Solid-State Relay vs PLC Relays: Comparative Study

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Relay Technology Evolution and Objectives

Relay technology has undergone significant evolution since its inception in the early 19th century. The first electromagnetic relay was invented by Joseph Henry in 1835, which laid the foundation for electrical switching mechanisms. Traditional electromechanical relays dominated industrial applications for over a century, characterized by physical contacts that open and close circuits through electromagnetic force. These mechanical components, while reliable for their time, presented inherent limitations in switching speed, size, and operational lifespan due to contact wear.

The 1970s marked a pivotal shift with the introduction of solid-state relays (SSRs), which eliminated moving parts by utilizing semiconductor devices like thyristors and transistors for switching operations. This innovation addressed many limitations of mechanical relays, offering faster switching speeds, enhanced durability, and silent operation. The evolution continued with the integration of relays into programmable logic controllers (PLCs) during the industrial automation revolution, creating specialized PLC relays designed for industrial control systems.

Recent decades have witnessed further advancements in both technologies. Modern SSRs have incorporated improved semiconductor materials, enhanced thermal management, and sophisticated control circuits, significantly reducing their historical limitations such as heat generation and leakage current. Concurrently, PLC relay systems have evolved to include advanced diagnostic capabilities, network connectivity, and integration with industrial IoT platforms.

The technological trajectory indicates a convergence of these technologies, with hybrid solutions emerging that combine the strengths of both solid-state and electromechanical approaches. These developments align with broader industrial trends toward miniaturization, energy efficiency, and intelligent control systems.

The primary objective of this comparative study is to provide a comprehensive analysis of solid-state relays versus PLC relays in contemporary industrial applications. Specifically, the study aims to evaluate performance metrics including switching speed, reliability, lifespan, power handling capabilities, and immunity to electrical noise. Additionally, it seeks to identify optimal application scenarios for each technology based on environmental conditions, control requirements, and economic considerations.

Further objectives include assessing the integration capabilities of both relay types with emerging industrial automation frameworks, evaluating their respective contributions to energy efficiency initiatives, and projecting their technological evolution paths in the context of Industry 4.0 and smart manufacturing paradigms. This analysis will serve as a foundation for strategic decision-making regarding relay technology selection and implementation in future industrial systems.

The 1970s marked a pivotal shift with the introduction of solid-state relays (SSRs), which eliminated moving parts by utilizing semiconductor devices like thyristors and transistors for switching operations. This innovation addressed many limitations of mechanical relays, offering faster switching speeds, enhanced durability, and silent operation. The evolution continued with the integration of relays into programmable logic controllers (PLCs) during the industrial automation revolution, creating specialized PLC relays designed for industrial control systems.

Recent decades have witnessed further advancements in both technologies. Modern SSRs have incorporated improved semiconductor materials, enhanced thermal management, and sophisticated control circuits, significantly reducing their historical limitations such as heat generation and leakage current. Concurrently, PLC relay systems have evolved to include advanced diagnostic capabilities, network connectivity, and integration with industrial IoT platforms.

The technological trajectory indicates a convergence of these technologies, with hybrid solutions emerging that combine the strengths of both solid-state and electromechanical approaches. These developments align with broader industrial trends toward miniaturization, energy efficiency, and intelligent control systems.

The primary objective of this comparative study is to provide a comprehensive analysis of solid-state relays versus PLC relays in contemporary industrial applications. Specifically, the study aims to evaluate performance metrics including switching speed, reliability, lifespan, power handling capabilities, and immunity to electrical noise. Additionally, it seeks to identify optimal application scenarios for each technology based on environmental conditions, control requirements, and economic considerations.

Further objectives include assessing the integration capabilities of both relay types with emerging industrial automation frameworks, evaluating their respective contributions to energy efficiency initiatives, and projecting their technological evolution paths in the context of Industry 4.0 and smart manufacturing paradigms. This analysis will serve as a foundation for strategic decision-making regarding relay technology selection and implementation in future industrial systems.

Industrial Automation Market Demand Analysis

The industrial automation market has witnessed significant growth over the past decade, driven by increasing demand for enhanced operational efficiency, reduced human intervention, and improved production quality. The global industrial automation market was valued at approximately 175 billion USD in 2020 and is projected to reach 265 billion USD by 2025, growing at a CAGR of 8.7%. Within this expanding market, relay technologies play a crucial role as fundamental components in control systems.

