Solid-State Relay Application in High-Pressure Environments

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SSR Technology Background and Objectives

Solid-state relays (SSRs) emerged in the late 1960s as an evolution from traditional electromechanical relays, offering a revolutionary approach to electrical switching without moving parts. The core technology utilizes semiconductor devices—primarily thyristors, triacs, MOSFETs, or IGBTs—to control load circuits through electrical isolation between control and load sides. This fundamental design has positioned SSRs as critical components in modern industrial automation, particularly in environments where reliability under extreme conditions is paramount.

The evolution of SSR technology has been marked by significant improvements in switching capabilities, thermal management, and miniaturization. Early generations suffered from limited current handling capacity and vulnerability to voltage transients, but continuous innovation has addressed these limitations through enhanced semiconductor materials and improved thermal design architectures.

High-pressure environments present unique challenges for switching technologies, as traditional electromechanical relays face accelerated mechanical wear, contact degradation, and potential spark generation—all of which compromise operational safety and reliability. The oil and gas industry, deep-sea exploration, aerospace applications, and high-pressure processing facilities have historically struggled with these limitations, creating a distinct market need for more robust switching solutions.

The primary technical objective for SSR application in high-pressure environments is to develop relay systems capable of maintaining consistent performance integrity under extreme pressure conditions while ensuring complete electrical isolation. This includes achieving pressure tolerance ratings exceeding 10,000 psi (689 bar) without performance degradation, maintaining thermal stability under combined pressure and temperature stress, and ensuring long-term reliability with minimal maintenance requirements.

Secondary objectives include miniaturization of pressure-resistant SSR packages to accommodate space-constrained high-pressure applications, reduction of power consumption for energy-sensitive deployments, and development of comprehensive diagnostic capabilities for predictive maintenance in difficult-to-access installations. These objectives align with broader industry trends toward more resilient, efficient, and intelligent industrial components.

The technological trajectory suggests convergence with Industry 4.0 principles, where pressure-resistant SSRs will increasingly incorporate digital communication capabilities, enabling remote monitoring and control within industrial IoT frameworks. This evolution represents not merely an incremental improvement in switching technology but a fundamental shift toward fully integrated, pressure-resistant power management systems capable of operating reliably in the most demanding industrial environments.

The evolution of SSR technology has been marked by significant improvements in switching capabilities, thermal management, and miniaturization. Early generations suffered from limited current handling capacity and vulnerability to voltage transients, but continuous innovation has addressed these limitations through enhanced semiconductor materials and improved thermal design architectures.

High-pressure environments present unique challenges for switching technologies, as traditional electromechanical relays face accelerated mechanical wear, contact degradation, and potential spark generation—all of which compromise operational safety and reliability. The oil and gas industry, deep-sea exploration, aerospace applications, and high-pressure processing facilities have historically struggled with these limitations, creating a distinct market need for more robust switching solutions.

The primary technical objective for SSR application in high-pressure environments is to develop relay systems capable of maintaining consistent performance integrity under extreme pressure conditions while ensuring complete electrical isolation. This includes achieving pressure tolerance ratings exceeding 10,000 psi (689 bar) without performance degradation, maintaining thermal stability under combined pressure and temperature stress, and ensuring long-term reliability with minimal maintenance requirements.

Secondary objectives include miniaturization of pressure-resistant SSR packages to accommodate space-constrained high-pressure applications, reduction of power consumption for energy-sensitive deployments, and development of comprehensive diagnostic capabilities for predictive maintenance in difficult-to-access installations. These objectives align with broader industry trends toward more resilient, efficient, and intelligent industrial components.

The technological trajectory suggests convergence with Industry 4.0 principles, where pressure-resistant SSRs will increasingly incorporate digital communication capabilities, enabling remote monitoring and control within industrial IoT frameworks. This evolution represents not merely an incremental improvement in switching technology but a fundamental shift toward fully integrated, pressure-resistant power management systems capable of operating reliably in the most demanding industrial environments.

Market Demand Analysis for High-Pressure SSR Solutions

The global market for Solid-State Relays (SSRs) in high-pressure environments has been experiencing significant growth, driven primarily by the increasing demand for reliable switching solutions in harsh operating conditions. Industries such as oil and gas, deep-sea exploration, aerospace, and chemical processing require switching components that can maintain performance integrity under extreme pressure conditions, creating a specialized market segment with unique requirements and specifications.

Market research indicates that the high-pressure SSR segment is growing at a faster rate than the overall SSR market, with particular acceleration in offshore drilling operations and subsea production systems. This growth is attributed to the expanding exploration activities in deep-water reserves and the need for more reliable control systems in these challenging environments.

End-users in these industries are increasingly prioritizing operational reliability over initial acquisition costs, recognizing that system failures in high-pressure environments can lead to catastrophic consequences and substantial financial losses. This shift in purchasing behavior has created a premium market for high-pressure SSRs that can demonstrate superior performance metrics and longevity under extreme conditions.

