Solid-state sodium battery developments in high-efficiency energy storage

OCT 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solid-State Sodium Battery Background and Objectives

The evolution of energy storage technologies has witnessed significant advancements over the past decades, with lithium-ion batteries dominating the commercial landscape. However, concerns regarding lithium resource scarcity, geographical concentration, and rising costs have prompted researchers to explore alternative battery chemistries. Sodium-ion batteries have emerged as a promising candidate due to sodium's natural abundance, wide geographical distribution, and similar electrochemical properties to lithium.

Solid-state sodium batteries represent the next frontier in this technological progression, addressing critical limitations of conventional liquid electrolyte systems. The development trajectory of solid-state sodium batteries can be traced back to the 1970s, when initial research on sodium-based conductors began. However, significant progress has only materialized in the last decade, driven by breakthroughs in materials science and increasing demand for sustainable energy storage solutions.

The fundamental technological challenge in solid-state sodium battery development lies in identifying solid electrolytes with high ionic conductivity at room temperature while maintaining mechanical stability and electrochemical compatibility with electrode materials. Early sodium-based solid electrolytes suffered from poor conductivity, limiting their practical applications. Recent advances in ceramic, polymer, and composite electrolytes have dramatically improved performance metrics, bringing solid-state sodium batteries closer to commercial viability.

Current research trends indicate a convergence toward hybrid approaches that combine the advantages of different electrolyte systems. Notably, the development of NASICON-type materials, sodium-beta-alumina, and sulfide-based solid electrolytes has demonstrated promising results in laboratory settings, achieving conductivities approaching those of liquid electrolytes while offering enhanced safety profiles.

The primary objectives of solid-state sodium battery research center on achieving energy densities exceeding 300 Wh/kg, cycle life beyond 1000 cycles, and cost reduction to below $100/kWh. These targets position solid-state sodium batteries as competitive alternatives not only to conventional sodium-ion batteries but potentially to lithium-ion technologies in specific applications. Additional goals include improving low-temperature performance, addressing interfacial resistance issues, and developing scalable manufacturing processes.

The strategic importance of this technology extends beyond performance metrics. As global energy systems transition toward renewable sources, the need for efficient, sustainable, and economical energy storage solutions becomes increasingly critical. Solid-state sodium batteries align with this trajectory, offering a pathway to reduce dependency on geographically concentrated resources while supporting grid-scale storage applications and electric mobility solutions in diverse markets.

Solid-state sodium batteries represent the next frontier in this technological progression, addressing critical limitations of conventional liquid electrolyte systems. The development trajectory of solid-state sodium batteries can be traced back to the 1970s, when initial research on sodium-based conductors began. However, significant progress has only materialized in the last decade, driven by breakthroughs in materials science and increasing demand for sustainable energy storage solutions.

The fundamental technological challenge in solid-state sodium battery development lies in identifying solid electrolytes with high ionic conductivity at room temperature while maintaining mechanical stability and electrochemical compatibility with electrode materials. Early sodium-based solid electrolytes suffered from poor conductivity, limiting their practical applications. Recent advances in ceramic, polymer, and composite electrolytes have dramatically improved performance metrics, bringing solid-state sodium batteries closer to commercial viability.

Current research trends indicate a convergence toward hybrid approaches that combine the advantages of different electrolyte systems. Notably, the development of NASICON-type materials, sodium-beta-alumina, and sulfide-based solid electrolytes has demonstrated promising results in laboratory settings, achieving conductivities approaching those of liquid electrolytes while offering enhanced safety profiles.

The primary objectives of solid-state sodium battery research center on achieving energy densities exceeding 300 Wh/kg, cycle life beyond 1000 cycles, and cost reduction to below $100/kWh. These targets position solid-state sodium batteries as competitive alternatives not only to conventional sodium-ion batteries but potentially to lithium-ion technologies in specific applications. Additional goals include improving low-temperature performance, addressing interfacial resistance issues, and developing scalable manufacturing processes.

The strategic importance of this technology extends beyond performance metrics. As global energy systems transition toward renewable sources, the need for efficient, sustainable, and economical energy storage solutions becomes increasingly critical. Solid-state sodium batteries align with this trajectory, offering a pathway to reduce dependency on geographically concentrated resources while supporting grid-scale storage applications and electric mobility solutions in diverse markets.

