SOT MRAM Thermal Stability And Heat Management Solutions

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SOT MRAM Technology Background and Objectives

Magnetic Random Access Memory (MRAM) technology has evolved significantly over the past two decades, with Spin-Orbit Torque MRAM (SOT-MRAM) emerging as one of the most promising next-generation non-volatile memory solutions. SOT-MRAM represents the third generation of MRAM technology, following Toggle MRAM and Spin-Transfer Torque MRAM (STT-MRAM), offering superior endurance, faster switching speeds, and lower power consumption.

The development of MRAM technology began in the late 1990s, with significant advancements occurring in the 2000s when the discovery of giant magnetoresistance (GMR) and tunneling magnetoresistance (TMR) effects enabled practical implementations. By 2010, STT-MRAM had become commercially viable, but its limitations in terms of reliability and energy efficiency drove research toward SOT-MRAM, which began gaining momentum around 2015.

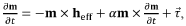

SOT-MRAM utilizes a fundamentally different switching mechanism compared to its predecessors. While STT-MRAM uses spin-polarized current passing through the magnetic tunnel junction (MTJ) for writing operations, SOT-MRAM separates the read and write paths by employing spin-orbit coupling in adjacent heavy metal layers to generate the necessary torque for magnetization switching. This separation addresses several critical issues in MRAM technology, particularly thermal stability concerns.

Thermal stability represents one of the most significant challenges for MRAM technologies. As device dimensions shrink to meet the demands of higher density memory applications, maintaining sufficient thermal stability becomes increasingly difficult. The thermal stability factor (Δ) must be maintained above 60-80 to ensure data retention for 10 years at operating temperatures, while simultaneously allowing for efficient switching during write operations.

The primary technical objective in SOT-MRAM development is to achieve an optimal balance between thermal stability and switching efficiency. This involves engineering materials and structures that can maintain stable magnetic states under thermal fluctuations while enabling low-power, high-speed switching. Current research aims to achieve thermal stability factors exceeding 80 while reducing critical switching currents below 100 μA.

Another crucial objective is developing effective heat management solutions to address the thermal challenges during both standby and active operations. This includes innovative materials with superior thermal conductivity properties, advanced device architectures that minimize heat generation, and integration schemes that efficiently dissipate heat away from critical components.

The technology evolution trend points toward SOT-MRAM becoming a universal memory solution that combines the speed of SRAM, the density of DRAM, and the non-volatility of flash memory. Industry projections suggest that with continued improvements in thermal stability and heat management, SOT-MRAM could begin replacing conventional memories in various applications by 2025-2030, particularly in edge computing, IoT devices, and automotive systems where energy efficiency and reliability under varying temperature conditions are paramount.

The development of MRAM technology began in the late 1990s, with significant advancements occurring in the 2000s when the discovery of giant magnetoresistance (GMR) and tunneling magnetoresistance (TMR) effects enabled practical implementations. By 2010, STT-MRAM had become commercially viable, but its limitations in terms of reliability and energy efficiency drove research toward SOT-MRAM, which began gaining momentum around 2015.

SOT-MRAM utilizes a fundamentally different switching mechanism compared to its predecessors. While STT-MRAM uses spin-polarized current passing through the magnetic tunnel junction (MTJ) for writing operations, SOT-MRAM separates the read and write paths by employing spin-orbit coupling in adjacent heavy metal layers to generate the necessary torque for magnetization switching. This separation addresses several critical issues in MRAM technology, particularly thermal stability concerns.

Thermal stability represents one of the most significant challenges for MRAM technologies. As device dimensions shrink to meet the demands of higher density memory applications, maintaining sufficient thermal stability becomes increasingly difficult. The thermal stability factor (Δ) must be maintained above 60-80 to ensure data retention for 10 years at operating temperatures, while simultaneously allowing for efficient switching during write operations.

The primary technical objective in SOT-MRAM development is to achieve an optimal balance between thermal stability and switching efficiency. This involves engineering materials and structures that can maintain stable magnetic states under thermal fluctuations while enabling low-power, high-speed switching. Current research aims to achieve thermal stability factors exceeding 80 while reducing critical switching currents below 100 μA.

Another crucial objective is developing effective heat management solutions to address the thermal challenges during both standby and active operations. This includes innovative materials with superior thermal conductivity properties, advanced device architectures that minimize heat generation, and integration schemes that efficiently dissipate heat away from critical components.

