Solid-State Relay and Heat Sink Optimization for Longevity

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SSR Technology Background and Longevity Goals

Solid-State Relays (SSRs) emerged in the late 1960s as an evolution from traditional electromechanical relays, offering a revolutionary approach to electrical switching without moving parts. The core technology utilizes semiconductor devices—typically thyristors, triacs, or MOSFETs—to control load circuits through electrical isolation achieved via optocouplers. This fundamental design has positioned SSRs as critical components in industrial automation, HVAC systems, and precision instrumentation where reliability and longevity are paramount.

The technological trajectory of SSRs has been marked by significant advancements in semiconductor materials and manufacturing processes. Early generations suffered from limited current handling capabilities and thermal management challenges. However, modern SSRs have overcome many of these limitations through innovations in silicon carbide (SiC) and gallium nitride (GaN) semiconductors, enabling higher temperature operation, faster switching speeds, and improved efficiency.

Despite these advancements, thermal management remains the primary factor affecting SSR longevity. When conducting current, semiconductor junctions generate heat that must be effectively dissipated to prevent premature failure. Industry data indicates that for every 10°C increase in operating temperature above rated specifications, an SSR's lifespan may decrease by approximately 50%. This thermal sensitivity establishes the critical relationship between heat sink design and relay durability.

The primary longevity goals for SSR systems center on achieving operational lifespans exceeding 10-15 years in industrial environments. This requires maintaining junction temperatures below critical thresholds—typically 125°C for silicon-based devices and up to 175°C for SiC alternatives—even under maximum load conditions and elevated ambient temperatures. Secondary objectives include minimizing thermal cycling stress, reducing voltage transients, and ensuring consistent performance across varying environmental conditions.

Recent technological trends focus on integrated thermal management solutions that combine advanced heat sink designs with active cooling mechanisms. These innovations aim to optimize heat dissipation while minimizing size and weight—critical factors for applications with space constraints. Computational fluid dynamics (CFD) modeling has become instrumental in predicting thermal behavior and optimizing heat sink geometries before physical prototyping.

The industry is progressively moving toward predictive maintenance approaches, incorporating temperature sensors and monitoring systems that can detect potential thermal issues before they lead to catastrophic failure. This shift represents a fundamental evolution from reactive replacement strategies to proactive management of SSR thermal conditions, ultimately extending operational lifespans and reducing system downtime in critical applications.

The technological trajectory of SSRs has been marked by significant advancements in semiconductor materials and manufacturing processes. Early generations suffered from limited current handling capabilities and thermal management challenges. However, modern SSRs have overcome many of these limitations through innovations in silicon carbide (SiC) and gallium nitride (GaN) semiconductors, enabling higher temperature operation, faster switching speeds, and improved efficiency.

Despite these advancements, thermal management remains the primary factor affecting SSR longevity. When conducting current, semiconductor junctions generate heat that must be effectively dissipated to prevent premature failure. Industry data indicates that for every 10°C increase in operating temperature above rated specifications, an SSR's lifespan may decrease by approximately 50%. This thermal sensitivity establishes the critical relationship between heat sink design and relay durability.

The primary longevity goals for SSR systems center on achieving operational lifespans exceeding 10-15 years in industrial environments. This requires maintaining junction temperatures below critical thresholds—typically 125°C for silicon-based devices and up to 175°C for SiC alternatives—even under maximum load conditions and elevated ambient temperatures. Secondary objectives include minimizing thermal cycling stress, reducing voltage transients, and ensuring consistent performance across varying environmental conditions.

Recent technological trends focus on integrated thermal management solutions that combine advanced heat sink designs with active cooling mechanisms. These innovations aim to optimize heat dissipation while minimizing size and weight—critical factors for applications with space constraints. Computational fluid dynamics (CFD) modeling has become instrumental in predicting thermal behavior and optimizing heat sink geometries before physical prototyping.