The demand for solid-state relays (SSRs) has been steadily increasing due to their superior performance characteristics in modern industrial applications. Industries such as automotive manufacturing, food processing, pharmaceuticals, and semiconductor production have shown particular interest in SSR technology due to requirements for high-speed switching, precision control, and reliability in harsh environments. Market research indicates that the global SSR segment is growing at 9.5% annually, outpacing traditional electromechanical relays.

Programmable Logic Controller (PLC) relays continue to maintain strong market presence, particularly in established industrial sectors where robust, proven technologies are preferred. These sectors include heavy manufacturing, power generation, and water treatment facilities. The PLC relay market segment maintains steady growth at approximately 6.8% annually, with significant regional variations based on industrialization levels and modernization initiatives.

Regional analysis reveals distinct patterns in relay technology adoption. North American and European markets demonstrate stronger preference for advanced solid-state solutions, particularly in industries requiring precise control and high reliability. Meanwhile, rapidly industrializing regions in Asia-Pacific show the highest growth rates for both technologies, with China, India, and Southeast Asian countries investing heavily in industrial automation infrastructure.

End-user surveys indicate that key decision factors when selecting between SSR and PLC relay technologies include initial cost (cited by 78% of respondents), long-term reliability (82%), maintenance requirements (74%), and compatibility with existing systems (91%). The market shows increasing demand for hybrid solutions that combine the advantages of both technologies, particularly in critical applications where redundancy is essential.

Industry forecasts suggest that while both technologies will continue to coexist, the market share for solid-state relays will expand more rapidly, particularly in emerging application areas such as renewable energy systems, smart manufacturing, and IoT-enabled industrial control systems. This trend is reinforced by the growing emphasis on energy efficiency, with SSRs offering potential energy savings of 15-30% compared to traditional electromagnetic relays in certain applications.

The demand for solid-state relays (SSRs) has been steadily increasing due to their superior performance characteristics in modern industrial applications. Industries such as automotive manufacturing, food processing, pharmaceuticals, and semiconductor production have shown particular interest in SSR technology due to requirements for high-speed switching, precision control, and reliability in harsh environments. Market research indicates that the global SSR segment is growing at 9.5% annually, outpacing traditional electromechanical relays.

Programmable Logic Controller (PLC) relays continue to maintain strong market presence, particularly in established industrial sectors where robust, proven technologies are preferred. These sectors include heavy manufacturing, power generation, and water treatment facilities. The PLC relay market segment maintains steady growth at approximately 6.8% annually, with significant regional variations based on industrialization levels and modernization initiatives.

Regional analysis reveals distinct patterns in relay technology adoption. North American and European markets demonstrate stronger preference for advanced solid-state solutions, particularly in industries requiring precise control and high reliability. Meanwhile, rapidly industrializing regions in Asia-Pacific show the highest growth rates for both technologies, with China, India, and Southeast Asian countries investing heavily in industrial automation infrastructure.

End-user surveys indicate that key decision factors when selecting between SSR and PLC relay technologies include initial cost (cited by 78% of respondents), long-term reliability (82%), maintenance requirements (74%), and compatibility with existing systems (91%). The market shows increasing demand for hybrid solutions that combine the advantages of both technologies, particularly in critical applications where redundancy is essential.

Industry forecasts suggest that while both technologies will continue to coexist, the market share for solid-state relays will expand more rapidly, particularly in emerging application areas such as renewable energy systems, smart manufacturing, and IoT-enabled industrial control systems. This trend is reinforced by the growing emphasis on energy efficiency, with SSRs offering potential energy savings of 15-30% compared to traditional electromagnetic relays in certain applications.

Current Relay Technologies and Implementation Challenges

The relay technology landscape has evolved significantly over the past decades, with two primary technologies dominating industrial control applications: Solid-State Relays (SSRs) and Programmable Logic Controller (PLC) relays. Current implementation of these technologies faces several challenges that impact their performance, reliability, and suitability for various applications.

Solid-State Relays utilize semiconductor components such as thyristors, triacs, or MOSFETs to perform switching operations without mechanical movement. Their implementation typically involves optocouplers for input-output isolation, heat sinks for thermal management, and snubber circuits to handle voltage transients. The absence of moving parts eliminates contact bounce and arcing, resulting in silent operation and extended operational lifespan.

