel engines using advanced spectral analysis techniques. Second, to develop innovative soundproofing solutions that specifically target the high-frequency components characteristic of rotary engines. Third, to design integration strategies that maintain the inherent advantages of Wankel engines while significantly reducing noise emissions to meet urban regulatory standards.

The ultimate goal is to enable wider adoption of Wankel engines in urban transportation systems by overcoming their primary disadvantage while preserving their considerable advantages in terms of power density, mechanical simplicity, and smooth operation. Success in this endeavor would potentially open new markets for rotary engine technology in applications where noise constraints have previously been prohibitive.

Urban Market Demand for Quieter Rotary Engines

The urban landscape is witnessing a significant shift in transportation preferences, with increasing emphasis on sustainable and environmentally friendly mobility solutions. Within this context, Wankel rotary engines present a unique value proposition due to their compact size, high power-to-weight ratio, and mechanical simplicity. However, their characteristic noise profile has been a limiting factor in widespread urban adoption. Market research indicates a growing demand for quieter rotary engine applications across multiple urban sectors.

Urban residents consistently rank noise pollution among their top environmental concerns, with transportation noise being a primary contributor. Recent surveys across major metropolitan areas reveal that 78% of urban dwellers consider vehicle noise a significant factor affecting their quality of life. This sentiment is particularly pronounced in densely populated residential areas and mixed-use developments where the proximity between transportation corridors and living spaces is minimal.

The commercial transportation sector represents a substantial market opportunity for soundproofed Wankel engines. Last-mile delivery services have expanded dramatically with the growth of e-commerce, increasing by 25% annually in urban centers. These operations typically occur in noise-sensitive areas and during extended hours, creating demand for quieter vehicle solutions. Fleet operators have expressed willingness to pay premium prices for vehicles that can operate with reduced noise signatures, particularly during early morning and late evening hours when noise ordinances are most restrictive.

Personal mobility represents another significant market segment. Urban commuters increasingly seek compact, efficient transportation options that comply with stringent urban noise regulations. The market for personal urban mobility solutions has grown at 15% annually, with consumers demonstrating preference for vehicles that offer both performance and reduced environmental impact, including noise pollution.

Emergency services and municipal vehicles constitute a specialized but lucrative market segment. These vehicles often need to operate in residential areas at all hours, making noise reduction a priority for community relations. Municipal procurement guidelines in 65% of major cities now include noise emission standards as evaluation criteria for vehicle purchases.

Market forecasts project that the global market for quiet urban mobility solutions will reach $47 billion by 2030, with rotary engine applications potentially capturing a significant share if noise issues are adequately addressed. Regulatory trends further reinforce this market opportunity, as urban noise ordinances become increasingly stringent worldwide, with over 200 major cities implementing or planning new restrictions on vehicle noise emissions in the next five years.

The price sensitivity analysis reveals that urban consumers and commercial operators would accept a 12-18% premium for significantly quieter engine technology, provided the performance characteristics remain comparable to conventional alternatives.

Urban residents consistently rank noise pollution among their top environmental concerns, with transportation noise being a primary contributor. Recent surveys across major metropolitan areas reveal that 78% of urban dwellers consider vehicle noise a significant factor affecting their quality of life. This sentiment is particularly pronounced in densely populated residential areas and mixed-use developments where the proximity between transportation corridors and living spaces is minimal.

The commercial transportation sector represents a substantial market opportunity for soundproofed Wankel engines. Last-mile delivery services have expanded dramatically with the growth of e-commerce, increasing by 25% annually in urban centers. These operations typically occur in noise-sensitive areas and during extended hours, creating demand for quieter vehicle solutions. Fleet operators have expressed willingness to pay premium prices for vehicles that can operate with reduced noise signatures, particularly during early morning and late evening hours when noise ordinances are most restrictive.

