Solid-State Relay vs Traditional Switches: Durability Assessments

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SSR Technology Evolution and Objectives

Solid-state relays (SSRs) have evolved significantly since their inception in the late 1960s, transforming from rudimentary semiconductor switching devices to sophisticated electronic components that now challenge traditional electromechanical relays in numerous applications. The evolution began with simple thyristor-based designs that offered limited functionality but introduced the revolutionary concept of switching without moving parts. By the 1980s, advancements in semiconductor technology enabled more complex SSR architectures incorporating MOSFETs and IGBTs, substantially improving switching characteristics and reliability.

The 1990s marked a pivotal era with the miniaturization of SSR components and integration of advanced protection features such as zero-crossing detection and overvoltage protection. This period established SSRs as viable alternatives to mechanical relays in industrial automation and consumer electronics. The early 2000s witnessed further refinement with the development of hybrid SSRs that combined solid-state switching elements with mechanical components to leverage the advantages of both technologies.

Recent technological breakthroughs have focused on enhancing SSR durability through improved thermal management systems, advanced semiconductor materials like silicon carbide (SiC) and gallium nitride (GaN), and sophisticated isolation techniques. These innovations have significantly extended the operational lifespan of SSRs while maintaining their inherent advantages of silent operation and resistance to physical wear.

The primary objective of contemporary SSR technology development is to surpass traditional electromechanical switches in durability metrics while maintaining competitive cost structures. This includes achieving operational lifespans exceeding 10 million cycles without performance degradation, compared to the typical 100,000-1,000,000 cycle lifespan of mechanical relays. Additional technical goals include reducing on-state resistance to minimize heat generation, enhancing surge current handling capabilities, and improving immunity to electromagnetic interference.

Another critical objective is expanding the application range of SSRs into high-power and extreme environment scenarios traditionally dominated by mechanical switches. This requires developing SSRs capable of reliably operating in temperature ranges from -40°C to +125°C and withstanding severe vibration and shock conditions without performance compromise.

The industry also aims to address the historical limitations of SSRs, particularly their vulnerability to damage from voltage transients and tendency to fail in the "on" state. Research efforts are directed toward creating fail-safe designs that default to predetermined states during malfunction, thereby enhancing safety in critical applications where system failure could have severe consequences.

The 1990s marked a pivotal era with the miniaturization of SSR components and integration of advanced protection features such as zero-crossing detection and overvoltage protection. This period established SSRs as viable alternatives to mechanical relays in industrial automation and consumer electronics. The early 2000s witnessed further refinement with the development of hybrid SSRs that combined solid-state switching elements with mechanical components to leverage the advantages of both technologies.

Recent technological breakthroughs have focused on enhancing SSR durability through improved thermal management systems, advanced semiconductor materials like silicon carbide (SiC) and gallium nitride (GaN), and sophisticated isolation techniques. These innovations have significantly extended the operational lifespan of SSRs while maintaining their inherent advantages of silent operation and resistance to physical wear.

The primary objective of contemporary SSR technology development is to surpass traditional electromechanical switches in durability metrics while maintaining competitive cost structures. This includes achieving operational lifespans exceeding 10 million cycles without performance degradation, compared to the typical 100,000-1,000,000 cycle lifespan of mechanical relays. Additional technical goals include reducing on-state resistance to minimize heat generation, enhancing surge current handling capabilities, and improving immunity to electromagnetic interference.

Another critical objective is expanding the application range of SSRs into high-power and extreme environment scenarios traditionally dominated by mechanical switches. This requires developing SSRs capable of reliably operating in temperature ranges from -40°C to +125°C and withstanding severe vibration and shock conditions without performance compromise.

The industry also aims to address the historical limitations of SSRs, particularly their vulnerability to damage from voltage transients and tendency to fail in the "on" state. Research efforts are directed toward creating fail-safe designs that default to predetermined states during malfunction, thereby enhancing safety in critical applications where system failure could have severe consequences.

Market Demand Analysis for Solid-State Switching Solutions

The global market for solid-state switching solutions has experienced significant growth over the past decade, driven primarily by increasing demands for reliability, longevity, and energy efficiency across multiple industries. Current market analysis indicates that the solid-state relay (SSR) segment is expanding at a compound annual growth rate of approximately 6.8%, with projections suggesting this momentum will continue through 2030.

