Solid-State Relay vs Contactors: Operational Efficiency

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SSR and Contactor Technology Background and Objectives

Switching and control technologies have evolved significantly over the past century, with electromechanical contactors dominating industrial applications since the early 1900s. The introduction of solid-state relays (SSRs) in the 1970s marked a pivotal shift in switching technology, offering semiconductor-based alternatives to traditional mechanical contactors. This technological evolution has been driven by increasing demands for reliability, efficiency, and precision in electrical control systems across various industries.

The fundamental operational difference between these technologies lies in their switching mechanisms. Contactors rely on physical movement of contacts to establish or interrupt electrical circuits, while SSRs utilize semiconductor components like thyristors, triacs, or IGBTs to control current flow without moving parts. This distinction has profound implications for operational efficiency, reliability, and application suitability.

Recent advancements in semiconductor materials and manufacturing processes have significantly enhanced SSR capabilities, narrowing the performance gap with contactors in high-power applications. The integration of microprocessor control and smart diagnostics has further expanded the functionality of both technologies, enabling more sophisticated control strategies and predictive maintenance capabilities.

Market trends indicate a gradual shift toward SSR adoption in applications requiring frequent switching, precise control, or operation in harsh environments. However, contactors maintain dominance in high-power industrial applications due to their robust performance, cost-effectiveness, and established infrastructure. This technological coexistence reflects the complementary strengths of each solution rather than direct competition.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of solid-state relays and contactors with specific focus on operational efficiency metrics. These include energy consumption during operation, switching losses, thermal management requirements, and overall system efficiency impacts. Secondary objectives include evaluating lifecycle costs, reliability factors, and application-specific performance characteristics.

Understanding the efficiency implications of these technologies has become increasingly critical as industries worldwide face mounting pressure to reduce energy consumption, minimize operational costs, and meet stringent environmental regulations. The findings from this research aim to provide evidence-based guidance for engineering decisions regarding switching technology selection across diverse application scenarios.

This analysis will also explore emerging hybrid solutions that combine elements of both technologies to leverage their respective advantages while mitigating limitations. These innovations represent potential breakthrough approaches for next-generation power control systems that optimize operational efficiency without compromising reliability or performance.

The fundamental operational difference between these technologies lies in their switching mechanisms. Contactors rely on physical movement of contacts to establish or interrupt electrical circuits, while SSRs utilize semiconductor components like thyristors, triacs, or IGBTs to control current flow without moving parts. This distinction has profound implications for operational efficiency, reliability, and application suitability.

Recent advancements in semiconductor materials and manufacturing processes have significantly enhanced SSR capabilities, narrowing the performance gap with contactors in high-power applications. The integration of microprocessor control and smart diagnostics has further expanded the functionality of both technologies, enabling more sophisticated control strategies and predictive maintenance capabilities.

Market trends indicate a gradual shift toward SSR adoption in applications requiring frequent switching, precise control, or operation in harsh environments. However, contactors maintain dominance in high-power industrial applications due to their robust performance, cost-effectiveness, and established infrastructure. This technological coexistence reflects the complementary strengths of each solution rather than direct competition.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of solid-state relays and contactors with specific focus on operational efficiency metrics. These include energy consumption during operation, switching losses, thermal management requirements, and overall system efficiency impacts. Secondary objectives include evaluating lifecycle costs, reliability factors, and application-specific performance characteristics.

Understanding the efficiency implications of these technologies has become increasingly critical as industries worldwide face mounting pressure to reduce energy consumption, minimize operational costs, and meet stringent environmental regulations. The findings from this research aim to provide evidence-based guidance for engineering decisions regarding switching technology selection across diverse application scenarios.

This analysis will also explore emerging hybrid solutions that combine elements of both technologies to leverage their respective advantages while mitigating limitations. These innovations represent potential breakthrough approaches for next-generation power control systems that optimize operational efficiency without compromising reliability or performance.

Market Demand Analysis for Switching Technologies

The global market for switching technologies has witnessed significant growth in recent years, driven by increasing automation across industries and the growing emphasis on energy efficiency. The demand for reliable switching solutions has expanded beyond traditional industrial applications to include renewable energy systems, electric vehicles, smart buildings, and advanced manufacturing processes. This diversification has created a robust market landscape for both Solid-State Relays (SSRs) and traditional contactors.