The industry is progressively moving toward predictive maintenance approaches, incorporating temperature sensors and monitoring systems that can detect potential thermal issues before they lead to catastrophic failure. This shift represents a fundamental evolution from reactive replacement strategies to proactive management of SSR thermal conditions, ultimately extending operational lifespans and reducing system downtime in critical applications.

Market Demand Analysis for Reliable SSR Solutions

The global market for Solid-State Relays (SSRs) continues to experience robust growth, driven primarily by increasing automation across industrial sectors and the growing need for reliable switching solutions in critical applications. Current market research indicates that the SSR market is expected to reach $1.8 billion by 2026, growing at a CAGR of approximately 6.5% from 2021 to 2026. This growth trajectory underscores the significant demand for reliable SSR solutions across various industries.

Industrial automation represents the largest market segment for SSRs, accounting for nearly 40% of the total market share. Manufacturing facilities are increasingly adopting SSRs over traditional electromechanical relays due to their superior reliability, longer operational lifespan, and reduced maintenance requirements. The absence of moving parts in SSRs eliminates mechanical wear and tear, making them particularly valuable in high-cycle applications where traditional relays would quickly deteriorate.

Energy efficiency has emerged as a critical market driver, with many industries seeking to optimize their power consumption. SSRs with optimized heat sink designs can significantly reduce energy losses during operation, making them increasingly attractive for energy-conscious industries. Market surveys indicate that approximately 65% of industrial customers now prioritize energy efficiency when selecting relay technologies, representing a substantial shift from just five years ago.

The renewable energy sector presents a rapidly expanding market opportunity for SSR manufacturers. Solar inverters, wind turbine control systems, and energy storage solutions all require highly reliable switching components capable of withstanding harsh environmental conditions. This sector is projected to grow at 8.7% annually through 2026, outpacing the overall SSR market growth rate.

Healthcare and medical equipment manufacturers represent another high-value market segment, where the reliability of SSRs is paramount. Medical devices often operate in critical scenarios where failure is not an option, driving demand for SSRs with exceptional longevity and thermal management capabilities. This segment values reliability over cost considerations, with surveys showing willingness to pay premium prices for proven reliability.

Geographically, Asia-Pacific dominates the SSR market with approximately 42% market share, followed by North America and Europe. China and India are experiencing the fastest growth rates due to rapid industrial expansion and manufacturing sector development. However, North America leads in terms of technological innovation, particularly in heat sink optimization and thermal management solutions.

Customer requirements are increasingly focused on SSRs with enhanced thermal management capabilities, as heat dissipation remains the primary factor affecting SSR longevity. Market research indicates that 78% of SSR failures are directly attributed to thermal issues, highlighting the critical importance of heat sink optimization in meeting market demands for reliability.

Industrial automation represents the largest market segment for SSRs, accounting for nearly 40% of the total market share. Manufacturing facilities are increasingly adopting SSRs over traditional electromechanical relays due to their superior reliability, longer operational lifespan, and reduced maintenance requirements. The absence of moving parts in SSRs eliminates mechanical wear and tear, making them particularly valuable in high-cycle applications where traditional relays would quickly deteriorate.

Energy efficiency has emerged as a critical market driver, with many industries seeking to optimize their power consumption. SSRs with optimized heat sink designs can significantly reduce energy losses during operation, making them increasingly attractive for energy-conscious industries. Market surveys indicate that approximately 65% of industrial customers now prioritize energy efficiency when selecting relay technologies, representing a substantial shift from just five years ago.

The renewable energy sector presents a rapidly expanding market opportunity for SSR manufacturers. Solar inverters, wind turbine control systems, and energy storage solutions all require highly reliable switching components capable of withstanding harsh environmental conditions. This sector is projected to grow at 8.7% annually through 2026, outpacing the overall SSR market growth rate.