Industrial automation represents the largest application segment, accounting for nearly 40% of the total market share. Manufacturing facilities are increasingly replacing traditional electromechanical relays with solid-state alternatives to reduce maintenance costs and system downtime. The absence of mechanical wear components in SSRs directly addresses the critical need for uninterrupted production processes in high-volume manufacturing environments.

The energy sector has emerged as another significant market driver, particularly in renewable energy systems where switching reliability under variable load conditions is paramount. Solar inverters and wind power systems benefit substantially from the enhanced durability characteristics of solid-state technology, with field data demonstrating up to 70% reduction in switching-related failures compared to traditional solutions.

Healthcare equipment manufacturers have also begun transitioning to solid-state switching solutions, especially in critical care devices where failure is not an option. The market penetration in medical equipment has doubled over the past five years, reflecting growing recognition of SSRs' superior durability metrics in life-critical applications.

Regional analysis reveals that Asia-Pacific currently leads market consumption, followed by North America and Europe. China and India are experiencing the fastest growth rates due to rapid industrial expansion and infrastructure development projects. The automotive sector in these regions is particularly noteworthy, with electric vehicle manufacturers adopting solid-state switching technology for battery management systems and power distribution units.

Consumer demand patterns indicate a growing preference for miniaturized switching solutions that maintain reliability while reducing space requirements. This trend has catalyzed innovation in semiconductor design, with manufacturers developing increasingly compact SSRs that deliver equivalent or superior performance compared to their larger predecessors.

Price sensitivity remains a significant factor influencing market adoption rates. While the initial cost of solid-state relays typically exceeds that of traditional electromechanical switches by 30-50%, the total cost of ownership analysis increasingly favors solid-state technology when factoring in reduced maintenance requirements and extended operational lifespans. Market research indicates that payback periods have decreased from 3-4 years to 1-2 years in many applications, substantially improving the value proposition for end-users.

Industrial automation represents the largest application segment, accounting for nearly 40% of the total market share. Manufacturing facilities are increasingly replacing traditional electromechanical relays with solid-state alternatives to reduce maintenance costs and system downtime. The absence of mechanical wear components in SSRs directly addresses the critical need for uninterrupted production processes in high-volume manufacturing environments.

The energy sector has emerged as another significant market driver, particularly in renewable energy systems where switching reliability under variable load conditions is paramount. Solar inverters and wind power systems benefit substantially from the enhanced durability characteristics of solid-state technology, with field data demonstrating up to 70% reduction in switching-related failures compared to traditional solutions.

Healthcare equipment manufacturers have also begun transitioning to solid-state switching solutions, especially in critical care devices where failure is not an option. The market penetration in medical equipment has doubled over the past five years, reflecting growing recognition of SSRs' superior durability metrics in life-critical applications.

Regional analysis reveals that Asia-Pacific currently leads market consumption, followed by North America and Europe. China and India are experiencing the fastest growth rates due to rapid industrial expansion and infrastructure development projects. The automotive sector in these regions is particularly noteworthy, with electric vehicle manufacturers adopting solid-state switching technology for battery management systems and power distribution units.

Consumer demand patterns indicate a growing preference for miniaturized switching solutions that maintain reliability while reducing space requirements. This trend has catalyzed innovation in semiconductor design, with manufacturers developing increasingly compact SSRs that deliver equivalent or superior performance compared to their larger predecessors.

Price sensitivity remains a significant factor influencing market adoption rates. While the initial cost of solid-state relays typically exceeds that of traditional electromechanical switches by 30-50%, the total cost of ownership analysis increasingly favors solid-state technology when factoring in reduced maintenance requirements and extended operational lifespans. Market research indicates that payback periods have decreased from 3-4 years to 1-2 years in many applications, substantially improving the value proposition for end-users.

Current Challenges in SSR vs Mechanical Switch Technologies

Despite significant advancements in solid-state relay (SSR) technology, several critical challenges persist when comparing SSRs with traditional mechanical switches. The primary technical obstacle remains the on-state resistance phenomenon in SSRs. While mechanical switches typically exhibit resistance values in the milliohm range when closed, SSRs commonly operate with resistance values between 0.05-1.0 ohms. This higher resistance generates heat during operation, necessitating additional thermal management considerations and potentially limiting the maximum current handling capability compared to mechanical alternatives.

