Sensor Fusion Techniques For Real-Time DED Process Control

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Process Control Background and Objectives

Directed Energy Deposition (DED) represents a transformative additive manufacturing technology that enables the direct fabrication of metal parts through the deposition of material using focused thermal energy. The evolution of DED technology spans several decades, originating from early laser cladding techniques in the 1980s and progressively advancing into sophisticated manufacturing systems capable of producing complex geometries with high precision. Recent technological developments have significantly enhanced DED capabilities, particularly in multi-material processing, functionally graded materials, and repair applications for high-value components.

The current trajectory of DED technology development is moving toward more intelligent and autonomous systems that can adapt to process variations in real-time. This evolution is driven by increasing demands for higher quality standards, improved process reliability, and enhanced production efficiency in industries such as aerospace, defense, and medical device manufacturing.

Despite these advancements, DED processes remain challenging to control due to their inherent complexity. The thermal dynamics, material flow characteristics, and rapid solidification phenomena create a multifaceted process environment that is difficult to monitor and regulate effectively. Traditional control approaches that rely on single-sensor feedback mechanisms have proven inadequate for capturing the full spectrum of process variables that influence build quality.

Sensor fusion techniques represent a promising approach to address these limitations by integrating data from multiple sensor modalities to provide comprehensive process monitoring and control capabilities. By combining information from thermal imaging, optical emissions, acoustic signatures, and other sensing methods, a more complete understanding of the process state can be achieved, enabling more effective control interventions.

The primary objectives of implementing sensor fusion techniques for real-time DED process control include: enhancing build quality consistency through adaptive control strategies; reducing defect rates by early detection of process anomalies; optimizing material properties through precise control of thermal conditions; and enabling the fabrication of components with complex geometries and material compositions that were previously unachievable.

Furthermore, the development of robust sensor fusion methodologies aims to establish a foundation for fully autonomous DED manufacturing systems that can self-optimize based on part requirements, material characteristics, and process conditions. This capability would significantly reduce the expertise barrier currently limiting wider industrial adoption of DED technology and enable more cost-effective production of customized components.

The ultimate goal is to transform DED from a specialized manufacturing process requiring extensive operator expertise into a reliable, repeatable production technology that can be seamlessly integrated into mainstream manufacturing operations across diverse industrial sectors.

The current trajectory of DED technology development is moving toward more intelligent and autonomous systems that can adapt to process variations in real-time. This evolution is driven by increasing demands for higher quality standards, improved process reliability, and enhanced production efficiency in industries such as aerospace, defense, and medical device manufacturing.

Despite these advancements, DED processes remain challenging to control due to their inherent complexity. The thermal dynamics, material flow characteristics, and rapid solidification phenomena create a multifaceted process environment that is difficult to monitor and regulate effectively. Traditional control approaches that rely on single-sensor feedback mechanisms have proven inadequate for capturing the full spectrum of process variables that influence build quality.

Sensor fusion techniques represent a promising approach to address these limitations by integrating data from multiple sensor modalities to provide comprehensive process monitoring and control capabilities. By combining information from thermal imaging, optical emissions, acoustic signatures, and other sensing methods, a more complete understanding of the process state can be achieved, enabling more effective control interventions.

The primary objectives of implementing sensor fusion techniques for real-time DED process control include: enhancing build quality consistency through adaptive control strategies; reducing defect rates by early detection of process anomalies; optimizing material properties through precise control of thermal conditions; and enabling the fabrication of components with complex geometries and material compositions that were previously unachievable.

Furthermore, the development of robust sensor fusion methodologies aims to establish a foundation for fully autonomous DED manufacturing systems that can self-optimize based on part requirements, material characteristics, and process conditions. This capability would significantly reduce the expertise barrier currently limiting wider industrial adoption of DED technology and enable more cost-effective production of customized components.

The ultimate goal is to transform DED from a specialized manufacturing process requiring extensive operator expertise into a reliable, repeatable production technology that can be seamlessly integrated into mainstream manufacturing operations across diverse industrial sectors.