Healthcare and medical equipment manufacturers represent another high-value market segment, where the reliability of SSRs is paramount. Medical devices often operate in critical scenarios where failure is not an option, driving demand for SSRs with exceptional longevity and thermal management capabilities. This segment values reliability over cost considerations, with surveys showing willingness to pay premium prices for proven reliability.

Geographically, Asia-Pacific dominates the SSR market with approximately 42% market share, followed by North America and Europe. China and India are experiencing the fastest growth rates due to rapid industrial expansion and manufacturing sector development. However, North America leads in terms of technological innovation, particularly in heat sink optimization and thermal management solutions.

Customer requirements are increasingly focused on SSRs with enhanced thermal management capabilities, as heat dissipation remains the primary factor affecting SSR longevity. Market research indicates that 78% of SSR failures are directly attributed to thermal issues, highlighting the critical importance of heat sink optimization in meeting market demands for reliability.

Current SSR Thermal Management Challenges

Solid-State Relays (SSRs) face significant thermal management challenges that directly impact their longevity and reliability. The primary issue stems from the semiconductor junction temperature, which must be maintained below critical thresholds (typically 125°C to 150°C) to prevent premature failure. During operation, SSRs generate substantial heat due to forward voltage drops across semiconductor components, with power dissipation often ranging from 0.8W to 2.5W per ampere of load current.

Traditional cooling solutions have proven inadequate for high-current applications, particularly in industrial environments where ambient temperatures can exceed 50°C. The thermal resistance pathway from junction to case (Rjc) and case to sink (Rcs) creates bottlenecks that limit heat transfer efficiency. Industry data indicates that approximately 40% of SSR failures are directly attributable to thermal stress and inadequate heat dissipation.

Contact resistance between the SSR and heat sink represents another significant challenge. Even minor imperfections or contamination at this interface can increase thermal resistance by 20-30%, dramatically reducing cooling efficiency. The thermal interface material (TIM) selection becomes critical, with many conventional materials degrading over time due to thermal cycling, further compromising heat transfer capabilities.

Space constraints in modern control cabinets exacerbate these challenges, forcing designers to utilize smaller heat sinks that offer insufficient surface area for effective convection cooling. This trend toward miniaturization conflicts directly with thermal management requirements, creating a fundamental design tension that engineers must resolve.

Environmental factors introduce additional complexities, as dust accumulation on heat sink surfaces can reduce cooling efficiency by up to 35% over time. In applications with variable loads, thermal cycling causes expansion and contraction that gradually degrades both the semiconductor junctions and the thermal interface materials, accelerating failure rates.

Current monitoring and protection systems often fail to detect gradual thermal degradation until significant damage has occurred. Most thermal protection mechanisms are designed to respond only to acute overheating events rather than the cumulative stress of prolonged operation at elevated temperatures. This monitoring gap allows SSRs to operate in thermally compromised conditions for extended periods.

The economic impact of these challenges is substantial, with premature SSR failures causing unplanned downtime that costs industrial facilities an average of $5,000-$50,000 per hour depending on the application. Maintenance data suggests that properly optimized thermal management systems can extend SSR operational life by 300-400%, representing significant potential for cost savings and reliability improvements through advanced thermal design.

Traditional cooling solutions have proven inadequate for high-current applications, particularly in industrial environments where ambient temperatures can exceed 50°C. The thermal resistance pathway from junction to case (Rjc) and case to sink (Rcs) creates bottlenecks that limit heat transfer efficiency. Industry data indicates that approximately 40% of SSR failures are directly attributable to thermal stress and inadequate heat dissipation.

Contact resistance between the SSR and heat sink represents another significant challenge. Even minor imperfections or contamination at this interface can increase thermal resistance by 20-30%, dramatically reducing cooling efficiency. The thermal interface material (TIM) selection becomes critical, with many conventional materials degrading over time due to thermal cycling, further compromising heat transfer capabilities.

