Solid-State Relay Input Sensitivity: Measurement Guidelines

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SSR Input Sensitivity Background and Objectives

Solid-state relays (SSRs) have evolved significantly since their introduction in the 1970s as alternatives to electromechanical relays. These semiconductor-based switching devices have transformed industrial automation, power control systems, and consumer electronics by offering enhanced reliability, faster switching speeds, and elimination of mechanical wear. The evolution of SSR technology has been driven by advancements in semiconductor materials, manufacturing processes, and circuit design techniques, resulting in progressively improved performance characteristics.

Input sensitivity represents a critical parameter in SSR design and application, defining the minimum control signal required to reliably activate the relay. This parameter has become increasingly important as modern systems demand precise control with minimal power consumption. The historical trajectory shows a clear trend toward lower activation thresholds, with early SSRs requiring control signals in the 10-30mA range, while contemporary designs can operate with inputs below 1mA in some applications.

The measurement and standardization of input sensitivity have not kept pace with technological advancements, creating challenges for engineers and system designers. Current industry practices exhibit significant variations in measurement methodologies, environmental conditions, and reporting formats, leading to inconsistencies in published specifications and potential integration issues in practical applications.

This technical research aims to establish comprehensive guidelines for measuring SSR input sensitivity with standardized procedures that account for temperature variations, load conditions, and aging effects. By developing these guidelines, we seek to enhance the reliability of SSR specifications, facilitate accurate comparisons between different products, and improve the predictability of SSR performance in diverse operating environments.

The objectives of this research include: identifying key factors affecting input sensitivity measurements; evaluating existing measurement techniques and their limitations; developing standardized test protocols that address environmental variables; creating reproducible measurement methodologies suitable for both laboratory and field conditions; and establishing reporting standards that provide meaningful data for system designers.

Additionally, this research will explore emerging trends in SSR technology, including the integration of advanced diagnostic capabilities, digital interfaces for precise control, and adaptive sensitivity features that automatically adjust to changing operating conditions. These developments point toward a future where SSRs will offer not only improved sensitivity but also enhanced intelligence and communication capabilities.

The findings from this research will contribute to the development of industry standards and best practices, ultimately supporting more efficient and reliable implementation of SSRs across various applications from industrial automation to smart grid technologies and IoT devices.

Input sensitivity represents a critical parameter in SSR design and application, defining the minimum control signal required to reliably activate the relay. This parameter has become increasingly important as modern systems demand precise control with minimal power consumption. The historical trajectory shows a clear trend toward lower activation thresholds, with early SSRs requiring control signals in the 10-30mA range, while contemporary designs can operate with inputs below 1mA in some applications.

The measurement and standardization of input sensitivity have not kept pace with technological advancements, creating challenges for engineers and system designers. Current industry practices exhibit significant variations in measurement methodologies, environmental conditions, and reporting formats, leading to inconsistencies in published specifications and potential integration issues in practical applications.

This technical research aims to establish comprehensive guidelines for measuring SSR input sensitivity with standardized procedures that account for temperature variations, load conditions, and aging effects. By developing these guidelines, we seek to enhance the reliability of SSR specifications, facilitate accurate comparisons between different products, and improve the predictability of SSR performance in diverse operating environments.

The objectives of this research include: identifying key factors affecting input sensitivity measurements; evaluating existing measurement techniques and their limitations; developing standardized test protocols that address environmental variables; creating reproducible measurement methodologies suitable for both laboratory and field conditions; and establishing reporting standards that provide meaningful data for system designers.

Additionally, this research will explore emerging trends in SSR technology, including the integration of advanced diagnostic capabilities, digital interfaces for precise control, and adaptive sensitivity features that automatically adjust to changing operating conditions. These developments point toward a future where SSRs will offer not only improved sensitivity but also enhanced intelligence and communication capabilities.

The findings from this research will contribute to the development of industry standards and best practices, ultimately supporting more efficient and reliable implementation of SSRs across various applications from industrial automation to smart grid technologies and IoT devices.

Market Demand Analysis for High-Sensitivity SSRs

The global market for high-sensitivity Solid-State Relays (SSRs) has been experiencing robust growth, driven primarily by the increasing automation across various industries. The demand for SSRs with enhanced input sensitivity is particularly pronounced in precision control applications where minimal trigger currents are essential for energy efficiency and system reliability.