Market Analysis for Sensor Fusion in Additive Manufacturing

The global market for sensor fusion technologies in additive manufacturing, particularly for Directed Energy Deposition (DED) processes, is experiencing significant growth driven by the increasing adoption of Industry 4.0 principles and smart manufacturing initiatives. The market size for sensor fusion in additive manufacturing was valued at approximately $1.2 billion in 2022 and is projected to reach $3.5 billion by 2028, representing a compound annual growth rate of 19.6%.

The demand for real-time process monitoring and control systems in DED applications is primarily fueled by industries requiring high-precision components, including aerospace, defense, medical devices, and automotive sectors. These industries collectively account for over 70% of the current market share, with aerospace leading at 32% due to stringent quality requirements and the high cost of component failures.

Regional analysis reveals North America dominates the market with approximately 42% share, followed by Europe (28%) and Asia-Pacific (24%). The Asia-Pacific region, particularly China and South Korea, is expected to witness the fastest growth rate of 23.8% through 2028, driven by substantial government investments in advanced manufacturing technologies and rapid industrialization.

Key market drivers include increasing demand for zero-defect manufacturing, rising material costs necessitating process optimization, and growing complexity of components that require precise control during fabrication. Additionally, regulatory requirements for traceability and quality assurance in critical applications are pushing manufacturers to implement comprehensive monitoring solutions.

The sensor fusion market for DED is segmented by sensor type, with thermal sensors leading at 35% market share, followed by optical sensors (28%), acoustic sensors (18%), and others including force and electromagnetic sensors. Multi-modal sensor fusion systems that integrate three or more sensor types are gaining traction, showing a growth rate of 25.3% annually.

Customer pain points in this market include high initial implementation costs, challenges in data integration from heterogeneous sensor networks, and the need for specialized expertise to interpret complex sensor data. The average return on investment period for comprehensive sensor fusion systems in DED applications is currently 18-24 months, though this is expected to decrease as technologies mature and standardization improves.

Market analysts predict that subscription-based sensor fusion solutions and cloud-based process monitoring services will gain significant market share, potentially reaching 40% of the total market by 2027, as manufacturers seek to reduce capital expenditures while maintaining access to cutting-edge monitoring capabilities.

The demand for real-time process monitoring and control systems in DED applications is primarily fueled by industries requiring high-precision components, including aerospace, defense, medical devices, and automotive sectors. These industries collectively account for over 70% of the current market share, with aerospace leading at 32% due to stringent quality requirements and the high cost of component failures.

Regional analysis reveals North America dominates the market with approximately 42% share, followed by Europe (28%) and Asia-Pacific (24%). The Asia-Pacific region, particularly China and South Korea, is expected to witness the fastest growth rate of 23.8% through 2028, driven by substantial government investments in advanced manufacturing technologies and rapid industrialization.

Key market drivers include increasing demand for zero-defect manufacturing, rising material costs necessitating process optimization, and growing complexity of components that require precise control during fabrication. Additionally, regulatory requirements for traceability and quality assurance in critical applications are pushing manufacturers to implement comprehensive monitoring solutions.

The sensor fusion market for DED is segmented by sensor type, with thermal sensors leading at 35% market share, followed by optical sensors (28%), acoustic sensors (18%), and others including force and electromagnetic sensors. Multi-modal sensor fusion systems that integrate three or more sensor types are gaining traction, showing a growth rate of 25.3% annually.

Customer pain points in this market include high initial implementation costs, challenges in data integration from heterogeneous sensor networks, and the need for specialized expertise to interpret complex sensor data. The average return on investment period for comprehensive sensor fusion systems in DED applications is currently 18-24 months, though this is expected to decrease as technologies mature and standardization improves.

Market analysts predict that subscription-based sensor fusion solutions and cloud-based process monitoring services will gain significant market share, potentially reaching 40% of the total market by 2027, as manufacturers seek to reduce capital expenditures while maintaining access to cutting-edge monitoring capabilities.