Market Analysis for High-Efficiency Energy Storage Solutions

The global market for high-efficiency energy storage solutions has witnessed significant growth in recent years, driven by increasing demand for renewable energy integration, grid stabilization, and electrification of transportation. Solid-state sodium batteries represent an emerging technology within this landscape, positioned as a potential alternative to conventional lithium-ion batteries due to sodium's greater abundance and lower cost compared to lithium.

Current market valuations indicate the global energy storage market reached approximately $130 billion in 2022, with projections suggesting growth to $500 billion by 2035. Within this broader market, sodium-based battery technologies currently occupy a small but rapidly growing segment, with annual growth rates exceeding 25% as research advances and commercial applications emerge.

Consumer electronics, electric vehicles, and grid-scale storage represent the primary application segments for high-efficiency energy storage solutions. While lithium-ion technologies currently dominate these markets, sodium-based alternatives are gaining traction particularly in stationary storage applications where energy density requirements are less stringent than in mobile applications.

Regional analysis reveals significant market development activities in Asia-Pacific, particularly China, Japan, and South Korea, where substantial investments in sodium battery research and manufacturing infrastructure are underway. European markets show increasing interest driven by sustainability initiatives and strategic autonomy concerns regarding critical materials. North American markets remain focused on lithium technologies but with growing research interest in sodium alternatives.

Key market drivers for solid-state sodium batteries include raw material availability and cost advantages, with sodium being approximately 1,000 times more abundant than lithium in the Earth's crust. Environmental considerations also favor sodium technologies, as they potentially offer reduced ecological impact compared to lithium extraction processes.

Market barriers include technical challenges related to energy density limitations, cycle life performance, and manufacturing scalability. Current sodium battery technologies typically achieve 90-120 Wh/kg energy density compared to 250-300 Wh/kg for advanced lithium-ion cells, presenting competitive challenges in mobile applications.

Industry forecasts suggest solid-state sodium battery technologies could capture 15-20% of the stationary storage market by 2030, with more limited penetration in electric vehicle applications unless significant energy density improvements are achieved. Grid-scale applications represent the most promising near-term market opportunity, with utility companies increasingly exploring sodium-based solutions for renewable energy integration and peak shaving applications.

Current market valuations indicate the global energy storage market reached approximately $130 billion in 2022, with projections suggesting growth to $500 billion by 2035. Within this broader market, sodium-based battery technologies currently occupy a small but rapidly growing segment, with annual growth rates exceeding 25% as research advances and commercial applications emerge.

Consumer electronics, electric vehicles, and grid-scale storage represent the primary application segments for high-efficiency energy storage solutions. While lithium-ion technologies currently dominate these markets, sodium-based alternatives are gaining traction particularly in stationary storage applications where energy density requirements are less stringent than in mobile applications.

Regional analysis reveals significant market development activities in Asia-Pacific, particularly China, Japan, and South Korea, where substantial investments in sodium battery research and manufacturing infrastructure are underway. European markets show increasing interest driven by sustainability initiatives and strategic autonomy concerns regarding critical materials. North American markets remain focused on lithium technologies but with growing research interest in sodium alternatives.

Key market drivers for solid-state sodium batteries include raw material availability and cost advantages, with sodium being approximately 1,000 times more abundant than lithium in the Earth's crust. Environmental considerations also favor sodium technologies, as they potentially offer reduced ecological impact compared to lithium extraction processes.

Market barriers include technical challenges related to energy density limitations, cycle life performance, and manufacturing scalability. Current sodium battery technologies typically achieve 90-120 Wh/kg energy density compared to 250-300 Wh/kg for advanced lithium-ion cells, presenting competitive challenges in mobile applications.

Industry forecasts suggest solid-state sodium battery technologies could capture 15-20% of the stationary storage market by 2030, with more limited penetration in electric vehicle applications unless significant energy density improvements are achieved. Grid-scale applications represent the most promising near-term market opportunity, with utility companies increasingly exploring sodium-based solutions for renewable energy integration and peak shaving applications.

Technical Status and Challenges in Solid-State Sodium Batteries

Solid-state sodium batteries (SSSBs) have emerged as a promising alternative to lithium-ion batteries, particularly for large-scale energy storage applications. Globally, research institutions and companies have made significant strides in developing this technology, with notable advancements in electrolyte materials, electrode designs, and manufacturing processes. The current technical landscape shows varying degrees of maturity across different components of these batteries.