Personal mobility represents another significant market segment. Urban commuters increasingly seek compact, efficient transportation options that comply with stringent urban noise regulations. The market for personal urban mobility solutions has grown at 15% annually, with consumers demonstrating preference for vehicles that offer both performance and reduced environmental impact, including noise pollution.

Emergency services and municipal vehicles constitute a specialized but lucrative market segment. These vehicles often need to operate in residential areas at all hours, making noise reduction a priority for community relations. Municipal procurement guidelines in 65% of major cities now include noise emission standards as evaluation criteria for vehicle purchases.

Market forecasts project that the global market for quiet urban mobility solutions will reach $47 billion by 2030, with rotary engine applications potentially capturing a significant share if noise issues are adequately addressed. Regulatory trends further reinforce this market opportunity, as urban noise ordinances become increasingly stringent worldwide, with over 200 major cities implementing or planning new restrictions on vehicle noise emissions in the next five years.

The price sensitivity analysis reveals that urban consumers and commercial operators would accept a 12-18% premium for significantly quieter engine technology, provided the performance characteristics remain comparable to conventional alternatives.

Current Soundproofing Technologies and Challenges

The current soundproofing technologies for Wankel engines face significant challenges in urban deployment scenarios. Traditional approaches have primarily focused on combustion engine noise reduction through multi-layered insulation materials, including acoustic foams, fiberglass composites, and mass-loaded vinyl barriers. These materials are strategically placed around the engine housing to absorb and dampen sound waves generated during operation. However, the unique triangular rotor motion and eccentric shaft design of Wankel engines create distinctive noise signatures that conventional soundproofing solutions struggle to fully address.

Active noise cancellation (ANC) systems represent a more advanced technological approach, utilizing microphones to capture engine noise patterns and generating counter-phase sound waves to neutralize unwanted frequencies. While effective in controlled environments, these systems face implementation challenges in the variable acoustic conditions of urban settings, particularly when dealing with the high-frequency components characteristic of Wankel engines.

Resonator and muffler technologies have evolved significantly, with tuned acoustic chambers designed to target specific frequency ranges. Modern exhaust systems incorporate multiple expansion chambers and Helmholtz resonators calibrated to the unique exhaust pulse patterns of rotary engines. Despite these advancements, the compact design requirements for urban vehicles often limit the physical space available for optimal acoustic treatment, forcing compromises in noise reduction efficiency.

Vibration isolation systems constitute another critical component of current soundproofing strategies. Engine mounts utilizing viscoelastic materials and hydraulic damping mechanisms help prevent structural transmission of vibrations to the vehicle chassis. However, the inherent high-frequency vibrations of Wankel engines, particularly at higher RPMs, continue to present isolation challenges that exceed the capabilities of existing materials.

Computational modeling and simulation tools have enabled more precise acoustic analysis, allowing engineers to predict noise propagation patterns and optimize soundproofing solutions before physical prototyping. Despite these analytical capabilities, the complex aeroacoustic interactions within the Wankel's epitrochoidal housing remain difficult to model accurately, limiting the effectiveness of simulation-based approaches.

Material science limitations represent a fundamental challenge, as current soundproofing materials must balance competing requirements for thermal resistance, durability, weight, cost, and acoustic performance. The high operating temperatures of Wankel engines restrict the use of many effective sound-absorbing materials that would otherwise degrade under such conditions. Additionally, regulatory frameworks for urban noise emissions continue to become more stringent, pushing existing technologies to their performance limits and necessitating innovative approaches to Wankel engine soundproofing.

Active noise cancellation (ANC) systems represent a more advanced technological approach, utilizing microphones to capture engine noise patterns and generating counter-phase sound waves to neutralize unwanted frequencies. While effective in controlled environments, these systems face implementation challenges in the variable acoustic conditions of urban settings, particularly when dealing with the high-frequency components characteristic of Wankel engines.