Current Sensor Technologies and Integration Challenges

The current landscape of sensor technologies for Directed Energy Deposition (DED) process control encompasses a diverse array of monitoring solutions, each with specific capabilities and limitations. Thermal sensors, including infrared cameras and pyrometers, provide critical temperature measurements of the melt pool, substrate, and surrounding areas. These sensors operate at different wavelengths to capture thermal gradients with varying degrees of precision, though they often struggle with accurate calibration in the presence of metal vapor and plasma emissions characteristic of DED processes.

Optical sensors represent another crucial category, with high-speed cameras and photodiodes enabling real-time monitoring of melt pool geometry, powder flow distribution, and layer formation. Advanced image processing algorithms have enhanced the utility of these sensors, though challenges persist in filtering out process-induced noise and maintaining consistent performance under varying lighting conditions.

Acoustic emission sensors detect ultrasonic waves generated during material deposition, offering insights into solidification dynamics and potential defect formation. These sensors provide complementary data that thermal and optical methods cannot capture, particularly regarding internal structural characteristics, though signal interpretation remains complex due to the noisy DED environment.

Process parameter sensors monitoring laser power, travel speed, and powder feed rate ensure adherence to predetermined process specifications. While these sensors offer high reliability, they provide only indirect information about the actual deposition quality, necessitating correlation with other sensor data for comprehensive process understanding.

The integration of these diverse sensor technologies presents significant challenges. Hardware compatibility issues arise from differing data formats, sampling rates, and communication protocols among sensors from various manufacturers. This heterogeneity complicates the development of unified monitoring systems capable of synchronized data collection and analysis.

Data synchronization represents another major hurdle, as different sensors operate at varying acquisition speeds and latencies. Ensuring temporal alignment of measurements from multiple sources requires sophisticated timing mechanisms and data processing algorithms that can account for these disparities without introducing artifacts or misinterpretations.

Computational demands for real-time processing of multi-sensor data streams are substantial, particularly when implementing advanced fusion algorithms. The volume and velocity of incoming data often exceed the capabilities of conventional computing systems deployed in manufacturing environments, necessitating edge computing solutions or dedicated high-performance hardware.

Environmental factors in DED processes, including electromagnetic interference, thermal variations, and mechanical vibrations, further complicate sensor integration by introducing noise and potential measurement errors. Robust sensor fusion techniques must incorporate effective filtering and error compensation mechanisms to maintain reliability under these challenging conditions.

Optical sensors represent another crucial category, with high-speed cameras and photodiodes enabling real-time monitoring of melt pool geometry, powder flow distribution, and layer formation. Advanced image processing algorithms have enhanced the utility of these sensors, though challenges persist in filtering out process-induced noise and maintaining consistent performance under varying lighting conditions.

Acoustic emission sensors detect ultrasonic waves generated during material deposition, offering insights into solidification dynamics and potential defect formation. These sensors provide complementary data that thermal and optical methods cannot capture, particularly regarding internal structural characteristics, though signal interpretation remains complex due to the noisy DED environment.

Process parameter sensors monitoring laser power, travel speed, and powder feed rate ensure adherence to predetermined process specifications. While these sensors offer high reliability, they provide only indirect information about the actual deposition quality, necessitating correlation with other sensor data for comprehensive process understanding.

The integration of these diverse sensor technologies presents significant challenges. Hardware compatibility issues arise from differing data formats, sampling rates, and communication protocols among sensors from various manufacturers. This heterogeneity complicates the development of unified monitoring systems capable of synchronized data collection and analysis.

Data synchronization represents another major hurdle, as different sensors operate at varying acquisition speeds and latencies. Ensuring temporal alignment of measurements from multiple sources requires sophisticated timing mechanisms and data processing algorithms that can account for these disparities without introducing artifacts or misinterpretations.