Industrial automation represents the largest market segment for high-sensitivity SSRs, accounting for a significant portion of the overall demand. Manufacturing facilities are increasingly adopting these components to improve energy efficiency and reduce maintenance costs associated with mechanical relay failures. The trend toward Industry 4.0 and smart manufacturing has further accelerated this demand, as high-sensitivity SSRs enable more precise control in automated systems.

The renewable energy sector has emerged as another critical market for high-sensitivity SSRs. Solar inverters and wind power systems require reliable switching components that can operate with minimal control signals. As global renewable energy capacity continues to expand, the demand for specialized SSRs with high input sensitivity is projected to grow substantially over the next five years.

Medical equipment manufacturers constitute another significant market segment. Diagnostic and therapeutic devices often require precise control with minimal power consumption, making high-sensitivity SSRs ideal components. The growing emphasis on portable and battery-powered medical devices has further intensified the need for relays that can operate with extremely low input currents.

Building automation systems represent an expanding application area for high-sensitivity SSRs. Smart building technologies require numerous switching components that must operate reliably with minimal control signals. Energy management systems, HVAC controls, and lighting automation are key applications driving demand in this sector.

Market research indicates that customers are increasingly prioritizing input sensitivity specifications when selecting SSRs. The ability to trigger reliably at lower current thresholds translates directly to energy savings and improved system performance. This has prompted manufacturers to focus R&D efforts on enhancing input sensitivity while maintaining other critical parameters such as isolation voltage and switching speed.

Regional analysis shows that Asia-Pacific currently leads the market for high-sensitivity SSRs, followed by North America and Europe. China and Japan are particularly significant markets due to their robust manufacturing sectors and rapid automation adoption. However, North America is expected to show the fastest growth rate in the coming years, driven by investments in industrial modernization and renewable energy infrastructure.

Industrial automation represents the largest market segment for high-sensitivity SSRs, accounting for a significant portion of the overall demand. Manufacturing facilities are increasingly adopting these components to improve energy efficiency and reduce maintenance costs associated with mechanical relay failures. The trend toward Industry 4.0 and smart manufacturing has further accelerated this demand, as high-sensitivity SSRs enable more precise control in automated systems.

The renewable energy sector has emerged as another critical market for high-sensitivity SSRs. Solar inverters and wind power systems require reliable switching components that can operate with minimal control signals. As global renewable energy capacity continues to expand, the demand for specialized SSRs with high input sensitivity is projected to grow substantially over the next five years.

Medical equipment manufacturers constitute another significant market segment. Diagnostic and therapeutic devices often require precise control with minimal power consumption, making high-sensitivity SSRs ideal components. The growing emphasis on portable and battery-powered medical devices has further intensified the need for relays that can operate with extremely low input currents.

Building automation systems represent an expanding application area for high-sensitivity SSRs. Smart building technologies require numerous switching components that must operate reliably with minimal control signals. Energy management systems, HVAC controls, and lighting automation are key applications driving demand in this sector.

Market research indicates that customers are increasingly prioritizing input sensitivity specifications when selecting SSRs. The ability to trigger reliably at lower current thresholds translates directly to energy savings and improved system performance. This has prompted manufacturers to focus R&D efforts on enhancing input sensitivity while maintaining other critical parameters such as isolation voltage and switching speed.

Regional analysis shows that Asia-Pacific currently leads the market for high-sensitivity SSRs, followed by North America and Europe. China and Japan are particularly significant markets due to their robust manufacturing sectors and rapid automation adoption. However, North America is expected to show the fastest growth rate in the coming years, driven by investments in industrial modernization and renewable energy infrastructure.

Current Technical Challenges in SSR Input Sensitivity

The measurement of input sensitivity in Solid-State Relays (SSRs) faces several significant technical challenges that impede standardization and reliable performance evaluation. One primary challenge is the lack of universally accepted measurement methodologies, resulting in inconsistent sensitivity specifications across manufacturers. This creates difficulties for engineers attempting to compare products or predict performance in specific applications.