Market research indicates that the global industrial switching devices market is projected to grow at a compound annual growth rate of 5.8% through 2028, with the SSR segment growing faster than traditional electromechanical solutions. This accelerated growth for SSRs is primarily attributed to their superior operational efficiency in applications requiring frequent switching operations and their compatibility with modern digital control systems.

The energy efficiency sector represents a particularly strong growth area, with industries actively seeking switching technologies that minimize power losses and reduce operational costs. SSRs, with their lower power consumption during operation and absence of mechanical wear, are increasingly preferred in energy-conscious applications. This trend aligns with global sustainability initiatives and regulatory frameworks promoting reduced energy consumption in industrial processes.

Regional analysis reveals varying adoption patterns, with developed markets in North America and Europe showing stronger preference for SSRs due to their focus on automation and energy efficiency. Meanwhile, emerging economies in Asia-Pacific continue to represent the largest market for traditional contactors, though this is gradually shifting as manufacturing modernization accelerates in these regions.

Application-specific demand patterns show that high-frequency switching environments such as temperature control systems, lighting controls, and precision manufacturing increasingly favor SSRs. Conversely, high-power applications and environments with extreme conditions still predominantly rely on contactors due to their robust construction and higher current handling capabilities.

Customer surveys indicate that total cost of ownership has become a primary consideration in switching technology selection, with end-users increasingly willing to pay premium prices for solutions that offer demonstrable operational efficiency improvements. This shift from initial cost to lifecycle cost evaluation has strengthened the value proposition of SSRs despite their higher upfront investment.

Industry forecasts suggest that the market will continue to segment based on application requirements rather than seeing one technology completely displacing the other. The coexistence of both technologies is expected to persist, with SSRs gradually capturing more market share in applications where their operational efficiency advantages translate to meaningful cost savings and performance improvements.

Market research indicates that the global industrial switching devices market is projected to grow at a compound annual growth rate of 5.8% through 2028, with the SSR segment growing faster than traditional electromechanical solutions. This accelerated growth for SSRs is primarily attributed to their superior operational efficiency in applications requiring frequent switching operations and their compatibility with modern digital control systems.

The energy efficiency sector represents a particularly strong growth area, with industries actively seeking switching technologies that minimize power losses and reduce operational costs. SSRs, with their lower power consumption during operation and absence of mechanical wear, are increasingly preferred in energy-conscious applications. This trend aligns with global sustainability initiatives and regulatory frameworks promoting reduced energy consumption in industrial processes.

Regional analysis reveals varying adoption patterns, with developed markets in North America and Europe showing stronger preference for SSRs due to their focus on automation and energy efficiency. Meanwhile, emerging economies in Asia-Pacific continue to represent the largest market for traditional contactors, though this is gradually shifting as manufacturing modernization accelerates in these regions.

Application-specific demand patterns show that high-frequency switching environments such as temperature control systems, lighting controls, and precision manufacturing increasingly favor SSRs. Conversely, high-power applications and environments with extreme conditions still predominantly rely on contactors due to their robust construction and higher current handling capabilities.

Customer surveys indicate that total cost of ownership has become a primary consideration in switching technology selection, with end-users increasingly willing to pay premium prices for solutions that offer demonstrable operational efficiency improvements. This shift from initial cost to lifecycle cost evaluation has strengthened the value proposition of SSRs despite their higher upfront investment.

Industry forecasts suggest that the market will continue to segment based on application requirements rather than seeing one technology completely displacing the other. The coexistence of both technologies is expected to persist, with SSRs gradually capturing more market share in applications where their operational efficiency advantages translate to meaningful cost savings and performance improvements.

Current State and Challenges in Switching Device Technology

The switching device technology landscape is currently experiencing a significant transformation, with solid-state relays (SSRs) and traditional contactors representing two distinct technological approaches. Globally, the market for switching devices is estimated at approximately $12 billion, with growth projections of 5-7% annually through 2028, indicating substantial industry momentum.