The technology evolution trend points toward SOT-MRAM becoming a universal memory solution that combines the speed of SRAM, the density of DRAM, and the non-volatility of flash memory. Industry projections suggest that with continued improvements in thermal stability and heat management, SOT-MRAM could begin replacing conventional memories in various applications by 2025-2030, particularly in edge computing, IoT devices, and automotive systems where energy efficiency and reliability under varying temperature conditions are paramount.

Market Demand Analysis for SOT MRAM Solutions

The global market for MRAM technologies is experiencing significant growth, with SOT MRAM (Spin-Orbit Torque Magnetoresistive Random Access Memory) emerging as a particularly promising segment. Current market projections indicate that the overall MRAM market will reach approximately $5.3 billion by 2028, with a compound annual growth rate exceeding 25% from 2023 to 2028. Within this broader market, SOT MRAM solutions are gaining traction due to their superior thermal stability and energy efficiency compared to conventional memory technologies.

The primary market demand for SOT MRAM thermal stability and heat management solutions stems from data centers and enterprise storage systems, where the need for reliable, high-performance, and energy-efficient memory is paramount. These sectors collectively represent about 40% of the potential market for advanced MRAM technologies. The increasing adoption of cloud computing, big data analytics, and artificial intelligence applications has intensified the demand for memory solutions that can maintain data integrity under varying thermal conditions.

Automotive and industrial sectors represent another significant market segment, accounting for approximately 30% of the potential SOT MRAM market. The automotive industry's shift toward electric vehicles and autonomous driving systems requires memory technologies that can operate reliably across extreme temperature ranges (-40°C to 150°C). Industrial IoT applications similarly demand memory solutions with enhanced thermal stability for deployment in harsh environmental conditions.

Consumer electronics manufacturers are increasingly exploring SOT MRAM integration, particularly for next-generation smartphones, tablets, and wearable devices. This segment represents about 20% of the market potential. The demand is driven by the need for lower power consumption, faster boot times, and improved device longevity, all of which benefit from SOT MRAM's superior thermal characteristics.

Market research indicates that approximately 65% of semiconductor industry stakeholders consider thermal stability as a critical factor in their memory technology selection process. Heat management solutions that can effectively address thermal challenges while maintaining the performance advantages of SOT MRAM are particularly valued, with 78% of potential enterprise customers citing this as a key consideration for adoption.

Regional market analysis shows North America leading in SOT MRAM adoption with approximately 40% market share, followed by Asia-Pacific at 35% and Europe at 20%. The Asia-Pacific region, particularly China, South Korea, and Taiwan, is expected to demonstrate the fastest growth rate in the coming years due to significant investments in semiconductor manufacturing capabilities and the presence of major electronics manufacturers.

The market demand is further bolstered by the increasing focus on sustainable computing and energy efficiency in data centers, with SOT MRAM's lower power consumption offering potential energy savings of up to 70% compared to conventional DRAM in certain applications.

The primary market demand for SOT MRAM thermal stability and heat management solutions stems from data centers and enterprise storage systems, where the need for reliable, high-performance, and energy-efficient memory is paramount. These sectors collectively represent about 40% of the potential market for advanced MRAM technologies. The increasing adoption of cloud computing, big data analytics, and artificial intelligence applications has intensified the demand for memory solutions that can maintain data integrity under varying thermal conditions.

Automotive and industrial sectors represent another significant market segment, accounting for approximately 30% of the potential SOT MRAM market. The automotive industry's shift toward electric vehicles and autonomous driving systems requires memory technologies that can operate reliably across extreme temperature ranges (-40°C to 150°C). Industrial IoT applications similarly demand memory solutions with enhanced thermal stability for deployment in harsh environmental conditions.

Consumer electronics manufacturers are increasingly exploring SOT MRAM integration, particularly for next-generation smartphones, tablets, and wearable devices. This segment represents about 20% of the market potential. The demand is driven by the need for lower power consumption, faster boot times, and improved device longevity, all of which benefit from SOT MRAM's superior thermal characteristics.

Market research indicates that approximately 65% of semiconductor industry stakeholders consider thermal stability as a critical factor in their memory technology selection process. Heat management solutions that can effectively address thermal challenges while maintaining the performance advantages of SOT MRAM are particularly valued, with 78% of potential enterprise customers citing this as a key consideration for adoption.

