Revisiting forgotten V16 engine configurations for potential revitalization

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V16 Engine History and Revival Goals

The V16 engine, a marvel of automotive engineering, has a rich history dating back to the early 20th century. First introduced in the 1930s, these powerful engines were primarily used in luxury automobiles and high-performance racing cars. The V16 configuration offered unprecedented smoothness and power, making it a symbol of automotive excellence and innovation.

During the golden age of V16 engines in the 1930s, iconic manufacturers such as Cadillac, Marmon, and Peerless showcased these engineering marvels. The Cadillac V16, introduced in 1930, set new standards for luxury and performance, producing an impressive 165 horsepower. This era marked the pinnacle of V16 engine development, with each manufacturer striving to outdo the others in terms of power, refinement, and prestige.

However, the advent of World War II and subsequent economic challenges led to a decline in V16 engine production. The high costs associated with manufacturing and maintaining these complex engines, coupled with advancements in smaller, more efficient powerplants, resulted in their gradual disappearance from mainstream automotive applications.

In recent years, there has been a renewed interest in revisiting and potentially revitalizing V16 engine configurations. This resurgence is driven by several factors, including advancements in materials science, manufacturing techniques, and a growing demand for unique, high-performance powertrains in the luxury and supercar segments.

The goals of this V16 engine revival are multifaceted. Firstly, there is a desire to push the boundaries of internal combustion engine technology, showcasing what is possible with modern engineering and materials. Secondly, manufacturers aim to create a new generation of ultra-luxury vehicles that harken back to the golden age of automotive excellence while incorporating cutting-edge technology.

Another objective is to explore the potential of V16 engines in addressing contemporary challenges, such as improving fuel efficiency and reducing emissions through advanced combustion techniques and hybrid integration. This revival also seeks to inspire a new generation of automotive enthusiasts and engineers, demonstrating that there is still room for innovation in traditional engine designs.

Furthermore, the resurgence of V16 engines could serve as a platform for developing and testing new technologies that could eventually trickle down to more mainstream applications. This includes advancements in thermal management, friction reduction, and power density optimization.

As we look towards the future, the revival of V16 engine configurations represents not just a nod to automotive history, but a bold step forward in engineering prowess and technological innovation. It challenges us to rethink the possibilities of internal combustion engines in an era increasingly focused on electrification, potentially paving the way for hybrid powertrains that combine the best of both worlds.

During the golden age of V16 engines in the 1930s, iconic manufacturers such as Cadillac, Marmon, and Peerless showcased these engineering marvels. The Cadillac V16, introduced in 1930, set new standards for luxury and performance, producing an impressive 165 horsepower. This era marked the pinnacle of V16 engine development, with each manufacturer striving to outdo the others in terms of power, refinement, and prestige.

However, the advent of World War II and subsequent economic challenges led to a decline in V16 engine production. The high costs associated with manufacturing and maintaining these complex engines, coupled with advancements in smaller, more efficient powerplants, resulted in their gradual disappearance from mainstream automotive applications.

In recent years, there has been a renewed interest in revisiting and potentially revitalizing V16 engine configurations. This resurgence is driven by several factors, including advancements in materials science, manufacturing techniques, and a growing demand for unique, high-performance powertrains in the luxury and supercar segments.

The goals of this V16 engine revival are multifaceted. Firstly, there is a desire to push the boundaries of internal combustion engine technology, showcasing what is possible with modern engineering and materials. Secondly, manufacturers aim to create a new generation of ultra-luxury vehicles that harken back to the golden age of automotive excellence while incorporating cutting-edge technology.

Another objective is to explore the potential of V16 engines in addressing contemporary challenges, such as improving fuel efficiency and reducing emissions through advanced combustion techniques and hybrid integration. This revival also seeks to inspire a new generation of automotive enthusiasts and engineers, demonstrating that there is still room for innovation in traditional engine designs.

Furthermore, the resurgence of V16 engines could serve as a platform for developing and testing new technologies that could eventually trickle down to more mainstream applications. This includes advancements in thermal management, friction reduction, and power density optimization.