Traditional electromechanical contactors remain dominant in high-power industrial applications, representing approximately 65% of the global switching device market. These devices rely on physical contacts to establish or interrupt electrical circuits, a mature technology with over a century of development. Meanwhile, solid-state relays, utilizing semiconductor technology without moving parts, have captured roughly 30% market share, with accelerating adoption rates in precision applications.

The primary technical challenge facing both technologies centers on efficiency optimization. Contactors exhibit power losses primarily during operation due to contact resistance (typically 50-100mΩ), generating heat that requires management in high-current applications. Additionally, they face mechanical wear limitations, with typical lifespans of 1-3 million operations before requiring replacement. Arcing during switching represents another significant challenge, particularly in DC applications where arc extinction is more difficult.

Conversely, solid-state relays face different efficiency challenges. Their on-state resistance, though improving with newer semiconductor materials, still results in higher voltage drops (typically 0.8-1.5V) compared to contactors. This translates to greater heat generation during continuous operation, necessitating sophisticated thermal management solutions. SSRs also exhibit higher leakage currents in the off-state (typically 1-10mA), which can be problematic in certain applications.

Geographically, technological development shows distinct patterns. North America and Europe lead in high-reliability SSR innovations, while Asian manufacturers, particularly in Japan and China, have made significant advances in cost-effective production techniques. The contactor technology landscape remains dominated by European industrial giants, with significant manufacturing capacity shifting to Asia.

Recent technological advancements have begun addressing these challenges. Hybrid solutions combining both technologies are emerging, utilizing SSRs for arc-free switching and contactors for low-loss continuous operation. Additionally, wide-bandgap semiconductors (SiC and GaN) are revolutionizing SSR performance, reducing on-state losses by up to 40% compared to traditional silicon-based devices.

Despite these advances, significant barriers remain. Cost differentials persist, with SSRs typically commanding a 30-50% price premium over comparable contactors. Reliability concerns in harsh environments continue to favor mechanical solutions in certain applications, while electromagnetic compatibility and surge protection represent ongoing challenges for solid-state technologies.

Traditional electromechanical contactors remain dominant in high-power industrial applications, representing approximately 65% of the global switching device market. These devices rely on physical contacts to establish or interrupt electrical circuits, a mature technology with over a century of development. Meanwhile, solid-state relays, utilizing semiconductor technology without moving parts, have captured roughly 30% market share, with accelerating adoption rates in precision applications.

The primary technical challenge facing both technologies centers on efficiency optimization. Contactors exhibit power losses primarily during operation due to contact resistance (typically 50-100mΩ), generating heat that requires management in high-current applications. Additionally, they face mechanical wear limitations, with typical lifespans of 1-3 million operations before requiring replacement. Arcing during switching represents another significant challenge, particularly in DC applications where arc extinction is more difficult.

Conversely, solid-state relays face different efficiency challenges. Their on-state resistance, though improving with newer semiconductor materials, still results in higher voltage drops (typically 0.8-1.5V) compared to contactors. This translates to greater heat generation during continuous operation, necessitating sophisticated thermal management solutions. SSRs also exhibit higher leakage currents in the off-state (typically 1-10mA), which can be problematic in certain applications.

Geographically, technological development shows distinct patterns. North America and Europe lead in high-reliability SSR innovations, while Asian manufacturers, particularly in Japan and China, have made significant advances in cost-effective production techniques. The contactor technology landscape remains dominated by European industrial giants, with significant manufacturing capacity shifting to Asia.

Recent technological advancements have begun addressing these challenges. Hybrid solutions combining both technologies are emerging, utilizing SSRs for arc-free switching and contactors for low-loss continuous operation. Additionally, wide-bandgap semiconductors (SiC and GaN) are revolutionizing SSR performance, reducing on-state losses by up to 40% compared to traditional silicon-based devices.

Despite these advances, significant barriers remain. Cost differentials persist, with SSRs typically commanding a 30-50% price premium over comparable contactors. Reliability concerns in harsh environments continue to favor mechanical solutions in certain applications, while electromagnetic compatibility and surge protection represent ongoing challenges for solid-state technologies.