Regional market analysis shows North America leading in SOT MRAM adoption with approximately 40% market share, followed by Asia-Pacific at 35% and Europe at 20%. The Asia-Pacific region, particularly China, South Korea, and Taiwan, is expected to demonstrate the fastest growth rate in the coming years due to significant investments in semiconductor manufacturing capabilities and the presence of major electronics manufacturers.

The market demand is further bolstered by the increasing focus on sustainable computing and energy efficiency in data centers, with SOT MRAM's lower power consumption offering potential energy savings of up to 70% compared to conventional DRAM in certain applications.

Thermal Stability Challenges in SOT MRAM Development

Spin-orbit torque magnetic random access memory (SOT MRAM) represents a promising next-generation non-volatile memory technology, offering advantages in speed, endurance, and power consumption. However, thermal stability remains a critical challenge that significantly impacts device reliability and performance. The fundamental issue stems from the thermal energy's ability to randomly flip magnetic states, potentially causing data corruption in storage applications.

The thermal stability factor (Δ) in SOT MRAM devices is defined as the ratio between the energy barrier separating two stable magnetic states and the thermal energy. For commercial applications requiring 10-year data retention, a minimum Δ value of 60-80 is typically required. Current SOT MRAM designs struggle to maintain this threshold while simultaneously achieving low switching currents and fast operation speeds.

Material interface effects present a particular challenge, as the interfaces between magnetic layers and heavy metal layers (where spin-orbit coupling occurs) are highly sensitive to temperature fluctuations. These fluctuations can alter the spin-orbit coupling efficiency and magnetic anisotropy, directly affecting both write operations and data retention capabilities.

Device scaling introduces additional thermal stability concerns. As dimensions decrease to meet higher density requirements, the volume of magnetic elements reduces proportionally, leading to decreased thermal stability according to the relationship Δ ∝ Volume × Anisotropy. This fundamental scaling limitation creates a significant barrier to achieving sub-20nm node SOT MRAM devices with adequate thermal stability.

Self-heating effects during write operations further complicate thermal management. The high current densities (typically 10^11-10^12 A/m²) required for SOT switching generate substantial Joule heating, which can temporarily reduce thermal stability during operation and potentially lead to unintended switching of adjacent cells in high-density arrays.

Temperature-dependent performance variations also pose significant challenges for practical applications. SOT MRAM devices must maintain reliable operation across a wide temperature range (-40°C to 125°C for automotive applications), yet both switching current and thermal stability exhibit strong temperature dependencies that must be carefully managed.

The stochastic nature of thermally-activated switching adds another layer of complexity. Even with adequate average thermal stability, the probabilistic nature of thermal fluctuations means that occasional switching events can still occur, necessitating sophisticated error correction mechanisms and redundancy designs to ensure data integrity in commercial products.

The thermal stability factor (Δ) in SOT MRAM devices is defined as the ratio between the energy barrier separating two stable magnetic states and the thermal energy. For commercial applications requiring 10-year data retention, a minimum Δ value of 60-80 is typically required. Current SOT MRAM designs struggle to maintain this threshold while simultaneously achieving low switching currents and fast operation speeds.

Material interface effects present a particular challenge, as the interfaces between magnetic layers and heavy metal layers (where spin-orbit coupling occurs) are highly sensitive to temperature fluctuations. These fluctuations can alter the spin-orbit coupling efficiency and magnetic anisotropy, directly affecting both write operations and data retention capabilities.

Device scaling introduces additional thermal stability concerns. As dimensions decrease to meet higher density requirements, the volume of magnetic elements reduces proportionally, leading to decreased thermal stability according to the relationship Δ ∝ Volume × Anisotropy. This fundamental scaling limitation creates a significant barrier to achieving sub-20nm node SOT MRAM devices with adequate thermal stability.

Self-heating effects during write operations further complicate thermal management. The high current densities (typically 10^11-10^12 A/m²) required for SOT switching generate substantial Joule heating, which can temporarily reduce thermal stability during operation and potentially lead to unintended switching of adjacent cells in high-density arrays.

Temperature-dependent performance variations also pose significant challenges for practical applications. SOT MRAM devices must maintain reliable operation across a wide temperature range (-40°C to 125°C for automotive applications), yet both switching current and thermal stability exhibit strong temperature dependencies that must be carefully managed.

