Solid-State Relay Current Capacity: Benchmark Evaluation

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SSR Current Capacity Background and Objectives

Solid-state relays (SSRs) have evolved significantly since their inception in the 1970s, transforming from simple switching devices to sophisticated power control components. The progression of semiconductor technology has enabled SSRs to handle increasingly higher current capacities while maintaining reliability and performance. This technological evolution has been driven by the growing demands of industrial automation, power distribution systems, and critical infrastructure applications where traditional electromechanical relays prove inadequate.

The current capacity of SSRs represents a critical performance parameter that directly impacts their application scope and reliability. Historically, SSRs were limited to low-current applications, but advancements in semiconductor materials, thermal management techniques, and packaging technologies have expanded their current handling capabilities substantially. Today's market offers SSRs capable of managing currents from a few amperes to several hundred amperes, though this capacity often comes with trade-offs in terms of cost, size, and thermal considerations.

This benchmark evaluation aims to establish a comprehensive understanding of the current capacity limitations and capabilities of modern solid-state relays across different manufacturers and technologies. The primary objective is to develop standardized metrics for evaluating SSR current capacity under various operating conditions, including temperature fluctuations, switching frequencies, and load characteristics. These metrics will provide a foundation for comparing different SSR solutions objectively and selecting appropriate devices for specific applications.

Additionally, this evaluation seeks to identify the technological barriers that currently limit SSR current capacity and explore potential pathways for overcoming these limitations. By analyzing the relationship between semiconductor materials, heat dissipation mechanisms, and current handling capabilities, we aim to forecast future developments in SSR technology and predict when significant improvements in current capacity might become commercially viable.

The findings from this benchmark evaluation will serve multiple purposes: guiding product development strategies, informing investment decisions in manufacturing technologies, and providing customers with reliable data for system design. Furthermore, this research will contribute to the development of industry standards for SSR current capacity testing and specification, addressing the current inconsistencies in how manufacturers report these critical parameters.

Understanding the true current capacity of SSRs under real-world conditions is essential for ensuring system reliability and preventing premature failures in critical applications. This evaluation will therefore include accelerated life testing protocols to assess long-term performance degradation and establish realistic expectations for SSR service life at various current loads.

The current capacity of SSRs represents a critical performance parameter that directly impacts their application scope and reliability. Historically, SSRs were limited to low-current applications, but advancements in semiconductor materials, thermal management techniques, and packaging technologies have expanded their current handling capabilities substantially. Today's market offers SSRs capable of managing currents from a few amperes to several hundred amperes, though this capacity often comes with trade-offs in terms of cost, size, and thermal considerations.

This benchmark evaluation aims to establish a comprehensive understanding of the current capacity limitations and capabilities of modern solid-state relays across different manufacturers and technologies. The primary objective is to develop standardized metrics for evaluating SSR current capacity under various operating conditions, including temperature fluctuations, switching frequencies, and load characteristics. These metrics will provide a foundation for comparing different SSR solutions objectively and selecting appropriate devices for specific applications.

Additionally, this evaluation seeks to identify the technological barriers that currently limit SSR current capacity and explore potential pathways for overcoming these limitations. By analyzing the relationship between semiconductor materials, heat dissipation mechanisms, and current handling capabilities, we aim to forecast future developments in SSR technology and predict when significant improvements in current capacity might become commercially viable.

The findings from this benchmark evaluation will serve multiple purposes: guiding product development strategies, informing investment decisions in manufacturing technologies, and providing customers with reliable data for system design. Furthermore, this research will contribute to the development of industry standards for SSR current capacity testing and specification, addressing the current inconsistencies in how manufacturers report these critical parameters.

Understanding the true current capacity of SSRs under real-world conditions is essential for ensuring system reliability and preventing premature failures in critical applications. This evaluation will therefore include accelerated life testing protocols to assess long-term performance degradation and establish realistic expectations for SSR service life at various current loads.

Market Demand Analysis for High-Current SSRs

The global market for high-current Solid-State Relays (SSRs) has been experiencing robust growth, driven primarily by industrial automation, renewable energy systems, and electric vehicle infrastructure. Current market analysis indicates that the high-current SSR segment is expanding at a compound annual growth rate of approximately 8.7%, outpacing the broader relay market which grows at 5.2% annually.