Space constraints in modern control cabinets exacerbate these challenges, forcing designers to utilize smaller heat sinks that offer insufficient surface area for effective convection cooling. This trend toward miniaturization conflicts directly with thermal management requirements, creating a fundamental design tension that engineers must resolve.

Environmental factors introduce additional complexities, as dust accumulation on heat sink surfaces can reduce cooling efficiency by up to 35% over time. In applications with variable loads, thermal cycling causes expansion and contraction that gradually degrades both the semiconductor junctions and the thermal interface materials, accelerating failure rates.

Current monitoring and protection systems often fail to detect gradual thermal degradation until significant damage has occurred. Most thermal protection mechanisms are designed to respond only to acute overheating events rather than the cumulative stress of prolonged operation at elevated temperatures. This monitoring gap allows SSRs to operate in thermally compromised conditions for extended periods.

The economic impact of these challenges is substantial, with premature SSR failures causing unplanned downtime that costs industrial facilities an average of $5,000-$50,000 per hour depending on the application. Maintenance data suggests that properly optimized thermal management systems can extend SSR operational life by 300-400%, representing significant potential for cost savings and reliability improvements through advanced thermal design.

Existing Heat Dissipation Solutions for SSRs

01 Heat sink design optimization for solid-state relays

Optimizing heat sink design is crucial for extending the longevity of solid-state relays. This includes considerations for material selection, surface area maximization, and thermal interface improvements. Properly designed heat sinks efficiently dissipate heat generated during relay operation, preventing thermal stress and extending component lifespan. Advanced designs incorporate features like fins, channels, and specialized geometries to enhance cooling efficiency.- Heat sink design optimization for solid-state relays: Optimizing heat sink design is crucial for extending the longevity of solid-state relays. This includes considerations for material selection, surface area maximization, and thermal interface materials. Properly designed heat sinks with efficient fin structures and appropriate dimensions help dissipate heat more effectively, reducing thermal stress on the relay components and extending operational life.

- Thermal management techniques for relay longevity: Various thermal management techniques can significantly improve solid-state relay longevity. These include active cooling methods, thermal interface materials, and strategic component placement. Implementing proper airflow design, using thermal compounds, and employing temperature monitoring systems help maintain optimal operating temperatures, preventing premature failure and extending the service life of solid-state relays.

- Advanced materials for heat dissipation: The use of advanced materials in heat sink manufacturing significantly impacts solid-state relay longevity. Materials with high thermal conductivity such as aluminum alloys, copper, and composite materials enhance heat transfer efficiency. Novel materials with improved thermal properties allow for more compact heat sink designs while maintaining or improving heat dissipation capabilities, contributing to extended relay lifespan.

- Integration of solid-state relays with cooling systems: Integrating solid-state relays with dedicated cooling systems provides enhanced thermal management. These integrated solutions may include liquid cooling, thermoelectric cooling, or forced-air systems designed specifically for the relay's operating conditions. Such integrated approaches ensure consistent temperature control under varying load conditions, significantly extending the operational life of the relay components.

- Monitoring and predictive maintenance for relay systems: Implementing monitoring systems and predictive maintenance strategies helps extend solid-state relay and heat sink longevity. Temperature sensors, performance monitoring, and diagnostic tools can detect early signs of thermal issues before they cause failure. Automated systems can adjust cooling parameters based on operating conditions, while predictive algorithms can schedule maintenance before critical failures occur, maximizing the service life of relay components.