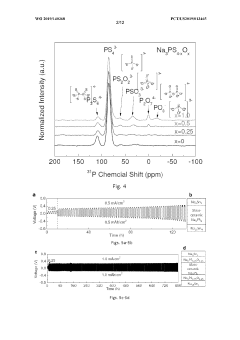

In terms of electrolyte development, several solid-state sodium ion conductors have demonstrated impressive ionic conductivities approaching 10^-3 S/cm at room temperature. NASICON-type materials (Na3Zr2Si2PO12), β-alumina, and sodium-containing sulfide glasses represent the most promising candidates. However, challenges persist in balancing high ionic conductivity with mechanical stability and electrochemical compatibility with electrode materials.

Electrode materials present another significant technical hurdle. Cathode materials such as layered oxides (NaxMO2, where M represents transition metals) and polyanionic compounds show promising sodium storage capabilities but suffer from volume expansion issues during cycling. Anode development has focused on hard carbons, titanium-based oxides, and alloy-type materials, each with their own limitations regarding capacity, cycling stability, and rate capability.

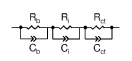

The interface between solid electrolytes and electrodes remains perhaps the most critical challenge. Unlike liquid electrolytes that can maintain intimate contact with electrodes during volume changes, solid-state systems struggle with maintaining stable interfaces. This results in high interfacial resistance and capacity fading over extended cycling. Current research focuses on interface engineering strategies including buffer layers, pressure application during cycling, and novel electrode architectures.

Manufacturing scalability presents another significant barrier to commercialization. Laboratory-scale fabrication methods often involve complex processes that are difficult to scale up economically. Techniques such as cold sintering, tape casting, and co-sintering show promise but require further optimization to achieve the necessary throughput and consistency for mass production.

Geographically, research efforts are distributed across Asia (particularly Japan, China, and South Korea), Europe, and North America. Japan leads in fundamental electrolyte research, while China has made substantial investments in manufacturing capabilities. European research clusters focus on novel materials discovery, and North American efforts emphasize system integration and commercialization pathways.

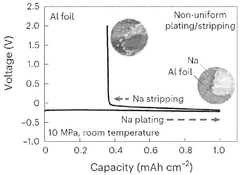

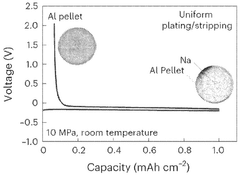

Safety concerns, while improved compared to liquid electrolyte systems, still require attention. Dendrite formation, though less prevalent than in lithium systems, remains a potential failure mode, particularly at high current densities. Additionally, thermal stability at elevated temperatures and mechanical integrity during cycling need further improvement before widespread adoption becomes feasible.

In terms of electrolyte development, several solid-state sodium ion conductors have demonstrated impressive ionic conductivities approaching 10^-3 S/cm at room temperature. NASICON-type materials (Na3Zr2Si2PO12), β-alumina, and sodium-containing sulfide glasses represent the most promising candidates. However, challenges persist in balancing high ionic conductivity with mechanical stability and electrochemical compatibility with electrode materials.

Electrode materials present another significant technical hurdle. Cathode materials such as layered oxides (NaxMO2, where M represents transition metals) and polyanionic compounds show promising sodium storage capabilities but suffer from volume expansion issues during cycling. Anode development has focused on hard carbons, titanium-based oxides, and alloy-type materials, each with their own limitations regarding capacity, cycling stability, and rate capability.

The interface between solid electrolytes and electrodes remains perhaps the most critical challenge. Unlike liquid electrolytes that can maintain intimate contact with electrodes during volume changes, solid-state systems struggle with maintaining stable interfaces. This results in high interfacial resistance and capacity fading over extended cycling. Current research focuses on interface engineering strategies including buffer layers, pressure application during cycling, and novel electrode architectures.

Manufacturing scalability presents another significant barrier to commercialization. Laboratory-scale fabrication methods often involve complex processes that are difficult to scale up economically. Techniques such as cold sintering, tape casting, and co-sintering show promise but require further optimization to achieve the necessary throughput and consistency for mass production.