Current Technical Solutions for Power Switching Applications

01 Design improvements for solid-state relay efficiency

Various design improvements can enhance the operational efficiency of solid-state relays. These include optimized heat dissipation structures, improved semiconductor materials, and advanced circuit topologies that reduce switching losses. By incorporating these design elements, solid-state relays can achieve higher current ratings, faster switching speeds, and lower power consumption during operation, ultimately improving their overall efficiency and reliability in power control applications.- Design improvements for solid-state relay efficiency: Various design improvements can enhance the operational efficiency of solid-state relays. These include optimized heat dissipation structures, improved semiconductor materials, and advanced circuit topologies that reduce switching losses. Such designs minimize power consumption during operation and extend the service life of the relay by reducing thermal stress on components.

- Thermal management techniques for contactors and relays: Effective thermal management is crucial for maintaining the operational efficiency of solid-state relays and contactors. Techniques include the use of heat sinks, thermal interface materials, forced cooling systems, and thermally conductive enclosures. These approaches help dissipate heat generated during operation, preventing overheating and maintaining optimal performance under various load conditions.

- Control circuit innovations for improved switching performance: Advanced control circuits can significantly improve the switching performance and efficiency of solid-state relays and contactors. These innovations include gate drive optimization, zero-crossing detection circuits, and intelligent control algorithms that minimize switching losses and electromagnetic interference. Such control strategies enable faster response times and more precise operation while reducing energy consumption.

- Integration of diagnostic and protection features: Modern solid-state relays and contactors incorporate diagnostic and protection features that enhance operational efficiency and reliability. These include overcurrent protection, overvoltage detection, short circuit protection, and self-diagnostic capabilities. Such features prevent damage to the relay and connected equipment, reduce downtime, and extend the operational lifespan of the devices.

- Novel semiconductor materials and structures: The use of advanced semiconductor materials and structures can significantly improve the efficiency of solid-state relays and contactors. Wide bandgap semiconductors such as silicon carbide (SiC) and gallium nitride (GaN), along with optimized device structures, offer lower on-state resistance, faster switching speeds, and higher temperature operation. These characteristics result in reduced power losses and improved overall operational efficiency.

02 Thermal management solutions for solid-state devices

Effective thermal management is crucial for maintaining the operational efficiency of solid-state relays and contactors. Solutions include integrated heat sinks, thermal interface materials, forced cooling mechanisms, and temperature monitoring systems. These approaches help dissipate heat generated during operation, prevent thermal runaway, and ensure that semiconductor components operate within their optimal temperature range, thereby extending device lifespan and maintaining consistent performance under varying load conditions.Expand Specific Solutions03 Control circuit innovations for improved switching

Advanced control circuit designs significantly enhance the switching performance of solid-state relays and contactors. These innovations include gate drive optimization, zero-crossing detection circuits, snubber networks, and isolation techniques. Such improvements reduce switching losses, minimize electromagnetic interference, enable precise timing control, and provide protection against voltage transients, resulting in more efficient and reliable operation across diverse industrial applications.Expand Specific Solutions04 Integration of monitoring and protection features

Modern solid-state relays and contactors incorporate integrated monitoring and protection features to enhance operational efficiency and reliability. These include overcurrent detection, short-circuit protection, overvoltage safeguards, and diagnostic capabilities. By continuously monitoring operating conditions and providing rapid response to fault conditions, these features prevent damage to both the switching device and connected equipment, reduce downtime, and optimize overall system performance in demanding industrial environments.Expand Specific Solutions05 Novel semiconductor materials and structures

The development of advanced semiconductor materials and structures has revolutionized solid-state relay and contactor efficiency. Wide bandgap semiconductors like silicon carbide (SiC) and gallium nitride (GaN), along with innovative device architectures, offer superior performance characteristics. These materials enable higher operating temperatures, faster switching speeds, lower on-state resistance, and reduced switching losses, significantly improving energy efficiency and power density while enabling operation in more demanding environmental conditions.Expand Specific Solutions