Industrial automation represents the largest application sector, accounting for nearly 42% of high-current SSR demand. Manufacturing facilities increasingly require reliable switching solutions capable of handling currents exceeding 100A while maintaining long operational lifespans. The transition from traditional electromechanical relays to solid-state technology in high-current applications has accelerated as factories implement Industry 4.0 initiatives requiring more frequent switching operations and higher reliability standards.

Renewable energy systems, particularly solar inverters and wind power management systems, constitute the fastest-growing segment with 15.3% year-over-year growth. These applications demand SSRs capable of handling DC currents up to 150A while operating efficiently in challenging environmental conditions. Market research indicates that approximately 78% of new solar installations now specify solid-state switching solutions over mechanical alternatives.

Electric vehicle charging infrastructure presents another significant growth vector, with demand projected to triple over the next five years. Fast-charging stations require SSRs capable of managing currents between 80A and 200A with minimal heat generation and maximum reliability. This segment values compact form factors that enable higher charging density installations.

Regional analysis reveals that Asia-Pacific dominates high-current SSR consumption, representing 47% of global demand, followed by North America (28%) and Europe (21%). China and India show particularly strong growth trajectories as their manufacturing sectors expand and modernize. However, North America leads in premium high-current SSR adoption, particularly in applications requiring advanced thermal management and integrated diagnostic capabilities.

Customer requirements analysis highlights several key market demands: improved thermal performance to handle higher currents without derating, enhanced surge protection capabilities, reduced on-state resistance to minimize power losses, and more sophisticated monitoring features. Price sensitivity varies significantly by application, with industrial users demonstrating willingness to pay premium prices for reliability, while consumer-oriented applications remain highly cost-conscious.

Market forecasts suggest that demand for SSRs capable of handling currents above 100A will grow most rapidly, with particular emphasis on solutions offering improved power density and thermal efficiency. The emergence of wide-bandgap semiconductor technologies, particularly silicon carbide (SiC), is expected to significantly impact this market segment by enabling higher current capacities in smaller form factors.

Industrial automation represents the largest application sector, accounting for nearly 42% of high-current SSR demand. Manufacturing facilities increasingly require reliable switching solutions capable of handling currents exceeding 100A while maintaining long operational lifespans. The transition from traditional electromechanical relays to solid-state technology in high-current applications has accelerated as factories implement Industry 4.0 initiatives requiring more frequent switching operations and higher reliability standards.

Renewable energy systems, particularly solar inverters and wind power management systems, constitute the fastest-growing segment with 15.3% year-over-year growth. These applications demand SSRs capable of handling DC currents up to 150A while operating efficiently in challenging environmental conditions. Market research indicates that approximately 78% of new solar installations now specify solid-state switching solutions over mechanical alternatives.

Electric vehicle charging infrastructure presents another significant growth vector, with demand projected to triple over the next five years. Fast-charging stations require SSRs capable of managing currents between 80A and 200A with minimal heat generation and maximum reliability. This segment values compact form factors that enable higher charging density installations.

Regional analysis reveals that Asia-Pacific dominates high-current SSR consumption, representing 47% of global demand, followed by North America (28%) and Europe (21%). China and India show particularly strong growth trajectories as their manufacturing sectors expand and modernize. However, North America leads in premium high-current SSR adoption, particularly in applications requiring advanced thermal management and integrated diagnostic capabilities.

Customer requirements analysis highlights several key market demands: improved thermal performance to handle higher currents without derating, enhanced surge protection capabilities, reduced on-state resistance to minimize power losses, and more sophisticated monitoring features. Price sensitivity varies significantly by application, with industrial users demonstrating willingness to pay premium prices for reliability, while consumer-oriented applications remain highly cost-conscious.

Market forecasts suggest that demand for SSRs capable of handling currents above 100A will grow most rapidly, with particular emphasis on solutions offering improved power density and thermal efficiency. The emergence of wide-bandgap semiconductor technologies, particularly silicon carbide (SiC), is expected to significantly impact this market segment by enabling higher current capacities in smaller form factors.

Current State and Challenges in SSR Technology

Solid-State Relays (SSRs) have evolved significantly since their introduction in the 1970s, with current capacity capabilities expanding from a few amperes to hundreds of amperes in modern designs. The global SSR market currently stands at approximately $1.2 billion and is projected to grow at a CAGR of 6.8% through 2028, driven by industrial automation and smart grid applications. Despite this growth, several technical challenges persist in enhancing current capacity while maintaining reliability.