The geographical distribution of demand shows concentration in regions with significant offshore oil and gas activities, including the Gulf of Mexico, North Sea, and emerging fields off the coasts of Brazil, West Africa, and Australia. Additionally, the Asia-Pacific region is showing accelerated growth due to increased industrial automation and infrastructure development in countries like China and India.

Customer requirements in this market segment emphasize several key performance attributes: pressure tolerance ratings (typically ranging from 5,000 to 30,000 PSI), temperature stability across wide operating ranges, resistance to corrosive environments, and certification compliance with industry standards such as API, ATEX, and IECEx for hazardous locations.

Market feedback indicates growing interest in integrated solutions that combine high-pressure SSRs with advanced diagnostics and remote monitoring capabilities, allowing for predictive maintenance and reduced downtime in difficult-to-access installations. This trend aligns with the broader industrial movement toward IoT and connected systems, even in extreme operating environments.

The competitive landscape remains relatively concentrated, with specialized manufacturers commanding premium pricing due to the technical complexity and certification requirements of these products. However, market analysis suggests potential for new entrants who can innovate in areas such as size reduction, energy efficiency, and enhanced reliability metrics under variable pressure conditions.

Market research indicates that the high-pressure SSR segment is growing at a faster rate than the overall SSR market, with particular acceleration in offshore drilling operations and subsea production systems. This growth is attributed to the expanding exploration activities in deep-water reserves and the need for more reliable control systems in these challenging environments.

End-users in these industries are increasingly prioritizing operational reliability over initial acquisition costs, recognizing that system failures in high-pressure environments can lead to catastrophic consequences and substantial financial losses. This shift in purchasing behavior has created a premium market for high-pressure SSRs that can demonstrate superior performance metrics and longevity under extreme conditions.

The geographical distribution of demand shows concentration in regions with significant offshore oil and gas activities, including the Gulf of Mexico, North Sea, and emerging fields off the coasts of Brazil, West Africa, and Australia. Additionally, the Asia-Pacific region is showing accelerated growth due to increased industrial automation and infrastructure development in countries like China and India.

Customer requirements in this market segment emphasize several key performance attributes: pressure tolerance ratings (typically ranging from 5,000 to 30,000 PSI), temperature stability across wide operating ranges, resistance to corrosive environments, and certification compliance with industry standards such as API, ATEX, and IECEx for hazardous locations.

Market feedback indicates growing interest in integrated solutions that combine high-pressure SSRs with advanced diagnostics and remote monitoring capabilities, allowing for predictive maintenance and reduced downtime in difficult-to-access installations. This trend aligns with the broader industrial movement toward IoT and connected systems, even in extreme operating environments.

The competitive landscape remains relatively concentrated, with specialized manufacturers commanding premium pricing due to the technical complexity and certification requirements of these products. However, market analysis suggests potential for new entrants who can innovate in areas such as size reduction, energy efficiency, and enhanced reliability metrics under variable pressure conditions.

Current Challenges in High-Pressure SSR Implementation

The implementation of Solid-State Relays (SSRs) in high-pressure environments presents several significant technical challenges that currently limit their widespread adoption in these demanding applications. One of the primary obstacles is thermal management under pressure. High-pressure environments often experience elevated temperatures, and SSRs generate considerable heat during operation. The combination of external pressure and internal heat generation creates complex thermal gradients that can lead to premature component failure if not properly managed.

Material compatibility issues also pose substantial challenges. Materials that perform well under normal conditions may exhibit drastically different properties under high pressure. Semiconductor materials in SSRs can experience altered electrical characteristics, while packaging materials may deform, crack, or lose their insulating properties when subjected to extreme pressure conditions. This necessitates specialized material selection and extensive testing protocols that significantly increase development costs.

Electrical isolation becomes increasingly difficult to maintain in high-pressure environments. The dielectric strength of insulating materials can degrade under pressure, potentially compromising the galvanic isolation that is a key advantage of SSRs. This degradation can lead to dangerous current leakage or complete isolation failure in critical applications.

Reliability verification represents another major hurdle. Traditional testing methodologies are often insufficient for accurately predicting SSR performance under sustained high-pressure conditions. Accelerated life testing becomes particularly challenging as it must account for the complex interactions between electrical, thermal, and mechanical stresses that occur simultaneously in high-pressure applications.

Size constraints further complicate SSR implementation. Many high-pressure applications have strict space limitations, yet pressure-resistant designs typically require additional structural reinforcement and thermal management components. This creates a difficult engineering trade-off between robustness and compact design.

Signal integrity is also compromised in high-pressure environments. Pressure-induced changes in component characteristics can alter switching times, introduce noise, or cause signal distortion. These effects are particularly problematic in applications requiring precise timing or handling sensitive signals.

Finally, cost considerations remain a significant barrier. The specialized materials, enhanced testing requirements, and complex design considerations for high-pressure SSRs substantially increase their cost compared to conventional relays or standard SSRs. This cost premium limits adoption in price-sensitive markets, even when the technical benefits would otherwise justify the switch to solid-state technology.