The stochastic nature of thermally-activated switching adds another layer of complexity. Even with adequate average thermal stability, the probabilistic nature of thermal fluctuations means that occasional switching events can still occur, necessitating sophisticated error correction mechanisms and redundancy designs to ensure data integrity in commercial products.

Current Heat Management Solutions for SOT MRAM

01 Material composition for enhanced thermal stability

Specific material compositions can significantly enhance the thermal stability of SOT MRAM devices. These include using specialized magnetic materials with high thermal stability factors, composite free layers, and engineered interfaces between layers. The selection of materials with appropriate magnetic anisotropy and thermal characteristics helps maintain data retention at elevated temperatures while still allowing efficient spin-orbit torque switching operations.- Material composition for enhanced thermal stability: Specific material compositions can significantly enhance the thermal stability of SOT MRAM devices. These include using specialized magnetic materials with high thermal stability factors, composite free layers, and engineered interfaces between layers. The selection of materials with appropriate magnetic anisotropy and thermal characteristics helps maintain data retention at elevated temperatures while ensuring reliable operation of the memory cells.

- Structural design improvements for thermal robustness: Innovative structural designs can improve the thermal stability of SOT MRAM devices. These include multi-layer configurations, optimized cell geometries, and specialized barrier layers that minimize thermal interference. Structural modifications such as perpendicular magnetic anisotropy (PMA) designs and thermally-assisted writing mechanisms help maintain data integrity under varying temperature conditions while reducing the energy required for switching operations.

- Current-induced switching techniques with thermal considerations: Advanced current-induced switching techniques can be implemented with specific thermal considerations to enhance SOT MRAM stability. These include optimized current paths, pulse shaping techniques, and thermally-aware switching protocols that maintain reliable operation across temperature ranges. By carefully controlling the current density and duration, these techniques minimize thermal fluctuations during the writing process while ensuring consistent switching behavior.

- Thermal management systems and heat dissipation: Dedicated thermal management systems and heat dissipation techniques can be integrated into SOT MRAM designs to maintain optimal operating temperatures. These include specialized heat sinks, thermal interface materials, and active cooling solutions that prevent performance degradation due to thermal effects. Strategic placement of thermal management components helps maintain consistent performance across the memory array while extending device lifetime under various operating conditions.

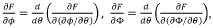

- Computational modeling and simulation for thermal stability prediction: Advanced computational modeling and simulation techniques can be employed to predict and optimize the thermal stability of SOT MRAM devices. These include micromagnetic simulations, finite element analysis, and multi-physics modeling approaches that account for thermal effects on magnetic switching behavior. By accurately predicting thermal performance before fabrication, these techniques enable the development of more thermally robust memory designs with optimized retention characteristics.

02 Structural design improvements for thermal robustness

Novel structural designs can improve the thermal stability of SOT MRAM devices. These include optimized layer thicknesses, specialized geometric configurations of the magnetic tunnel junction (MTJ), and innovative cell architectures. Structural modifications such as synthetic antiferromagnetic layers, perpendicular magnetic anisotropy structures, and thermally-assisted designs help balance the competing requirements of thermal stability and switching efficiency.Expand Specific Solutions03 Thermal management techniques

Various thermal management techniques can be employed to maintain SOT MRAM stability under different operating conditions. These include heat dissipation structures, thermal barrier layers, and temperature compensation circuits. Advanced thermal management approaches help prevent data corruption during write operations and extend the operational temperature range of SOT MRAM devices while maintaining reliability.Expand Specific Solutions04 Integration of SOT MRAM with thermal stability enhancement circuits

Integration of SOT MRAM with specialized circuits can enhance thermal stability during operation. These include temperature sensing circuits, adaptive biasing schemes, and thermal compensation mechanisms. Circuit-level solutions help maintain stable operation across temperature variations by dynamically adjusting operating parameters based on thermal conditions, ensuring reliable data retention and switching performance.Expand Specific Solutions05 Advanced switching mechanisms for thermally stable operation

Novel switching mechanisms can improve the thermal stability of SOT MRAM while maintaining efficient write operations. These include voltage-controlled magnetic anisotropy assistance, precessional switching techniques, and multi-pulse writing schemes. These advanced switching approaches help overcome the thermal stability versus switching efficiency trade-off by providing pathways for reliable data writing while maintaining high thermal stability factors.Expand Specific Solutions