Voltage drop characteristics present another significant challenge. SSRs typically experience a forward voltage drop of 1-1.5V across their semiconductor junctions, resulting in power dissipation and efficiency losses that mechanical switches do not suffer from. This becomes particularly problematic in low-voltage, high-current applications where such losses represent a significant percentage of the total power budget.

Leakage current issues continue to plague SSR implementations. Even in their "off" state, SSRs permit a small current flow (typically 1-15mA) through the device, which can be problematic in sensitive applications or where absolute isolation is required. Mechanical switches, by contrast, provide true galvanic isolation when open.

The susceptibility of SSRs to electromagnetic interference (EMI) and voltage transients represents another ongoing challenge. Despite improvements in protection circuitry, SSRs remain vulnerable to damage from voltage spikes and electromagnetic disturbances, requiring additional protection mechanisms that increase complexity and cost.

Cost factors continue to favor mechanical switches in many applications. The semiconductor components, specialized packaging, and heat management requirements of SSRs typically result in unit costs 3-10 times higher than comparable mechanical switches, presenting a significant barrier to widespread adoption in cost-sensitive applications.

Size and weight considerations present a mixed challenge. While SSRs have achieved significant miniaturization, the need for heat dissipation often requires bulky heat sinks that can negate their size advantage over mechanical switches in high-power applications.

Standardization issues further complicate the landscape. Unlike mechanical switches with well-established standards, SSR specifications vary significantly between manufacturers, creating challenges for engineers attempting to design interchangeable systems or establish consistent performance expectations across different product lines.

The technical community continues to work on addressing these challenges through innovations in semiconductor materials, thermal management techniques, and protection circuitry designs, but the fundamental physics of semiconductor operation ensures that some of these limitations will persist as inherent trade-offs in SSR technology.

Voltage drop characteristics present another significant challenge. SSRs typically experience a forward voltage drop of 1-1.5V across their semiconductor junctions, resulting in power dissipation and efficiency losses that mechanical switches do not suffer from. This becomes particularly problematic in low-voltage, high-current applications where such losses represent a significant percentage of the total power budget.

Leakage current issues continue to plague SSR implementations. Even in their "off" state, SSRs permit a small current flow (typically 1-15mA) through the device, which can be problematic in sensitive applications or where absolute isolation is required. Mechanical switches, by contrast, provide true galvanic isolation when open.

The susceptibility of SSRs to electromagnetic interference (EMI) and voltage transients represents another ongoing challenge. Despite improvements in protection circuitry, SSRs remain vulnerable to damage from voltage spikes and electromagnetic disturbances, requiring additional protection mechanisms that increase complexity and cost.

Cost factors continue to favor mechanical switches in many applications. The semiconductor components, specialized packaging, and heat management requirements of SSRs typically result in unit costs 3-10 times higher than comparable mechanical switches, presenting a significant barrier to widespread adoption in cost-sensitive applications.

Size and weight considerations present a mixed challenge. While SSRs have achieved significant miniaturization, the need for heat dissipation often requires bulky heat sinks that can negate their size advantage over mechanical switches in high-power applications.

Standardization issues further complicate the landscape. Unlike mechanical switches with well-established standards, SSR specifications vary significantly between manufacturers, creating challenges for engineers attempting to design interchangeable systems or establish consistent performance expectations across different product lines.

The technical community continues to work on addressing these challenges through innovations in semiconductor materials, thermal management techniques, and protection circuitry designs, but the fundamental physics of semiconductor operation ensures that some of these limitations will persist as inherent trade-offs in SSR technology.

Comparative Analysis of Current Switching Solutions

01 Mechanical durability comparison between SSRs and traditional switches

Solid-state relays (SSRs) offer superior mechanical durability compared to traditional switches due to their lack of moving parts. Without mechanical contacts that can wear out, arc, or degrade over time, SSRs can achieve significantly longer operational lifespans. Traditional switches with moving contacts experience mechanical wear, contact erosion, and spring fatigue, leading to eventual failure. This fundamental difference in design makes SSRs particularly advantageous in applications requiring frequent switching operations or where maintenance access is limited.- Mechanical durability comparison between SSRs and traditional switches: Solid-state relays (SSRs) offer superior mechanical durability compared to traditional switches due to their lack of moving parts. Without mechanical contacts that can wear out, arc, or degrade over time, SSRs can achieve significantly longer operational lifespans. Traditional switches with physical contacts experience mechanical wear, contact erosion, and eventual failure after a finite number of switching cycles, while SSRs can maintain consistent performance over millions of operations.