As we look towards the future, the revival of V16 engine configurations represents not just a nod to automotive history, but a bold step forward in engineering prowess and technological innovation. It challenges us to rethink the possibilities of internal combustion engines in an era increasingly focused on electrification, potentially paving the way for hybrid powertrains that combine the best of both worlds.

Market Demand Analysis for High-Performance Engines

The market demand for high-performance engines, particularly in the context of revisiting forgotten V16 engine configurations, presents a complex landscape driven by various factors. While the automotive industry has largely moved towards smaller, more efficient engines, there remains a niche but passionate market for high-performance powerplants.

In the luxury and ultra-luxury segments, there is a growing appetite for exclusive, high-powered vehicles that offer unparalleled performance and prestige. This demand is primarily fueled by high-net-worth individuals and collectors who seek unique driving experiences and status symbols. The revival of V16 engines could cater to this market, offering a blend of nostalgia and cutting-edge engineering.

The motorsport sector also presents potential opportunities for V16 engines. As racing series continue to evolve, there's a constant search for innovative powertrains that can deliver both performance and spectacle. A modern V16 configuration could offer a unique selling point for teams and manufacturers looking to differentiate themselves in competitive racing environments.

However, it's crucial to note that the overall market size for V16 engines is relatively small compared to mainstream engine configurations. The development and production costs associated with such specialized engines would likely result in very high price points, limiting their accessibility to a select few customers and applications.

Environmental regulations and the global push towards electrification pose significant challenges to the revival of V16 engines. Many countries have set ambitious targets for reducing emissions and phasing out internal combustion engines. This regulatory landscape may restrict the potential market for V16 engines, particularly in road-going vehicles.

Despite these challenges, there are emerging trends that could support the development of high-performance engines. The growing popularity of restomod culture, where classic vehicles are updated with modern technology, could create a market for V16 engines as part of high-end restoration projects. Additionally, the synthetic fuel industry's advancements may offer a pathway for powerful internal combustion engines to coexist with environmental goals.

In conclusion, while the market for V16 engines is niche, there exists a dedicated segment of enthusiasts, collectors, and performance-oriented customers who would be interested in such powerplants. The key to successfully reintroducing V16 engines lies in identifying and targeting these specific market segments, while also addressing the broader industry trends towards efficiency and sustainability.

In the luxury and ultra-luxury segments, there is a growing appetite for exclusive, high-powered vehicles that offer unparalleled performance and prestige. This demand is primarily fueled by high-net-worth individuals and collectors who seek unique driving experiences and status symbols. The revival of V16 engines could cater to this market, offering a blend of nostalgia and cutting-edge engineering.

The motorsport sector also presents potential opportunities for V16 engines. As racing series continue to evolve, there's a constant search for innovative powertrains that can deliver both performance and spectacle. A modern V16 configuration could offer a unique selling point for teams and manufacturers looking to differentiate themselves in competitive racing environments.

However, it's crucial to note that the overall market size for V16 engines is relatively small compared to mainstream engine configurations. The development and production costs associated with such specialized engines would likely result in very high price points, limiting their accessibility to a select few customers and applications.

Environmental regulations and the global push towards electrification pose significant challenges to the revival of V16 engines. Many countries have set ambitious targets for reducing emissions and phasing out internal combustion engines. This regulatory landscape may restrict the potential market for V16 engines, particularly in road-going vehicles.

Despite these challenges, there are emerging trends that could support the development of high-performance engines. The growing popularity of restomod culture, where classic vehicles are updated with modern technology, could create a market for V16 engines as part of high-end restoration projects. Additionally, the synthetic fuel industry's advancements may offer a pathway for powerful internal combustion engines to coexist with environmental goals.

In conclusion, while the market for V16 engines is niche, there exists a dedicated segment of enthusiasts, collectors, and performance-oriented customers who would be interested in such powerplants. The key to successfully reintroducing V16 engines lies in identifying and targeting these specific market segments, while also addressing the broader industry trends towards efficiency and sustainability.

Current V16 Technology Challenges

The revival of V16 engine configurations faces several significant technological challenges in the current automotive landscape. One of the primary obstacles is the inherent complexity of these engines, which require precise engineering and manufacturing processes to ensure optimal performance and reliability. The sheer number of components involved in a V16 engine, including pistons, valves, and crankshafts, increases the potential for mechanical issues and raises production costs substantially.

