Standardization of Superhydrophobic Coating for Water Filtration Systems

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Superhydrophobic Coating Technology Evolution and Objectives

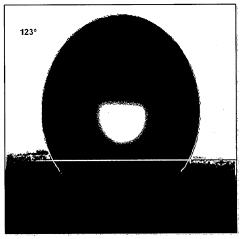

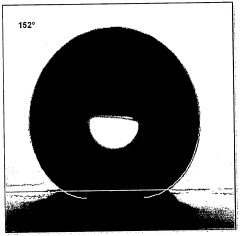

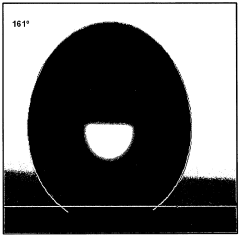

Superhydrophobic surfaces, characterized by water contact angles exceeding 150° and sliding angles below 10°, have emerged as a revolutionary technology inspired by natural phenomena such as the lotus leaf effect. The evolution of this technology began in the early 1990s with fundamental research into surface wettability, progressing through significant breakthroughs in the 2000s when researchers developed the first synthetic superhydrophobic coatings with practical applications.

The field experienced rapid advancement between 2010-2015 with the development of more durable coatings capable of withstanding harsh environmental conditions. This period marked the transition from laboratory curiosities to commercially viable products, particularly in industrial applications. By 2018-2020, researchers successfully addressed key limitations regarding coating durability and scalability, enabling wider adoption across various sectors.

Current technological trends focus on developing standardized superhydrophobic coatings specifically engineered for water filtration systems. These specialized coatings aim to reduce biofouling, enhance filtration efficiency, and extend the operational lifespan of filtration membranes. The integration of nanotechnology has been particularly influential, allowing precise control over surface morphology at the nanoscale to optimize hydrophobic properties.

The primary technical objectives for standardization include establishing uniform testing protocols to evaluate coating performance under various water conditions, developing consistent manufacturing processes to ensure quality control across production batches, and creating industry-wide specifications for durability, chemical resistance, and anti-fouling capabilities. These standards must address the unique challenges of water filtration environments, including continuous water exposure, varying pH levels, and the presence of biological contaminants.

Long-term technological goals include developing self-healing superhydrophobic coatings capable of maintaining performance despite mechanical damage, creating environmentally friendly formulations free from harmful chemicals such as perfluorinated compounds, and achieving cost-effective manufacturing methods suitable for large-scale industrial implementation. The ultimate objective is to establish a comprehensive framework that enables consistent production of superhydrophobic coatings with predictable performance characteristics.

The standardization effort must balance innovation with practical implementation considerations, addressing not only technical performance but also economic viability, environmental impact, and regulatory compliance. Success in this domain would significantly advance water treatment technologies, potentially revolutionizing approaches to global water purification challenges while establishing a foundation for future innovations in surface engineering for fluid management applications.

The field experienced rapid advancement between 2010-2015 with the development of more durable coatings capable of withstanding harsh environmental conditions. This period marked the transition from laboratory curiosities to commercially viable products, particularly in industrial applications. By 2018-2020, researchers successfully addressed key limitations regarding coating durability and scalability, enabling wider adoption across various sectors.

Current technological trends focus on developing standardized superhydrophobic coatings specifically engineered for water filtration systems. These specialized coatings aim to reduce biofouling, enhance filtration efficiency, and extend the operational lifespan of filtration membranes. The integration of nanotechnology has been particularly influential, allowing precise control over surface morphology at the nanoscale to optimize hydrophobic properties.

The primary technical objectives for standardization include establishing uniform testing protocols to evaluate coating performance under various water conditions, developing consistent manufacturing processes to ensure quality control across production batches, and creating industry-wide specifications for durability, chemical resistance, and anti-fouling capabilities. These standards must address the unique challenges of water filtration environments, including continuous water exposure, varying pH levels, and the presence of biological contaminants.

Long-term technological goals include developing self-healing superhydrophobic coatings capable of maintaining performance despite mechanical damage, creating environmentally friendly formulations free from harmful chemicals such as perfluorinated compounds, and achieving cost-effective manufacturing methods suitable for large-scale industrial implementation. The ultimate objective is to establish a comprehensive framework that enables consistent production of superhydrophobic coatings with predictable performance characteristics.