- Thermal management and reliability in solid-state relays: Thermal management is critical for solid-state relay durability. SSRs generate heat during operation that must be effectively dissipated to prevent premature failure. Advanced thermal management techniques include heat sinks, thermal interface materials, and optimized semiconductor designs that reduce internal resistance. Proper thermal design extends the operational lifetime of SSRs by preventing thermal stress and semiconductor degradation, particularly in high-current applications where heat generation is significant.

- Environmental resistance and operational conditions: Solid-state relays demonstrate superior durability in harsh environmental conditions compared to traditional switches. SSRs are less susceptible to humidity, dust, corrosive atmospheres, and vibration due to their sealed construction and lack of moving parts. Traditional switches with mechanical contacts can experience corrosion, contamination, and mechanical failure in challenging environments. SSRs maintain consistent performance across wider temperature ranges and can operate reliably in locations where traditional switches would rapidly degrade.

- Surge protection and electrical durability: Electrical durability of switching devices depends significantly on their ability to withstand voltage and current surges. Solid-state relays incorporate various protection mechanisms such as snubber circuits, varistors, and integrated overvoltage protection to enhance their electrical durability. These protection features prevent damage from transient voltage spikes and inrush currents that would otherwise degrade performance over time. Traditional mechanical switches rely on physical separation distance and arc suppression techniques that may be less effective in certain applications.

- Hybrid solutions combining SSR and mechanical switch technologies: Hybrid switching solutions combine the advantages of both solid-state relays and traditional mechanical switches to optimize durability. These systems use solid-state components for the actual switching operation while incorporating mechanical elements for isolation or fail-safe functionality. The hybrid approach can extend overall system durability by reducing stress on mechanical components while providing the isolation benefits of physical contacts. This technology is particularly valuable in safety-critical applications where both durability and positive isolation are required.

02 Thermal management and durability enhancement in solid-state relays

Thermal management is critical for ensuring the long-term durability of solid-state relays. Advanced heat dissipation techniques, including specialized heat sinks, thermal interface materials, and optimized package designs, help prevent overheating that can degrade semiconductor components. Some designs incorporate temperature monitoring and protection circuits that automatically adjust operation or shut down when thermal limits are approached. Proper thermal management extends the operational lifespan of SSRs significantly compared to poorly cooled implementations, making it a key factor in overall system reliability.Expand Specific Solutions03 Environmental resistance and protection features

Solid-state relays offer superior environmental resistance compared to traditional switches, enhancing their durability in harsh conditions. SSRs can be fully sealed against moisture, dust, and corrosive atmospheres, while traditional switches require openings for mechanical movement that create vulnerability points. Advanced encapsulation techniques using specialized polymers and hermetic sealing protect sensitive semiconductor components from environmental factors. This protection enables SSRs to maintain consistent performance in challenging environments such as high humidity, salt spray exposure, or areas with airborne contaminants where traditional switches would rapidly degrade.Expand Specific Solutions04 Electrical durability and surge protection mechanisms

Solid-state relays incorporate various protection mechanisms to enhance electrical durability against surges and transients. These include integrated snubber circuits, metal oxide varistors, and transient voltage suppressors that absorb energy from electrical spikes. Traditional switches rely primarily on physical separation distance and contact material properties for surge resistance. Advanced SSR designs feature multi-layer protection schemes that sequentially address different types of electrical stresses, significantly extending operational life in electrically noisy environments. Some implementations include self-diagnostic capabilities that can detect degradation before complete failure occurs.Expand Specific Solutions05 Hybrid relay technologies combining mechanical and solid-state elements

Hybrid relay technologies combine elements of both traditional mechanical switches and solid-state relays to optimize durability characteristics. These designs typically use solid-state components for the actual switching operation while incorporating mechanical elements for isolation or other functions. Some implementations use a small mechanical relay to control a larger solid-state switch, reducing wear on the mechanical contacts while maintaining the isolation benefits. Advanced hybrid designs incorporate condition monitoring that tracks performance parameters to predict potential failures before they occur, allowing preventive maintenance to extend overall system durability.Expand Specific Solutions