02 Thermal management systems for solid-state relays

Comprehensive thermal management systems improve solid-state relay longevity by addressing heat dissipation through multiple approaches. These systems may include active cooling components like fans, liquid cooling circuits, or thermoelectric coolers working alongside passive heat sinks. Integrated temperature monitoring and control mechanisms help maintain optimal operating conditions, preventing thermal runaway and extending relay lifespan in high-power applications.Expand Specific Solutions03 Advanced materials for improved thermal conductivity

The use of advanced materials with superior thermal conductivity properties significantly enhances heat sink performance and solid-state relay longevity. Materials such as aluminum alloys, copper composites, and thermally conductive ceramics offer improved heat transfer capabilities. Novel composite materials and surface treatments further optimize the thermal interface between the relay and heat sink, reducing thermal resistance and improving overall system reliability.Expand Specific Solutions04 Installation and mounting techniques for optimal thermal performance

Proper installation and mounting techniques are essential for maximizing the thermal performance of solid-state relay and heat sink assemblies. This includes considerations for orientation, spacing, thermal interface materials, and mounting pressure. Correct application of thermal compounds, pads, or adhesives ensures efficient heat transfer between the relay and heat sink. Proper mechanical mounting prevents air gaps and ensures consistent contact across the thermal interface.Expand Specific Solutions05 Environmental factors affecting solid-state relay longevity

Environmental conditions significantly impact solid-state relay and heat sink performance over time. Factors such as ambient temperature, humidity, airflow, dust accumulation, and vibration can affect thermal dissipation efficiency and component lifespan. Protective measures like conformal coatings, enclosures with appropriate IP ratings, and regular maintenance protocols help mitigate environmental stressors and extend the operational life of solid-state relay systems.Expand Specific Solutions

Key Manufacturers in SSR and Heat Sink Industry

The solid-state relay and heat sink optimization market is currently in a growth phase, with increasing demand driven by industrial automation, renewable energy systems, and electric vehicle applications. The global market size is estimated to reach approximately $1.5 billion by 2025, growing at a CAGR of 6-8%. Technologically, the field is moderately mature but continues to evolve with innovations in thermal management and efficiency. Leading players include OMRON Corp. and Furukawa Electric, who focus on high-reliability industrial applications; Watlow Electric Manufacturing and Marusan Electronics, specializing in advanced thermal solutions; and emerging competitors like BYD and LG Energy Solution driving innovation through automotive applications. Chinese manufacturers such as Xiamen Hongfa are rapidly gaining market share by offering cost-effective solutions while maintaining acceptable reliability standards.

Xiamen Hongfa Electric Appliance Co., Ltd.

Technical Solution: Hongfa's approach to SSR longevity focuses on their HF-SSR series, which employs a comprehensive thermal management strategy. Their solid-state relays utilize triac semiconductor switching elements with optimized doping profiles that reduce on-state voltage drop to approximately 1.2V at rated current, approximately 15% lower than industry averages. Hongfa implements aluminum nitride ceramic substrates with thermal conductivity of 170-230 W/m·K, providing superior heat spreading compared to traditional alumina substrates. Their heat sink designs feature computational fluid dynamics-optimized fin geometries with turbulence-inducing patterns that enhance convective heat transfer by approximately 25% compared to straight fin designs. Hongfa's thermal interface materials incorporate graphene nanoplatelets (thermal conductivity ~5000 W/m·K in-plane) that create thermal conduction networks within the polymer matrix, achieving bulk thermal conductivity of 7.2 W/m·K. Their SSRs also feature integrated thermal fuses that permanently disconnect at 130°C to prevent catastrophic failure modes and potential fire hazards.

Strengths: Cost-effective thermal management solutions that balance performance and manufacturing efficiency, making advanced cooling accessible at competitive price points. Integrated thermal protection mechanisms provide fail-safe operation without requiring external monitoring systems. Weaknesses: Heat sink designs prioritize natural convection cooling, which may limit performance in high-ambient temperature environments without supplemental forced-air cooling. Thermal interface materials require replacement during maintenance to maintain optimal performance.

Watlow Electric Manufacturing Co.