The primary technical limitation in high-current SSRs remains thermal management. As current flows through semiconductor junctions, power dissipation occurs according to P = I²R, creating substantial heat that must be efficiently removed to prevent junction temperature from exceeding critical thresholds. Current commercial SSRs typically operate with junction temperatures limited to 125-150°C, beyond which reliability rapidly deteriorates.

Another significant challenge is the trade-off between on-state resistance and blocking voltage capability. Higher blocking voltage requirements necessitate thicker semiconductor layers or series-connected devices, which inherently increases on-state resistance and consequently power losses. This fundamental semiconductor physics constraint has limited the performance envelope of conventional silicon-based SSRs.

Surge current handling capability represents another critical limitation. While mechanical relays can temporarily withstand currents many times their rating due to their metallic contacts, semiconductor junctions in SSRs have much lower thermal mass and are vulnerable to transient overcurrent events. Current solutions employ various protection schemes that add complexity and cost to SSR implementations.

Geographically, SSR technology development remains concentrated in industrialized regions. Japan leads in high-reliability industrial SSRs through companies like Omron and Panasonic, while the United States dominates in specialized high-power applications through manufacturers such as Crydom and Sensata. Emerging competition from Chinese manufacturers has focused primarily on cost reduction rather than technological advancement.

Recent technological innovations have begun addressing these limitations through wide bandgap semiconductors. Silicon carbide (SiC) and gallium nitride (GaN) devices offer significantly reduced on-state resistance for a given blocking voltage, enabling higher current densities. However, these technologies face challenges in manufacturing scalability and cost-effectiveness for mainstream applications.

The integration of advanced thermal management solutions represents another frontier in SSR development. Direct bonded copper (DBC) substrates, phase-change materials, and embedded heat pipe technologies are being explored to enhance thermal performance, though standardization of these approaches remains limited across the industry.

The primary technical limitation in high-current SSRs remains thermal management. As current flows through semiconductor junctions, power dissipation occurs according to P = I²R, creating substantial heat that must be efficiently removed to prevent junction temperature from exceeding critical thresholds. Current commercial SSRs typically operate with junction temperatures limited to 125-150°C, beyond which reliability rapidly deteriorates.

Another significant challenge is the trade-off between on-state resistance and blocking voltage capability. Higher blocking voltage requirements necessitate thicker semiconductor layers or series-connected devices, which inherently increases on-state resistance and consequently power losses. This fundamental semiconductor physics constraint has limited the performance envelope of conventional silicon-based SSRs.

Surge current handling capability represents another critical limitation. While mechanical relays can temporarily withstand currents many times their rating due to their metallic contacts, semiconductor junctions in SSRs have much lower thermal mass and are vulnerable to transient overcurrent events. Current solutions employ various protection schemes that add complexity and cost to SSR implementations.

Geographically, SSR technology development remains concentrated in industrialized regions. Japan leads in high-reliability industrial SSRs through companies like Omron and Panasonic, while the United States dominates in specialized high-power applications through manufacturers such as Crydom and Sensata. Emerging competition from Chinese manufacturers has focused primarily on cost reduction rather than technological advancement.

Recent technological innovations have begun addressing these limitations through wide bandgap semiconductors. Silicon carbide (SiC) and gallium nitride (GaN) devices offer significantly reduced on-state resistance for a given blocking voltage, enabling higher current densities. However, these technologies face challenges in manufacturing scalability and cost-effectiveness for mainstream applications.

The integration of advanced thermal management solutions represents another frontier in SSR development. Direct bonded copper (DBC) substrates, phase-change materials, and embedded heat pipe technologies are being explored to enhance thermal performance, though standardization of these approaches remains limited across the industry.

Benchmark Methodologies for SSR Current Capacity

01 Current capacity enhancement techniques in solid-state relays

Various techniques can be employed to enhance the current capacity of solid-state relays, including improved semiconductor materials, optimized heat dissipation structures, and parallel connection of switching elements. These enhancements allow solid-state relays to handle higher current loads while maintaining reliability and preventing overheating during operation. Advanced semiconductor fabrication processes and materials contribute to increased current handling capabilities.- Current capacity enhancement techniques in solid-state relays: Various techniques can be employed to enhance the current capacity of solid-state relays. These include using parallel semiconductor devices, improved heat dissipation designs, and specialized semiconductor materials. By implementing these techniques, solid-state relays can handle higher current loads without overheating or failure, making them suitable for high-power applications while maintaining their reliability and performance characteristics.