Signal noise interference presents another substantial obstacle in accurate sensitivity measurement. The low-level input signals required to trigger SSRs are particularly susceptible to electromagnetic interference (EMI), radio frequency interference (RFI), and power supply fluctuations. These noise sources can lead to false triggering or masking of legitimate trigger signals, complicating reliable measurement procedures.

Temperature dependency further complicates sensitivity measurements. The semiconductor materials in SSRs exhibit significant parameter shifts across operating temperature ranges, with input sensitivity typically decreasing at higher temperatures. Current measurement protocols often fail to adequately account for these temperature-induced variations, leading to discrepancies between laboratory measurements and real-world performance.

The diversity of input circuit designs across different SSR types creates additional measurement challenges. Optically-coupled SSRs, transformer-coupled variants, and direct-coupled designs each require different measurement approaches due to their unique input characteristics. This diversity has prevented the development of a single, comprehensive measurement standard applicable across all SSR types.

Aging effects and long-term stability represent another critical measurement challenge. Input sensitivity can drift over time due to degradation of internal components, particularly in optically-coupled SSRs where LED efficiency decreases with age. Current measurement guidelines rarely address methodologies for predicting or quantifying these long-term sensitivity changes.

Measurement equipment limitations also contribute to the challenge. Precise measurement of trigger thresholds requires specialized equipment capable of generating highly controlled, low-level signals while simultaneously monitoring SSR state transitions. The cost and complexity of such equipment often lead to simplified testing methodologies that sacrifice accuracy for practicality.

Finally, application-specific factors significantly impact real-world SSR sensitivity but are difficult to incorporate into standardized measurements. Factors such as input signal rise time, pulse width, duty cycle, and load characteristics all influence effective sensitivity in practical applications. Developing measurement protocols that meaningfully account for these application-specific variables remains an ongoing challenge for the industry.

Signal noise interference presents another substantial obstacle in accurate sensitivity measurement. The low-level input signals required to trigger SSRs are particularly susceptible to electromagnetic interference (EMI), radio frequency interference (RFI), and power supply fluctuations. These noise sources can lead to false triggering or masking of legitimate trigger signals, complicating reliable measurement procedures.

Temperature dependency further complicates sensitivity measurements. The semiconductor materials in SSRs exhibit significant parameter shifts across operating temperature ranges, with input sensitivity typically decreasing at higher temperatures. Current measurement protocols often fail to adequately account for these temperature-induced variations, leading to discrepancies between laboratory measurements and real-world performance.

The diversity of input circuit designs across different SSR types creates additional measurement challenges. Optically-coupled SSRs, transformer-coupled variants, and direct-coupled designs each require different measurement approaches due to their unique input characteristics. This diversity has prevented the development of a single, comprehensive measurement standard applicable across all SSR types.

Aging effects and long-term stability represent another critical measurement challenge. Input sensitivity can drift over time due to degradation of internal components, particularly in optically-coupled SSRs where LED efficiency decreases with age. Current measurement guidelines rarely address methodologies for predicting or quantifying these long-term sensitivity changes.

Measurement equipment limitations also contribute to the challenge. Precise measurement of trigger thresholds requires specialized equipment capable of generating highly controlled, low-level signals while simultaneously monitoring SSR state transitions. The cost and complexity of such equipment often lead to simplified testing methodologies that sacrifice accuracy for practicality.

Finally, application-specific factors significantly impact real-world SSR sensitivity but are difficult to incorporate into standardized measurements. Factors such as input signal rise time, pulse width, duty cycle, and load characteristics all influence effective sensitivity in practical applications. Developing measurement protocols that meaningfully account for these application-specific variables remains an ongoing challenge for the industry.

Current Methodologies for SSR Input Sensitivity Measurement

01 Input sensitivity enhancement techniques

Various techniques can be used to enhance the input sensitivity of solid-state relays. These include using specialized input circuits, amplification stages, and trigger mechanisms that allow the relay to respond to lower input signals. Enhanced sensitivity designs enable operation with weaker control signals while maintaining reliable switching performance. These improvements are particularly valuable in applications where control signals may be limited in strength or where energy efficiency is a priority.- Input sensitivity enhancement techniques: Various techniques can be used to enhance the input sensitivity of solid-state relays. These include optimizing the input circuit design, using high-gain amplifiers, and implementing signal conditioning circuits. Enhanced input sensitivity allows the relay to operate with lower input current or voltage signals, making it more responsive to weak control signals while maintaining reliable switching performance.