Computational demands for real-time processing of multi-sensor data streams are substantial, particularly when implementing advanced fusion algorithms. The volume and velocity of incoming data often exceed the capabilities of conventional computing systems deployed in manufacturing environments, necessitating edge computing solutions or dedicated high-performance hardware.

Environmental factors in DED processes, including electromagnetic interference, thermal variations, and mechanical vibrations, further complicate sensor integration by introducing noise and potential measurement errors. Robust sensor fusion techniques must incorporate effective filtering and error compensation mechanisms to maintain reliability under these challenging conditions.

Real-Time Monitoring Solutions for DED Processes

01 Multi-sensor fusion for autonomous systems

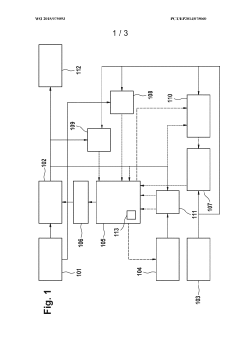

Multi-sensor fusion techniques integrate data from various sensors to enhance the perception capabilities of autonomous systems. By combining information from different sensor types such as cameras, LiDAR, radar, and ultrasonic sensors, these systems can achieve more accurate environmental awareness and obstacle detection. This approach improves decision-making reliability in real-time control applications by reducing individual sensor limitations and providing redundancy in critical situations.- Multi-sensor fusion for autonomous vehicles: Sensor fusion techniques that combine data from multiple sensors such as LiDAR, radar, cameras, and GPS to enhance perception and navigation capabilities in autonomous vehicles. This approach improves obstacle detection, path planning, and real-time decision making by leveraging the strengths of different sensor types while compensating for their individual limitations. The integrated data provides a more comprehensive environmental awareness, enabling safer and more reliable autonomous operation in diverse conditions.

- Kalman filter-based sensor fusion algorithms: Implementation of Kalman filter and its variants (Extended Kalman Filter, Unscented Kalman Filter) for optimal estimation in sensor fusion applications. These algorithms provide statistical methods to combine measurements from multiple sensors with different accuracies and sampling rates, reducing noise and uncertainty in the fused data. This approach is particularly effective for real-time control systems requiring precise state estimation, such as in robotics, navigation systems, and industrial automation where accurate tracking and prediction are essential.

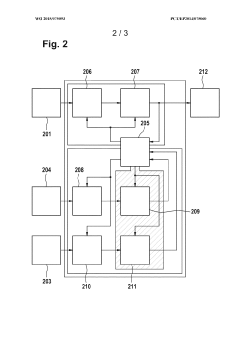

- Distributed sensor networks for industrial control: Architectures for distributed sensor networks that collect and process data from multiple points in industrial environments to enable real-time monitoring and control. These systems utilize edge computing to process sensor data locally before transmission to central control systems, reducing latency and bandwidth requirements. The fusion of distributed sensor data provides comprehensive visibility into industrial processes, enabling predictive maintenance, quality control, and adaptive manufacturing with improved efficiency and reduced downtime.

- AI and machine learning for adaptive sensor fusion: Integration of artificial intelligence and machine learning techniques to enhance sensor fusion capabilities through adaptive algorithms that can learn from historical data and improve over time. These approaches include deep neural networks, reinforcement learning, and other AI methods that can identify patterns, detect anomalies, and make predictions based on complex sensor data relationships. The adaptive nature of these systems allows for improved performance in dynamic environments and changing conditions, making them particularly valuable for real-time control applications.

- Time-synchronized fusion for high-precision control: Methods for achieving precise time synchronization across multiple sensors to enable high-accuracy fusion for real-time control applications. These techniques address challenges related to varying sensor latencies, sampling rates, and clock drifts that can impact the quality of fused data. By ensuring temporal alignment of sensor measurements, these approaches enable more precise state estimation and control actions, which is critical for applications requiring high-precision coordination such as collaborative robotics, automated manufacturing, and advanced motion control systems.