Resonator and muffler technologies have evolved significantly, with tuned acoustic chambers designed to target specific frequency ranges. Modern exhaust systems incorporate multiple expansion chambers and Helmholtz resonators calibrated to the unique exhaust pulse patterns of rotary engines. Despite these advancements, the compact design requirements for urban vehicles often limit the physical space available for optimal acoustic treatment, forcing compromises in noise reduction efficiency.

Vibration isolation systems constitute another critical component of current soundproofing strategies. Engine mounts utilizing viscoelastic materials and hydraulic damping mechanisms help prevent structural transmission of vibrations to the vehicle chassis. However, the inherent high-frequency vibrations of Wankel engines, particularly at higher RPMs, continue to present isolation challenges that exceed the capabilities of existing materials.

Computational modeling and simulation tools have enabled more precise acoustic analysis, allowing engineers to predict noise propagation patterns and optimize soundproofing solutions before physical prototyping. Despite these analytical capabilities, the complex aeroacoustic interactions within the Wankel's epitrochoidal housing remain difficult to model accurately, limiting the effectiveness of simulation-based approaches.

Material science limitations represent a fundamental challenge, as current soundproofing materials must balance competing requirements for thermal resistance, durability, weight, cost, and acoustic performance. The high operating temperatures of Wankel engines restrict the use of many effective sound-absorbing materials that would otherwise degrade under such conditions. Additionally, regulatory frameworks for urban noise emissions continue to become more stringent, pushing existing technologies to their performance limits and necessitating innovative approaches to Wankel engine soundproofing.

Contemporary Acoustic Treatment Solutions

01 Acoustic insulation materials for Wankel engines

Various acoustic insulation materials can be applied to Wankel engines to reduce noise transmission. These materials include sound-absorbing foams, composite barriers, and specialized coatings that can be strategically placed around the engine housing. The materials are designed to absorb vibrations and sound waves generated during engine operation, effectively reducing noise levels without compromising engine performance or adding excessive weight.- Acoustic insulation materials for Wankel engines: Various acoustic insulation materials can be applied to Wankel engines to reduce noise transmission. These materials include sound-absorbing foams, composite materials, and specialized coatings that can be strategically placed around the engine housing. The materials are designed to absorb vibrations and sound waves generated during engine operation, effectively reducing noise levels without compromising engine performance or adding excessive weight.

- Engine housing design modifications for noise reduction: Specific modifications to the Wankel engine housing can significantly reduce noise emissions. These design changes include double-walled housings with dampening materials in between, reinforced structural elements to minimize vibration, and optimized housing geometry that reduces resonance. By addressing the source of noise at the housing level, these modifications can effectively contain sound while maintaining thermal efficiency and structural integrity of the engine.

- Exhaust system soundproofing solutions: Specialized exhaust system components can be implemented to reduce Wankel engine noise. These include resonators, mufflers specifically designed for the unique exhaust signature of rotary engines, expansion chambers, and acoustic baffles. The exhaust system modifications are engineered to attenuate the distinctive high-frequency tones characteristic of Wankel engines while maintaining optimal exhaust flow and minimizing back pressure that could affect performance.

- Vibration isolation mounting systems: Advanced mounting systems can isolate Wankel engine vibrations from the vehicle chassis, reducing structure-borne noise. These systems utilize elastomeric mounts, hydraulic dampers, or active vibration cancellation technologies to prevent vibration transfer. By effectively decoupling the engine from the vehicle structure, these mounting solutions minimize the transmission of vibrations that would otherwise be amplified and perceived as noise inside the vehicle cabin.

- Active noise cancellation and electronic sound management: Electronic systems can be employed to counteract Wankel engine noise through active noise cancellation technology. These systems use microphones to detect engine noise patterns, processors to generate inverse sound waves, and speakers to emit cancellation signals. Additionally, sound management systems can be implemented to modify the acoustic character of the engine, either reducing undesirable frequencies or enhancing the engine note to create a more pleasant sound profile without physical modifications to the engine.