Material compatibility issues also pose substantial challenges. Materials that perform well under normal conditions may exhibit drastically different properties under high pressure. Semiconductor materials in SSRs can experience altered electrical characteristics, while packaging materials may deform, crack, or lose their insulating properties when subjected to extreme pressure conditions. This necessitates specialized material selection and extensive testing protocols that significantly increase development costs.

Electrical isolation becomes increasingly difficult to maintain in high-pressure environments. The dielectric strength of insulating materials can degrade under pressure, potentially compromising the galvanic isolation that is a key advantage of SSRs. This degradation can lead to dangerous current leakage or complete isolation failure in critical applications.

Reliability verification represents another major hurdle. Traditional testing methodologies are often insufficient for accurately predicting SSR performance under sustained high-pressure conditions. Accelerated life testing becomes particularly challenging as it must account for the complex interactions between electrical, thermal, and mechanical stresses that occur simultaneously in high-pressure applications.

Size constraints further complicate SSR implementation. Many high-pressure applications have strict space limitations, yet pressure-resistant designs typically require additional structural reinforcement and thermal management components. This creates a difficult engineering trade-off between robustness and compact design.

Signal integrity is also compromised in high-pressure environments. Pressure-induced changes in component characteristics can alter switching times, introduce noise, or cause signal distortion. These effects are particularly problematic in applications requiring precise timing or handling sensitive signals.

Finally, cost considerations remain a significant barrier. The specialized materials, enhanced testing requirements, and complex design considerations for high-pressure SSRs substantially increase their cost compared to conventional relays or standard SSRs. This cost premium limits adoption in price-sensitive markets, even when the technical benefits would otherwise justify the switch to solid-state technology.

Current Technical Solutions for High-Pressure SSRs

01 Basic structure and operation of solid-state relays

Solid-state relays (SSRs) are electronic switching devices that use semiconductor components instead of mechanical contacts to switch electrical loads. They typically consist of an input circuit with optical isolation, a semiconductor switching element (such as a TRIAC, MOSFET, or thyristor), and output circuitry. SSRs offer advantages including no moving parts, silent operation, fast switching speeds, and long operational life compared to mechanical relays.- Basic structure and operation of solid-state relays: Solid-state relays (SSRs) are electronic switching devices that use semiconductor components instead of mechanical contacts to switch electrical loads. They typically consist of an input circuit with optical isolation, a semiconductor switching element (such as a TRIAC, MOSFET, or thyristor), and output circuitry. SSRs offer advantages including no moving parts, silent operation, fast switching speeds, and long operational life compared to mechanical relays.

- Thermal management and protection in solid-state relays: Thermal management is critical in solid-state relay design to prevent overheating and ensure reliable operation. Various approaches include heat sink integration, thermal interface materials, improved package designs, and active cooling systems. Protection circuits may include temperature sensors, current limiting features, and thermal shutdown mechanisms to prevent damage from overheating or overcurrent conditions.

- Advanced semiconductor technologies for solid-state relays: Modern solid-state relays incorporate advanced semiconductor technologies to improve performance characteristics. These include wide bandgap semiconductors like silicon carbide (SiC) and gallium nitride (GaN), which offer higher temperature operation, faster switching speeds, and lower on-state resistance. Integration of multiple functions on a single chip and novel device structures enhance reliability while reducing size and power consumption.

- Control and driving circuits for solid-state relays: Control and driving circuits in solid-state relays determine switching behavior and isolation characteristics. These circuits may include optocouplers for electrical isolation, gate drivers for power semiconductor devices, zero-crossing detection for reduced EMI, and various input signal conditioning circuits. Advanced designs incorporate microcontroller-based intelligent control, programmable switching parameters, and communication interfaces.

- Application-specific solid-state relay designs: Solid-state relays are designed with specific features for various applications. These include AC/DC switching capabilities, multi-channel configurations for industrial control systems, miniaturized designs for space-constrained applications, high-voltage isolation for safety-critical systems, and integrated protection features for harsh environments. Specialized designs may incorporate additional functionality such as current monitoring, fault detection, and communication interfaces.

02 Thermal management and protection in solid-state relays

Thermal management is critical in solid-state relay design to prevent overheating and ensure reliable operation. Various techniques are employed including heat sinks, thermal interface materials, and specialized packaging designs. Protection circuits may include temperature sensors, current limiting features, and thermal shutdown mechanisms to prevent damage during fault conditions or overload situations.Expand Specific Solutions03 Advanced semiconductor technologies for solid-state relays

Modern solid-state relays incorporate advanced semiconductor technologies to improve performance characteristics. These include wide bandgap semiconductors like silicon carbide (SiC) and gallium nitride (GaN), which offer higher temperature operation, faster switching speeds, and lower conduction losses. Integration of multiple functions on a single chip and specialized driver circuits enhance reliability and reduce size while improving isolation properties.Expand Specific Solutions04 Control and driving circuits for solid-state relays