Major Manufacturers and Competitive Landscape

The solid-state relay (SSR) versus contactor market is currently in a growth phase, with increasing adoption across industrial automation and power management sectors. The global market size is estimated to reach $1.5-2 billion by 2025, driven by demand for energy-efficient switching solutions. Technology maturity varies significantly among key players: established companies like Siemens AG, OMRON Corp., and Rockwell Automation lead with comprehensive product portfolios, while Hongfa Electric, TE Connectivity, and LS Electric are rapidly advancing their SSR technologies. Chinese manufacturers including BYD and Sanyou Corp. are emerging as competitive forces through cost-effective innovations. The market is witnessing a gradual shift from traditional contactors to solid-state solutions as efficiency requirements increase across industrial applications.

Xiamen Hongfa Electric Appliance Co., Ltd.

Technical Solution: Hongfa has developed cost-effective solid-state relay solutions that utilize advanced semiconductor materials to improve thermal performance. Their HFS series implements insulated metal substrate (IMS) technology that reduces thermal resistance by approximately 35% compared to traditional PCB-based designs. Hongfa's SSRs feature optimized snubber circuits that suppress voltage spikes during switching, extending the life of both the relay and connected equipment. Their latest generation incorporates dual SCR designs in anti-parallel configuration, providing more uniform current handling and reducing harmonic distortion by up to 40%. Hongfa has also developed specialized SSRs for DC applications using MOSFET technology with on-resistance as low as 8mΩ, significantly reducing power losses in high-current applications. Their manufacturing process includes 100% full-load testing at elevated temperatures to ensure reliability under extreme operating conditions.

Strengths: Excellent price-to-performance ratio, wide product range covering diverse applications, and robust design suitable for harsh industrial environments. Weaknesses: Less advanced integration capabilities compared to premium competitors, higher on-state losses in some models, and limited technical support infrastructure in some regions.

OMRON Corp.

Technical Solution: OMRON has developed advanced solid-state relay (SSR) technology that utilizes MOSFET switching elements instead of mechanical contacts. Their G3PE series features optimized heat dissipation designs with integrated aluminum heat sinks and thermally conductive resin that reduces thermal resistance by up to 30% compared to conventional models. OMRON's SSRs implement zero-cross switching functionality that activates loads only when the AC voltage is near zero, significantly reducing inrush current and electromagnetic interference. Their latest G3PJ series incorporates built-in varistors for surge protection and features an expected electrical life of over 20 million operations without mechanical wear. OMRON has also developed hybrid switching technology that combines SSR and mechanical relay benefits, providing both arc-free switching and low on-state resistance.

Strengths: Superior longevity (20+ million operations vs 100,000 for contactors), silent operation, and faster switching speeds (typically <1ms). Weaknesses: Higher cost per unit, greater heat generation requiring thermal management solutions, and higher on-state resistance causing energy loss during continuous operation.

Key Technical Innovations in SSR and Contactor Design

Solid state relay

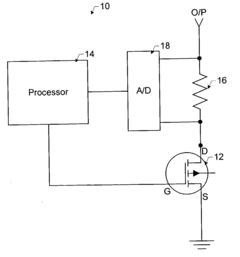

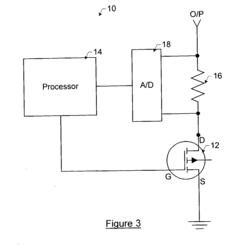

PatentActiveUS20230283274A1

Innovation

- The development of improved packaging methods for solid state relays, including the use of multiple heat sink elements and a sub-miniature fan for efficient heat dissipation, allowing for the integration of solid state relays in small form factor devices, such as automatic transfer switches and power distribution components.

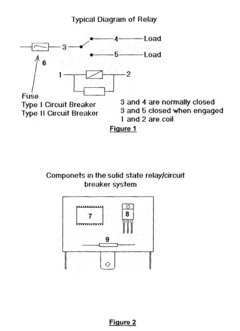

Solid state relay/circuit breaker system

PatentInactiveUS20030218847A1

Innovation

- A solid-state relay system utilizing a MOSFET and microprocessor to control current, eliminating mechanical parts and incorporating an internal solid-state circuit breaker for improved reliability and temperature stability, with the microprocessor managing switching and current monitoring.