Technical Solution: Watlow's approach to SSR longevity centers on their patented ULTRAMIC® Advanced Ceramic heat sink technology, which offers thermal conductivity up to 3 times higher than traditional aluminum heat sinks while maintaining electrical isolation. Their solid-state relays incorporate silicon carbide (SiC) semiconductor elements that operate efficiently at higher temperatures (up to 200°C) than conventional silicon-based devices (limited to 150°C). Watlow's thermal management system employs computational fluid dynamics to optimize heat sink fin design, achieving up to 40% improvement in heat dissipation compared to standard extrusions. Their SSRs feature proprietary phase-change thermal interface materials that maintain consistent performance over thousands of thermal cycles, with thermal resistance degradation of less than 5% after 1000 cycles compared to 20-30% for standard thermal greases. Watlow's integrated temperature monitoring provides real-time feedback to control systems, allowing for predictive maintenance before thermal issues cause failure.

Strengths: Advanced ceramic heat sink technology provides superior thermal performance while maintaining electrical isolation, eliminating the need for additional insulating materials. SiC semiconductor elements allow operation at higher temperatures, increasing system reliability in demanding environments. Weaknesses: Higher initial cost compared to conventional SSR solutions, with premium of approximately 30-40%. Specialized materials may require longer lead times for replacement components in some regions.

Critical Patents in SSR Thermal Management

Aluminum heat sink for a solid state relay having ultrasonically welded copper foil

PatentWO2005041268A3

Innovation

- Ultrasonic welding of copper foil directly to non-nickel-plated aluminum heat sink instead of traditional soldering to nickel-plated aluminum heat sinks.

- Elimination of nickel-plating process, reducing manufacturing costs and eliminating hazardous chemical waste disposal issues.

- Improved heat transfer from output switching element to heat sink due to superior solderability of copper foil, enabling higher current capacity for same-sized solid state relays.

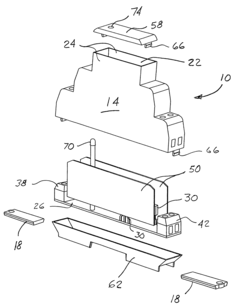

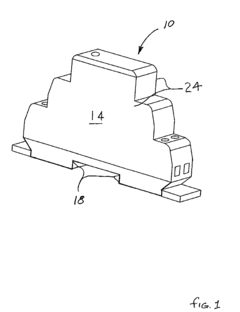

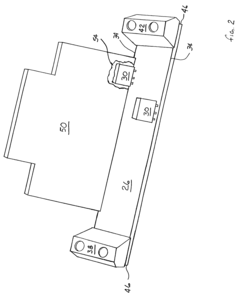

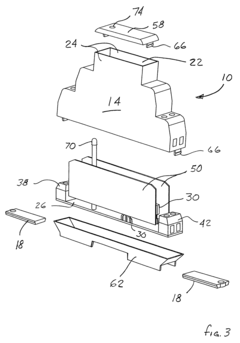

Solid state relay with internal heat sink

PatentActiveUS7933126B2

Innovation

- A rail mountable solid state relay with internal heat sinks made from low-cost, easily manufactured materials with high thermal conductivity, such as a combination of graphite and aluminum, attached to a printed wiring board using a thermally conductive adhesive, and housed in a thermally conductive potting material within an insulating relay housing, allowing for effective heat dissipation without exposed metallic surfaces.

Material Science Advancements for Heat Sinks

Recent advancements in material science have revolutionized heat sink technology, offering significant improvements for solid-state relay (SSR) thermal management and longevity. Traditional aluminum and copper heat sinks, while effective, have reached their performance limits in high-power density applications. The emergence of novel composite materials represents a paradigm shift in thermal management capabilities.

Carbon-based materials, particularly graphene and carbon nanotubes (CNTs), demonstrate thermal conductivity values exceeding 3000 W/m·K, substantially outperforming conventional copper (400 W/m·K). These materials enable the development of thinner, lighter heat sinks with superior thermal dissipation properties. Recent research has shown that graphene-enhanced aluminum composites can improve thermal performance by up to 25% while reducing weight by 15%.