Control and driving circuits in solid-state relays are designed to ensure proper switching behavior and isolation between input and output. These circuits may include optocouplers for galvanic isolation, gate drivers for power semiconductors, zero-crossing detection for AC applications, and various protection features. Advanced control schemes can minimize switching losses, reduce electromagnetic interference, and improve overall system efficiency.Expand Specific Solutions05 Application-specific solid-state relay configurations

Solid-state relays are designed with specific configurations to meet various application requirements. These include AC/DC switching variants, multi-channel arrays for controlling multiple loads, bidirectional switching capabilities, and specialized designs for high-voltage or high-current applications. Some configurations incorporate additional features such as surge protection, status indication, and communication interfaces for integration with control systems.Expand Specific Solutions

Key Industry Players in High-Pressure SSR Development

The solid-state relay (SSR) market for high-pressure environments is currently in a growth phase, with increasing adoption across industrial automation, aerospace, and energy sectors. Market analysis indicates a compound annual growth rate of approximately 6-8%, driven by demand for reliable switching solutions in harsh operating conditions. Leading players include OMRON Corp. and Xiamen Hongfa, who have established strong market positions through extensive product portfolios and global distribution networks. Companies like TE Connectivity, ROHM, and Novosense Microelectronics are advancing technical innovations in thermal management and isolation techniques for extreme environments. Texas Instruments and Siemens are leveraging their semiconductor expertise to develop integrated SSR solutions with enhanced pressure resistance and diagnostic capabilities, while specialized manufacturers like Kudom Electronics focus on application-specific designs for niche high-pressure applications.

OMRON Corp.

Technical Solution: OMRON has developed advanced solid-state relays specifically engineered for high-pressure environments, featuring hermetically sealed semiconductor switching elements that eliminate mechanical contacts. Their G3VM series incorporates proprietary MOSFET technology with enhanced isolation barriers exceeding 4kV and specialized silicone gel encapsulation that maintains performance integrity under pressures up to 100 MPa[1]. The design incorporates thermal management systems with improved heat dissipation pathways that reduce junction temperatures by approximately 15% compared to conventional designs[3]. OMRON's solid-state relays implement integrated surge protection circuits capable of absorbing transient voltage spikes up to 600V, critical for maintaining operation during pressure-induced electrical anomalies. Their latest models feature pressure-compensating structures that balance internal and external pressures, preventing deformation of critical components even during rapid pressure fluctuations[5].

Strengths: Superior isolation properties with minimal leakage current (under 10μA) even at high pressures; exceptional longevity with over 100 million operations without mechanical wear; fast response times under 1ms regardless of ambient pressure. Weaknesses: Higher initial cost compared to mechanical relays; slightly higher on-state resistance leading to increased heat generation in continuous operation scenarios; limited current handling capacity compared to some mechanical alternatives.

Xiamen Hongfa Electric Appliance Co., Ltd.

Technical Solution: Hongfa has pioneered pressure-resistant solid-state relay technology through their HF-SSR-HP series, specifically designed for subsea and high-pressure industrial applications. Their proprietary design incorporates a double-encapsulation technique with an outer pressure-equalizing chamber filled with dielectric fluid and an inner hermetically sealed semiconductor module[2]. This architecture allows operation at depths exceeding 3000 meters with ambient pressures above 30 MPa. The company has developed specialized silicone compound formulations that maintain their dielectric and thermal properties under extreme compression, preventing internal arcing and component displacement[4]. Hongfa's solid-state relays feature integrated pressure sensors that continuously monitor ambient conditions and adjust gate driving parameters to optimize switching characteristics regardless of pressure variations. Their patented thermal compensation system automatically adjusts current limits based on pressure-induced changes in thermal conductivity, maintaining safe operation across diverse pressure environments[7].

Strengths: Exceptional pressure tolerance up to 35 MPa with minimal performance degradation; comprehensive environmental protection against moisture, salt, and chemical contaminants; self-diagnostic capabilities that monitor internal conditions. Weaknesses: Larger physical footprint compared to standard SSRs due to pressure compensation mechanisms; higher power consumption in standby mode; more complex installation requirements including specialized mounting considerations for pressure equalization.