- Optical coupling and isolation methods: Solid-state relays often employ optical coupling techniques to improve input sensitivity while maintaining electrical isolation between input and output circuits. These methods use LEDs and photodetectors to convert electrical input signals to light and back to electrical signals, providing high noise immunity and enhanced sensitivity. Advanced optical coupling designs can significantly reduce the minimum current required to trigger the relay.

- Temperature compensation for input sensitivity: Temperature variations can affect the input sensitivity of solid-state relays. Compensation circuits and materials are implemented to maintain consistent input sensitivity across a wide temperature range. These solutions may include thermistors, temperature-sensing feedback loops, or specially designed semiconductor structures that counteract temperature-induced changes in sensitivity parameters.

- Low-voltage triggering mechanisms: Advanced solid-state relays incorporate specialized low-voltage triggering mechanisms to improve input sensitivity. These mechanisms may include threshold detection circuits, voltage multipliers, or specialized semiconductor structures that can respond to very small input signals. Such designs enable operation with minimal control power while ensuring reliable switching of the load circuit.

- Input circuit protection and noise immunity: To maintain optimal input sensitivity while preventing false triggering, solid-state relays incorporate protection circuits and noise immunity features. These include input filters, Schmitt triggers, hysteresis circuits, and transient suppression components. Such features ensure that the relay responds only to valid control signals while rejecting electrical noise and transients that could otherwise cause unintended operation.

02 Optically coupled SSR input designs

Optically coupled solid-state relay designs use light-emitting components and photosensitive receivers to achieve electrical isolation between input and output circuits. These designs can be optimized for input sensitivity by selecting appropriate photodiodes, phototransistors, or other photosensitive components. The optical coupling approach provides excellent isolation while allowing for adjustments to input sensitivity through optical component selection and input circuit design. This technology is widely used in applications requiring high isolation and reliable operation.Expand Specific Solutions03 Input circuit protection and filtering

Input protection and filtering circuits are essential components that affect the sensitivity and reliability of solid-state relays. These circuits protect the input stage from voltage spikes and transients while ensuring proper triggering thresholds. Advanced filtering techniques can improve noise immunity while maintaining sensitivity to legitimate control signals. The design of these protection circuits must balance sensitivity requirements with the need for robust operation in electrically noisy environments.Expand Specific Solutions04 Temperature compensation for input sensitivity

Temperature compensation techniques are implemented in solid-state relays to maintain consistent input sensitivity across a wide operating temperature range. These methods include using temperature-stable components, feedback circuits, and specialized biasing arrangements that adjust sensitivity parameters based on temperature changes. By incorporating temperature compensation, solid-state relays can maintain reliable triggering thresholds despite environmental temperature variations, ensuring consistent operation in diverse applications and environments.Expand Specific Solutions05 Low-power input control circuits

Low-power input control circuits are designed to maximize the sensitivity of solid-state relays while minimizing power consumption. These designs incorporate energy-efficient components and circuit topologies that can operate with minimal input current or voltage. Advanced semiconductor materials and structures are utilized to achieve high sensitivity with low power requirements. These innovations are particularly important for battery-powered applications, energy harvesting systems, and other scenarios where power efficiency is critical.Expand Specific Solutions

Major Manufacturers and Industry Competition Landscape

The solid-state relay input sensitivity measurement landscape is evolving rapidly, with the market currently in a growth phase driven by increasing automation and smart grid applications. The global market size is expanding at approximately 6-8% annually, reaching nearly $1.5 billion. Technologically, the field shows varying maturity levels across applications, with companies demonstrating different specialization areas. State Grid Corp. of China and Huawei lead in grid applications, while Applied Materials and Samsung focus on semiconductor integration. BYD and BlackBerry are advancing automotive implementations, and Anritsu Corp. provides specialized measurement solutions. University collaborations, particularly with Harbin Institute of Technology and Beihang University, are accelerating innovation in sensitivity measurement standardization and miniaturization techniques.