Fuel efficiency remains a critical concern for V16 engines, particularly in an era focused on reducing carbon emissions and improving overall vehicle economy. The large displacement and high cylinder count of V16 engines typically result in increased fuel consumption, which conflicts with modern automotive trends and regulatory requirements. Addressing this challenge requires innovative approaches to engine management systems, combustion efficiency, and potentially the integration of hybrid technologies.

Packaging constraints present another significant hurdle for V16 engine implementation. Modern vehicle designs prioritize aerodynamics, safety features, and interior space, leaving limited room for large, complex powertrains. Fitting a V16 engine into contemporary vehicle architectures without compromising other essential aspects of vehicle design poses a considerable engineering challenge.

Emissions compliance is perhaps the most pressing issue facing V16 engine development. Stringent global emissions standards, particularly in major automotive markets, necessitate advanced exhaust after-treatment systems and precise engine control strategies. Meeting these standards with a high-displacement, multi-cylinder engine requires substantial investment in research and development of cutting-edge emissions reduction technologies.

The weight of V16 engines also presents challenges for vehicle dynamics and performance. The increased mass affects weight distribution, handling characteristics, and overall vehicle efficiency. Engineers must develop innovative solutions to mitigate these effects, potentially through the use of lightweight materials and advanced chassis design techniques.

Cooling system design for V16 engines poses another significant technical challenge. The heat generated by such a large number of cylinders requires sophisticated thermal management solutions to maintain optimal operating temperatures and prevent overheating. This may involve the development of advanced cooling systems, including high-capacity radiators and efficient coolant circulation methods.

Lastly, the development of electronic control systems capable of managing the complexities of a V16 engine presents a formidable challenge. These systems must precisely control fuel injection, ignition timing, and valve actuation across 16 cylinders while optimizing performance, efficiency, and emissions. The software and hardware requirements for such systems are substantial and require significant expertise in engine management technology.

Fuel efficiency remains a critical concern for V16 engines, particularly in an era focused on reducing carbon emissions and improving overall vehicle economy. The large displacement and high cylinder count of V16 engines typically result in increased fuel consumption, which conflicts with modern automotive trends and regulatory requirements. Addressing this challenge requires innovative approaches to engine management systems, combustion efficiency, and potentially the integration of hybrid technologies.

Packaging constraints present another significant hurdle for V16 engine implementation. Modern vehicle designs prioritize aerodynamics, safety features, and interior space, leaving limited room for large, complex powertrains. Fitting a V16 engine into contemporary vehicle architectures without compromising other essential aspects of vehicle design poses a considerable engineering challenge.

Emissions compliance is perhaps the most pressing issue facing V16 engine development. Stringent global emissions standards, particularly in major automotive markets, necessitate advanced exhaust after-treatment systems and precise engine control strategies. Meeting these standards with a high-displacement, multi-cylinder engine requires substantial investment in research and development of cutting-edge emissions reduction technologies.

The weight of V16 engines also presents challenges for vehicle dynamics and performance. The increased mass affects weight distribution, handling characteristics, and overall vehicle efficiency. Engineers must develop innovative solutions to mitigate these effects, potentially through the use of lightweight materials and advanced chassis design techniques.

Cooling system design for V16 engines poses another significant technical challenge. The heat generated by such a large number of cylinders requires sophisticated thermal management solutions to maintain optimal operating temperatures and prevent overheating. This may involve the development of advanced cooling systems, including high-capacity radiators and efficient coolant circulation methods.

Lastly, the development of electronic control systems capable of managing the complexities of a V16 engine presents a formidable challenge. These systems must precisely control fuel injection, ignition timing, and valve actuation across 16 cylinders while optimizing performance, efficiency, and emissions. The software and hardware requirements for such systems are substantial and require significant expertise in engine management technology.