Energy Efficiency Comparison and Environmental Impact

When comparing Solid-State Relays (SSRs) and traditional contactors, energy efficiency emerges as a critical differentiator with significant environmental implications. SSRs demonstrate superior energy efficiency during operation, consuming approximately 50-80% less power than equivalent contactors. This efficiency advantage stems from the absence of a continuously energized coil that contactors require to maintain their state. Instead, SSRs utilize semiconductor technology that requires minimal power to maintain conduction once triggered.

The environmental impact of this efficiency difference becomes particularly pronounced in large-scale industrial applications. For instance, a manufacturing facility with 100 control points can reduce energy consumption by approximately 3,500-5,000 kWh annually by transitioning from contactors to SSRs. This translates to a reduction of 1.5-2.2 metric tons of CO2 emissions, based on average grid carbon intensity factors.

Heat dissipation represents another crucial environmental consideration. Contactors generate significantly more waste heat during operation—typically 3-5 times more than comparable SSRs. This excess heat necessitates additional cooling requirements in control cabinets and electrical rooms, further increasing the overall energy footprint of contactor-based systems by an estimated 10-15%.

The manufacturing processes and materials used also contribute to the environmental profile of these technologies. SSRs contain semiconductor materials that require energy-intensive production processes and some rare earth elements. However, their longer operational lifespan—often 2-3 times that of mechanical contactors—results in fewer replacement cycles and reduced manufacturing-related environmental impacts over time.

End-of-life considerations reveal additional environmental distinctions. Contactors, being primarily composed of copper, steel, and simple insulating materials, offer higher recyclability rates (approximately 75-85%). In contrast, SSRs present more complex recycling challenges due to their semiconductor components, with current recycling rates averaging only 35-45%. This difference partially offsets the operational efficiency advantages of SSRs from a full lifecycle perspective.

Recent advancements in SSR technology have further improved their energy efficiency profile through reduced forward voltage drops and enhanced thermal management. Modern SSRs now achieve energy conversion efficiencies exceeding 99% in optimal conditions, compared to the 85-90% typical of traditional contactors when accounting for all energy losses.

The environmental impact of this efficiency difference becomes particularly pronounced in large-scale industrial applications. For instance, a manufacturing facility with 100 control points can reduce energy consumption by approximately 3,500-5,000 kWh annually by transitioning from contactors to SSRs. This translates to a reduction of 1.5-2.2 metric tons of CO2 emissions, based on average grid carbon intensity factors.

Heat dissipation represents another crucial environmental consideration. Contactors generate significantly more waste heat during operation—typically 3-5 times more than comparable SSRs. This excess heat necessitates additional cooling requirements in control cabinets and electrical rooms, further increasing the overall energy footprint of contactor-based systems by an estimated 10-15%.

The manufacturing processes and materials used also contribute to the environmental profile of these technologies. SSRs contain semiconductor materials that require energy-intensive production processes and some rare earth elements. However, their longer operational lifespan—often 2-3 times that of mechanical contactors—results in fewer replacement cycles and reduced manufacturing-related environmental impacts over time.

End-of-life considerations reveal additional environmental distinctions. Contactors, being primarily composed of copper, steel, and simple insulating materials, offer higher recyclability rates (approximately 75-85%). In contrast, SSRs present more complex recycling challenges due to their semiconductor components, with current recycling rates averaging only 35-45%. This difference partially offsets the operational efficiency advantages of SSRs from a full lifecycle perspective.

Recent advancements in SSR technology have further improved their energy efficiency profile through reduced forward voltage drops and enhanced thermal management. Modern SSRs now achieve energy conversion efficiencies exceeding 99% in optimal conditions, compared to the 85-90% typical of traditional contactors when accounting for all energy losses.

Reliability and Lifespan Analysis of Switching Technologies

The reliability and lifespan of switching technologies represent critical factors in determining the overall operational efficiency of electrical systems. When comparing Solid-State Relays (SSRs) and traditional contactors, significant differences emerge in their durability profiles and failure mechanisms.