State Grid Corp. of China

Technical Solution: State Grid Corporation of China has pioneered comprehensive solid-state relay input sensitivity measurement guidelines specifically designed for high-voltage power distribution networks. Their methodology incorporates multi-point distributed sensing technology that enables precise measurement of SSR input thresholds across geographically dispersed power systems. The company's approach features adaptive sensitivity calibration that automatically adjusts measurement parameters based on grid load conditions and environmental factors. State Grid's guidelines specify a three-tier verification process: initial laboratory characterization under controlled conditions, field validation in actual installation environments, and continuous monitoring during operation. Their measurement system employs high-precision digital signal processing with 24-bit ADC resolution to detect minute variations in input sensitivity thresholds. The guidelines include detailed procedures for measuring hysteresis effects in SSR triggering, which is critical for preventing oscillation in power switching applications. State Grid has also developed specialized test equipment that can simulate various grid disturbance scenarios to evaluate SSR performance under transient conditions, ensuring reliable operation during grid anomalies.

Strengths: Exceptional adaptability to varying grid conditions and environmental factors; comprehensive validation process ensures reliability in critical infrastructure. Weaknesses: Implementation requires significant technical infrastructure and expertise; measurement system complexity increases maintenance requirements and potential points of failure.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced solid-state relay input sensitivity measurement guidelines specifically optimized for semiconductor manufacturing environments. Their approach utilizes precision semiconductor parametric test methodologies adapted for SSR characterization, achieving measurement resolution in the sub-millivolt range. The company's guidelines incorporate automated statistical process control techniques that continuously monitor and analyze SSR input sensitivity variations across large production volumes. Applied Materials' measurement system features specialized test fixtures with four-wire Kelvin connections to eliminate contact resistance effects that could otherwise introduce measurement errors. Their methodology includes comprehensive electromagnetic compatibility (EMC) testing protocols to verify SSR performance under various interference conditions common in industrial environments. The guidelines specify detailed procedures for characterizing temperature-dependent sensitivity drift using precision thermal chambers with stability of ±0.1°C. Applied Materials has implemented advanced data analytics capabilities that can identify subtle trends in sensitivity measurements before they become operational issues, enabling predictive maintenance. Their approach also includes accelerated life testing protocols that correlate input sensitivity changes with long-term reliability metrics.

Strengths: Exceptional measurement precision suitable for critical semiconductor applications; comprehensive statistical analysis enables early detection of potential reliability issues. Weaknesses: Implementation requires clean-room level environmental controls for maximum accuracy; system complexity necessitates specialized operator training and maintenance.

Key Technical Innovations in SSR Sensitivity Enhancement

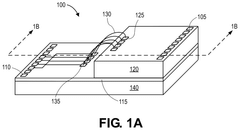

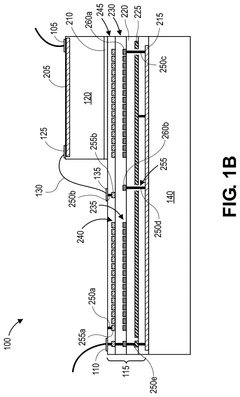

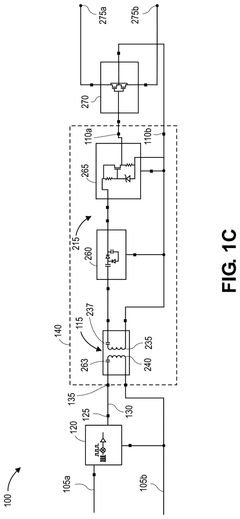

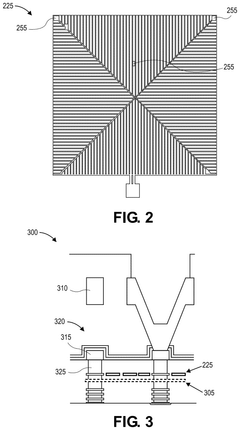

Method of forming and operating a solid-state relay device

PatentPendingUS20250253844A1

Innovation

- A signal isolation device comprising a transmit die and a receiver die with a coupler region, including transmit and receiver coils, shield layers, and circuitry to generate an isolated drive signal for a solid-state switch, capable of high voltage operation and compact integration.