Geographically, research efforts are distributed across Asia (particularly Japan, China, and South Korea), Europe, and North America. Japan leads in fundamental electrolyte research, while China has made substantial investments in manufacturing capabilities. European research clusters focus on novel materials discovery, and North American efforts emphasize system integration and commercialization pathways.

Safety concerns, while improved compared to liquid electrolyte systems, still require attention. Dendrite formation, though less prevalent than in lithium systems, remains a potential failure mode, particularly at high current densities. Additionally, thermal stability at elevated temperatures and mechanical integrity during cycling need further improvement before widespread adoption becomes feasible.

Current Technical Solutions for Solid-State Sodium Batteries

01 Electrode materials for solid-state sodium batteries

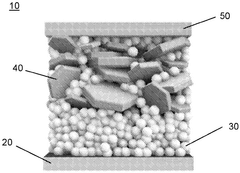

Advanced electrode materials play a crucial role in enhancing the efficiency of solid-state sodium batteries. These materials include specially designed cathodes and anodes that facilitate faster sodium ion transport and improve energy density. Innovations in electrode composition, structure, and manufacturing techniques contribute to better electrochemical performance, longer cycle life, and higher energy efficiency in solid-state sodium battery systems.- Solid-state electrolyte materials for sodium batteries: Various solid-state electrolyte materials can be used in sodium batteries to enhance efficiency and safety. These materials include sodium-ion conducting ceramics, polymer electrolytes, and composite materials that facilitate fast sodium ion transport while preventing dendrite formation. The solid-state electrolytes provide higher ionic conductivity at room temperature, which is crucial for high-efficiency operation of sodium batteries.

- Electrode design and interface engineering: Advanced electrode designs and interface engineering techniques are essential for high-efficiency solid-state sodium batteries. This includes structured electrodes with optimized porosity, surface modifications to reduce interfacial resistance, and novel architectures that accommodate volume changes during cycling. Proper interface engineering between the electrodes and solid electrolyte minimizes resistance and enhances the overall energy efficiency of the battery.

- Novel cathode materials for sodium batteries: High-capacity cathode materials are being developed specifically for solid-state sodium batteries. These include layered transition metal oxides, polyanionic compounds, and sodium-rich materials that offer higher energy density and better cycling stability. The cathode materials are designed to facilitate rapid sodium ion insertion/extraction, which contributes to the high efficiency of the battery system.

- Anode materials and sodium storage mechanisms: Innovative anode materials for solid-state sodium batteries include carbon-based materials, alloys, and conversion-type materials that can store sodium ions efficiently. These materials are designed to have high sodium storage capacity, fast kinetics, and structural stability during repeated cycling. Understanding and optimizing sodium storage mechanisms at the anode is crucial for developing high-efficiency solid-state sodium batteries.

- Manufacturing processes and cell assembly techniques: Advanced manufacturing processes and cell assembly techniques are being developed to produce high-efficiency solid-state sodium batteries at scale. These include dry processing methods, hot pressing techniques, and novel approaches to create intimate contact between components. Proper cell assembly minimizes interfacial resistance and ensures uniform current distribution, which are critical factors for achieving high energy efficiency in solid-state sodium batteries.

02 Solid electrolyte compositions for sodium batteries

Novel solid electrolyte compositions are being developed to enhance ionic conductivity in sodium batteries. These electrolytes facilitate efficient sodium ion transport between electrodes while preventing dendrite formation. Materials such as sodium-based ceramics, polymer electrolytes, and composite structures are engineered to achieve high ionic conductivity at room temperature, improving overall battery efficiency and safety compared to conventional liquid electrolyte systems.Expand Specific Solutions03 Interface engineering for high-efficiency sodium batteries

Interface engineering focuses on optimizing the contact between electrodes and solid electrolytes to reduce resistance and enhance ion transfer. This approach involves surface modifications, buffer layers, and specialized coatings that stabilize the electrode-electrolyte interface. By minimizing interfacial resistance and preventing unwanted side reactions, these techniques significantly improve energy efficiency, power density, and the operational lifespan of solid-state sodium batteries.Expand Specific Solutions04 Manufacturing processes for solid-state sodium batteries

Advanced manufacturing techniques are being developed to produce high-efficiency solid-state sodium batteries at scale. These processes include novel sintering methods, pressure-assisted assembly, and precision deposition techniques that ensure optimal component integration. Innovations in manufacturing help achieve uniform interfaces, reduce defects, and enhance the structural integrity of battery components, resulting in improved performance metrics and production efficiency.Expand Specific Solutions05 System integration and battery management for efficiency optimization