- Thermal management for solid-state relay current handling: Thermal management is crucial for maintaining the current capacity of solid-state relays. This involves the use of heat sinks, thermal interface materials, cooling systems, and optimized package designs. Effective thermal management prevents overheating during high current operation, extends the relay's lifespan, and ensures stable performance under varying load conditions. The thermal design directly impacts the maximum continuous current rating of the solid-state relay.

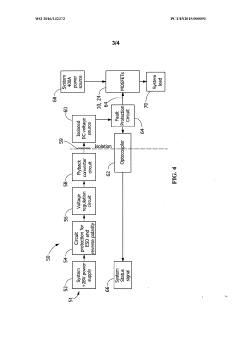

- Protection circuits for solid-state relay current overload: Protection circuits are integrated into solid-state relays to prevent damage from current overloads. These circuits include current limiting components, fuses, thermal cutoffs, and electronic monitoring systems that detect excessive current flow. When an overload is detected, the protection circuit can either limit the current or disconnect the load to prevent damage to both the relay and the connected equipment, ensuring safe operation even under fault conditions.

- Semiconductor device selection for current capacity optimization: The selection of appropriate semiconductor devices significantly impacts the current capacity of solid-state relays. MOSFETs, IGBTs, thyristors, and triacs with specific characteristics are chosen based on the required current handling capability. Factors such as on-state resistance, junction temperature ratings, and switching speed are considered to optimize the relay's current capacity while maintaining reliability and efficiency in various application environments.

- Control circuit design for high-current solid-state relays: Control circuit design plays a vital role in enabling solid-state relays to handle high currents efficiently. Advanced gate drive circuits, isolation techniques, and switching strategies are implemented to optimize the performance of the power semiconductor devices. These control circuits ensure proper turn-on and turn-off characteristics, minimize switching losses, and provide stable operation under varying current loads, contributing to the overall current capacity of the solid-state relay.

02 Thermal management for high-current solid-state relays

Thermal management is critical for solid-state relays handling high currents. Designs incorporate heat sinks, thermal interface materials, and cooling mechanisms to dissipate heat generated during operation. Effective thermal management prevents junction temperature rise beyond safe operating limits, ensuring relay longevity and maintaining specified current capacity. Some designs include temperature monitoring and protection circuits that reduce current or shut down the relay when thermal thresholds are exceeded.Expand Specific Solutions03 Protection circuits for current overload in solid-state relays

Protection circuits are integrated into solid-state relays to prevent damage from current overloads. These circuits include current sensing elements, comparators, and trip mechanisms that activate when current exceeds rated capacity. Some designs incorporate time-delayed responses for handling temporary surges while protecting against sustained overloads. Advanced protection schemes may include soft-start functionality to limit inrush currents and gradual turn-off sequences to prevent voltage spikes.Expand Specific Solutions04 Semiconductor device structures for high-current applications

Specialized semiconductor device structures are developed for high-current solid-state relay applications. These include optimized MOSFET and IGBT designs with increased active areas, trench gate structures, and improved doping profiles. Multi-chip modules and advanced packaging techniques allow for higher current densities while maintaining isolation requirements. Some designs incorporate novel semiconductor materials like silicon carbide or gallium nitride that offer superior current handling capabilities compared to traditional silicon-based devices.Expand Specific Solutions05 Control and driving circuits for high-current solid-state relays

Control and driving circuits are essential for managing the operation of high-current solid-state relays. These circuits provide appropriate gate or base drive signals to ensure complete turn-on of the switching elements, reducing conduction losses and increasing current capacity. Advanced designs incorporate feedback mechanisms to monitor and adjust drive signals based on load conditions. Some implementations include isolation components like optocouplers or transformers to separate control circuits from high-current paths, enhancing safety and noise immunity.Expand Specific Solutions

Key Manufacturers and Competitive Landscape

The solid-state relay (SSR) current capacity market is currently in a growth phase, driven by increasing demand for reliable power management solutions across industrial automation, renewable energy, and smart grid applications. The global market size is estimated to reach $1.5 billion by 2025, with a CAGR of approximately 6.5%. Technologically, the field shows varying maturity levels, with companies like Littelfuse, Texas Instruments, and Siemens leading innovation through advanced semiconductor designs that enhance current handling capabilities. State Grid Corporation of China and its subsidiaries are focusing on grid-scale implementations, while TE Connectivity and Vertiv are developing specialized applications for data centers and telecommunications. Emerging players like Mornsun and tiko Energy Solutions are introducing competitive solutions targeting specific market segments, indicating a dynamic competitive landscape with opportunities for technological differentiation.