The standardization effort must balance innovation with practical implementation considerations, addressing not only technical performance but also economic viability, environmental impact, and regulatory compliance. Success in this domain would significantly advance water treatment technologies, potentially revolutionizing approaches to global water purification challenges while establishing a foundation for future innovations in surface engineering for fluid management applications.

Market Analysis for Advanced Water Filtration Solutions

The global water filtration market is experiencing robust growth, driven by increasing water scarcity, deteriorating water quality, and stringent regulations regarding water safety. Currently valued at approximately 30 billion USD, the market is projected to reach 44 billion USD by 2028, representing a compound annual growth rate of 6.8%. Advanced filtration technologies, particularly those incorporating superhydrophobic coatings, are positioned to capture a significant portion of this expanding market.

Demand for superhydrophobic coating technologies in water filtration systems is primarily fueled by their ability to reduce biofouling, minimize maintenance requirements, and extend system lifespan. Municipal water treatment facilities represent the largest market segment, accounting for nearly 40% of the total market share, followed by industrial applications at 35% and residential systems at 25%.

Regionally, North America and Europe currently dominate the advanced water filtration market, collectively holding approximately 60% market share. However, the Asia-Pacific region is emerging as the fastest-growing market with an annual growth rate exceeding 8%, driven by rapid industrialization, urbanization, and increasing government investments in water infrastructure in countries like China and India.

Consumer behavior analysis indicates a growing willingness to pay premium prices for advanced filtration solutions that offer superior performance and reduced maintenance requirements. This trend is particularly evident in developed economies where end-users increasingly prioritize sustainability and long-term operational efficiency over initial acquisition costs.

Market penetration of superhydrophobic coating technologies remains relatively low at approximately 15% of the total filtration market, indicating substantial growth potential. Early adopters have primarily been high-end industrial applications and specialized municipal systems where performance justifies the higher initial investment.

Competitive analysis reveals that the market for advanced filtration solutions remains fragmented, with no single company controlling more than 12% of the global market share. This fragmentation presents opportunities for new entrants with innovative technologies, particularly those offering standardized superhydrophobic coating solutions that can be integrated into existing filtration systems.

Market forecasts suggest that standardized superhydrophobic coatings could potentially capture 25-30% of the water filtration market within the next decade, representing a market opportunity of approximately 12 billion USD. This growth trajectory is contingent upon successful standardization efforts, cost reduction through economies of scale, and increased awareness of the technology's benefits among end-users and system integrators.

Demand for superhydrophobic coating technologies in water filtration systems is primarily fueled by their ability to reduce biofouling, minimize maintenance requirements, and extend system lifespan. Municipal water treatment facilities represent the largest market segment, accounting for nearly 40% of the total market share, followed by industrial applications at 35% and residential systems at 25%.

Regionally, North America and Europe currently dominate the advanced water filtration market, collectively holding approximately 60% market share. However, the Asia-Pacific region is emerging as the fastest-growing market with an annual growth rate exceeding 8%, driven by rapid industrialization, urbanization, and increasing government investments in water infrastructure in countries like China and India.

Consumer behavior analysis indicates a growing willingness to pay premium prices for advanced filtration solutions that offer superior performance and reduced maintenance requirements. This trend is particularly evident in developed economies where end-users increasingly prioritize sustainability and long-term operational efficiency over initial acquisition costs.

Market penetration of superhydrophobic coating technologies remains relatively low at approximately 15% of the total filtration market, indicating substantial growth potential. Early adopters have primarily been high-end industrial applications and specialized municipal systems where performance justifies the higher initial investment.

Competitive analysis reveals that the market for advanced filtration solutions remains fragmented, with no single company controlling more than 12% of the global market share. This fragmentation presents opportunities for new entrants with innovative technologies, particularly those offering standardized superhydrophobic coating solutions that can be integrated into existing filtration systems.

Market forecasts suggest that standardized superhydrophobic coatings could potentially capture 25-30% of the water filtration market within the next decade, representing a market opportunity of approximately 12 billion USD. This growth trajectory is contingent upon successful standardization efforts, cost reduction through economies of scale, and increased awareness of the technology's benefits among end-users and system integrators.