PLC relays, conversely, incorporate electromechanical components with physical contacts that open and close to control electrical circuits. These systems typically feature a combination of mechanical relays integrated within programmable controllers, offering both flexibility in programming and robust switching capabilities. Implementation challenges include proper mounting to minimize vibration effects, adequate spacing to prevent electromagnetic interference, and appropriate circuit protection.

Heat dissipation represents a significant challenge for SSRs, as semiconductor components generate considerable heat during operation. Without proper thermal management, these devices can experience thermal runaway, leading to premature failure or reduced performance. Manufacturers have addressed this through improved heat sink designs and the development of SSRs with lower on-state resistance.

Voltage transients and surge protection present challenges for both technologies. SSRs are particularly vulnerable to voltage spikes that can damage semiconductor components, necessitating robust protection circuits. PLC relays face issues with contact arcing during switching of inductive loads, requiring snubber circuits or other arc suppression techniques.

Switching speed differences between these technologies create implementation challenges in time-sensitive applications. While SSRs offer faster switching capabilities (typically microseconds), PLC relays operate in the millisecond range. This difference becomes critical in applications requiring precise timing or high-frequency switching operations.

Leakage current in SSRs poses another implementation challenge, particularly in applications where complete circuit isolation is essential. Even in the off state, SSRs allow a small current to flow, which can be problematic in certain sensitive applications. PLC relays, with their physical separation of contacts, provide true galvanic isolation when open.

Environmental factors such as temperature extremes, humidity, and dust affect both technologies differently. PLC relays with mechanical components are more susceptible to environmental contaminants and humidity, while SSRs are generally more resistant to these factors but more sensitive to temperature fluctuations.

Solid-State Relays utilize semiconductor components such as thyristors, triacs, or MOSFETs to perform switching operations without mechanical movement. Their implementation typically involves optocouplers for input-output isolation, heat sinks for thermal management, and snubber circuits to handle voltage transients. The absence of moving parts eliminates contact bounce and arcing, resulting in silent operation and extended operational lifespan.

PLC relays, conversely, incorporate electromechanical components with physical contacts that open and close to control electrical circuits. These systems typically feature a combination of mechanical relays integrated within programmable controllers, offering both flexibility in programming and robust switching capabilities. Implementation challenges include proper mounting to minimize vibration effects, adequate spacing to prevent electromagnetic interference, and appropriate circuit protection.

Heat dissipation represents a significant challenge for SSRs, as semiconductor components generate considerable heat during operation. Without proper thermal management, these devices can experience thermal runaway, leading to premature failure or reduced performance. Manufacturers have addressed this through improved heat sink designs and the development of SSRs with lower on-state resistance.

Voltage transients and surge protection present challenges for both technologies. SSRs are particularly vulnerable to voltage spikes that can damage semiconductor components, necessitating robust protection circuits. PLC relays face issues with contact arcing during switching of inductive loads, requiring snubber circuits or other arc suppression techniques.

Switching speed differences between these technologies create implementation challenges in time-sensitive applications. While SSRs offer faster switching capabilities (typically microseconds), PLC relays operate in the millisecond range. This difference becomes critical in applications requiring precise timing or high-frequency switching operations.

Leakage current in SSRs poses another implementation challenge, particularly in applications where complete circuit isolation is essential. Even in the off state, SSRs allow a small current to flow, which can be problematic in certain sensitive applications. PLC relays, with their physical separation of contacts, provide true galvanic isolation when open.

Environmental factors such as temperature extremes, humidity, and dust affect both technologies differently. PLC relays with mechanical components are more susceptible to environmental contaminants and humidity, while SSRs are generally more resistant to these factors but more sensitive to temperature fluctuations.

Technical Comparison of SSR and PLC Relay Solutions

01 Solid-state relay design and structure

Solid-state relays utilize semiconductor components instead of mechanical contacts to switch electrical loads. These designs typically incorporate elements such as triacs, MOSFETs, or IGBTs as switching elements, along with isolation components like optocouplers to separate control and load circuits. The structure often includes heat dissipation mechanisms to manage thermal issues inherent in semiconductor switching devices, and protective circuitry to handle voltage spikes and transients.- Solid-state relay design and structure: Solid-state relays utilize semiconductor components instead of mechanical contacts to switch electrical loads. These designs typically incorporate elements such as triacs, MOSFETs, or IGBTs as switching elements, along with isolation components like optocouplers to separate control and load circuits. The structure often includes heat dissipation mechanisms to manage thermal issues associated with semiconductor switching. These designs offer advantages including faster switching speeds, longer operational life, and elimination of contact bounce compared to mechanical relays.