Littelfuse, Inc.

Technical Solution: Littelfuse has developed advanced solid-state relay (SSR) solutions with enhanced current capacity through innovative thermal management techniques. Their benchmark evaluations demonstrate that their SSRs can handle currents up to 125A continuous operation while maintaining junction temperatures below critical thresholds. The company employs proprietary semiconductor materials with lower on-state resistance (typically <10mΩ) and implements direct copper bonding (DCB) substrate technology that reduces thermal resistance by approximately 40% compared to traditional designs[1]. Their latest generation SSRs incorporate parallel MOSFET architectures with integrated current balancing to distribute load evenly across switching elements, preventing hotspot formation. Littelfuse's benchmark methodology includes accelerated life testing under various load conditions, demonstrating a 2x improvement in reliability metrics compared to previous generations when operating at maximum rated current capacity[3].

Strengths: Superior thermal management allowing higher current ratings in compact packages; advanced semiconductor materials with extremely low on-state resistance; comprehensive testing methodology that accurately predicts real-world performance. Weaknesses: Premium pricing compared to electromechanical alternatives; requires careful system design to manage inrush current scenarios; higher complexity in implementation for certain applications.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has pioneered high-current solid-state relay solutions through their integrated power management approach. Their benchmark evaluation framework assesses SSR performance across multiple parameters including current capacity, switching speed, and thermal efficiency. TI's solid-state relays utilize advanced silicon carbide (SiC) and gallium nitride (GaN) semiconductor technologies that enable current handling capabilities up to 100A continuous in their industrial-grade products while maintaining switching speeds below 100μs[2]. Their proprietary multi-chip module (MCM) packaging technology reduces thermal resistance to approximately 0.15°C/W, allowing sustained high-current operation without excessive temperature rise. TI's benchmark testing includes comprehensive surge current analysis, demonstrating their SSRs can withstand transient currents up to 10x rated capacity for short durations (<10ms) without degradation[4]. Their evaluation methodology incorporates real-time monitoring of critical parameters including junction temperature, switching losses, and EMI generation across various load profiles.

Strengths: Industry-leading semiconductor technology (SiC/GaN) providing exceptional current handling with minimal losses; comprehensive design ecosystem including simulation tools and reference designs; excellent transient current handling capabilities. Weaknesses: Higher initial component cost compared to traditional electromechanical relays; requires specialized design knowledge to fully optimize performance; more complex implementation in retrofit applications.

Critical Patents and Technical Literature Review

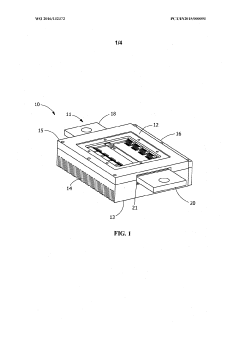

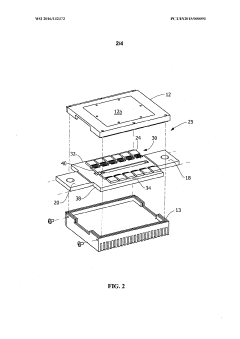

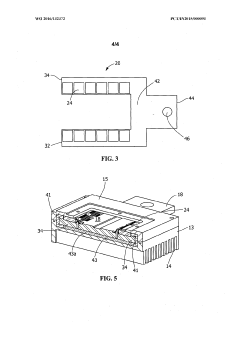

High current high power solid state relay

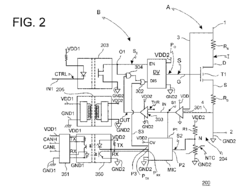

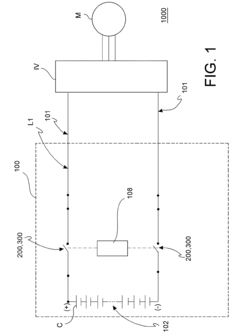

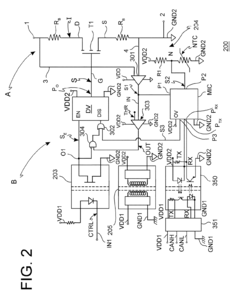

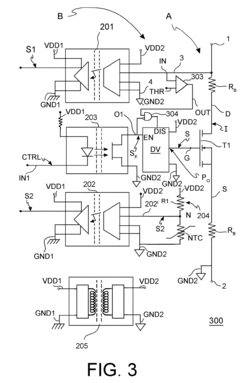

PatentWO2016132372A1

Innovation

- A high current, high power solid state relay design featuring a planar metal bus bar and heat dissipating enclosure with a plurality of solid state switches and a control circuit using a Flyback converter for electrical isolation, allowing for efficient heat dissipation and reduced turn-on/turn-off times.