Global Status and Technical Barriers in Superhydrophobic Coatings

The global landscape of superhydrophobic coating technology presents a complex picture of advancement and challenges. Currently, research institutions and companies across North America, Europe, and East Asia lead in developing superhydrophobic coatings for water filtration applications. The United States, China, Japan, Germany, and South Korea have established significant patent portfolios and research outputs in this domain, with notable contributions from institutions like MIT, Stanford University, Chinese Academy of Sciences, and Max Planck Institute.

Despite considerable progress, the field faces substantial technical barriers that impede widespread commercial adoption. A primary challenge is durability - most superhydrophobic coatings exhibit limited mechanical robustness and wear resistance under operational conditions. When subjected to continuous water flow, abrasion, and chemical exposure typical in filtration systems, these coatings often degrade rapidly, losing their water-repellent properties within weeks or months rather than maintaining effectiveness for years as required for commercial viability.

Scalability represents another significant obstacle. Laboratory-scale fabrication techniques such as chemical vapor deposition, sol-gel processes, and layer-by-layer assembly have demonstrated excellent superhydrophobic properties. However, translating these methods to industrial-scale production while maintaining consistent quality, performance, and cost-effectiveness remains problematic. The intricate micro/nano-hierarchical structures essential for superhydrophobicity are particularly difficult to reproduce uniformly across large surface areas.

Chemical stability presents additional challenges, especially in water treatment applications where coatings must withstand exposure to various contaminants, disinfectants, and pH variations. Many current formulations show vulnerability to chemical degradation, particularly from oxidizing agents commonly used in water treatment processes.

Environmental and health concerns further complicate development efforts. Traditional superhydrophobic coatings often incorporate fluorinated compounds that raise significant environmental persistence and bioaccumulation concerns. Regulatory frameworks in Europe and North America increasingly restrict these substances, driving research toward environmentally benign alternatives that frequently demonstrate inferior performance or durability.

Standardization itself represents a critical barrier. The field lacks universally accepted testing protocols and performance metrics for evaluating superhydrophobic coatings in water filtration contexts. Different research groups employ varied methodologies for measuring contact angles, sliding angles, and durability, making direct comparisons between studies challenging and hindering systematic progress toward optimized solutions.

Cost factors also limit commercial adoption, with current high-performance coatings requiring expensive materials and complex fabrication processes that make them economically unfeasible for large-scale water treatment infrastructure.

Despite considerable progress, the field faces substantial technical barriers that impede widespread commercial adoption. A primary challenge is durability - most superhydrophobic coatings exhibit limited mechanical robustness and wear resistance under operational conditions. When subjected to continuous water flow, abrasion, and chemical exposure typical in filtration systems, these coatings often degrade rapidly, losing their water-repellent properties within weeks or months rather than maintaining effectiveness for years as required for commercial viability.

Scalability represents another significant obstacle. Laboratory-scale fabrication techniques such as chemical vapor deposition, sol-gel processes, and layer-by-layer assembly have demonstrated excellent superhydrophobic properties. However, translating these methods to industrial-scale production while maintaining consistent quality, performance, and cost-effectiveness remains problematic. The intricate micro/nano-hierarchical structures essential for superhydrophobicity are particularly difficult to reproduce uniformly across large surface areas.

Chemical stability presents additional challenges, especially in water treatment applications where coatings must withstand exposure to various contaminants, disinfectants, and pH variations. Many current formulations show vulnerability to chemical degradation, particularly from oxidizing agents commonly used in water treatment processes.

Environmental and health concerns further complicate development efforts. Traditional superhydrophobic coatings often incorporate fluorinated compounds that raise significant environmental persistence and bioaccumulation concerns. Regulatory frameworks in Europe and North America increasingly restrict these substances, driving research toward environmentally benign alternatives that frequently demonstrate inferior performance or durability.

Standardization itself represents a critical barrier. The field lacks universally accepted testing protocols and performance metrics for evaluating superhydrophobic coatings in water filtration contexts. Different research groups employ varied methodologies for measuring contact angles, sliding angles, and durability, making direct comparisons between studies challenging and hindering systematic progress toward optimized solutions.

Cost factors also limit commercial adoption, with current high-performance coatings requiring expensive materials and complex fabrication processes that make them economically unfeasible for large-scale water treatment infrastructure.