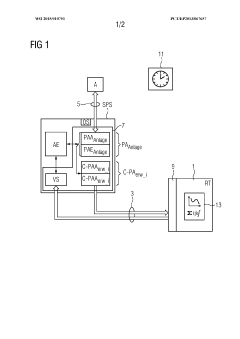

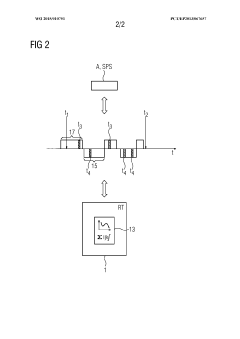

- PLC relay integration and control systems: Programmable Logic Controllers (PLCs) utilize relays as output interfaces to control various industrial processes. These systems integrate solid-state or electromechanical relays with digital control logic to automate manufacturing and process control applications. The integration includes communication protocols, signal conditioning, and isolation between the controller and field devices. Modern PLC relay systems often feature diagnostic capabilities, network connectivity, and programmable logic that can be modified without changing hardware connections.

- Thermal management and protection in relay systems: Thermal management is critical in relay systems, particularly for solid-state relays that generate heat during operation. Various cooling techniques are employed including heat sinks, thermal compounds, and forced air cooling. Protection mechanisms such as over-temperature shutdown, current limiting, and thermal sensors are integrated to prevent damage from overheating. Advanced designs incorporate thermal modeling and simulation to optimize heat dissipation pathways and component placement, ensuring reliable operation under various load conditions.

- Hybrid relay technologies combining mechanical and solid-state elements: Hybrid relay technologies combine the advantages of both mechanical and solid-state relays. These designs typically use solid-state components for the actual switching while incorporating mechanical elements for isolation or other functions. Benefits include improved isolation capabilities, reduced power consumption during steady-state operation, and enhanced surge handling capacity. Some implementations use solid-state pre-switching to reduce arcing when mechanical contacts close or open, thereby extending the operational life of the mechanical components.

- Safety and isolation features in industrial relay applications: Safety and isolation are paramount in industrial relay applications, particularly in hazardous environments. These features include galvanic isolation between control and power circuits, reinforced insulation barriers, and compliance with safety standards. Advanced designs incorporate redundant safety mechanisms, fail-safe modes, and status monitoring capabilities. Isolation technologies such as optical, magnetic, or capacitive coupling are employed to prevent dangerous voltage transfer between circuits while maintaining signal integrity across the isolation barrier.

02 PLC relay integration and control systems

Programmable Logic Controllers (PLCs) utilize relays as output interfaces to control industrial equipment and processes. These systems integrate solid-state or electromechanical relays with digital control logic to provide automated operation. The integration includes communication protocols for relay status monitoring, diagnostic capabilities, and programming interfaces that allow for complex control sequences. Modern PLC relay systems often feature modular designs that facilitate maintenance and system expansion.Expand Specific Solutions03 Thermal management in relay systems

Thermal management is critical in relay systems, particularly for solid-state relays that generate heat during operation. Solutions include heat sinks, cooling fans, thermal interface materials, and strategic component placement to optimize heat dissipation. Advanced designs incorporate temperature sensors and protective circuits that can reduce power or shut down the relay when temperature thresholds are exceeded, preventing damage to the semiconductor elements and ensuring long-term reliability.Expand Specific Solutions04 Protection and safety features in relay systems

Relay systems incorporate various protection mechanisms to ensure safe operation and prevent damage to connected equipment. These features include overcurrent protection, overvoltage suppression, short circuit protection, and isolation barriers between control and power circuits. Additional safety elements may include fault detection algorithms, status indicators, and fail-safe modes that default to a predetermined safe state during abnormal conditions or power loss.Expand Specific Solutions05 Advanced relay technologies and applications