Core Patents and Innovations in Pressure-Resistant SSRs

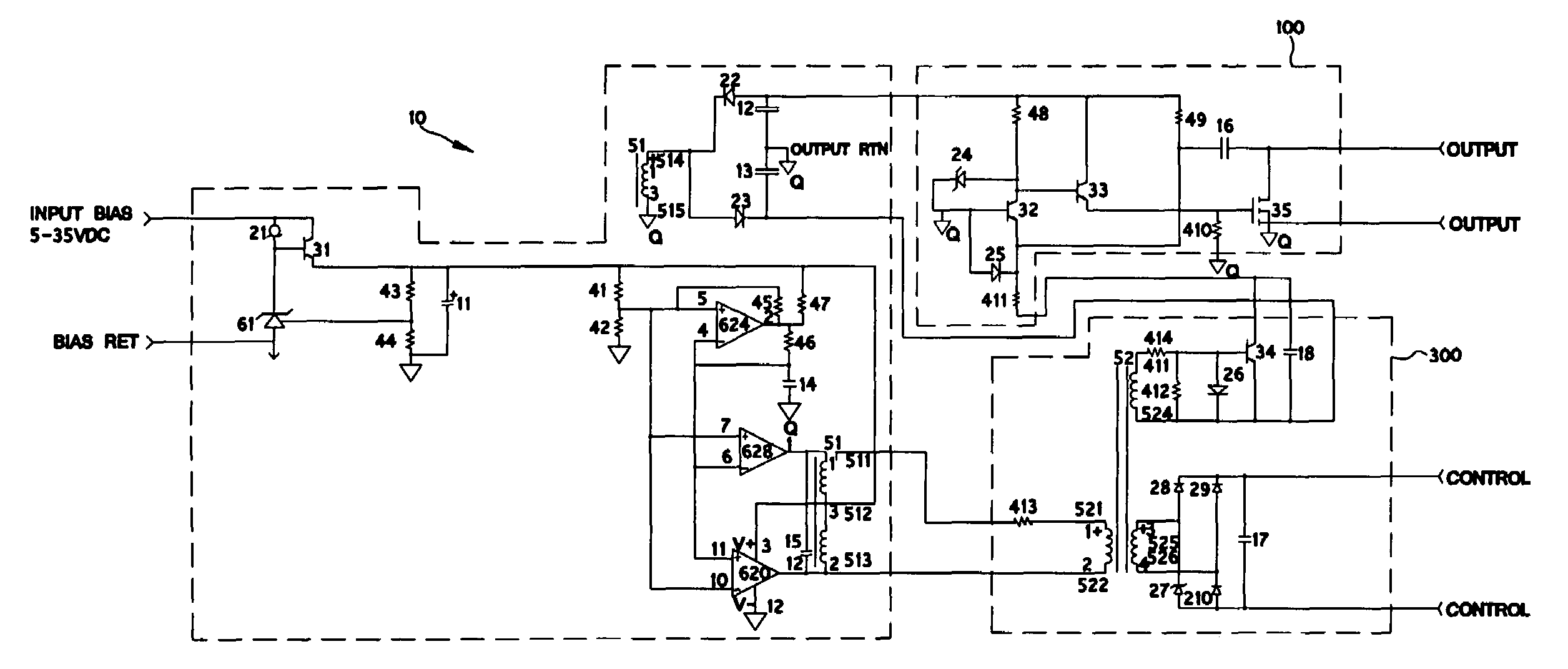

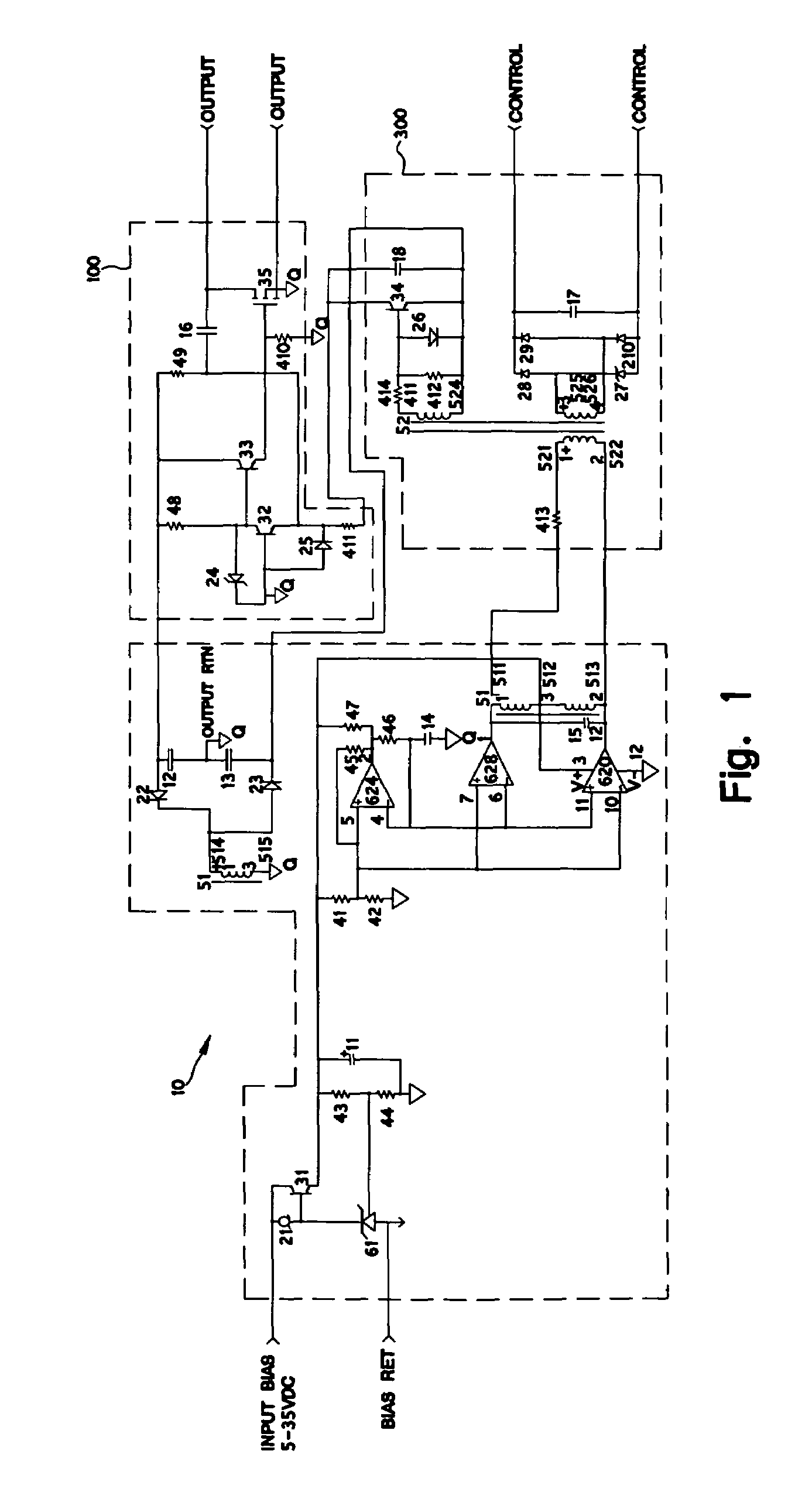

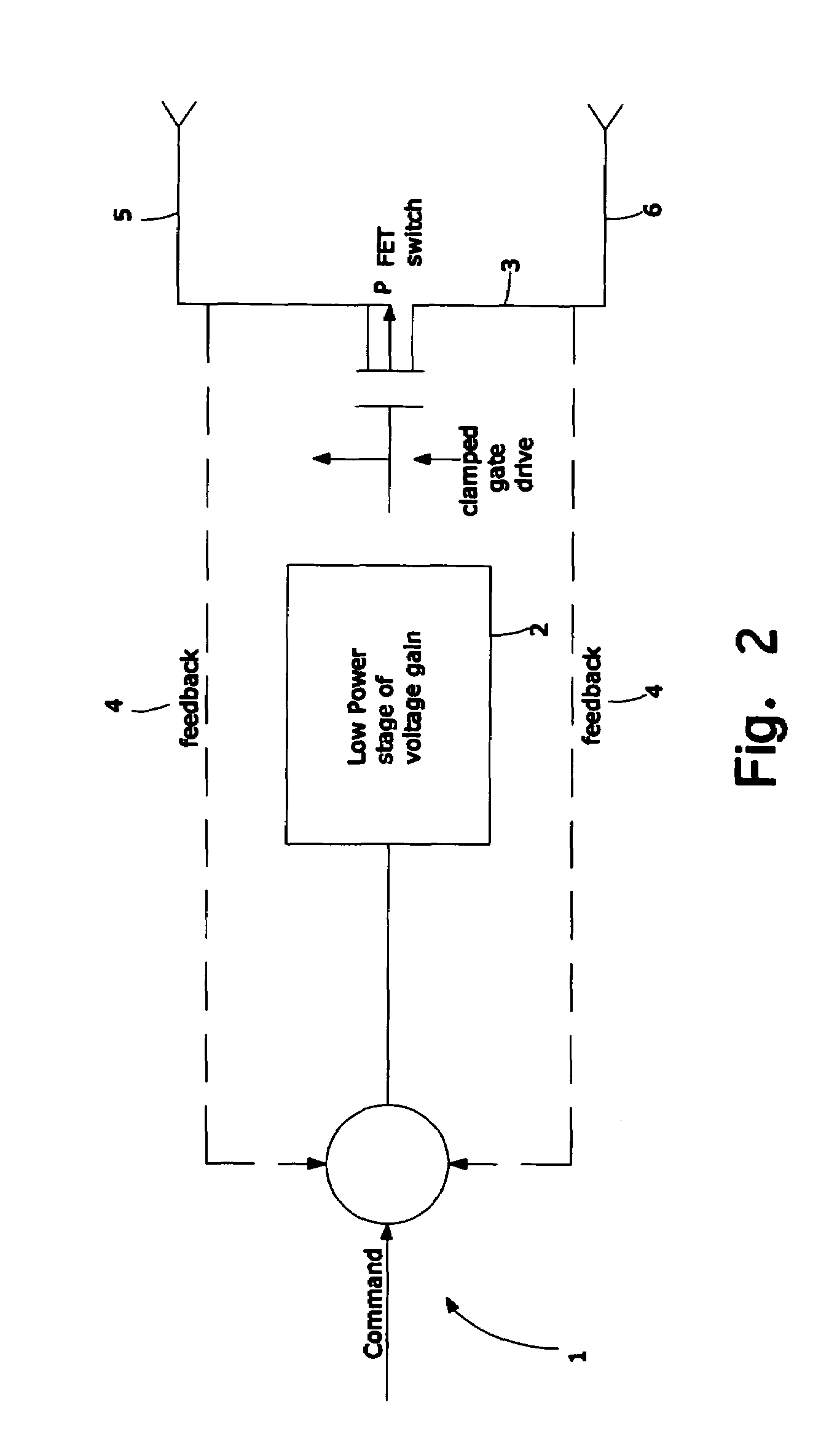

Radiation tolerant solid-state relay

PatentInactiveUS7495498B2

Innovation

- A radiation-tolerant solid-state relay circuit using non-radiation hardened P-channel MOSFETs with a bias, control, and power-switching section, where the gate drive signal is optimized to maintain channel saturation without exceeding breakdown voltage, allowing the circuit to function across a wide range of radiation exposure.