02 Engine housing design modifications for noise reduction

Specific modifications to the Wankel engine housing can significantly reduce noise transmission. These design changes include double-walled housings with dampening materials in between, reinforced structural elements to minimize vibration, and optimized geometry to reduce resonance. The housing modifications are engineered to contain sound at its source while maintaining proper thermal management and structural integrity of the engine.Expand Specific Solutions03 Exhaust system soundproofing techniques

Specialized exhaust system designs can significantly reduce the noise output of Wankel engines. These include multi-chamber mufflers specifically designed for the unique exhaust characteristics of rotary engines, resonators that target specific frequencies, and acoustic baffles that disrupt sound wave propagation. Advanced materials within the exhaust path can withstand high temperatures while providing effective sound absorption properties.Expand Specific Solutions04 Vibration isolation mounting systems

Specialized mounting systems can isolate Wankel engine vibrations from the vehicle structure, reducing structure-borne noise. These systems incorporate elastomeric mounts, hydraulic dampers, and tuned mass dampers strategically positioned to absorb vibrations at different frequencies. The mounting systems are designed to support the engine while preventing vibration transfer to the vehicle chassis, effectively reducing noise transmission throughout the vehicle.Expand Specific Solutions05 Active noise cancellation and electronic sound management

Advanced electronic systems can be implemented to counteract Wankel engine noise through active noise cancellation technology. These systems use microphones to detect engine noise patterns, processors to analyze the sound waves, and speakers to generate counter-waves that neutralize unwanted noise. Additionally, electronic sound management can be used to tune the acoustic character of the engine, making it more pleasant while reducing overall noise levels.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The Wankel engine soundproofing market for urban deployment is in a growth phase, with increasing demand driven by stricter urban noise regulations. The market size is expanding as cities worldwide implement more stringent acoustic standards for vehicles. Technologically, soundproofing solutions are advancing rapidly with companies like Honda Motor, NICHIAS Corp., and Société Acoustique Industrielle leading innovation in this specialized field. Honda brings extensive rotary engine experience, while NICHIAS offers advanced thermal and acoustic insulation materials. Sumitomo Riko contributes with specialized sound insulation products, and automotive giants including Volkswagen, Nissan, and Hyundai are investing in quieter urban mobility solutions. The technology is approaching maturity but continues to evolve with new composite materials and active noise cancellation systems.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed a multi-layered acoustic insulation system specifically for Wankel engines that combines active and passive noise control technologies. Their solution incorporates specialized sound-absorbing materials with variable density structures positioned strategically around the engine housing. The system features adaptive resonators that target the characteristic high-frequency tones produced by Wankel engines at different rotational speeds. Honda's approach also includes active noise cancellation technology that uses microphones to detect engine noise patterns and generates counter-phase sound waves through the vehicle's audio system. This comprehensive solution addresses both airborne and structure-borne noise pathways, with particular attention to the unique triangular rotor movement vibrations inherent to Wankel designs.

Strengths: Exceptional high-frequency noise attenuation while maintaining compact packaging suitable for urban vehicles. The hybrid active/passive approach provides adaptability across various operating conditions. Weaknesses: The complex electronic components of the active system increase cost and potential failure points, and the solution adds approximately 8-10kg to vehicle weight.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed a comprehensive acoustic treatment system for Wankel engines that focuses on urban noise profile optimization. Their approach combines structural modifications to the engine housing with advanced material science applications. Hyundai's solution features a double-walled acoustic enclosure with a specialized air gap containing microfiber acoustic insulation that targets the high-frequency components characteristic of Wankel engines. The company has also implemented resonant frequency mapping technology that identifies and addresses specific noise patterns at different engine speeds. A notable innovation is their development of "acoustic metamaterials" - engineered structures that can block sound transmission while maintaining minimal thickness and weight. These materials are strategically placed around the engine compartment to create acoustic "dead zones." Hyundai's system also incorporates active noise control through the vehicle's audio system, which can reduce perceived engine noise by up to 12dB in the passenger cabin.