Modern V16 Engine Design Solutions

01 V16 engine cylinder arrangement

V16 engines feature a unique cylinder arrangement where two banks of eight cylinders are positioned in a V-shape. This configuration allows for a compact design while providing high power output. The V-angle between the cylinder banks can vary, affecting engine balance and overall dimensions.- V16 engine cylinder arrangement: V16 engines feature a unique cylinder arrangement where two banks of eight cylinders are positioned in a V-shape. This configuration allows for a compact design while providing high power output. The V-angle between the cylinder banks can vary, affecting the engine's balance and overall dimensions.

- Fuel injection systems for V16 engines: Advanced fuel injection systems are crucial for optimizing the performance of V16 engines. These systems can include direct injection, multi-point injection, or a combination of both. Precise fuel delivery and timing contribute to improved fuel efficiency, power output, and emissions control in V16 configurations.

- Cooling systems for V16 engines: Effective cooling is essential for V16 engines due to their high power output and compact design. Cooling systems may incorporate advanced radiator designs, multiple coolant circuits, and precision-controlled electric water pumps to maintain optimal operating temperatures across all cylinders and prevent overheating.

- Electronic control units for V16 engines: Sophisticated electronic control units (ECUs) are employed to manage the complex operations of V16 engines. These ECUs control various aspects such as fuel injection, ignition timing, valve timing, and boost pressure in turbocharged variants. Advanced algorithms and sensors ensure optimal performance and efficiency across different operating conditions.

- Turbocharging and supercharging V16 engines: To further enhance the power output of V16 engines, forced induction systems such as turbochargers or superchargers can be implemented. These systems increase the air intake pressure, allowing for more fuel to be burned and resulting in higher power output. Careful design considerations are necessary to manage the increased heat and stress on engine components.

02 Fuel injection systems for V16 engines

Advanced fuel injection systems are crucial for V16 engines to ensure optimal fuel distribution and combustion efficiency. These systems may include direct injection technology, multiple injectors per cylinder, or variable injection timing to maximize power output and minimize fuel consumption.Expand Specific Solutions03 Cooling systems for V16 engines

Efficient cooling systems are essential for V16 engines due to their high power output and heat generation. These may include advanced liquid cooling circuits, oil coolers, and intercoolers to maintain optimal operating temperatures and prevent overheating.Expand Specific Solutions04 V16 engine control systems

Sophisticated electronic control systems are employed in V16 engines to manage various aspects such as fuel injection, ignition timing, and valve timing. These systems may incorporate advanced sensors and algorithms to optimize performance, fuel efficiency, and emissions across different operating conditions.Expand Specific Solutions05 V16 engine applications

V16 engines find applications in various high-performance and heavy-duty scenarios. These may include marine propulsion systems, large-scale power generation, luxury automobiles, and specialized military vehicles. The high power output and torque characteristics of V16 engines make them suitable for demanding applications requiring significant power.Expand Specific Solutions

Key Players in V16 Engine Development

The V16 engine configuration market is currently in a niche revival phase, with limited market size but growing interest. The technology's maturity varies across manufacturers, with established automotive giants like Ford Global Technologies LLC, GM Global Technology Operations LLC, and Volkswagen AG potentially leveraging their extensive R&D capabilities to explore V16 applications. Luxury and performance-oriented brands such as Mercedes-Benz Group AG might see opportunities in high-end vehicles. However, the market faces challenges from stricter emissions regulations and the shift towards electrification, which companies like Honda Motor Co., Ltd. and AVIC Shenyang Liming Aero-Engine are actively pursuing. The revival of V16 engines likely requires innovative approaches to balance performance with efficiency and environmental concerns.

Ford Global Technologies LLC

Technical Solution: Ford has been exploring the revival of V16 engine configurations, focusing on advanced materials and manufacturing techniques to address historical challenges. Their approach involves using lightweight alloys and 3D printing for complex components, potentially reducing the engine's weight by up to 30% compared to traditional V16 designs[1]. Ford is also investigating variable valve timing and cylinder deactivation technologies to improve fuel efficiency and reduce emissions in these large displacement engines. The company's research includes integrating hybrid systems with V16 engines, aiming to combine high performance with improved fuel economy[3].