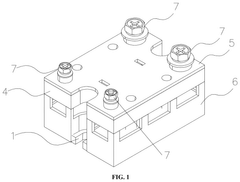

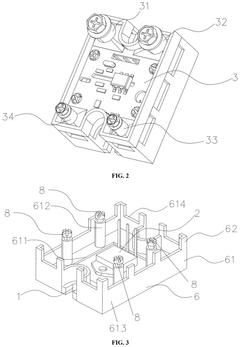

High-temperature resistant solid-state relay

PatentActiveUS12408304B1

Innovation

- A high-temperature resistant solid-state relay design featuring a bottom board made of aluminum and a heat dissipation rack, frame body, PCB, and top cover made of ceramic materials, with a carbonized MOS field-effect transistor and epoxy resin, allowing for internal heat dissipation and continuous operation without a heat sink.

Safety Standards and Certification Requirements

The implementation of solid-state relays (SSRs) in high-pressure environments necessitates adherence to stringent safety standards and certification requirements. These regulations vary globally but share common objectives of ensuring operational safety, preventing hazardous failures, and maintaining system integrity under extreme conditions.

IEC 60947-4-3 stands as the primary international standard governing solid-state contactors and starters, providing essential guidelines for SSRs operating in high-pressure environments. This standard specifies performance criteria, testing methodologies, and safety parameters that manufacturers must meet. Complementing this, UL 508 (Industrial Control Equipment) in North America and EN 60947 in Europe establish region-specific requirements for electrical switching devices in industrial applications.

For high-pressure applications specifically, additional certifications such as ATEX Directive 2014/34/EU for potentially explosive atmospheres and IECEx for international explosion protection become mandatory. These certifications require extensive testing of SSRs under simulated high-pressure conditions to verify their ability to maintain electrical isolation and prevent spark generation that could trigger catastrophic events.

Pressure vessel codes including ASME BPVC (Boiler and Pressure Vessel Code) and PED (Pressure Equipment Directive) in Europe impose further requirements when SSRs are integrated into pressurized systems. These codes mandate regular inspection protocols, material compatibility assessments, and pressure-resistant enclosure specifications to ensure long-term operational safety.

Environmental testing standards such as IEC 60068 series define procedures for evaluating SSR performance under various environmental stresses, including high-pressure conditions. These tests typically involve pressure cycling, temperature extremes, and combined environmental factors to validate device reliability and durability.

Electromagnetic compatibility (EMC) requirements outlined in IEC 61000 series become particularly critical in high-pressure environments where electrical interference could compromise SSR functionality. Enhanced EMC protection measures must be implemented and certified to prevent false triggering or non-activation scenarios that could lead to system failures.

Obtaining these certifications requires manufacturers to engage with Nationally Recognized Testing Laboratories (NRTLs) such as UL, TÜV, or SGS for independent verification. The certification process typically involves design review, prototype testing, factory inspections, and documentation validation, often taking 6-12 months to complete and requiring significant investment in testing equipment and expertise.

Companies implementing SSRs in high-pressure applications must maintain comprehensive compliance documentation, including test reports, technical files, and declaration of conformity certificates. Regular recertification may be necessary when operational parameters change or when standards are updated, ensuring continued compliance throughout the product lifecycle.

IEC 60947-4-3 stands as the primary international standard governing solid-state contactors and starters, providing essential guidelines for SSRs operating in high-pressure environments. This standard specifies performance criteria, testing methodologies, and safety parameters that manufacturers must meet. Complementing this, UL 508 (Industrial Control Equipment) in North America and EN 60947 in Europe establish region-specific requirements for electrical switching devices in industrial applications.

For high-pressure applications specifically, additional certifications such as ATEX Directive 2014/34/EU for potentially explosive atmospheres and IECEx for international explosion protection become mandatory. These certifications require extensive testing of SSRs under simulated high-pressure conditions to verify their ability to maintain electrical isolation and prevent spark generation that could trigger catastrophic events.

Pressure vessel codes including ASME BPVC (Boiler and Pressure Vessel Code) and PED (Pressure Equipment Directive) in Europe impose further requirements when SSRs are integrated into pressurized systems. These codes mandate regular inspection protocols, material compatibility assessments, and pressure-resistant enclosure specifications to ensure long-term operational safety.