Solid state relay protective device

PatentInactiveEP3031136A1

Innovation

- An electrical circuit with a switch element, sensing element, and feedback element that monitors operating parameters such as current or temperature, switching the solid-state relay to an energized or de-energized state to prevent overload and allow cooling, using a comparator and microprocessor-based control to manage the drive signal and prevent damage.

Standards and Compliance Requirements for SSR Testing

Compliance with established standards is paramount for ensuring the reliability, safety, and interoperability of Solid-State Relays (SSRs) in various applications. The testing of SSR input sensitivity must adhere to several international and regional standards that govern electronic component performance and safety.

IEC 60747-5 specifically addresses semiconductor devices and integrated circuits, with particular sections dedicated to optoelectronic components like those found in SSRs. This standard outlines the measurement methodologies for determining input sensitivity thresholds and provides guidelines for consistent testing procedures across different manufacturing environments.

UL 508, focused on industrial control equipment, establishes critical safety requirements for SSRs used in control systems. The standard mandates specific input sensitivity ranges based on the intended application environment, with more stringent requirements for SSRs deployed in safety-critical systems. Manufacturers must demonstrate compliance through rigorous testing protocols that evaluate performance under various electrical and environmental conditions.

IEEE 1836 provides comprehensive guidelines for the measurement of electrical parameters in solid-state switching devices, including detailed procedures for characterizing input sensitivity. The standard emphasizes the importance of accounting for temperature variations, which can significantly affect SSR triggering thresholds.

For SSRs intended for global markets, compliance with regional standards becomes essential. European markets require adherence to EN 60950 for information technology equipment and EN 61010 for measurement and control equipment. These standards specify additional testing requirements related to input circuit isolation and sensitivity stability over time.

Testing laboratories must maintain calibrated equipment traceable to national standards when performing input sensitivity measurements. This typically includes precision current sources capable of delivering controlled step inputs with rise times under 1μs, and high-resolution measurement systems for detecting switching thresholds with accuracy better than ±2%.

Documentation requirements for compliance testing are equally rigorous. Test reports must include detailed information about the testing environment, including ambient temperature, humidity, and electromagnetic conditions that might influence measurement results. Statistical analysis of multiple samples is typically required to establish confidence in the consistency of manufacturing processes.

Periodic re-certification is necessary for maintaining compliance status, particularly for SSRs used in medical, aerospace, or industrial safety applications. The frequency of re-certification varies by industry, ranging from annual testing for critical applications to three-year cycles for general industrial use.

IEC 60747-5 specifically addresses semiconductor devices and integrated circuits, with particular sections dedicated to optoelectronic components like those found in SSRs. This standard outlines the measurement methodologies for determining input sensitivity thresholds and provides guidelines for consistent testing procedures across different manufacturing environments.

UL 508, focused on industrial control equipment, establishes critical safety requirements for SSRs used in control systems. The standard mandates specific input sensitivity ranges based on the intended application environment, with more stringent requirements for SSRs deployed in safety-critical systems. Manufacturers must demonstrate compliance through rigorous testing protocols that evaluate performance under various electrical and environmental conditions.

IEEE 1836 provides comprehensive guidelines for the measurement of electrical parameters in solid-state switching devices, including detailed procedures for characterizing input sensitivity. The standard emphasizes the importance of accounting for temperature variations, which can significantly affect SSR triggering thresholds.

For SSRs intended for global markets, compliance with regional standards becomes essential. European markets require adherence to EN 60950 for information technology equipment and EN 61010 for measurement and control equipment. These standards specify additional testing requirements related to input circuit isolation and sensitivity stability over time.

Testing laboratories must maintain calibrated equipment traceable to national standards when performing input sensitivity measurements. This typically includes precision current sources capable of delivering controlled step inputs with rise times under 1μs, and high-resolution measurement systems for detecting switching thresholds with accuracy better than ±2%.

Documentation requirements for compliance testing are equally rigorous. Test reports must include detailed information about the testing environment, including ambient temperature, humidity, and electromagnetic conditions that might influence measurement results. Statistical analysis of multiple samples is typically required to establish confidence in the consistency of manufacturing processes.

Periodic re-certification is necessary for maintaining compliance status, particularly for SSRs used in medical, aerospace, or industrial safety applications. The frequency of re-certification varies by industry, ranging from annual testing for critical applications to three-year cycles for general industrial use.