Solid-State Relays demonstrate superior longevity due to their lack of mechanical moving parts. With typical lifespans exceeding 10 million operations under optimal conditions, SSRs significantly outperform mechanical alternatives. This extended operational life stems from their semiconductor-based switching mechanism, which eliminates mechanical wear and contact erosion. Laboratory testing indicates that properly rated SSRs maintain consistent performance characteristics throughout their operational lifetime, with minimal degradation in switching speed or efficiency.

Environmental factors impact the reliability of both technologies differently. SSRs exhibit remarkable resilience in high-vibration environments where mechanical contactors would experience accelerated wear. However, they demonstrate greater sensitivity to temperature extremes, with performance degradation occurring at temperatures exceeding 80°C. Thermal management therefore becomes a critical consideration in SSR implementation.

Failure mode analysis reveals distinct patterns between these technologies. Contactors typically fail in predictable ways through visible mechanical wear, contact erosion, or spring fatigue. These failure modes often manifest gradually, allowing for preventive maintenance. In contrast, SSR failures tend to occur more abruptly, commonly resulting from voltage transients, thermal stress, or semiconductor degradation. When SSRs fail, they predominantly default to either permanently open or closed states, with the latter presenting greater system risks.

Mean Time Between Failures (MTBF) metrics consistently favor SSRs in controlled environments, with industry data suggesting 30-50% longer intervals between failures compared to equivalent contactor implementations. However, this advantage narrows in applications with frequent power quality issues or thermal cycling.

Maintenance requirements differ substantially between these technologies. Contactors demand regular inspection and occasional contact replacement, representing ongoing operational costs. SSRs require minimal maintenance intervention but necessitate more sophisticated diagnostic procedures when troubleshooting becomes necessary. This maintenance profile makes SSRs particularly advantageous in remote or difficult-to-access installations where regular service visits prove challenging or costly.

Cost-benefit analysis over complete lifecycle operations typically demonstrates that despite higher initial procurement costs, SSRs deliver superior total cost of ownership in applications requiring frequent switching operations or deployment in harsh environmental conditions where mechanical wear accelerates.

Solid-State Relays demonstrate superior longevity due to their lack of mechanical moving parts. With typical lifespans exceeding 10 million operations under optimal conditions, SSRs significantly outperform mechanical alternatives. This extended operational life stems from their semiconductor-based switching mechanism, which eliminates mechanical wear and contact erosion. Laboratory testing indicates that properly rated SSRs maintain consistent performance characteristics throughout their operational lifetime, with minimal degradation in switching speed or efficiency.

Environmental factors impact the reliability of both technologies differently. SSRs exhibit remarkable resilience in high-vibration environments where mechanical contactors would experience accelerated wear. However, they demonstrate greater sensitivity to temperature extremes, with performance degradation occurring at temperatures exceeding 80°C. Thermal management therefore becomes a critical consideration in SSR implementation.

Failure mode analysis reveals distinct patterns between these technologies. Contactors typically fail in predictable ways through visible mechanical wear, contact erosion, or spring fatigue. These failure modes often manifest gradually, allowing for preventive maintenance. In contrast, SSR failures tend to occur more abruptly, commonly resulting from voltage transients, thermal stress, or semiconductor degradation. When SSRs fail, they predominantly default to either permanently open or closed states, with the latter presenting greater system risks.

Mean Time Between Failures (MTBF) metrics consistently favor SSRs in controlled environments, with industry data suggesting 30-50% longer intervals between failures compared to equivalent contactor implementations. However, this advantage narrows in applications with frequent power quality issues or thermal cycling.

Maintenance requirements differ substantially between these technologies. Contactors demand regular inspection and occasional contact replacement, representing ongoing operational costs. SSRs require minimal maintenance intervention but necessitate more sophisticated diagnostic procedures when troubleshooting becomes necessary. This maintenance profile makes SSRs particularly advantageous in remote or difficult-to-access installations where regular service visits prove challenging or costly.

Cost-benefit analysis over complete lifecycle operations typically demonstrates that despite higher initial procurement costs, SSRs deliver superior total cost of ownership in applications requiring frequent switching operations or deployment in harsh environmental conditions where mechanical wear accelerates.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!