Strengths: Extensive experience in engine development, access to advanced manufacturing technologies. Weaknesses: High development costs, potential market limitations for V16 engines in modern automotive landscape.

Caterpillar, Inc.

Technical Solution: Caterpillar's approach to V16 engine configurations focuses on heavy-duty industrial and marine applications. Their research involves developing high-efficiency, large displacement V16 engines that can meet stringent emissions regulations while providing the power and reliability required for demanding applications. Caterpillar is exploring advanced fuel injection systems, including common rail technology with pressures exceeding 2,500 bar, to improve combustion efficiency and reduce emissions[9]. The company is also investigating the use of alternative fuels, such as hydrogen and ammonia, in V16 engines for industrial applications. Caterpillar's V16 design incorporates advanced aftertreatment systems and selective catalytic reduction (SCR) technology to meet Tier 4 Final and IMO Tier III emissions standards. Additionally, the company is developing predictive maintenance systems using IoT and AI technologies to optimize the performance and longevity of these large engines[10].

Strengths: Extensive experience in large engine design for industrial applications, strong global service network. Weaknesses: Limited applicability outside of heavy industry and marine sectors.

Innovative V16 Technologies

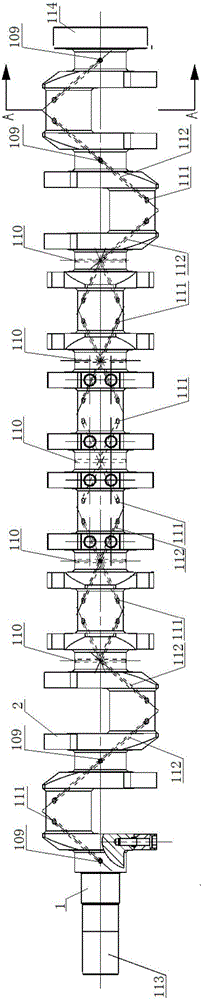

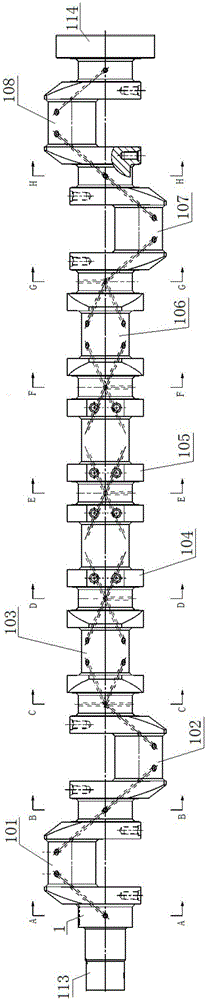

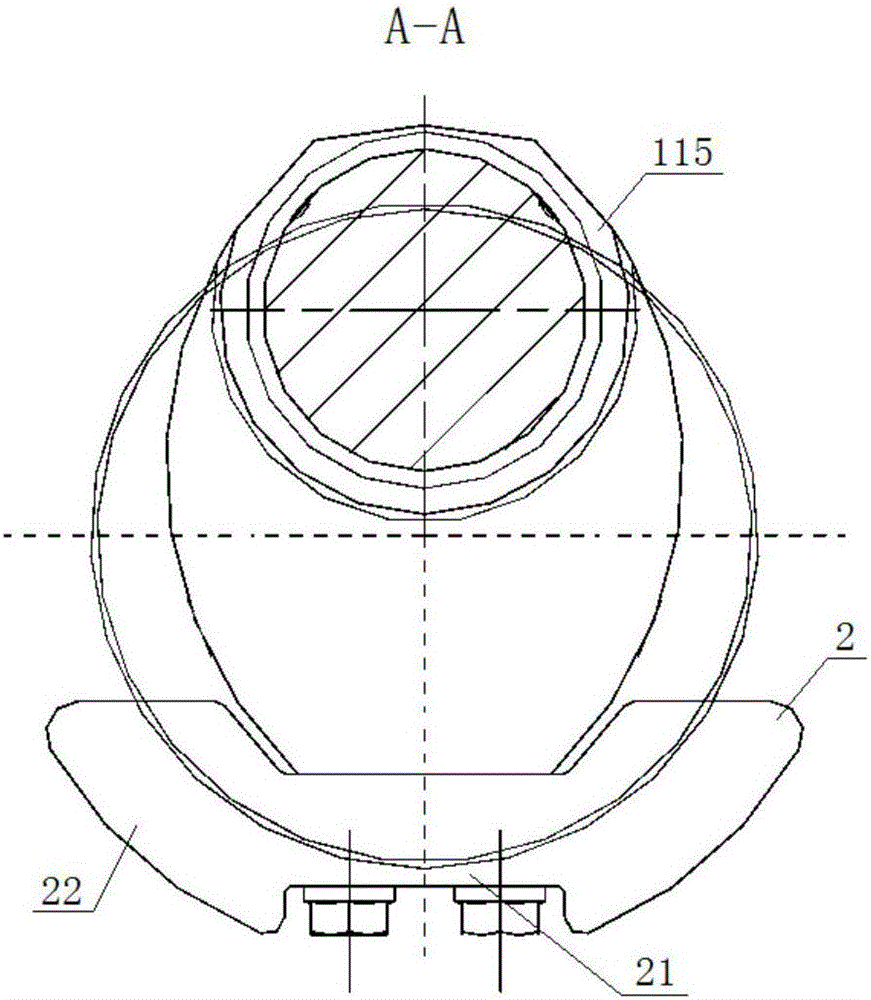

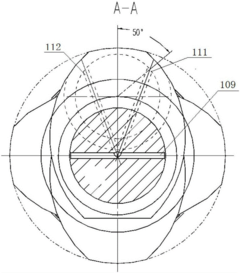

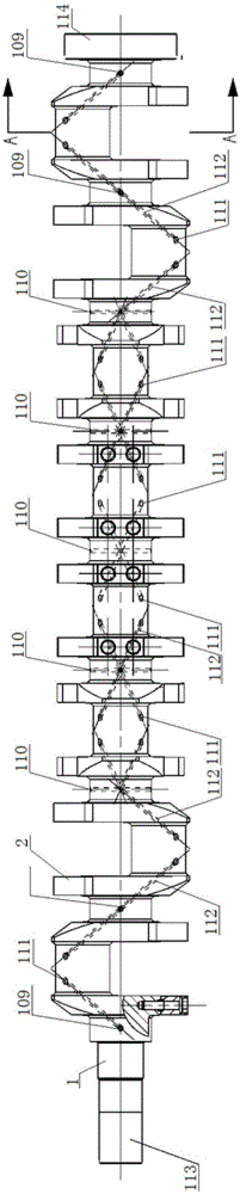

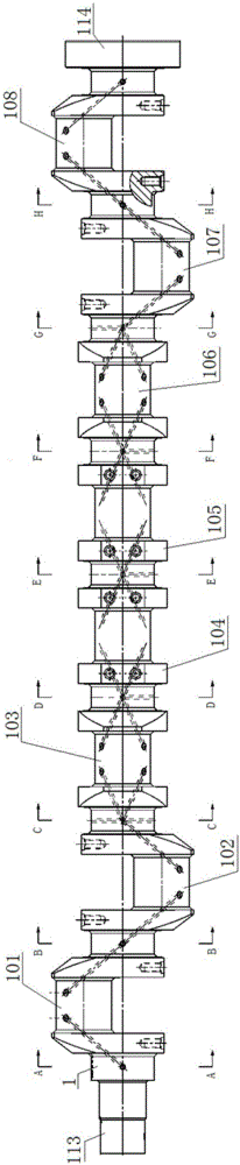

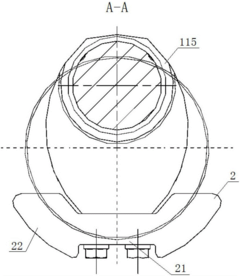

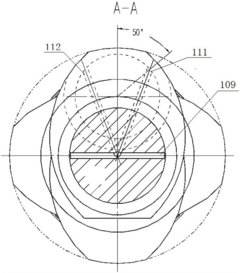

Crankshaft structure of V-shaped 16-cylinder engine

PatentInactiveCN106089974A

Innovation

- A V-shaped 16-cylinder engine crankshaft structure is designed, using horizontal and vertical oil passage arrangements on multiple cranks and connecting rod journals, combined with symmetrical crank arms and counterweights, to optimize the oil passage arrangement and firing sequence. , enhanced lubrication effect and dynamic balance.