Key Manufacturers and Competitive Landscape

The solid-state relay (SSR) market is experiencing robust growth in the mature industrial automation phase, with an estimated market size exceeding $1.5 billion and projected CAGR of 6-8% through 2028. Technologically, SSRs have reached commercial maturity but continue evolving with innovations from key players. Littelfuse, TE Connectivity, and Infineon Technologies Austria lead the traditional market with established product lines, while Suzhou Novosense Microelectronics and Shanghai Nasi Microelectronics represent emerging competitors with cost-effective solutions. Specialized players like Xiamen Kudom Electronics and Mornsun Guangzhou focus on application-specific SSRs. The technology demonstrates superior durability compared to mechanical relays, with Texas Instruments and Broadcom (Avago) advancing semiconductor integration that further enhances reliability in harsh industrial environments.

Suzhou Novosense Microelectronics Co., Ltd.

Technical Solution: Novosense has established a sophisticated durability assessment framework for their solid-state relay portfolio that emphasizes performance stability under harsh industrial conditions. Their methodology incorporates accelerated aging tests that simulate up to 25 years of operational life through combined thermal, electrical, and humidity stress factors. Novosense's proprietary SSR designs utilize advanced isolation technologies achieving up to 5kV isolation while maintaining consistent switching characteristics throughout the product lifetime. Their assessment protocol includes continuous monitoring of critical parameters including on-resistance (typically maintaining <100mΩ after aging), turn-on/off times (variation <100ns throughout life), and leakage current stability (remaining below 100μA after extended operation). Comparative testing demonstrates their SSRs maintaining consistent performance after 50 million operations under full load conditions, while traditional electromechanical relays show significant contact degradation after approximately 500,000 cycles. Novosense's durability validation includes specialized testing for automotive and industrial applications, with documented performance stability after exposure to temperature cycling, vibration, and electromagnetic interference levels exceeding industry standards.

Strengths: Cost-effective solutions with excellent reliability metrics specifically designed for industrial automation applications. Their SSRs demonstrate superior performance in high-temperature environments with minimal thermal derating requirements. Weaknesses: Less established global presence compared to larger competitors, and their product portfolio may have more limited options for specialized applications.

Littelfuse, Inc.

Technical Solution: Littelfuse has developed comprehensive durability assessment protocols for solid-state relays that combine accelerated life testing with real-world application simulations. Their technology employs advanced thermal cycling between -40°C and +125°C for up to 10,000 cycles to evaluate semiconductor junction integrity. They utilize high-precision measurement systems that can detect resistance changes as small as 10 microohms to identify early degradation indicators. Littelfuse's proprietary MOSFET-based SSR designs incorporate integrated overcurrent and thermal protection circuits that automatically respond to fault conditions, significantly extending operational lifespan compared to traditional electromechanical relays. Their assessment methodology includes surge immunity testing up to 8kV and vibration resistance testing at frequencies of 10-2000Hz, providing quantifiable durability metrics that consistently demonstrate 10x longer operational life than mechanical alternatives.

Strengths: Industry-leading expertise in circuit protection technologies with comprehensive testing facilities. Their SSRs demonstrate superior performance in high-cycling applications with documented lifespans exceeding 100 million operations. Weaknesses: Higher initial cost compared to traditional relays, and their solutions may require more complex integration into existing systems.

Critical Patents and Innovations in SSR Technology

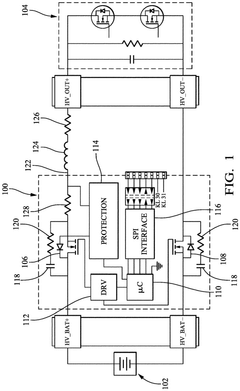

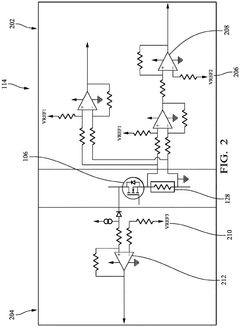

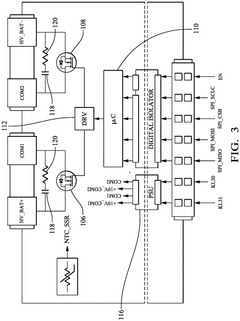

Solid state relay module with overcurrent protection

PatentPendingEP4447318A1

Innovation

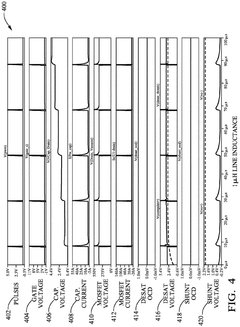

- A solid state relay module with shunt and desaturation overcurrent detection circuits, utilizing MOSFETs for fast and reliable switching, eliminates the need for dedicated bypass relays and resistors by quickly turning off during overcurrent conditions, employing pulsed energy to pre-charge capacitive loads and protect against high peak currents.