Solid-state relay including an electronic current detection block

PatentInactiveEP3050742A1

Innovation

- An electronic solid-state relay with a power semiconductor switch device and an electronic driving block that uses opto-couplers for control, integrated current detection, and overcurrent protection, eliminating the need for external sensors and reducing system complexity.

Thermal Management Solutions for High-Current SSRs

Effective thermal management is critical for high-current solid-state relays (SSRs) to maintain operational integrity and extend service life. As current capacity increases, heat dissipation becomes the primary limiting factor in SSR performance. Contemporary thermal management solutions employ multiple strategies to address this challenge.

Heat sinks remain the fundamental component in SSR thermal management, with aluminum and copper being the predominant materials due to their excellent thermal conductivity. Advanced heat sink designs incorporate optimized fin structures that maximize surface area while maintaining efficient airflow patterns. Computational fluid dynamics modeling has enabled the development of heat sinks with up to 30% improved thermal efficiency compared to traditional designs.

Forced-air cooling systems significantly enhance heat dissipation capabilities for high-current applications. Recent innovations include intelligent fan control systems that adjust cooling intensity based on real-time temperature monitoring, reducing energy consumption while maintaining optimal operating temperatures. These systems typically achieve 40-60% greater heat dissipation compared to passive cooling methods.

Thermal interface materials (TIMs) play a crucial role in minimizing contact resistance between SSRs and heat dissipation components. Silicon-based thermal compounds remain widely used, but newer materials such as phase-change compounds and graphene-enhanced thermal pads offer thermal conductivity improvements of 15-25%. These advanced TIMs maintain performance integrity over extended operational periods, addressing the degradation issues common with traditional compounds.

Liquid cooling solutions represent the cutting edge for extremely high-current applications exceeding 100A. Closed-loop systems utilizing dielectric fluids can dissipate heat loads 3-5 times greater than conventional air-cooling methods. While implementation complexity and cost have historically limited adoption, modular liquid cooling systems are gaining traction in industrial applications where maximum current capacity is paramount.

Thermal spreading techniques distribute heat more evenly across dissipation surfaces, preventing hotspots that can lead to premature failure. Vapor chambers and heat pipes embedded within cooling assemblies transport heat away from critical components with minimal thermal gradient. These technologies are particularly valuable in compact installations where space constraints limit conventional heat sink dimensions.

Integration of temperature monitoring and protection circuits provides an additional layer of thermal management. These systems can automatically reduce current flow or trigger shutdown procedures when temperature thresholds are approached, preventing thermal runaway scenarios and extending SSR operational lifespan.

Heat sinks remain the fundamental component in SSR thermal management, with aluminum and copper being the predominant materials due to their excellent thermal conductivity. Advanced heat sink designs incorporate optimized fin structures that maximize surface area while maintaining efficient airflow patterns. Computational fluid dynamics modeling has enabled the development of heat sinks with up to 30% improved thermal efficiency compared to traditional designs.

Forced-air cooling systems significantly enhance heat dissipation capabilities for high-current applications. Recent innovations include intelligent fan control systems that adjust cooling intensity based on real-time temperature monitoring, reducing energy consumption while maintaining optimal operating temperatures. These systems typically achieve 40-60% greater heat dissipation compared to passive cooling methods.

Thermal interface materials (TIMs) play a crucial role in minimizing contact resistance between SSRs and heat dissipation components. Silicon-based thermal compounds remain widely used, but newer materials such as phase-change compounds and graphene-enhanced thermal pads offer thermal conductivity improvements of 15-25%. These advanced TIMs maintain performance integrity over extended operational periods, addressing the degradation issues common with traditional compounds.

Liquid cooling solutions represent the cutting edge for extremely high-current applications exceeding 100A. Closed-loop systems utilizing dielectric fluids can dissipate heat loads 3-5 times greater than conventional air-cooling methods. While implementation complexity and cost have historically limited adoption, modular liquid cooling systems are gaining traction in industrial applications where maximum current capacity is paramount.