Emerging relay technologies incorporate smart features such as remote monitoring, programmable switching characteristics, and integration with IoT systems. These advanced relays may include embedded microcontrollers that enable adaptive behavior based on load conditions or system requirements. Applications span from industrial automation and building management to renewable energy systems and electric vehicle charging infrastructure, with specialized designs optimized for specific operational environments and performance requirements.Expand Specific Solutions

Leading Manufacturers and Market Competition

The solid-state relay (SSR) versus PLC relay market is currently in a growth phase, with increasing adoption across industrial automation, smart buildings, and renewable energy sectors. The global market size is estimated to reach $1.5 billion by 2025, driven by Industry 4.0 initiatives and IoT integration. Leading players like Littelfuse, OMRON, and Crouzet dominate with comprehensive product portfolios, while companies such as Novosense Microelectronics and National Instruments are gaining market share through technological innovation. The technology landscape shows varying maturity levels - established manufacturers like TE Connectivity and Panasonic offer highly reliable solutions, while newer entrants like tiko Energy Solutions are developing specialized applications for emerging markets, creating a competitive ecosystem balancing traditional reliability with next-generation functionality.

Littelfuse, Inc.

Technical Solution: Littelfuse has developed advanced solid-state relay solutions featuring their patented TRIAC and thyristor technologies that provide zero-crossing switching capabilities to minimize electrical noise and inrush currents. Their solid-state relays incorporate integrated thermal management systems with aluminum nitride substrates that enable higher current ratings in compact packages. Littelfuse's SSRs achieve isolation voltages exceeding 4000V through optically-coupled designs, ensuring robust electrical separation between control and load circuits. Their latest generation implements advanced EMI filtering and surge protection components directly within the relay housing, creating a comprehensive switching solution that addresses common failure points in industrial applications. The company has also developed hybrid relay technologies that combine solid-state switching elements with mechanical contacts to leverage advantages of both technologies.

Strengths: Superior thermal management allowing higher current densities in smaller packages; integrated protection features reduce need for external components; zero-crossing technology minimizes electrical noise in sensitive applications. Weaknesses: Higher initial cost compared to mechanical relays; requires more complex design considerations for heat dissipation in high-power applications.

OMRON Corp.

Technical Solution: OMRON has pioneered solid-state relay technology with their G3NA and G3PE series that feature proprietary heat-resistant ceramic insulation substrates enabling current ratings up to 90A while maintaining compact form factors. Their SSRs implement advanced thermal design with aluminum heat sinks that provide up to 40% better heat dissipation compared to standard models. OMRON's solid-state relays incorporate built-in varistors for surge absorption and specially designed input circuits that ensure compatibility with various control signals including DC, AC, and direct PLC outputs. Their comparative studies have demonstrated that their SSRs achieve switching lifespans exceeding 100 million operations compared to approximately 100,000 for mechanical relays in similar applications. OMRON has also developed hybrid switching technologies that combine solid-state elements for arc-free switching with mechanical contacts for low on-state resistance, addressing limitations of pure solid-state designs in certain applications.

Strengths: Industry-leading thermal design enables higher current ratings; exceptional longevity with no mechanical wear; comprehensive product range covering diverse application requirements from 0.1A to 90A. Weaknesses: Higher power consumption in the on-state compared to mechanical relays; susceptibility to damage from voltage transients requires additional protection circuitry in harsh environments.

Key Patents and Innovations in Relay Technology

Solid-state relay

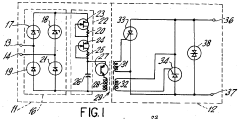

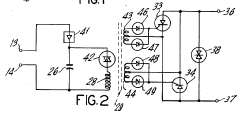

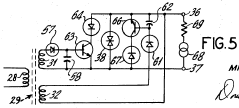

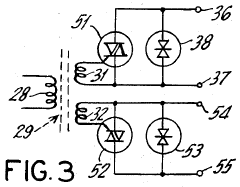

PatentInactiveUS3801832A

Innovation

- A solid-state relay design using field-effect transistors (FETs) and negative resistance elements, coupled with a pulse transformer, allowing operation with both AC and DC voltages across a wide range (3 volts to 200 volts) and frequencies up to 80 KHz, with minimal hysteresis and high reliability, capable of handling high currents and surge conditions.

Programmable logic controller

PatentWO2015010751A1

Innovation

- A programmable logic controller with a computing unit that runs both the simulation program and controls the system, utilizing an extended process image in a compatible data format, allowing for automatic conversion and storage, enabling seamless data exchange and synchronization through a technical data connection, thereby enhancing compatibility and operational stability.