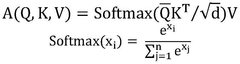

02 Kalman filtering and advanced estimation algorithms

Advanced estimation algorithms, particularly Kalman filtering and its variants, form the backbone of many sensor fusion implementations for real-time control. These mathematical techniques optimally combine measurements from multiple sensors while accounting for uncertainties and noise. Extended and unscented Kalman filters are particularly valuable for nonlinear systems, enabling accurate state estimation for navigation, tracking, and control applications where real-time performance is critical.Expand Specific Solutions03 Distributed sensor networks for industrial control

Distributed sensor networks implement fusion techniques across multiple nodes to enable comprehensive monitoring and control of industrial processes. These systems synchronize data from geographically dispersed sensors to create cohesive operational awareness. Edge computing capabilities within these networks allow for localized processing that reduces latency in control responses, while maintaining communication with centralized systems for higher-level decision making and coordination.Expand Specific Solutions04 Machine learning approaches to sensor fusion

Machine learning algorithms enhance sensor fusion by adaptively learning optimal ways to combine heterogeneous sensor data. Deep neural networks, particularly convolutional and recurrent architectures, can extract meaningful features from raw sensor inputs and fuse them at various levels of abstraction. These approaches enable systems to improve performance over time through training on diverse operational scenarios, leading to more robust real-time control in complex and dynamic environments.Expand Specific Solutions05 Fault-tolerant sensor fusion architectures

Fault-tolerant sensor fusion architectures ensure continuous system operation despite sensor failures or degradation. These designs incorporate redundancy, anomaly detection, and graceful degradation mechanisms to maintain reliable control even when individual sensors malfunction. Dynamic reconfiguration capabilities allow the system to adapt its fusion strategy in real-time based on current sensor health status, ensuring critical control functions remain operational under adverse conditions.Expand Specific Solutions

Key Sensor Fusion Algorithms and Implementations

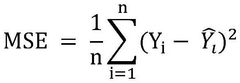

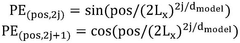

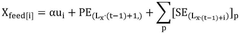

Direct energy deposition (DED) process neural network online monitoring system and method based on time sequence data set

PatentPendingCN119442861A

Innovation

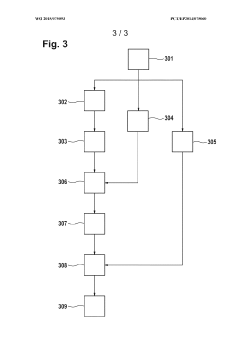

- A direct energy deposition DED process neural network online monitoring system based on a time series data set is adopted, which includes obtaining time series data, predicting temperature trends, determining defect prediction results, and optimizing process parameters.

Method, fusion filter, and system for fusing sensor signals with different temporal signal output delays into a fusion data set

PatentWO2015075093A1

Innovation

- A method that merges sensor signals with different temporal delays by determining error values using comparisons with other sensor systems, assuming they remain constant between adjustments, allowing for real-time and accurate fusion of sensor data while avoiding redundant corrections and maintaining data consistency.

Quality Assurance Standards for DED Manufacturing

Quality assurance in Directed Energy Deposition (DED) manufacturing requires comprehensive standards to ensure consistent part quality and process reliability. The integration of sensor fusion techniques for real-time process control necessitates adherence to established quality frameworks that govern both the manufacturing process and the resulting components.

International standards organizations including ISO, ASTM, and AWS have developed specific guidelines for additive manufacturing processes that apply to DED technologies. ISO/ASTM 52901:2017 provides requirements for purchased parts made by additive manufacturing, while ASTM F3187 specifically addresses directed energy deposition processes. These standards establish baseline requirements for material properties, dimensional accuracy, and surface finish that must be maintained through sensor-based control systems.

Process monitoring through sensor fusion must comply with quality control parameters defined in these standards. Critical process variables including melt pool temperature, dimensions, cooling rates, and material feed rates require continuous monitoring within specified tolerance ranges. The sensor fusion architecture must demonstrate measurement accuracy and precision according to metrology standards such as ISO 10012, with calibration procedures traceable to national measurement institutes.