Thermal spreading techniques distribute heat more evenly across dissipation surfaces, preventing hotspots that can lead to premature failure. Vapor chambers and heat pipes embedded within cooling assemblies transport heat away from critical components with minimal thermal gradient. These technologies are particularly valuable in compact installations where space constraints limit conventional heat sink dimensions.

Integration of temperature monitoring and protection circuits provides an additional layer of thermal management. These systems can automatically reduce current flow or trigger shutdown procedures when temperature thresholds are approached, preventing thermal runaway scenarios and extending SSR operational lifespan.

Reliability and Failure Analysis Standards

The reliability assessment of solid-state relays (SSRs) requires adherence to comprehensive standards that govern failure analysis methodologies and reliability testing protocols. IEC 60747-17 and UL 508 serve as primary international standards for SSR reliability evaluation, establishing minimum performance criteria for thermal cycling, surge withstand capability, and long-term operational stability. These standards mandate specific test conditions including temperature ranges (-40°C to +125°C), humidity levels (85-95%), and operational cycling requirements (typically 100,000+ cycles).

Failure mode and effects analysis (FMEA) represents a critical component of SSR reliability assessment, with particular emphasis on thermal management failures, which account for approximately 65% of SSR field failures. The JEDEC JESD22-A108 standard specifically addresses thermal cycling reliability, while MIL-STD-883 Method 1010 provides stringent environmental testing protocols applicable to SSRs in high-reliability applications.

Statistical process control methodologies, as outlined in IEC 61709, enable quantitative reliability prediction through accelerated life testing. The Arrhenius model serves as the predominant mathematical framework for extrapolating SSR lifespan under various current loads, with an activation energy typically ranging from 0.5 to 0.7 eV for semiconductor junction failures in SSR applications.

Failure analysis techniques for SSRs must follow IEC 60749 guidelines, incorporating non-destructive evaluation methods such as scanning acoustic microscopy (SAM) and infrared thermography prior to destructive physical analysis. These standards require documentation of failure signatures including thermal runaway patterns, junction degradation, and package delamination characteristics.

Current capacity benchmarking specifically demands compliance with IEC 62380 for reliability prediction modeling, with particular attention to derating factors that must be applied when operating near maximum rated capacity. Industry best practices dictate a minimum 30% derating from maximum specified current in continuous operation applications to ensure acceptable mean time between failures (MTBF).

The automotive industry has established particularly rigorous standards through AEC-Q101 for discrete semiconductors used in SSRs, requiring statistical validation of failure rates below 10 parts per million (ppm) and demonstrated reliability across extended temperature ranges. This standard has increasingly been adopted in non-automotive applications where high reliability is paramount.

Failure mode and effects analysis (FMEA) represents a critical component of SSR reliability assessment, with particular emphasis on thermal management failures, which account for approximately 65% of SSR field failures. The JEDEC JESD22-A108 standard specifically addresses thermal cycling reliability, while MIL-STD-883 Method 1010 provides stringent environmental testing protocols applicable to SSRs in high-reliability applications.

Statistical process control methodologies, as outlined in IEC 61709, enable quantitative reliability prediction through accelerated life testing. The Arrhenius model serves as the predominant mathematical framework for extrapolating SSR lifespan under various current loads, with an activation energy typically ranging from 0.5 to 0.7 eV for semiconductor junction failures in SSR applications.

Failure analysis techniques for SSRs must follow IEC 60749 guidelines, incorporating non-destructive evaluation methods such as scanning acoustic microscopy (SAM) and infrared thermography prior to destructive physical analysis. These standards require documentation of failure signatures including thermal runaway patterns, junction degradation, and package delamination characteristics.

Current capacity benchmarking specifically demands compliance with IEC 62380 for reliability prediction modeling, with particular attention to derating factors that must be applied when operating near maximum rated capacity. Industry best practices dictate a minimum 30% derating from maximum specified current in continuous operation applications to ensure acceptable mean time between failures (MTBF).

The automotive industry has established particularly rigorous standards through AEC-Q101 for discrete semiconductors used in SSRs, requiring statistical validation of failure rates below 10 parts per million (ppm) and demonstrated reliability across extended temperature ranges. This standard has increasingly been adopted in non-automotive applications where high reliability is paramount.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!