Current Standardization Approaches for Hydrophobic Coatings

01 Testing methods and standards for superhydrophobic coatings

Various testing methods and standards have been developed to evaluate the performance of superhydrophobic coatings. These include measurements of contact angle, sliding angle, and durability under different environmental conditions. Standardized testing protocols ensure consistent evaluation of coating properties such as water repellency, self-cleaning capabilities, and long-term stability. These standards help in comparing different superhydrophobic formulations and ensuring quality control in manufacturing processes.- Testing methods and standards for superhydrophobic coatings: Various testing methods and standards have been developed to evaluate the performance of superhydrophobic coatings. These include measurements of contact angle, sliding angle, and durability under different environmental conditions. Standardized testing protocols ensure consistent evaluation of coating properties such as water repellency, self-cleaning capabilities, and long-term stability. These standards help in comparing different superhydrophobic formulations and ensuring quality control in manufacturing processes.

- Fabrication techniques for standardized superhydrophobic surfaces: Standardized fabrication techniques for superhydrophobic coatings include methods such as spray coating, dip coating, and layer-by-layer deposition. These techniques focus on creating consistent micro and nano-scale surface roughness combined with low surface energy materials. Standardization of these processes ensures reproducibility in manufacturing and helps achieve uniform superhydrophobic properties across different batches and applications. Parameters such as curing time, temperature, and application methods are carefully controlled to maintain quality standards.

- Durability and wear resistance standardization: Standardization of durability and wear resistance for superhydrophobic coatings involves testing protocols for mechanical abrasion, chemical exposure, and weathering resistance. These standards help evaluate how well coatings maintain their superhydrophobic properties under various stress conditions. Testing methods include cyclic abrasion tests, exposure to UV radiation, temperature cycling, and chemical resistance evaluations. Standardized durability metrics enable comparison between different coating formulations and guide improvements in coating longevity.

- Environmental and safety standards for superhydrophobic materials: Environmental and safety standards for superhydrophobic coatings address concerns related to toxicity, environmental impact, and regulatory compliance. These standards ensure that coating materials and application processes meet health and safety requirements while minimizing environmental footprint. Guidelines cover volatile organic compound (VOC) content, biodegradability, and potential ecological impacts. Standardization in this area helps manufacturers develop environmentally friendly superhydrophobic coatings that comply with global regulations while maintaining desired performance characteristics.

- Quality control and performance metrics standardization: Standardized quality control processes and performance metrics for superhydrophobic coatings include specifications for contact angle measurements, transparency, adhesion strength, and functional performance. These standards establish minimum requirements for coatings to be classified as superhydrophobic and provide benchmarks for comparing different products. Quality control protocols ensure consistency in manufacturing and application processes, while standardized performance metrics help end-users select appropriate coatings for specific applications based on quantifiable parameters rather than marketing claims.

02 Fabrication techniques for standardized superhydrophobic surfaces

Standardized fabrication techniques for superhydrophobic coatings include methods such as sol-gel processing, layer-by-layer deposition, spray coating, and lithography. These techniques aim to create reproducible micro and nano-scale surface structures that are essential for superhydrophobicity. Standardization of these fabrication processes ensures consistent surface morphology, roughness parameters, and chemical composition, which are critical factors affecting the hydrophobic properties of the coating.Expand Specific Solutions03 Material composition standards for superhydrophobic coatings

Standardization of material compositions for superhydrophobic coatings involves specifications for base polymers, hydrophobic additives, nanoparticles, and other components. These standards define acceptable ranges for chemical constituents, particle size distributions, and concentration ratios. Material composition standards ensure that coatings meet environmental and safety regulations while maintaining optimal superhydrophobic properties. They also facilitate quality control in manufacturing and enable consistent performance across different production batches.Expand Specific Solutions04 Performance metrics and classification systems

Standardized performance metrics and classification systems have been established to categorize superhydrophobic coatings based on their properties. These include quantitative measures such as water contact angle (typically >150°), contact angle hysteresis, sliding angle, and durability ratings. Classification systems help in selecting appropriate coatings for specific applications and environmental conditions. These standardized metrics enable objective comparison between different superhydrophobic products and guide further development of improved formulations.Expand Specific Solutions05 Application-specific standardization for superhydrophobic coatings