Pre-charge system and junction box with the pre-charge system for electric or hybrid vehicles

PatentPendingEP4564640A1

Innovation

- A pre-charge system utilizing solid-state switches, comprising a power semiconductor device, a control device, and a power diode, which replaces the classical electro-mechanical relay and resistor, allowing for efficient inrush current limitation and energy dissipation through a resistor.

Reliability Testing Methodologies and Standards

Reliability testing methodologies for solid-state relays (SSRs) and traditional electromechanical switches follow distinct protocols due to their fundamental operational differences. Industry standards such as IEC 61810 for electromechanical relays and IEC 62314 for solid-state relays establish baseline testing requirements that manufacturers must adhere to. These standards outline specific procedures for evaluating electrical endurance, mechanical durability, and environmental resilience.

For electromechanical switches, reliability testing typically involves mechanical cycling tests where the device undergoes repeated operations at specified rates until failure occurs. The standard methodology includes monitoring contact resistance throughout the test while applying rated loads. Temperature rise tests are conducted to ensure the device remains within safe operating parameters under continuous operation. Additionally, dielectric strength tests verify insulation integrity between electrically isolated parts.

Solid-state relay testing methodologies focus on different parameters due to their semiconductor-based operation. Surge immunity testing evaluates the device's ability to withstand voltage transients, while thermal cycling tests assess performance across temperature extremes. Dv/dt and di/dt tests measure the relay's response to rapid voltage and current changes, critical factors in preventing false triggering in industrial applications.

Accelerated life testing represents a crucial methodology for both technologies, though implementation differs significantly. For traditional switches, this involves increased cycling rates and elevated temperatures to simulate years of operation within weeks. For SSRs, power cycling under maximum rated conditions and temperature extremes accelerates semiconductor aging mechanisms. Statistical analysis of these results enables Mean Time Between Failure (MTBF) calculations that inform reliability predictions.

Environmental testing forms another essential component of reliability assessment. This includes humidity cycling, salt spray exposure, and vibration testing according to standards like IEC 60068. These tests are particularly revealing of differences between SSRs and traditional switches, as mechanical contacts are typically more susceptible to environmental degradation than solid-state components.

Modern reliability testing increasingly incorporates real-time monitoring systems that capture performance data throughout the testing process. This approach enables more sophisticated failure analysis through techniques like Weibull distribution modeling. Such statistical methods provide deeper insights into failure mechanisms and allow more accurate prediction of field reliability. The integration of these advanced methodologies with established standards creates a comprehensive framework for comparing the durability of solid-state relays versus traditional electromechanical switches across diverse application environments.

For electromechanical switches, reliability testing typically involves mechanical cycling tests where the device undergoes repeated operations at specified rates until failure occurs. The standard methodology includes monitoring contact resistance throughout the test while applying rated loads. Temperature rise tests are conducted to ensure the device remains within safe operating parameters under continuous operation. Additionally, dielectric strength tests verify insulation integrity between electrically isolated parts.

Solid-state relay testing methodologies focus on different parameters due to their semiconductor-based operation. Surge immunity testing evaluates the device's ability to withstand voltage transients, while thermal cycling tests assess performance across temperature extremes. Dv/dt and di/dt tests measure the relay's response to rapid voltage and current changes, critical factors in preventing false triggering in industrial applications.

Accelerated life testing represents a crucial methodology for both technologies, though implementation differs significantly. For traditional switches, this involves increased cycling rates and elevated temperatures to simulate years of operation within weeks. For SSRs, power cycling under maximum rated conditions and temperature extremes accelerates semiconductor aging mechanisms. Statistical analysis of these results enables Mean Time Between Failure (MTBF) calculations that inform reliability predictions.