System-level approaches focus on optimizing the overall efficiency of solid-state sodium batteries through advanced battery management systems and thermal regulation. These solutions include sophisticated monitoring algorithms, thermal management strategies, and charge control systems that maximize energy utilization. By optimizing operating conditions and managing battery parameters in real-time, these technologies enhance efficiency, extend cycle life, and improve the practical implementation of solid-state sodium batteries in various applications.Expand Specific Solutions

Key Industry Players and Competitive Landscape

Solid-state sodium battery technology is currently in an early growth phase, with significant research momentum but limited commercial deployment. The market is projected to expand rapidly due to increasing demand for sustainable energy storage solutions, with estimates suggesting a multi-billion dollar opportunity by 2030. Leading academic institutions (University of California, University of Michigan, University of Maryland) are driving fundamental research, while established corporations (Honda, IBM, LG Energy Solution) are developing practical applications. Emerging players like Nextech Batteries are focusing exclusively on next-generation battery technologies. Chinese entities, including CATL and multiple universities, are making substantial investments, indicating a competitive landscape where collaboration between research institutions and industry partners is accelerating technology maturation toward commercial viability.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed advanced solid-state sodium battery technology utilizing a proprietary ceramic-polymer composite electrolyte system that enables stable sodium ion transport while maintaining mechanical flexibility. Their approach incorporates a NASICON-type (Na Super Ionic CONductor) ceramic framework integrated with polymer matrices to overcome the brittleness of pure ceramic electrolytes. The company has achieved energy densities exceeding 160 Wh/kg at the cell level with demonstrated cycle stability of over 1000 cycles while maintaining 80% capacity retention. Their manufacturing process employs roll-to-roll techniques compatible with existing lithium-ion production lines, allowing for cost-effective scaling. LG's solid-state sodium batteries operate effectively across a wider temperature range (-20°C to 60°C) compared to conventional lithium-ion systems, making them suitable for diverse applications from grid storage to electric vehicles.

Strengths: Leverages existing manufacturing infrastructure for cost-effective production; achieves good energy density for sodium technology; demonstrates superior temperature performance. Weaknesses: Energy density still lags behind advanced lithium-ion systems; cycle life needs further improvement for long-term grid storage applications; sodium supply chain less developed than lithium.

Nextech Batteries, Inc.

Technical Solution: Nextech Batteries has developed a proprietary solid-state sodium battery platform utilizing a sulfide-based solid electrolyte system with enhanced ionic conductivity. Their technology employs a unique "composite electrode" architecture that integrates active materials with ionic conductors and electronic conductors in a carefully engineered microstructure to optimize ion transport pathways. Nextech's approach addresses the critical challenge of maintaining intimate contact between solid electrolyte and electrode materials through a proprietary sintering process that minimizes interfacial resistance. Their batteries utilize a high-capacity Prussian white cathode (Na₂FeFe(CN)₆) paired with a carbon-based anode, achieving energy densities of approximately 130-150 Wh/kg with demonstrated cycle life exceeding 1000 cycles at 80% depth of discharge. A key innovation in Nextech's technology is their scalable manufacturing process that enables the production of large-format cells suitable for stationary energy storage applications, with projected costs below $100/kWh at scale.

Strengths: Purpose-built technology for stationary storage applications; scalable manufacturing approach; good cycle life performance; competitive cost projections. Weaknesses: Lower energy density compared to some competitors; limited high-rate performance; technology primarily focused on stationary applications rather than broader use cases.

Core Patents and Innovations in Sodium Battery Technology

Solid electrolyte for sodium batteries

PatentWO2019140368A1

Innovation

- A new class of sodium oxy-sulfide solid-state electrolytes with a microstructure approaching a continuous glass is developed, providing enhanced chemical stability and mechanical strength, achieved through a low-temperature ball-milling and pressing process, allowing for the formation of a nearly flawless glassy structure that is stable with sodium metal or alloys.