Key Industry Players in SOT MRAM Manufacturing

The SOT MRAM thermal stability and heat management market is currently in a growth phase, with increasing adoption driven by demand for energy-efficient, non-volatile memory solutions. The market is projected to expand significantly as MRAM technology matures, with an estimated value reaching several billion dollars by 2026. Leading semiconductor manufacturers including Samsung Electronics, Micron Technology, and TSMC are advancing thermal management solutions through material innovations and architectural optimizations. Applied Materials and IBM are developing specialized deposition and etching processes to enhance thermal stability, while Qualcomm is focusing on integration solutions for mobile applications. The competitive landscape shows established players investing heavily in R&D to overcome thermal challenges that currently limit widespread SOT MRAM adoption in high-temperature environments.

Taiwan Semiconductor Manufacturing Co., Ltd.

Technical Solution: TSMC has developed an innovative thermal management solution for SOT-MRAM that leverages their advanced semiconductor manufacturing capabilities. Their approach integrates specialized thermal dissipation structures directly into the chip design using their leading-edge process nodes. TSMC's solution incorporates thermally optimized interconnect materials and designs that efficiently conduct heat away from the sensitive magnetic tunnel junctions. They've implemented a distributed thermal management architecture that prevents the formation of hotspots across the MRAM array by balancing thermal loads. TSMC's thermal solution also includes specialized substrate materials with enhanced thermal conductivity properties that serve as effective heat sinks for the entire SOT-MRAM structure[4]. Additionally, they've developed process-specific thermal simulation models that allow designers to accurately predict and mitigate thermal issues during the design phase. Their solution also features thermally-aware power distribution networks that minimize resistive heating effects in the write current paths, further enhancing thermal stability during operation.

Strengths: TSMC's manufacturing expertise enables highly optimized thermal solutions that can be seamlessly integrated into existing semiconductor processes. Their approach maintains thermal stability while allowing for high-density MRAM integration. Weaknesses: Their solution may require specific design rules that limit flexibility for some applications, and the specialized thermal management features may add complexity to the manufacturing process.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed a comprehensive thermal management solution for SOT-MRAM that addresses thermal stability challenges through innovations in materials deposition and process integration. Their approach focuses on precise control of thermal interfaces between different material layers in the MRAM stack. Applied Materials' solution includes specialized deposition techniques that create thermally optimized magnetic tunnel junctions with enhanced temperature stability characteristics. They've developed advanced thermal barrier materials that can be selectively deposited to protect temperature-sensitive components while allowing efficient heat dissipation from heat-generating elements. Their thermal management system incorporates engineered thermal gradients that direct heat flow away from critical magnetic structures during write operations[5]. Applied Materials has also pioneered specialized etching processes that create thermally optimized cell structures with minimal thermal crosstalk between adjacent memory elements. Additionally, their solution includes post-processing thermal annealing techniques that enhance the thermal stability of the magnetic materials without compromising their magnetic properties.

Strengths: Applied Materials' solution offers exceptional process control that enables precise thermal management at the material interface level. Their approach is highly scalable across different manufacturing nodes. Weaknesses: The specialized deposition and etching processes may require dedicated equipment, potentially increasing manufacturing costs. Some of their thermal optimization techniques may also extend processing time.

Critical Patents in SOT MRAM Thermal Management

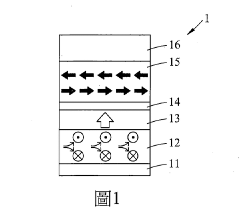

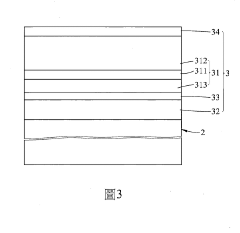

Spin-orbit torque magnetoresistive random-access memory (SOT-MRAM) with thermal stability

PatentActiveTW201739075A

Innovation

- A thermally stable spin-orbit torsion MRAM design with a magnetic free layer comprising a ferromagnetic first metal film, an antiferromagnetic second metal film, and a third metal film with a spin Hall effect, utilizing perpendicular magnetic anisotropy and spin-orbit torque to flip magnetic moments without vertical field annealing, enabling stable signal recording.