Real-time data acquisition systems employed in sensor fusion must meet minimum sampling rates and signal-to-noise ratios to ensure detection of process anomalies. Standards such as AMS 7003 for laser powder bed fusion provide guidance on process monitoring requirements that can be adapted for DED applications. These standards typically mandate documentation of sensor types, locations, calibration methods, and data processing algorithms.

Post-process verification remains essential even with real-time monitoring. Non-destructive testing methods including ultrasonic testing, X-ray computed tomography, and dye penetrant inspection must follow standards such as ASTM E1417 and ASTM E1742 to validate internal structure integrity. Mechanical testing according to ASTM E8 for tensile properties and ASTM E18 for hardness provides quantitative verification of material performance.

Quality management systems integrating sensor fusion technologies should align with ISO 9001 and AS9100 for aerospace applications. These frameworks require documented procedures for sensor calibration, data validation, and corrective action protocols when process deviations are detected. Traceability of all process parameters and sensor readings must be maintained throughout the manufacturing workflow, with data retention policies complying with industry-specific requirements.

Emerging standards specifically addressing in-situ monitoring for additive manufacturing, such as those under development by ASTM Committee F42, will further refine requirements for sensor fusion implementation in DED processes. These standards aim to establish correlation methodologies between sensor data and final part quality, enabling statistical process control approaches for quality assurance.

International standards organizations including ISO, ASTM, and AWS have developed specific guidelines for additive manufacturing processes that apply to DED technologies. ISO/ASTM 52901:2017 provides requirements for purchased parts made by additive manufacturing, while ASTM F3187 specifically addresses directed energy deposition processes. These standards establish baseline requirements for material properties, dimensional accuracy, and surface finish that must be maintained through sensor-based control systems.

Process monitoring through sensor fusion must comply with quality control parameters defined in these standards. Critical process variables including melt pool temperature, dimensions, cooling rates, and material feed rates require continuous monitoring within specified tolerance ranges. The sensor fusion architecture must demonstrate measurement accuracy and precision according to metrology standards such as ISO 10012, with calibration procedures traceable to national measurement institutes.

Real-time data acquisition systems employed in sensor fusion must meet minimum sampling rates and signal-to-noise ratios to ensure detection of process anomalies. Standards such as AMS 7003 for laser powder bed fusion provide guidance on process monitoring requirements that can be adapted for DED applications. These standards typically mandate documentation of sensor types, locations, calibration methods, and data processing algorithms.

Post-process verification remains essential even with real-time monitoring. Non-destructive testing methods including ultrasonic testing, X-ray computed tomography, and dye penetrant inspection must follow standards such as ASTM E1417 and ASTM E1742 to validate internal structure integrity. Mechanical testing according to ASTM E8 for tensile properties and ASTM E18 for hardness provides quantitative verification of material performance.

Quality management systems integrating sensor fusion technologies should align with ISO 9001 and AS9100 for aerospace applications. These frameworks require documented procedures for sensor calibration, data validation, and corrective action protocols when process deviations are detected. Traceability of all process parameters and sensor readings must be maintained throughout the manufacturing workflow, with data retention policies complying with industry-specific requirements.

Emerging standards specifically addressing in-situ monitoring for additive manufacturing, such as those under development by ASTM Committee F42, will further refine requirements for sensor fusion implementation in DED processes. These standards aim to establish correlation methodologies between sensor data and final part quality, enabling statistical process control approaches for quality assurance.

Energy Efficiency Considerations in Sensor-Driven DED

Energy efficiency has emerged as a critical consideration in the implementation of sensor fusion techniques for Directed Energy Deposition (DED) process control. The integration of multiple sensor systems, while providing comprehensive monitoring capabilities, introduces significant energy consumption challenges that must be addressed for sustainable manufacturing operations.