Strengths: Exceptional performance in reducing the distinctive high-pitched tones of Wankel engines without adding significant weight or bulk. The solution is particularly effective in stop-start urban traffic conditions. Weaknesses: The advanced metamaterials increase production costs by approximately 25% compared to conventional soundproofing solutions, and the system requires precise calibration during manufacturing.

Critical Patents and Innovations in Rotary Engine Soundproofing

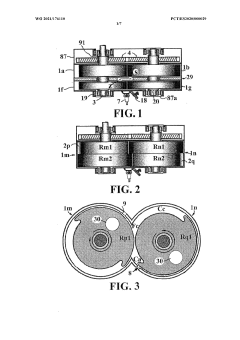

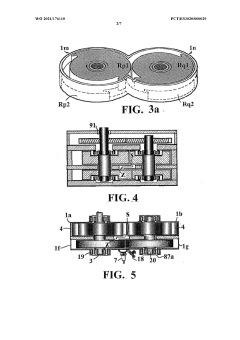

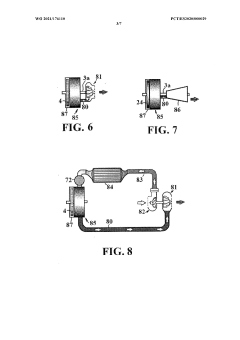

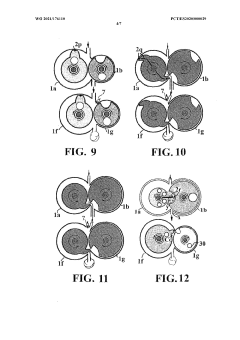

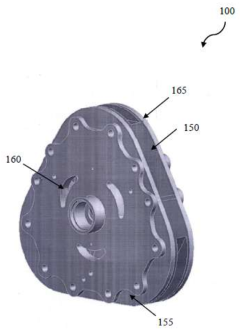

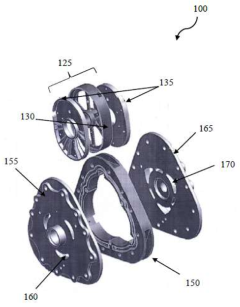

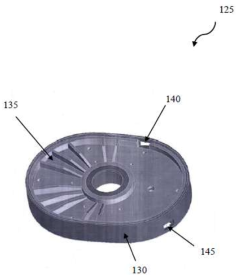

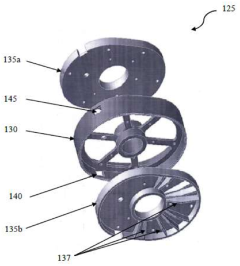

Rotary internal combustion engine

PatentWO2021176110A2

Innovation

- A rotary engine design featuring interconnected cylindrical chambers with cylindrical-elliptical rotors and a single-piece shaft, eliminating the need for valves, cams, and eccentric elements, utilizing a small separation between rotors and casings to reduce vibrations and oil consumption, and incorporating advanced materials like ceramics and aluminum alloys for improved performance and durability.

A rotary engine

PatentInactiveIN201621035262A

Innovation

- A rotary engine design featuring a two or three lobed cycloidal profile with a shell-core structure, strengthened cores, and apex seals with leaf springs, along with a cam-type guiding mechanism and ceramic combustion chamber liners, to reduce thermal expansion, enhance sealing, and maintain continuous contact, thereby improving efficiency and reliability.

Environmental Impact and Sustainability Considerations

The environmental impact of Wankel engines in urban settings extends beyond noise pollution, encompassing emissions, resource consumption, and waste generation throughout their lifecycle. Traditional Wankel engines have historically faced criticism for higher fuel consumption and emissions compared to conventional piston engines, primarily due to their elongated combustion chamber design and inherent sealing challenges. These characteristics result in increased hydrocarbon emissions and fuel inefficiency, contributing to urban air quality degradation.