Application-specific standards have been developed for superhydrophobic coatings used in various industries such as automotive, construction, textiles, and electronics. These standards address specific requirements like weathering resistance, abrasion resistance, chemical stability, and compatibility with substrates. They also include guidelines for application methods, curing conditions, and quality control procedures. Application-specific standardization ensures that superhydrophobic coatings meet the performance requirements of their intended use environments.Expand Specific Solutions

Leading Companies and Research Institutions in Coating Industry

The standardization of superhydrophobic coating for water filtration systems is currently in an emerging growth phase, with the market expected to reach significant expansion as water scarcity concerns intensify globally. The competitive landscape features a diverse mix of academic institutions and commercial entities, with research leadership from institutions like Indian Institute of Technology Kanpur, University of North Carolina at Chapel Hill, and Council of Scientific & Industrial Research. Companies including Nanosys, Sun Chemical, and Honeywell Federal Manufacturing & Technologies are advancing commercial applications, though technical challenges in durability and scalability persist. The technology is approaching commercial viability but requires further standardization efforts to address performance consistency, environmental safety, and cost-effectiveness before widespread adoption in municipal and industrial water treatment systems.

Council of Scientific & Industrial Research

Technical Solution: CSIR has developed a standardized approach to superhydrophobic coatings for water filtration systems using a sol-gel technique combined with hydrothermal treatment. Their technology creates hierarchical micro-nano structures with controlled roughness parameters (Ra=1.5-2.5μm) and uniform surface chemistry. The coating process has been standardized for various substrate materials including polymeric membranes, ceramic filters, and metallic meshes. CSIR's standardization protocol includes quantitative metrics for water contact angle (>160°), sliding angle (<5°), and mechanical durability (maintaining superhydrophobicity after 500 abrasion cycles). Their approach incorporates environmentally friendly silane chemistry without fluorinated compounds while achieving comparable performance. The standardization framework includes specific testing methodologies for different water contaminants including oils, heavy metals, and biological materials, with established performance benchmarks for each category.

Strengths: Versatile application across multiple substrate types; environmentally friendly chemistry; comprehensive standardization protocols. Weaknesses: Slightly lower durability compared to fluorinated alternatives; more complex application process; potential challenges in scaling to industrial volumes.

Indian Institute of Technology Kanpur

Technical Solution: IIT Kanpur has developed a standardized superhydrophobic coating technology for water filtration systems using a spray-coating method with modified silica nanoparticles. Their approach creates a dual-scale roughness with micro-structures (5-10μm) and nano-features (50-100nm) that maintain water contact angles >165° and sliding angles <3°. The standardization protocol includes specific metrics for coating thickness (optimal range 3-5μm), uniformity (variation <10% across surface), and adhesion strength (>4B on ASTM D3359 scale). Their technology incorporates self-healing capabilities through incorporation of mobile hydrophobic agents that migrate to damaged areas, extending coating lifetime by 40-60% compared to conventional superhydrophobic surfaces. The institute has established standardized testing procedures for different water qualities (turbidity, hardness, biological content) and operational conditions (flow rate, pressure, temperature), creating a comprehensive framework for industrial implementation and quality control.

Strengths: Innovative self-healing properties; easily scalable spray-coating application; comprehensive standardization metrics. Weaknesses: Slightly higher material costs; potential limitations in extremely high-pressure applications; requires periodic maintenance for optimal self-healing functionality.

Key Patents and Scientific Breakthroughs in Superhydrophobic Materials

A superhydrophobic anticorrosive coating without fluoro compounds and inhibitive pigments and the process thereof

PatentInactiveIN201711001141A

Innovation

- Development of a superhydrophobic anticorrosive coating with water contact angle of 152° and sliding angle of 20° without using environmentally harmful fluoro compounds and inhibitive pigments.

- Utilization of a unique combination of silicone binder, nanotitania, nanosilica, magnesium silicate, and aluminum stearate to create a micro/nano roughness that effectively entraps air and decreases the solid-liquid interface.

- Development of a technically simple and easily manageable process suitable for large-scale industrial application of superhydrophobic coatings in water filtration systems.