The power requirements of sensor arrays in DED systems vary considerably based on sensor type and quantity. Thermal cameras typically consume 5-10W, while high-speed cameras may require 15-25W. Pyrometers operate at 2-5W, and spectroscopic sensors demand 10-20W. When multiple sensors operate simultaneously for fusion purposes, the cumulative energy demand becomes substantial, potentially reaching 50-100W for comprehensive monitoring setups.

Edge computing implementations for real-time sensor fusion processing introduce additional energy considerations. Local processing units handling complex fusion algorithms may consume 30-80W depending on computational intensity. This represents a significant portion of the overall energy footprint of sensor-driven DED systems, particularly in continuous production environments.

Recent advancements in energy-efficient sensor technologies have yielded promising results for DED applications. Low-power MEMS sensors consume 50-80% less energy than traditional counterparts while maintaining acceptable accuracy levels. Adaptive sampling techniques that dynamically adjust sensor activation based on process phases have demonstrated energy savings of 25-40% in experimental DED setups without compromising monitoring quality.

Energy harvesting technologies present innovative approaches to powering sensor networks in DED environments. Thermal gradient harvesting, utilizing the significant temperature differentials inherent in DED processes, has shown potential to generate 1-3W of supplementary power. Vibration-based energy harvesting from machine operations can contribute an additional 0.5-1W, potentially offsetting a portion of sensor energy requirements.

The implementation of intelligent power management strategies has proven effective in optimizing energy consumption. Sensor fusion architectures incorporating sleep-wake scheduling protocols have demonstrated 30-45% energy savings compared to continuously active systems. Context-aware sensor activation, where sensors operate at variable rates based on process criticality, offers a balanced approach to energy conservation while maintaining monitoring integrity during crucial process phases.

As DED technologies advance toward industrial-scale implementation, the energy efficiency of sensor fusion systems will increasingly influence total operational costs and environmental impact. Developing energy-optimized sensor fusion architectures represents a significant opportunity for enhancing the sustainability profile of additive manufacturing operations while maintaining the precision control benefits that sensor fusion technologies provide.

The power requirements of sensor arrays in DED systems vary considerably based on sensor type and quantity. Thermal cameras typically consume 5-10W, while high-speed cameras may require 15-25W. Pyrometers operate at 2-5W, and spectroscopic sensors demand 10-20W. When multiple sensors operate simultaneously for fusion purposes, the cumulative energy demand becomes substantial, potentially reaching 50-100W for comprehensive monitoring setups.

Edge computing implementations for real-time sensor fusion processing introduce additional energy considerations. Local processing units handling complex fusion algorithms may consume 30-80W depending on computational intensity. This represents a significant portion of the overall energy footprint of sensor-driven DED systems, particularly in continuous production environments.

Recent advancements in energy-efficient sensor technologies have yielded promising results for DED applications. Low-power MEMS sensors consume 50-80% less energy than traditional counterparts while maintaining acceptable accuracy levels. Adaptive sampling techniques that dynamically adjust sensor activation based on process phases have demonstrated energy savings of 25-40% in experimental DED setups without compromising monitoring quality.

Energy harvesting technologies present innovative approaches to powering sensor networks in DED environments. Thermal gradient harvesting, utilizing the significant temperature differentials inherent in DED processes, has shown potential to generate 1-3W of supplementary power. Vibration-based energy harvesting from machine operations can contribute an additional 0.5-1W, potentially offsetting a portion of sensor energy requirements.

The implementation of intelligent power management strategies has proven effective in optimizing energy consumption. Sensor fusion architectures incorporating sleep-wake scheduling protocols have demonstrated 30-45% energy savings compared to continuously active systems. Context-aware sensor activation, where sensors operate at variable rates based on process criticality, offers a balanced approach to energy conservation while maintaining monitoring integrity during crucial process phases.

As DED technologies advance toward industrial-scale implementation, the energy efficiency of sensor fusion systems will increasingly influence total operational costs and environmental impact. Developing energy-optimized sensor fusion architectures represents a significant opportunity for enhancing the sustainability profile of additive manufacturing operations while maintaining the precision control benefits that sensor fusion technologies provide.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!