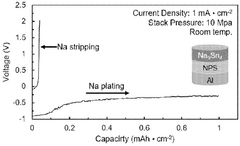

Anode-free sodium all-solid-state battery

PatentWO2025085362A1

Innovation

- The development of an anode-free sodium solid-state battery cell using a solid electrolyte separator made from sodium borohydride particles and a current collector formed from compressed metal particles, such as aluminum, to facilitate direct sodium deposition and improve solid-solid contact.

Material Supply Chain Analysis and Sustainability

The sodium battery material supply chain presents a fundamentally different landscape compared to lithium-based technologies, offering significant advantages in terms of resource abundance and geographical distribution. Sodium resources are approximately 1,000 times more abundant than lithium in the Earth's crust, with substantial deposits available across multiple continents. This abundance translates to potentially lower raw material costs and reduced geopolitical supply risks that currently plague lithium supply chains.

Key raw materials for solid-state sodium batteries include sodium salts (primarily sodium carbonate and sodium hydroxide), solid electrolyte materials (NASICON-type ceramics, sodium beta-alumina, and polymer-based electrolytes), and cathode materials (typically layered transition metal oxides or Prussian blue analogues). The extraction and processing of these materials generally require less energy and water compared to lithium extraction, particularly from hard rock sources.

Current supply chain structures remain underdeveloped compared to lithium-ion battery ecosystems, with limited specialized manufacturing capacity dedicated to sodium battery components. However, this presents an opportunity to establish more regionalized and resilient supply chains from the outset, avoiding the high concentration risks evident in lithium battery production.

From a sustainability perspective, solid-state sodium batteries offer several environmental advantages. Life cycle assessments indicate potential for 20-30% lower carbon footprint compared to conventional lithium-ion batteries, primarily due to less energy-intensive material extraction and processing. Water usage in sodium extraction is significantly lower than lithium brine operations, which can consume 500,000+ gallons of water per ton of lithium produced.

Recycling infrastructure for sodium batteries remains nascent but promising. The higher value of transition metals in cathodes (nickel, manganese) rather than sodium itself will likely drive recycling economics. Current estimates suggest 80-90% of cathode materials could be recoverable through hydrometallurgical processes, though commercial-scale operations have yet to be established.

Supply chain challenges include scaling production of high-quality solid electrolytes, establishing consistent quality standards across the supply chain, and developing specialized manufacturing equipment. The transition from laboratory to industrial scale production represents a significant hurdle, with current solid electrolyte production volumes orders of magnitude below commercial requirements.

Future supply chain resilience will depend on diversified sourcing strategies, co-location of material processing and cell manufacturing facilities, and continued investment in recycling technologies. As the technology matures, vertical integration strategies may emerge among major manufacturers seeking to secure critical material inputs and intellectual property.

Key raw materials for solid-state sodium batteries include sodium salts (primarily sodium carbonate and sodium hydroxide), solid electrolyte materials (NASICON-type ceramics, sodium beta-alumina, and polymer-based electrolytes), and cathode materials (typically layered transition metal oxides or Prussian blue analogues). The extraction and processing of these materials generally require less energy and water compared to lithium extraction, particularly from hard rock sources.

Current supply chain structures remain underdeveloped compared to lithium-ion battery ecosystems, with limited specialized manufacturing capacity dedicated to sodium battery components. However, this presents an opportunity to establish more regionalized and resilient supply chains from the outset, avoiding the high concentration risks evident in lithium battery production.

From a sustainability perspective, solid-state sodium batteries offer several environmental advantages. Life cycle assessments indicate potential for 20-30% lower carbon footprint compared to conventional lithium-ion batteries, primarily due to less energy-intensive material extraction and processing. Water usage in sodium extraction is significantly lower than lithium brine operations, which can consume 500,000+ gallons of water per ton of lithium produced.

Recycling infrastructure for sodium batteries remains nascent but promising. The higher value of transition metals in cathodes (nickel, manganese) rather than sodium itself will likely drive recycling economics. Current estimates suggest 80-90% of cathode materials could be recoverable through hydrometallurgical processes, though commercial-scale operations have yet to be established.

Supply chain challenges include scaling production of high-quality solid electrolytes, establishing consistent quality standards across the supply chain, and developing specialized manufacturing equipment. The transition from laboratory to industrial scale production represents a significant hurdle, with current solid electrolyte production volumes orders of magnitude below commercial requirements.