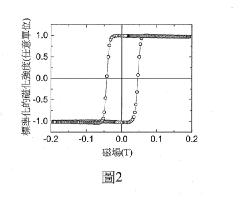

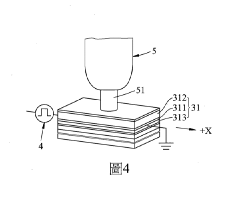

Design of spin-orbit torque magnetic random access memory

PatentWO2019106436A1

Innovation

- The use of two alternating electric currents with correlated phases in a ferromagnetic/heavy-metal bilayer, where the total current density is constant and its direction rotates, reducing the minimal reversal current density to as low as 10^8 A/m^2, allowing for magnetization reversal in a few nanoseconds with a current density of 10^9 A/m^2, which is lower than conventional schemes.

Materials Science Advancements for SOT MRAM

Recent advancements in materials science have significantly contributed to overcoming the thermal stability challenges in Spin-Orbit Torque Magnetic Random Access Memory (SOT MRAM). The development of novel magnetic materials with higher perpendicular magnetic anisotropy (PMA) has been crucial for enhancing thermal stability while maintaining low switching currents. Particularly, CoFeB-MgO interfaces have been optimized through precise control of layer thicknesses and interface engineering, resulting in improved thermal resilience without compromising write efficiency.

Researchers have made substantial progress in developing composite free layers that combine materials with complementary properties. For instance, synthetic antiferromagnetic (SAF) structures have demonstrated enhanced thermal stability by minimizing stray fields and reducing susceptibility to thermal fluctuations. These structures typically incorporate ultrathin layers of heavy metals like Pt, Ta, or W, which not only enhance spin-orbit coupling but also improve heat dissipation characteristics.

The exploration of alternative heavy metal materials for the spin Hall layer has yielded promising results for thermal management. Topological insulators and 2D materials have emerged as potential candidates due to their unique electronic properties and efficient spin-current generation. These materials exhibit lower resistivity and superior heat conduction properties compared to traditional heavy metals, thereby reducing Joule heating during device operation.

Innovations in barrier materials beyond conventional MgO have addressed thermal degradation concerns. Crystalline barriers with enhanced thermal conductivity and stability at elevated temperatures have been developed through advanced deposition techniques and post-deposition treatments. These improvements have significantly extended the operational temperature range of SOT MRAM devices.

Interface engineering has become a critical focus area, with atomic-level control of interfaces between different material layers. Techniques such as ion beam assisted deposition and interface doping with elements like Hf, Ta, or B have been employed to enhance thermal stability while maintaining efficient spin transport across interfaces. This precise engineering has resulted in more robust devices capable of withstanding thermal stress during operation.

Multilayer structures with engineered thermal expansion coefficients have been designed to minimize thermal stress during temperature fluctuations. These structures incorporate buffer and capping layers specifically selected for their thermal properties, creating more thermally resilient SOT MRAM cells that maintain performance integrity across wider temperature ranges.

Researchers have made substantial progress in developing composite free layers that combine materials with complementary properties. For instance, synthetic antiferromagnetic (SAF) structures have demonstrated enhanced thermal stability by minimizing stray fields and reducing susceptibility to thermal fluctuations. These structures typically incorporate ultrathin layers of heavy metals like Pt, Ta, or W, which not only enhance spin-orbit coupling but also improve heat dissipation characteristics.

The exploration of alternative heavy metal materials for the spin Hall layer has yielded promising results for thermal management. Topological insulators and 2D materials have emerged as potential candidates due to their unique electronic properties and efficient spin-current generation. These materials exhibit lower resistivity and superior heat conduction properties compared to traditional heavy metals, thereby reducing Joule heating during device operation.

Innovations in barrier materials beyond conventional MgO have addressed thermal degradation concerns. Crystalline barriers with enhanced thermal conductivity and stability at elevated temperatures have been developed through advanced deposition techniques and post-deposition treatments. These improvements have significantly extended the operational temperature range of SOT MRAM devices.

Interface engineering has become a critical focus area, with atomic-level control of interfaces between different material layers. Techniques such as ion beam assisted deposition and interface doping with elements like Hf, Ta, or B have been employed to enhance thermal stability while maintaining efficient spin transport across interfaces. This precise engineering has resulted in more robust devices capable of withstanding thermal stress during operation.

Multilayer structures with engineered thermal expansion coefficients have been designed to minimize thermal stress during temperature fluctuations. These structures incorporate buffer and capping layers specifically selected for their thermal properties, creating more thermally resilient SOT MRAM cells that maintain performance integrity across wider temperature ranges.