Crankshaft structure for V-type 16 cylinder engine

PatentInactiveCN106089975A

Innovation

- A V-shaped 16-cylinder engine crankshaft structure was designed, using a symmetrical crank arm and counterweight design to optimize the firing sequence, and set up horizontal and vertical oil passages on the crankshaft journal to form an inclined oil passage to improve the lubrication effect.

Environmental Impact Assessment

The environmental impact assessment of revisiting forgotten V16 engine configurations for potential revitalization is a critical aspect that requires thorough examination. These large displacement engines, while historically significant, pose substantial challenges in the context of modern environmental regulations and sustainability goals.

Fuel consumption is a primary concern with V16 engines. Their inherently large displacement and high cylinder count result in significantly higher fuel consumption compared to more compact engine designs. This increased fuel usage directly correlates to higher carbon dioxide emissions, contributing to greenhouse gas accumulation and climate change. The carbon footprint of manufacturing and operating V16 engines is considerably larger than that of smaller, more efficient engine configurations.

Emissions control presents another significant challenge. V16 engines, particularly those based on older designs, may struggle to meet current and future emissions standards. The complexity of managing exhaust from 16 cylinders requires advanced catalytic converter systems and sophisticated engine management technology. Retrofitting these engines with modern emissions control equipment could be technically challenging and economically unfeasible.

Noise pollution is an additional environmental factor to consider. V16 engines are known for their distinctive sound, which, while appealing to enthusiasts, may exceed noise regulations in many jurisdictions. Implementing effective noise reduction measures without compromising the engine's character and performance would be a significant engineering challenge.

The materials used in V16 engine production also have environmental implications. These engines require larger quantities of metals and other resources compared to smaller engines, increasing the environmental impact of their manufacture. The extraction and processing of these materials contribute to resource depletion and generate additional pollution.

However, the potential for technological advancements in V16 engine design could mitigate some of these environmental concerns. Integration of hybrid technologies, advanced materials, and cutting-edge combustion techniques could potentially improve efficiency and reduce emissions. For instance, cylinder deactivation technology could allow a V16 to operate as a smaller engine under light loads, improving fuel economy.

In conclusion, while the revival of V16 engine configurations presents significant environmental challenges, it also offers opportunities for innovative solutions in engine design and emissions control. Any potential revitalization must carefully balance the historical and performance aspects of these engines with the pressing need for environmental sustainability in the automotive industry.

Fuel consumption is a primary concern with V16 engines. Their inherently large displacement and high cylinder count result in significantly higher fuel consumption compared to more compact engine designs. This increased fuel usage directly correlates to higher carbon dioxide emissions, contributing to greenhouse gas accumulation and climate change. The carbon footprint of manufacturing and operating V16 engines is considerably larger than that of smaller, more efficient engine configurations.

Emissions control presents another significant challenge. V16 engines, particularly those based on older designs, may struggle to meet current and future emissions standards. The complexity of managing exhaust from 16 cylinders requires advanced catalytic converter systems and sophisticated engine management technology. Retrofitting these engines with modern emissions control equipment could be technically challenging and economically unfeasible.

Noise pollution is an additional environmental factor to consider. V16 engines are known for their distinctive sound, which, while appealing to enthusiasts, may exceed noise regulations in many jurisdictions. Implementing effective noise reduction measures without compromising the engine's character and performance would be a significant engineering challenge.

The materials used in V16 engine production also have environmental implications. These engines require larger quantities of metals and other resources compared to smaller engines, increasing the environmental impact of their manufacture. The extraction and processing of these materials contribute to resource depletion and generate additional pollution.

However, the potential for technological advancements in V16 engine design could mitigate some of these environmental concerns. Integration of hybrid technologies, advanced materials, and cutting-edge combustion techniques could potentially improve efficiency and reduce emissions. For instance, cylinder deactivation technology could allow a V16 to operate as a smaller engine under light loads, improving fuel economy.