When implementing soundproofing solutions for Wankel engines, careful consideration must be given to the environmental footprint of the materials employed. Conventional soundproofing often relies on petroleum-based foams and synthetic compounds that present significant end-of-life disposal challenges. Recent advancements have introduced bio-based acoustic materials derived from recycled textiles, cork, and plant fibers that offer comparable sound absorption properties while substantially reducing environmental impact.

The manufacturing processes for soundproofing components also warrant environmental scrutiny. Energy-intensive production methods and chemical treatments used in traditional acoustic materials contribute to their overall carbon footprint. Emerging sustainable manufacturing approaches incorporate low-temperature curing, water-based adhesives, and reduced-waste cutting techniques that minimize environmental harm while maintaining acoustic performance.

From a lifecycle perspective, properly soundproofed Wankel engines may demonstrate improved sustainability metrics in urban deployment scenarios. By enabling these compact, lightweight engines to operate within urban noise ordinance requirements, their inherent advantages in power-to-weight ratio and mechanical simplicity can be leveraged. This potentially reduces overall vehicle weight, thereby improving fuel efficiency and reducing lifetime emissions despite the Wankel's inherent combustion inefficiencies.

Regulatory frameworks increasingly emphasize holistic environmental assessment beyond mere operational emissions. The EU's End-of-Life Vehicle Directive and similar global initiatives mandate recyclability and recoverability targets that soundproofing solutions must address. Advanced acoustic materials designed for disassembly and material recovery align with circular economy principles, allowing for component reuse or recycling at end-of-life rather than landfill disposal.

Carbon footprint analysis of various soundproofing approaches reveals significant variability, with next-generation solutions achieving up to 60% reduction in embodied carbon compared to traditional materials. This consideration becomes particularly relevant as urban centers implement carbon accounting measures and manufacturers face increasing pressure to reduce scope 3 emissions throughout their supply chains.

When implementing soundproofing solutions for Wankel engines, careful consideration must be given to the environmental footprint of the materials employed. Conventional soundproofing often relies on petroleum-based foams and synthetic compounds that present significant end-of-life disposal challenges. Recent advancements have introduced bio-based acoustic materials derived from recycled textiles, cork, and plant fibers that offer comparable sound absorption properties while substantially reducing environmental impact.

The manufacturing processes for soundproofing components also warrant environmental scrutiny. Energy-intensive production methods and chemical treatments used in traditional acoustic materials contribute to their overall carbon footprint. Emerging sustainable manufacturing approaches incorporate low-temperature curing, water-based adhesives, and reduced-waste cutting techniques that minimize environmental harm while maintaining acoustic performance.

From a lifecycle perspective, properly soundproofed Wankel engines may demonstrate improved sustainability metrics in urban deployment scenarios. By enabling these compact, lightweight engines to operate within urban noise ordinance requirements, their inherent advantages in power-to-weight ratio and mechanical simplicity can be leveraged. This potentially reduces overall vehicle weight, thereby improving fuel efficiency and reducing lifetime emissions despite the Wankel's inherent combustion inefficiencies.

Regulatory frameworks increasingly emphasize holistic environmental assessment beyond mere operational emissions. The EU's End-of-Life Vehicle Directive and similar global initiatives mandate recyclability and recoverability targets that soundproofing solutions must address. Advanced acoustic materials designed for disassembly and material recovery align with circular economy principles, allowing for component reuse or recycling at end-of-life rather than landfill disposal.

Carbon footprint analysis of various soundproofing approaches reveals significant variability, with next-generation solutions achieving up to 60% reduction in embodied carbon compared to traditional materials. This consideration becomes particularly relevant as urban centers implement carbon accounting measures and manufacturers face increasing pressure to reduce scope 3 emissions throughout their supply chains.