Reliability and Longevity Considerations for SSR Applications

The reliability and longevity of Solid-State Relays (SSRs) represent critical factors in their industrial application, particularly when considering input sensitivity measurements. SSRs typically offer superior longevity compared to mechanical relays due to their lack of moving parts, with typical lifespans ranging from 10 to 20 years under optimal operating conditions. However, several factors can significantly impact this expected service life.

Temperature management stands as perhaps the most crucial consideration affecting SSR reliability. Operating temperatures exceeding manufacturer specifications can dramatically reduce component lifespan, with each 10°C increase above rated temperature potentially halving the expected service life. This thermal sensitivity directly impacts input circuit performance, as elevated temperatures can alter the threshold sensitivity of optocouplers and other input stage components.

Voltage transients and surges represent another significant threat to SSR longevity. Input circuits lacking adequate protection may experience degradation of optocoupler performance over time, resulting in shifting input sensitivity thresholds. Implementation of appropriate surge protection devices and filtering capacitors can substantially extend operational life while maintaining consistent input response characteristics.

Humidity and environmental contaminants pose additional reliability challenges, particularly in industrial settings. Moisture ingress can lead to corrosion of internal components and degradation of insulation materials, potentially altering input impedance characteristics. Conformal coating application and appropriate enclosure selection can mitigate these environmental effects, preserving input sensitivity parameters throughout the device's operational life.

Cycling frequency also impacts SSR longevity, though to a lesser extent than with mechanical relays. High-frequency switching operations can generate thermal stress through repeated heating and cooling cycles, potentially affecting input stage components over time. Derating switching frequency by 20-30% below maximum specifications can significantly extend service life while maintaining consistent input sensitivity.

Preventive maintenance protocols should include periodic verification of input sensitivity parameters against baseline measurements. Drift exceeding 10% from initial values may indicate impending failure or degradation. Implementation of condition monitoring systems capable of tracking input threshold changes over time enables predictive maintenance approaches, reducing unexpected failures and extending effective service life.

When designing systems incorporating SSRs, redundancy architectures and fault tolerance mechanisms should be considered for critical applications. Parallel redundant configurations with monitoring capabilities can detect sensitivity shifts in individual units, allowing for scheduled replacement before catastrophic failure occurs, thereby enhancing overall system reliability while maintaining consistent input response characteristics.

Temperature management stands as perhaps the most crucial consideration affecting SSR reliability. Operating temperatures exceeding manufacturer specifications can dramatically reduce component lifespan, with each 10°C increase above rated temperature potentially halving the expected service life. This thermal sensitivity directly impacts input circuit performance, as elevated temperatures can alter the threshold sensitivity of optocouplers and other input stage components.

Voltage transients and surges represent another significant threat to SSR longevity. Input circuits lacking adequate protection may experience degradation of optocoupler performance over time, resulting in shifting input sensitivity thresholds. Implementation of appropriate surge protection devices and filtering capacitors can substantially extend operational life while maintaining consistent input response characteristics.

Humidity and environmental contaminants pose additional reliability challenges, particularly in industrial settings. Moisture ingress can lead to corrosion of internal components and degradation of insulation materials, potentially altering input impedance characteristics. Conformal coating application and appropriate enclosure selection can mitigate these environmental effects, preserving input sensitivity parameters throughout the device's operational life.

Cycling frequency also impacts SSR longevity, though to a lesser extent than with mechanical relays. High-frequency switching operations can generate thermal stress through repeated heating and cooling cycles, potentially affecting input stage components over time. Derating switching frequency by 20-30% below maximum specifications can significantly extend service life while maintaining consistent input sensitivity.

Preventive maintenance protocols should include periodic verification of input sensitivity parameters against baseline measurements. Drift exceeding 10% from initial values may indicate impending failure or degradation. Implementation of condition monitoring systems capable of tracking input threshold changes over time enables predictive maintenance approaches, reducing unexpected failures and extending effective service life.

When designing systems incorporating SSRs, redundancy architectures and fault tolerance mechanisms should be considered for critical applications. Parallel redundant configurations with monitoring capabilities can detect sensitivity shifts in individual units, allowing for scheduled replacement before catastrophic failure occurs, thereby enhancing overall system reliability while maintaining consistent input response characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!