Environmental testing standards such as IEC 60068 series define procedures for evaluating SSR performance under various environmental stresses, including high-pressure conditions. These tests typically involve pressure cycling, temperature extremes, and combined environmental factors to validate device reliability and durability.

Electromagnetic compatibility (EMC) requirements outlined in IEC 61000 series become particularly critical in high-pressure environments where electrical interference could compromise SSR functionality. Enhanced EMC protection measures must be implemented and certified to prevent false triggering or non-activation scenarios that could lead to system failures.

Obtaining these certifications requires manufacturers to engage with Nationally Recognized Testing Laboratories (NRTLs) such as UL, TÜV, or SGS for independent verification. The certification process typically involves design review, prototype testing, factory inspections, and documentation validation, often taking 6-12 months to complete and requiring significant investment in testing equipment and expertise.

Companies implementing SSRs in high-pressure applications must maintain comprehensive compliance documentation, including test reports, technical files, and declaration of conformity certificates. Regular recertification may be necessary when operational parameters change or when standards are updated, ensuring continued compliance throughout the product lifecycle.

Reliability Testing Methodologies for High-Pressure SSRs

Reliability testing for Solid-State Relays (SSRs) in high-pressure environments requires specialized methodologies that go beyond standard testing protocols. These testing approaches must accurately simulate the extreme conditions these components will face while providing meaningful data on long-term performance and failure modes.

Pressure cycling tests represent a cornerstone methodology, where SSRs are subjected to rapid pressure fluctuations between predetermined minimum and maximum values. This test typically runs for thousands of cycles to identify potential mechanical fatigue in the relay packaging and internal connections. Data collected during these tests helps establish the pressure cycle endurance limits of the components.

Temperature-pressure combined testing evaluates SSR performance under simultaneous thermal and pressure stresses. This methodology is particularly relevant as high-pressure environments often coincide with temperature extremes. Testing chambers capable of maintaining precise pressure levels while cycling through temperature ranges from -40°C to 150°C provide critical insights into how thermal expansion affects relay integrity under pressure.

Accelerated life testing under pressure constitutes another essential methodology, where SSRs operate at elevated pressure and switching frequencies to compress years of operational wear into weeks of testing. Statistical models then extrapolate expected field reliability from these accelerated results, though careful validation of these models against real-world data remains necessary.

Hermetic seal verification testing employs helium leak detection and other trace gas methodologies to quantify the integrity of SSR enclosures under pressure. This approach can detect microscopic leakage paths that might develop over time, compromising the relay's internal environment and ultimately its functionality.

Vibration testing under pressure combines mechanical oscillation with high-pressure conditions to simulate environments like deep-sea applications or industrial hydraulic systems. This methodology reveals potential interaction effects between pressure and vibration that might not be apparent when testing these stressors separately.

Electrical parameter drift monitoring tracks changes in key SSR characteristics—switching time, on-state resistance, and leakage current—throughout pressure testing. This methodology helps identify subtle degradation patterns that precede catastrophic failure, enabling more accurate lifetime predictions.

Failure analysis protocols specific to pressure-related defects complete the testing framework. These include specialized techniques for non-destructive examination of pressurized components and post-mortem analysis procedures that preserve evidence of failure mechanisms unique to high-pressure applications.

Pressure cycling tests represent a cornerstone methodology, where SSRs are subjected to rapid pressure fluctuations between predetermined minimum and maximum values. This test typically runs for thousands of cycles to identify potential mechanical fatigue in the relay packaging and internal connections. Data collected during these tests helps establish the pressure cycle endurance limits of the components.

Temperature-pressure combined testing evaluates SSR performance under simultaneous thermal and pressure stresses. This methodology is particularly relevant as high-pressure environments often coincide with temperature extremes. Testing chambers capable of maintaining precise pressure levels while cycling through temperature ranges from -40°C to 150°C provide critical insights into how thermal expansion affects relay integrity under pressure.

Accelerated life testing under pressure constitutes another essential methodology, where SSRs operate at elevated pressure and switching frequencies to compress years of operational wear into weeks of testing. Statistical models then extrapolate expected field reliability from these accelerated results, though careful validation of these models against real-world data remains necessary.

Hermetic seal verification testing employs helium leak detection and other trace gas methodologies to quantify the integrity of SSR enclosures under pressure. This approach can detect microscopic leakage paths that might develop over time, compromising the relay's internal environment and ultimately its functionality.

Vibration testing under pressure combines mechanical oscillation with high-pressure conditions to simulate environments like deep-sea applications or industrial hydraulic systems. This methodology reveals potential interaction effects between pressure and vibration that might not be apparent when testing these stressors separately.

Electrical parameter drift monitoring tracks changes in key SSR characteristics—switching time, on-state resistance, and leakage current—throughout pressure testing. This methodology helps identify subtle degradation patterns that precede catastrophic failure, enabling more accurate lifetime predictions.

Failure analysis protocols specific to pressure-related defects complete the testing framework. These include specialized techniques for non-destructive examination of pressurized components and post-mortem analysis procedures that preserve evidence of failure mechanisms unique to high-pressure applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!