Superhydrophobic poly(dimethylsiloxane) and methods for making the same

PatentInactiveUS20130129982A1

Innovation

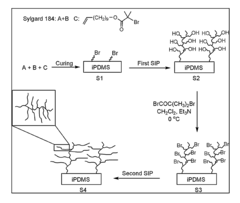

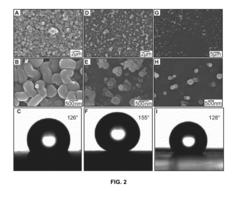

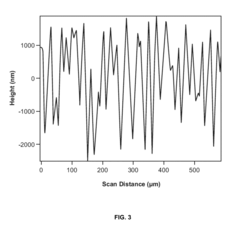

- A relayed surface-initiated polymerization (SIP) strategy with ultra-low initiator density and the use of a hydrophobic monomer to create a multi-layered polymer structure on a polymer substrate, specifically incorporating a first linker at a controlled surface density and subsequent polymer layers to achieve a contact angle of at least 150 degrees.

Environmental Impact Assessment of Coating Materials

The environmental impact of superhydrophobic coatings for water filtration systems requires comprehensive assessment across their entire lifecycle. Current coating materials predominantly utilize fluorinated compounds, silicones, and various nanoparticles which present significant environmental concerns. Fluorinated compounds, particularly per- and polyfluoroalkyl substances (PFAS), demonstrate exceptional persistence in the environment, earning the designation "forever chemicals" due to their resistance to natural degradation processes. These substances have been detected in water bodies globally and are linked to adverse ecological and human health effects.

Silicone-based coatings, while less persistent than PFAS, still present challenges regarding biodegradability and potential microplastic formation when degraded. Nanoparticle components, including titanium dioxide, zinc oxide, and silver nanoparticles, raise emerging concerns regarding their bioaccumulation potential and ecotoxicological effects on aquatic organisms when released into water systems.

Manufacturing processes for these coatings typically involve organic solvents and energy-intensive production methods. Volatile organic compounds (VOCs) released during production and application contribute to air pollution and potential health hazards for workers. The energy consumption associated with high-temperature curing processes further increases the carbon footprint of these materials.

Lifecycle analysis reveals that while superhydrophobic coatings can improve filtration efficiency and reduce energy consumption during operation, their end-of-life management remains problematic. Most coating materials cannot be easily separated from filter substrates, complicating recycling efforts and potentially introducing harmful substances into waste streams.

Recent advancements in green chemistry approaches show promise for developing environmentally benign alternatives. Bio-inspired coatings derived from plant waxes, cellulose derivatives, and chitosan demonstrate comparable hydrophobic properties with significantly reduced environmental impact. These materials exhibit enhanced biodegradability and reduced ecotoxicity compared to conventional synthetic options.

Regulatory frameworks worldwide are increasingly addressing the environmental implications of coating materials. The European Union's REACH regulation has placed restrictions on several PFAS compounds, while similar regulatory actions are emerging in North America and Asia. These developments are driving industry innovation toward more sustainable formulations that maintain performance while minimizing environmental harm.

Standardization efforts must incorporate comprehensive environmental impact criteria, including biodegradability, ecotoxicity, bioaccumulation potential, and carbon footprint assessments. Implementing these standards would facilitate the transition toward more sustainable coating technologies while ensuring consistent environmental performance across the industry.

Silicone-based coatings, while less persistent than PFAS, still present challenges regarding biodegradability and potential microplastic formation when degraded. Nanoparticle components, including titanium dioxide, zinc oxide, and silver nanoparticles, raise emerging concerns regarding their bioaccumulation potential and ecotoxicological effects on aquatic organisms when released into water systems.

Manufacturing processes for these coatings typically involve organic solvents and energy-intensive production methods. Volatile organic compounds (VOCs) released during production and application contribute to air pollution and potential health hazards for workers. The energy consumption associated with high-temperature curing processes further increases the carbon footprint of these materials.

Lifecycle analysis reveals that while superhydrophobic coatings can improve filtration efficiency and reduce energy consumption during operation, their end-of-life management remains problematic. Most coating materials cannot be easily separated from filter substrates, complicating recycling efforts and potentially introducing harmful substances into waste streams.