In conclusion, while the revival of V16 engine configurations presents significant environmental challenges, it also offers opportunities for innovative solutions in engine design and emissions control. Any potential revitalization must carefully balance the historical and performance aspects of these engines with the pressing need for environmental sustainability in the automotive industry.

V16 Engine Manufacturing Feasibility

The manufacturing feasibility of V16 engines presents unique challenges and opportunities in today's automotive landscape. While these engines have largely fallen out of favor due to their complexity and cost, recent advancements in manufacturing technologies and materials science offer potential for their revival.

Modern precision manufacturing techniques, such as computer numerical control (CNC) machining and 3D printing, have significantly improved the ability to produce complex engine components with high accuracy and consistency. These technologies allow for tighter tolerances and more intricate designs, potentially addressing some of the historical challenges associated with V16 engine production.

Advanced materials, including lightweight alloys and composites, offer new possibilities for reducing the overall weight of V16 engines. This could help mitigate one of the primary drawbacks of these engines - their substantial mass. Implementing these materials could potentially improve the power-to-weight ratio, making V16 engines more viable for high-performance applications.

The advent of modular manufacturing processes presents an interesting avenue for V16 engine production. By designing the engine as a series of interconnected modules, manufacturers could potentially streamline assembly and reduce production costs. This approach could also facilitate easier maintenance and repairs, addressing another historical concern with V16 engines.

However, significant challenges remain. The sheer number of components in a V16 engine increases the complexity of assembly and quality control processes. Ensuring proper balance and minimizing vibration across such a large number of cylinders requires sophisticated engineering and precise manufacturing.

Environmental regulations and the push towards electrification pose additional hurdles. Manufacturers would need to invest heavily in emissions control technologies to meet stringent standards. The question of whether such investment is justifiable in the face of increasing electrification trends is a critical consideration.

From a supply chain perspective, the specialized nature of V16 engine components may necessitate the development of new supplier relationships or in-house production capabilities. This could significantly impact the overall cost and feasibility of manufacturing.

In conclusion, while modern manufacturing technologies offer new possibilities for V16 engine production, the economic and regulatory landscape presents significant challenges. The feasibility of manufacturing these engines on a commercial scale would likely depend on identifying niche markets where their unique characteristics provide substantial value, justifying the increased complexity and cost of production.

Modern precision manufacturing techniques, such as computer numerical control (CNC) machining and 3D printing, have significantly improved the ability to produce complex engine components with high accuracy and consistency. These technologies allow for tighter tolerances and more intricate designs, potentially addressing some of the historical challenges associated with V16 engine production.

Advanced materials, including lightweight alloys and composites, offer new possibilities for reducing the overall weight of V16 engines. This could help mitigate one of the primary drawbacks of these engines - their substantial mass. Implementing these materials could potentially improve the power-to-weight ratio, making V16 engines more viable for high-performance applications.

The advent of modular manufacturing processes presents an interesting avenue for V16 engine production. By designing the engine as a series of interconnected modules, manufacturers could potentially streamline assembly and reduce production costs. This approach could also facilitate easier maintenance and repairs, addressing another historical concern with V16 engines.

However, significant challenges remain. The sheer number of components in a V16 engine increases the complexity of assembly and quality control processes. Ensuring proper balance and minimizing vibration across such a large number of cylinders requires sophisticated engineering and precise manufacturing.

Environmental regulations and the push towards electrification pose additional hurdles. Manufacturers would need to invest heavily in emissions control technologies to meet stringent standards. The question of whether such investment is justifiable in the face of increasing electrification trends is a critical consideration.

From a supply chain perspective, the specialized nature of V16 engine components may necessitate the development of new supplier relationships or in-house production capabilities. This could significantly impact the overall cost and feasibility of manufacturing.

In conclusion, while modern manufacturing technologies offer new possibilities for V16 engine production, the economic and regulatory landscape presents significant challenges. The feasibility of manufacturing these engines on a commercial scale would likely depend on identifying niche markets where their unique characteristics provide substantial value, justifying the increased complexity and cost of production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!