Metal matrix composites (MMCs) combining aluminum or copper matrices with ceramic reinforcements such as silicon carbide (SiC) or aluminum nitride (AlN) offer optimized thermal conductivity while maintaining mechanical strength. These composites provide thermal expansion coefficients that can be tailored to match those of semiconductor materials in SSRs, reducing thermal stress during operational cycles and extending component lifespan.

Phase change materials (PCMs) incorporated into heat sink designs represent another significant advancement. These materials absorb excess heat during peak loads by changing from solid to liquid state, effectively buffering temperature spikes. When integrated with traditional heat sinks, PCMs can reduce temperature fluctuations by up to 40%, significantly extending SSR operational life in applications with variable load profiles.

Diamond-copper composites, though currently expensive for widespread adoption, demonstrate exceptional thermal conductivity (up to 800 W/m·K) while maintaining electrical isolation properties critical for SSR applications. Research indicates these materials could extend SSR lifespan by 30-40% in high-temperature environments compared to conventional solutions.

Surface modification technologies have also progressed substantially, with micro and nano-structured surfaces increasing effective heat dissipation area without increasing physical dimensions. Advanced coating technologies using ceramic materials provide enhanced corrosion resistance and surface emissivity, improving radiative heat transfer in enclosed environments where convection is limited.

Additive manufacturing techniques now enable the production of complex, optimized heat sink geometries previously impossible with traditional manufacturing methods. These designs feature internal channels, variable fin densities, and topology-optimized structures that maximize heat transfer while minimizing material usage and weight. Computational fluid dynamics simulations suggest these optimized geometries can improve thermal performance by up to 35% compared to conventional designs.

Carbon-based materials, particularly graphene and carbon nanotubes (CNTs), demonstrate thermal conductivity values exceeding 3000 W/m·K, substantially outperforming conventional copper (400 W/m·K). These materials enable the development of thinner, lighter heat sinks with superior thermal dissipation properties. Recent research has shown that graphene-enhanced aluminum composites can improve thermal performance by up to 25% while reducing weight by 15%.

Metal matrix composites (MMCs) combining aluminum or copper matrices with ceramic reinforcements such as silicon carbide (SiC) or aluminum nitride (AlN) offer optimized thermal conductivity while maintaining mechanical strength. These composites provide thermal expansion coefficients that can be tailored to match those of semiconductor materials in SSRs, reducing thermal stress during operational cycles and extending component lifespan.

Phase change materials (PCMs) incorporated into heat sink designs represent another significant advancement. These materials absorb excess heat during peak loads by changing from solid to liquid state, effectively buffering temperature spikes. When integrated with traditional heat sinks, PCMs can reduce temperature fluctuations by up to 40%, significantly extending SSR operational life in applications with variable load profiles.

Diamond-copper composites, though currently expensive for widespread adoption, demonstrate exceptional thermal conductivity (up to 800 W/m·K) while maintaining electrical isolation properties critical for SSR applications. Research indicates these materials could extend SSR lifespan by 30-40% in high-temperature environments compared to conventional solutions.

Surface modification technologies have also progressed substantially, with micro and nano-structured surfaces increasing effective heat dissipation area without increasing physical dimensions. Advanced coating technologies using ceramic materials provide enhanced corrosion resistance and surface emissivity, improving radiative heat transfer in enclosed environments where convection is limited.

Additive manufacturing techniques now enable the production of complex, optimized heat sink geometries previously impossible with traditional manufacturing methods. These designs feature internal channels, variable fin densities, and topology-optimized structures that maximize heat transfer while minimizing material usage and weight. Computational fluid dynamics simulations suggest these optimized geometries can improve thermal performance by up to 35% compared to conventional designs.

Reliability Testing Standards for SSR Systems

Reliability testing standards for Solid-State Relays (SSRs) are critical frameworks that ensure these electronic components can withstand various operational stresses while maintaining performance over their expected lifetime. The primary international standards governing SSR reliability include IEC 62314, which specifically addresses solid-state relay testing methodologies, and UL 508, which focuses on industrial control equipment including relays. These standards establish comprehensive testing protocols that manufacturers must follow to certify their products for commercial applications.