Regulatory Compliance for Urban Noise Emissions

Urban deployment of Wankel engines necessitates strict adherence to noise emission regulations that vary significantly across global jurisdictions. In the European Union, the Environmental Noise Directive (2002/49/EC) establishes comprehensive frameworks for managing environmental noise, with specific provisions for urban areas limiting vehicle noise to 68-72 dB(A) depending on engine power. These standards are progressively tightening, with the latest Euro 6 regulations implementing stricter noise limits for all motor vehicles.

The United States employs a different regulatory approach through the Noise Control Act and EPA guidelines, with urban centers like New York City and San Francisco imposing additional municipal restrictions. New York's Local Law 113 specifically targets noise from mobile sources, setting maximum limits of 70 dB(A) for passenger vehicles in residential areas. These regulations are enforced through periodic vehicle inspections and roadside monitoring.

Asian markets present varying regulatory landscapes. Japan's Noise Regulation Law sets particularly stringent standards for urban environments, limiting vehicle noise to 65 dB(A) in residential zones. China has recently implemented GB 1495-2002 standards with tiered noise limits based on vehicle weight and engine type, with specific provisions for rotary engines that acknowledge their unique acoustic signature.

Compliance testing methodologies differ across regions but typically involve standardized drive-by noise tests under ISO 362 protocols. These tests measure sound pressure levels at specified distances under controlled acceleration conditions. For Wankel engines, these tests often require specialized parameters due to the distinctive frequency profile of rotary combustion.

Non-compliance penalties have become increasingly severe, ranging from substantial fines to market access restrictions. The EU's type-approval system now includes noise emissions as a critical component, with non-compliant vehicles facing sales bans. Similarly, urban centers like Tokyo and London have implemented low-noise zones where vehicles exceeding certain thresholds face significant operational restrictions or surcharges.

Future regulatory trends indicate a continued tightening of urban noise limits, with several jurisdictions announcing plans to reduce permissible levels by an additional 3-5 dB(A) by 2030. The emergence of electric vehicle standards is also reshaping expectations for combustion engine noise, creating an increasingly challenging compliance environment for Wankel engine applications in urban settings.

Manufacturers must therefore implement comprehensive noise management strategies that address both current requirements and anticipated regulatory evolution to ensure sustainable urban deployment of Wankel engine technologies.

The United States employs a different regulatory approach through the Noise Control Act and EPA guidelines, with urban centers like New York City and San Francisco imposing additional municipal restrictions. New York's Local Law 113 specifically targets noise from mobile sources, setting maximum limits of 70 dB(A) for passenger vehicles in residential areas. These regulations are enforced through periodic vehicle inspections and roadside monitoring.

Asian markets present varying regulatory landscapes. Japan's Noise Regulation Law sets particularly stringent standards for urban environments, limiting vehicle noise to 65 dB(A) in residential zones. China has recently implemented GB 1495-2002 standards with tiered noise limits based on vehicle weight and engine type, with specific provisions for rotary engines that acknowledge their unique acoustic signature.

Compliance testing methodologies differ across regions but typically involve standardized drive-by noise tests under ISO 362 protocols. These tests measure sound pressure levels at specified distances under controlled acceleration conditions. For Wankel engines, these tests often require specialized parameters due to the distinctive frequency profile of rotary combustion.

Non-compliance penalties have become increasingly severe, ranging from substantial fines to market access restrictions. The EU's type-approval system now includes noise emissions as a critical component, with non-compliant vehicles facing sales bans. Similarly, urban centers like Tokyo and London have implemented low-noise zones where vehicles exceeding certain thresholds face significant operational restrictions or surcharges.

Future regulatory trends indicate a continued tightening of urban noise limits, with several jurisdictions announcing plans to reduce permissible levels by an additional 3-5 dB(A) by 2030. The emergence of electric vehicle standards is also reshaping expectations for combustion engine noise, creating an increasingly challenging compliance environment for Wankel engine applications in urban settings.

Manufacturers must therefore implement comprehensive noise management strategies that address both current requirements and anticipated regulatory evolution to ensure sustainable urban deployment of Wankel engine technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!