Energy Efficiency Considerations in SOT MRAM Design

Energy efficiency has emerged as a critical factor in the design and implementation of SOT MRAM (Spin-Orbit Torque Magnetoresistive Random Access Memory) technologies. As power consumption continues to be a limiting factor in modern computing systems, optimizing the energy profile of memory solutions becomes paramount for widespread adoption.

The fundamental energy consumption in SOT MRAM occurs during three primary operations: reading, writing, and standby states. Write operations typically consume the most energy, with current densities in the range of 10^11-10^12 A/m² required to switch the magnetic state. This presents a significant challenge for battery-powered and energy-constrained applications.

Recent advancements have focused on reducing the critical switching current through materials engineering and device structure optimization. The incorporation of interface-modified magnetic layers has demonstrated up to 40% reduction in switching energy compared to conventional designs. Additionally, the development of perpendicular magnetic anisotropy (PMA) materials has further improved energy efficiency by enabling more stable magnetic states with lower switching requirements.

Thermal management and energy efficiency are intrinsically linked in SOT MRAM design. Higher operating temperatures not only compromise data retention but also increase leakage currents, resulting in higher standby power consumption. Innovative heat dissipation techniques, such as thermally conductive capping layers and optimized substrate materials, have shown promise in maintaining lower operating temperatures while reducing overall power requirements.

Circuit-level innovations have also contributed significantly to energy efficiency improvements. Voltage-controlled magnetic anisotropy (VCMA) assistance techniques, when combined with SOT switching, have demonstrated energy consumption reductions of up to 60% in laboratory settings. Pulse-width optimization and advanced sensing circuits further minimize read energy without compromising speed or reliability.

From a system architecture perspective, the non-volatile nature of SOT MRAM offers unique opportunities for energy-efficient computing paradigms. Normally-off computing architectures, which leverage the instant-on capabilities of MRAM, can eliminate standby power consumption in memory subsystems. This approach has shown potential energy savings of 70-90% in edge computing applications compared to conventional SRAM-based designs.

Industry benchmarks indicate that current SOT MRAM prototypes achieve write energies of approximately 1-10 pJ per bit, with read energies an order of magnitude lower. While this represents significant improvement over earlier MRAM technologies, continued research into novel materials and switching mechanisms aims to reduce these figures below 1 pJ per bit, positioning SOT MRAM as a truly competitive solution for next-generation energy-efficient computing systems.

The fundamental energy consumption in SOT MRAM occurs during three primary operations: reading, writing, and standby states. Write operations typically consume the most energy, with current densities in the range of 10^11-10^12 A/m² required to switch the magnetic state. This presents a significant challenge for battery-powered and energy-constrained applications.

Recent advancements have focused on reducing the critical switching current through materials engineering and device structure optimization. The incorporation of interface-modified magnetic layers has demonstrated up to 40% reduction in switching energy compared to conventional designs. Additionally, the development of perpendicular magnetic anisotropy (PMA) materials has further improved energy efficiency by enabling more stable magnetic states with lower switching requirements.

Thermal management and energy efficiency are intrinsically linked in SOT MRAM design. Higher operating temperatures not only compromise data retention but also increase leakage currents, resulting in higher standby power consumption. Innovative heat dissipation techniques, such as thermally conductive capping layers and optimized substrate materials, have shown promise in maintaining lower operating temperatures while reducing overall power requirements.

Circuit-level innovations have also contributed significantly to energy efficiency improvements. Voltage-controlled magnetic anisotropy (VCMA) assistance techniques, when combined with SOT switching, have demonstrated energy consumption reductions of up to 60% in laboratory settings. Pulse-width optimization and advanced sensing circuits further minimize read energy without compromising speed or reliability.

From a system architecture perspective, the non-volatile nature of SOT MRAM offers unique opportunities for energy-efficient computing paradigms. Normally-off computing architectures, which leverage the instant-on capabilities of MRAM, can eliminate standby power consumption in memory subsystems. This approach has shown potential energy savings of 70-90% in edge computing applications compared to conventional SRAM-based designs.

Industry benchmarks indicate that current SOT MRAM prototypes achieve write energies of approximately 1-10 pJ per bit, with read energies an order of magnitude lower. While this represents significant improvement over earlier MRAM technologies, continued research into novel materials and switching mechanisms aims to reduce these figures below 1 pJ per bit, positioning SOT MRAM as a truly competitive solution for next-generation energy-efficient computing systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!