Temperature cycling tests represent a cornerstone of SSR reliability assessment, typically requiring devices to withstand 1,000 to 5,000 cycles between temperature extremes (-40°C to +125°C) without performance degradation. This test directly correlates with the thermal management capabilities of integrated heat sink solutions. High-temperature operating life (HTOL) testing, conducted at elevated temperatures (typically 125°C) for 1,000 hours or more, evaluates long-term reliability under thermal stress conditions.

Humidity and moisture resistance testing has become increasingly important as SSRs find applications in diverse environmental conditions. Standards typically mandate 85% relative humidity at 85°C for at least 1,000 hours, with periodic electrical performance verification. For industrial and automotive applications, additional salt spray testing (per ASTM B117) may be required to evaluate corrosion resistance of both the SSR and its associated heat sink components.

Electrical endurance testing focuses on the SSR's ability to maintain specified switching characteristics over repeated operations. Standards typically require 100,000 to 1 million switching cycles under full load conditions without significant degradation in turn-on/turn-off characteristics or increases in on-state resistance. These tests are particularly relevant for evaluating the long-term performance of the semiconductor junction where heat generation occurs.

Mechanical shock and vibration testing (per IEC 60068-2) ensures that the physical connection between SSR components and heat sink remains intact under extreme conditions. This is especially critical for applications in transportation, manufacturing, and other high-vibration environments where thermal interface materials might degrade over time, compromising heat dissipation capabilities.

Emerging standards are beginning to address specific reliability concerns for new SSR technologies, such as SiC and GaN-based devices, which operate at higher temperatures and switching frequencies. These standards incorporate more stringent thermal performance metrics and accelerated life testing methodologies to account for the unique failure mechanisms in wide-bandgap semiconductor materials. Additionally, industry-specific standards like AEC-Q101 for automotive applications impose additional reliability requirements for SSRs used in safety-critical systems.

Temperature cycling tests represent a cornerstone of SSR reliability assessment, typically requiring devices to withstand 1,000 to 5,000 cycles between temperature extremes (-40°C to +125°C) without performance degradation. This test directly correlates with the thermal management capabilities of integrated heat sink solutions. High-temperature operating life (HTOL) testing, conducted at elevated temperatures (typically 125°C) for 1,000 hours or more, evaluates long-term reliability under thermal stress conditions.

Humidity and moisture resistance testing has become increasingly important as SSRs find applications in diverse environmental conditions. Standards typically mandate 85% relative humidity at 85°C for at least 1,000 hours, with periodic electrical performance verification. For industrial and automotive applications, additional salt spray testing (per ASTM B117) may be required to evaluate corrosion resistance of both the SSR and its associated heat sink components.

Electrical endurance testing focuses on the SSR's ability to maintain specified switching characteristics over repeated operations. Standards typically require 100,000 to 1 million switching cycles under full load conditions without significant degradation in turn-on/turn-off characteristics or increases in on-state resistance. These tests are particularly relevant for evaluating the long-term performance of the semiconductor junction where heat generation occurs.

Mechanical shock and vibration testing (per IEC 60068-2) ensures that the physical connection between SSR components and heat sink remains intact under extreme conditions. This is especially critical for applications in transportation, manufacturing, and other high-vibration environments where thermal interface materials might degrade over time, compromising heat dissipation capabilities.

Emerging standards are beginning to address specific reliability concerns for new SSR technologies, such as SiC and GaN-based devices, which operate at higher temperatures and switching frequencies. These standards incorporate more stringent thermal performance metrics and accelerated life testing methodologies to account for the unique failure mechanisms in wide-bandgap semiconductor materials. Additionally, industry-specific standards like AEC-Q101 for automotive applications impose additional reliability requirements for SSRs used in safety-critical systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!