Future supply chain resilience will depend on diversified sourcing strategies, co-location of material processing and cell manufacturing facilities, and continued investment in recycling technologies. As the technology matures, vertical integration strategies may emerge among major manufacturers seeking to secure critical material inputs and intellectual property.

Cost-Performance Comparison with Lithium-Ion Technologies

When comparing solid-state sodium batteries (SSNBs) with conventional lithium-ion technologies, cost emerges as a significant advantage. Sodium resources are approximately 1,000 times more abundant than lithium in the Earth's crust, with global reserves estimated at 300 billion tons compared to lithium's 21 million tons. This abundance translates directly to raw material costs, with sodium carbonate priced at approximately $300-500 per ton versus lithium carbonate at $10,000-15,000 per ton (as of 2023).

Manufacturing processes for SSNBs potentially offer additional cost benefits. The elimination of flammable liquid electrolytes reduces safety equipment requirements and simplifies battery management systems. Current estimates suggest that at scale, SSNBs could achieve 30-40% lower production costs compared to lithium-ion batteries, primarily due to material costs and simplified manufacturing processes.

Performance metrics present a more nuanced comparison. Current lithium-ion technologies maintain advantages in energy density, with commercial cells achieving 250-300 Wh/kg versus 120-180 Wh/kg for prototype sodium-based cells. However, recent laboratory demonstrations of SSNBs have reached 200 Wh/kg, suggesting the gap is narrowing rapidly.

Cycle life comparisons show promising results for SSNBs. While commercial lithium-ion batteries typically deliver 1,000-2,000 cycles before significant capacity degradation, advanced SSNB prototypes have demonstrated 1,500+ cycles with less than 20% capacity loss. This longevity partially compensates for lower energy density in total lifetime energy storage capacity calculations.

Power density remains a challenge for SSNBs, with current designs achieving 300-500 W/kg compared to 500-2000 W/kg for lithium-ion technologies. This limitation primarily stems from solid-state interface resistance issues that researchers are actively addressing through interface engineering and composite electrolyte development.

Temperature performance represents a significant advantage for SSNBs, which maintain stable operation between -20°C and 80°C, compared to lithium-ion's typical range of 0°C to 45°C. This expanded operating window eliminates the need for costly thermal management systems in many applications, further enhancing the total cost-performance ratio.

The levelized cost of storage (LCOS) metric, which accounts for initial investment, lifetime, efficiency, and maintenance costs, suggests SSNBs could achieve 15-25% lower lifetime costs compared to lithium-ion technologies in stationary storage applications, despite higher initial costs per kWh of capacity.

Manufacturing processes for SSNBs potentially offer additional cost benefits. The elimination of flammable liquid electrolytes reduces safety equipment requirements and simplifies battery management systems. Current estimates suggest that at scale, SSNBs could achieve 30-40% lower production costs compared to lithium-ion batteries, primarily due to material costs and simplified manufacturing processes.

Performance metrics present a more nuanced comparison. Current lithium-ion technologies maintain advantages in energy density, with commercial cells achieving 250-300 Wh/kg versus 120-180 Wh/kg for prototype sodium-based cells. However, recent laboratory demonstrations of SSNBs have reached 200 Wh/kg, suggesting the gap is narrowing rapidly.

Cycle life comparisons show promising results for SSNBs. While commercial lithium-ion batteries typically deliver 1,000-2,000 cycles before significant capacity degradation, advanced SSNB prototypes have demonstrated 1,500+ cycles with less than 20% capacity loss. This longevity partially compensates for lower energy density in total lifetime energy storage capacity calculations.

Power density remains a challenge for SSNBs, with current designs achieving 300-500 W/kg compared to 500-2000 W/kg for lithium-ion technologies. This limitation primarily stems from solid-state interface resistance issues that researchers are actively addressing through interface engineering and composite electrolyte development.

Temperature performance represents a significant advantage for SSNBs, which maintain stable operation between -20°C and 80°C, compared to lithium-ion's typical range of 0°C to 45°C. This expanded operating window eliminates the need for costly thermal management systems in many applications, further enhancing the total cost-performance ratio.

The levelized cost of storage (LCOS) metric, which accounts for initial investment, lifetime, efficiency, and maintenance costs, suggests SSNBs could achieve 15-25% lower lifetime costs compared to lithium-ion technologies in stationary storage applications, despite higher initial costs per kWh of capacity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!