Environmental testing forms another essential component of reliability assessment. This includes humidity cycling, salt spray exposure, and vibration testing according to standards like IEC 60068. These tests are particularly revealing of differences between SSRs and traditional switches, as mechanical contacts are typically more susceptible to environmental degradation than solid-state components.

Modern reliability testing increasingly incorporates real-time monitoring systems that capture performance data throughout the testing process. This approach enables more sophisticated failure analysis through techniques like Weibull distribution modeling. Such statistical methods provide deeper insights into failure mechanisms and allow more accurate prediction of field reliability. The integration of these advanced methodologies with established standards creates a comprehensive framework for comparing the durability of solid-state relays versus traditional electromechanical switches across diverse application environments.

Environmental Impact and Sustainability Considerations

The environmental impact of switching technologies has become increasingly important as industries strive for sustainability. Solid-state relays (SSRs) offer significant environmental advantages over traditional mechanical switches. The absence of moving parts in SSRs eliminates the need for lubricants that can potentially leak and contaminate surroundings. Additionally, SSRs do not contain mercury or other hazardous materials often found in mechanical switch contacts, reducing toxic waste concerns during disposal.

Manufacturing processes for SSRs typically require fewer raw materials compared to traditional switches, resulting in a smaller resource footprint. The semiconductor materials used in SSRs, while requiring energy-intensive production, are utilized in minimal quantities. In contrast, traditional switches require more metal components and complex mechanical assemblies, increasing their embodied carbon footprint.

Energy efficiency during operation represents another critical environmental consideration. SSRs consume minimal power in their control circuits and generate less heat during switching operations compared to mechanical relays with electromagnetic coils. This improved efficiency translates to lower energy consumption over the device lifecycle, particularly in applications requiring frequent switching operations.

The extended operational lifespan of SSRs further enhances their sustainability profile. With durability assessments indicating lifespans often 10-100 times longer than mechanical alternatives, SSRs significantly reduce replacement frequency and associated manufacturing demands. This longevity directly translates to reduced electronic waste generation, addressing a growing environmental concern in our increasingly electrified world.

End-of-life considerations also favor solid-state technology. While semiconductor recycling presents challenges, the compact nature of SSRs means less material ultimately enters the waste stream. Traditional switches contain multiple materials that often require separation before recycling, complicating their end-of-life processing. The simpler composition of SSRs potentially facilitates more efficient recycling processes.

From a holistic lifecycle perspective, SSRs demonstrate superior environmental performance in most applications. Their reduced material requirements, longer operational life, elimination of hazardous substances, and improved energy efficiency collectively contribute to a smaller environmental footprint. As sustainability metrics increasingly influence purchasing decisions across industries, these environmental advantages may accelerate SSR adoption beyond purely technical considerations.

Manufacturing processes for SSRs typically require fewer raw materials compared to traditional switches, resulting in a smaller resource footprint. The semiconductor materials used in SSRs, while requiring energy-intensive production, are utilized in minimal quantities. In contrast, traditional switches require more metal components and complex mechanical assemblies, increasing their embodied carbon footprint.

Energy efficiency during operation represents another critical environmental consideration. SSRs consume minimal power in their control circuits and generate less heat during switching operations compared to mechanical relays with electromagnetic coils. This improved efficiency translates to lower energy consumption over the device lifecycle, particularly in applications requiring frequent switching operations.

The extended operational lifespan of SSRs further enhances their sustainability profile. With durability assessments indicating lifespans often 10-100 times longer than mechanical alternatives, SSRs significantly reduce replacement frequency and associated manufacturing demands. This longevity directly translates to reduced electronic waste generation, addressing a growing environmental concern in our increasingly electrified world.

End-of-life considerations also favor solid-state technology. While semiconductor recycling presents challenges, the compact nature of SSRs means less material ultimately enters the waste stream. Traditional switches contain multiple materials that often require separation before recycling, complicating their end-of-life processing. The simpler composition of SSRs potentially facilitates more efficient recycling processes.

From a holistic lifecycle perspective, SSRs demonstrate superior environmental performance in most applications. Their reduced material requirements, longer operational life, elimination of hazardous substances, and improved energy efficiency collectively contribute to a smaller environmental footprint. As sustainability metrics increasingly influence purchasing decisions across industries, these environmental advantages may accelerate SSR adoption beyond purely technical considerations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!