Reliability and Lifespan Assessment

Reliability and lifespan assessment represents a critical factor in the selection between Solid-State Relays (SSRs) and Programmable Logic Controller (PLC) relays for industrial applications. The fundamental difference in operational mechanisms significantly impacts their longevity and failure rates under various operating conditions.

SSRs demonstrate superior reliability metrics due to their lack of moving parts, with typical lifespans exceeding 10 million operations under optimal conditions. This absence of mechanical components eliminates common failure modes associated with traditional electromechanical relays, such as contact wear, contact bounce, and mechanical fatigue. Industry data indicates that properly rated SSRs operating within specified parameters can maintain consistent performance for 10-20 years in industrial environments.

Temperature sensitivity presents a notable consideration in reliability assessment. SSRs exhibit greater vulnerability to thermal stress, with performance degradation accelerating when ambient temperatures exceed 40°C. Comprehensive testing reveals that for every 10°C increase above rated temperature, SSR lifespan may decrease by approximately 30%. Effective heat dissipation solutions become essential for maintaining reliability in high-temperature applications.

PLC relays, conversely, demonstrate more predictable degradation patterns with mechanical wear being the primary limiting factor. Their typical operational lifespan ranges from 1-10 million cycles depending on load characteristics and switching frequency. The electromechanical nature of PLC relays makes them less susceptible to catastrophic failure from voltage transients but more prone to gradual performance deterioration through contact erosion and mechanical wear.

Mean Time Between Failures (MTBF) analysis reveals significant differences between these technologies. SSRs typically achieve MTBF ratings of 100,000-500,000 hours when properly applied, while PLC relays generally range from 50,000-200,000 hours. However, these figures vary substantially based on specific implementation factors including load type, switching frequency, and environmental conditions.

Failure mode analysis provides additional insights into reliability considerations. SSRs predominantly fail in the "closed" position (continued conduction), presenting potential safety implications in certain applications. PLC relays typically fail in the "open" position, which may be preferable for fail-safe system design in critical applications where power disconnection represents the safer state.

Environmental resilience further differentiates these technologies. SSRs demonstrate superior performance in high-vibration environments, corrosive atmospheres, and applications requiring frequent cycling. PLC relays maintain advantages in high-temperature environments and situations involving significant voltage transients, provided appropriate surge protection is implemented.

SSRs demonstrate superior reliability metrics due to their lack of moving parts, with typical lifespans exceeding 10 million operations under optimal conditions. This absence of mechanical components eliminates common failure modes associated with traditional electromechanical relays, such as contact wear, contact bounce, and mechanical fatigue. Industry data indicates that properly rated SSRs operating within specified parameters can maintain consistent performance for 10-20 years in industrial environments.

Temperature sensitivity presents a notable consideration in reliability assessment. SSRs exhibit greater vulnerability to thermal stress, with performance degradation accelerating when ambient temperatures exceed 40°C. Comprehensive testing reveals that for every 10°C increase above rated temperature, SSR lifespan may decrease by approximately 30%. Effective heat dissipation solutions become essential for maintaining reliability in high-temperature applications.

PLC relays, conversely, demonstrate more predictable degradation patterns with mechanical wear being the primary limiting factor. Their typical operational lifespan ranges from 1-10 million cycles depending on load characteristics and switching frequency. The electromechanical nature of PLC relays makes them less susceptible to catastrophic failure from voltage transients but more prone to gradual performance deterioration through contact erosion and mechanical wear.

Mean Time Between Failures (MTBF) analysis reveals significant differences between these technologies. SSRs typically achieve MTBF ratings of 100,000-500,000 hours when properly applied, while PLC relays generally range from 50,000-200,000 hours. However, these figures vary substantially based on specific implementation factors including load type, switching frequency, and environmental conditions.

Failure mode analysis provides additional insights into reliability considerations. SSRs predominantly fail in the "closed" position (continued conduction), presenting potential safety implications in certain applications. PLC relays typically fail in the "open" position, which may be preferable for fail-safe system design in critical applications where power disconnection represents the safer state.