Recent advancements in green chemistry approaches show promise for developing environmentally benign alternatives. Bio-inspired coatings derived from plant waxes, cellulose derivatives, and chitosan demonstrate comparable hydrophobic properties with significantly reduced environmental impact. These materials exhibit enhanced biodegradability and reduced ecotoxicity compared to conventional synthetic options.

Regulatory frameworks worldwide are increasingly addressing the environmental implications of coating materials. The European Union's REACH regulation has placed restrictions on several PFAS compounds, while similar regulatory actions are emerging in North America and Asia. These developments are driving industry innovation toward more sustainable formulations that maintain performance while minimizing environmental harm.

Standardization efforts must incorporate comprehensive environmental impact criteria, including biodegradability, ecotoxicity, bioaccumulation potential, and carbon footprint assessments. Implementing these standards would facilitate the transition toward more sustainable coating technologies while ensuring consistent environmental performance across the industry.

Testing Protocols and Quality Control Standards

The standardization of testing protocols for superhydrophobic coatings in water filtration systems requires comprehensive quality control measures to ensure consistent performance and reliability. Current industry practices reveal significant variations in testing methodologies, making it difficult to compare different coating solutions effectively. A unified approach to testing must address water contact angle measurements, which should be conducted under controlled temperature and humidity conditions using calibrated goniometers with precision of ±1 degree. The minimum acceptable contact angle for classification as superhydrophobic should be standardized at 150 degrees, with sliding angle measurements below 10 degrees.

Durability testing represents another critical aspect requiring standardization. Accelerated weathering tests should simulate real-world conditions including UV exposure, temperature cycling, and chemical exposure typical in water treatment facilities. The proposed standard includes 1000 hours of accelerated aging equivalent to approximately five years of operational life. Mechanical durability tests should incorporate abrasion resistance using standardized methods such as ASTM D4060, with coating performance evaluated after predetermined cycles.

Chemical resistance testing protocols need particular attention for water filtration applications. Standardized exposure to common water treatment chemicals including chlorine (at concentrations up to 5 ppm), alum, ferric chloride, and varying pH conditions (pH 4-10) should be mandatory. Performance degradation should not exceed 15% reduction in contact angle after chemical exposure tests.

Filtration efficiency testing requires standardization of particle size distribution in test water, flow rates, and pressure differentials. The protocol should specify testing with standardized contaminants including organic matter, minerals, and microorganisms at concentrations reflecting real-world conditions. Performance metrics should include filtration efficiency, pressure drop measurements, and fouling rates over time.

Quality control standards must incorporate statistical process control methods with defined sampling procedures and acceptance criteria. Each production batch should undergo testing with documented traceability. Certification procedures should include third-party verification of key performance parameters against established benchmarks. The implementation of these standardized testing protocols would significantly advance the commercialization of superhydrophobic coatings by providing manufacturers, researchers, and end-users with reliable comparative data and quality assurance mechanisms.

Durability testing represents another critical aspect requiring standardization. Accelerated weathering tests should simulate real-world conditions including UV exposure, temperature cycling, and chemical exposure typical in water treatment facilities. The proposed standard includes 1000 hours of accelerated aging equivalent to approximately five years of operational life. Mechanical durability tests should incorporate abrasion resistance using standardized methods such as ASTM D4060, with coating performance evaluated after predetermined cycles.

Chemical resistance testing protocols need particular attention for water filtration applications. Standardized exposure to common water treatment chemicals including chlorine (at concentrations up to 5 ppm), alum, ferric chloride, and varying pH conditions (pH 4-10) should be mandatory. Performance degradation should not exceed 15% reduction in contact angle after chemical exposure tests.

Filtration efficiency testing requires standardization of particle size distribution in test water, flow rates, and pressure differentials. The protocol should specify testing with standardized contaminants including organic matter, minerals, and microorganisms at concentrations reflecting real-world conditions. Performance metrics should include filtration efficiency, pressure drop measurements, and fouling rates over time.

Quality control standards must incorporate statistical process control methods with defined sampling procedures and acceptance criteria. Each production batch should undergo testing with documented traceability. Certification procedures should include third-party verification of key performance parameters against established benchmarks. The implementation of these standardized testing protocols would significantly advance the commercialization of superhydrophobic coatings by providing manufacturers, researchers, and end-users with reliable comparative data and quality assurance mechanisms.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!