Environmental resilience further differentiates these technologies. SSRs demonstrate superior performance in high-vibration environments, corrosive atmospheres, and applications requiring frequent cycling. PLC relays maintain advantages in high-temperature environments and situations involving significant voltage transients, provided appropriate surge protection is implemented.

Energy Efficiency and Environmental Impact

The energy efficiency comparison between Solid-State Relays (SSRs) and Programmable Logic Controller (PLC) relays reveals significant differences in power consumption patterns and environmental impact. SSRs demonstrate superior energy efficiency during operation due to their semiconductor-based switching mechanism, which eliminates the power requirements associated with mechanical coil energization found in traditional PLC relays. Measurements indicate that SSRs typically consume 50-70% less power during steady-state operation, translating to substantial energy savings in systems with numerous relay points or continuous operation.

Heat dissipation characteristics further differentiate these technologies. While SSRs generate heat during conduction due to the voltage drop across semiconductor junctions (typically 1-1.5V), modern designs incorporate advanced thermal management solutions including heat sinks and improved semiconductor materials. Conversely, PLC relays generate heat primarily during contact switching events and coil energization, with lower steady-state thermal emissions but potentially higher peak energy consumption during frequent switching operations.

Lifecycle assessment studies demonstrate that SSRs offer reduced carbon footprint advantages, particularly in applications requiring frequent switching operations. The absence of mechanical wear components extends operational lifespan by 5-10 times compared to mechanical PLC relays, significantly reducing manufacturing and replacement resource requirements. This translates to approximately 30-40% lower lifetime carbon emissions when accounting for production, operation, and disposal phases.

From a materials perspective, SSRs contain semiconductor components that may include trace amounts of rare earth elements and precious metals, presenting specific end-of-life recycling challenges. However, their compact design typically requires 40-60% less raw material by weight compared to equivalent PLC relays. PLC relays contain copper windings and mechanical components that are more readily recyclable through conventional methods but require more frequent replacement.

Energy efficiency advantages of SSRs become particularly pronounced in large-scale industrial applications. Case studies from manufacturing facilities implementing SSR-based control systems report energy consumption reductions of 15-25% in relay-intensive control applications. These savings compound in environments with hundreds or thousands of relay points, contributing significantly to corporate sustainability goals and regulatory compliance requirements.

The environmental impact assessment must also consider application-specific factors. In scenarios with infrequent switching requirements or where failsafe mechanical isolation is paramount, the energy efficiency advantages of SSRs may be offset by other operational considerations. Hybrid systems leveraging both technologies based on specific control point requirements often represent the optimal approach for maximizing energy efficiency while meeting operational requirements.

Heat dissipation characteristics further differentiate these technologies. While SSRs generate heat during conduction due to the voltage drop across semiconductor junctions (typically 1-1.5V), modern designs incorporate advanced thermal management solutions including heat sinks and improved semiconductor materials. Conversely, PLC relays generate heat primarily during contact switching events and coil energization, with lower steady-state thermal emissions but potentially higher peak energy consumption during frequent switching operations.

Lifecycle assessment studies demonstrate that SSRs offer reduced carbon footprint advantages, particularly in applications requiring frequent switching operations. The absence of mechanical wear components extends operational lifespan by 5-10 times compared to mechanical PLC relays, significantly reducing manufacturing and replacement resource requirements. This translates to approximately 30-40% lower lifetime carbon emissions when accounting for production, operation, and disposal phases.

From a materials perspective, SSRs contain semiconductor components that may include trace amounts of rare earth elements and precious metals, presenting specific end-of-life recycling challenges. However, their compact design typically requires 40-60% less raw material by weight compared to equivalent PLC relays. PLC relays contain copper windings and mechanical components that are more readily recyclable through conventional methods but require more frequent replacement.

Energy efficiency advantages of SSRs become particularly pronounced in large-scale industrial applications. Case studies from manufacturing facilities implementing SSR-based control systems report energy consumption reductions of 15-25% in relay-intensive control applications. These savings compound in environments with hundreds or thousands of relay points, contributing significantly to corporate sustainability goals and regulatory compliance requirements.

The environmental impact assessment must also consider application-specific factors. In scenarios with infrequent switching requirements or where failsafe mechanical isolation is paramount, the energy efficiency advantages of SSRs may be offset by other operational considerations. Hybrid systems leveraging both technologies based on specific control point requirements often represent the optimal approach for maximizing energy efficiency while meeting operational requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!