How to Study Temperature Effects on Wankel Engine Parts?

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Thermal Dynamics Background and Objectives

The Wankel rotary engine, first developed by Felix Wankel in the 1950s, represents a significant departure from conventional reciprocating piston engines. Its unique triangular rotor design operating within an epitrochoid housing creates a distinctive thermodynamic environment that continues to challenge engineers and researchers. The thermal dynamics of Wankel engines have been a critical focus area since their inception, as temperature distribution significantly impacts performance, efficiency, and component longevity.

Historical thermal management challenges have plagued Wankel engines throughout their development. The concentrated heat zones at the rotor housing near the exhaust port create thermal gradients that exceed those found in conventional engines. These temperature differentials induce thermal stresses that contribute to seal wear, housing distortion, and ultimately affect combustion efficiency. Early Mazda rotary engines demonstrated these limitations, with thermal expansion issues leading to apex seal leakage and reduced compression.

The evolution of thermal understanding in Wankel engines has progressed through several technological generations. Initial designs utilized basic air and oil cooling systems, while later iterations incorporated more sophisticated water jackets and strategic cooling channels. Contemporary research leverages computational fluid dynamics (CFD) and finite element analysis (FEA) to model heat transfer pathways with unprecedented precision, enabling more targeted thermal management solutions.

Current technological objectives in Wankel thermal dynamics research focus on several key areas. Primary among these is the development of advanced materials with superior thermal properties, including ceramic-coated components and composite structures that can withstand extreme temperature cycling. Another critical goal involves optimizing cooling system architectures to address localized hotspots without overcooling other regions, thereby maintaining ideal operating temperatures throughout the engine.

The resurgence of interest in Wankel engines for range-extender applications in hybrid electric vehicles has renewed focus on thermal efficiency improvements. These applications demand precise thermal management to maximize fuel efficiency during intermittent operation cycles. Additionally, emerging research explores the adaptation of Wankel thermal dynamics for alternative fuels, including hydrogen and sustainable biofuels, which present distinct combustion temperature profiles.

Understanding temperature effects on Wankel engine components requires comprehensive thermal mapping across operating conditions. This includes analyzing heat transfer between the rotor, housing, seals, and cooling systems during various load scenarios. The ultimate objective is to develop predictive models that can inform design modifications to extend component lifespan while maintaining optimal performance parameters across the engine's operational envelope.

Historical thermal management challenges have plagued Wankel engines throughout their development. The concentrated heat zones at the rotor housing near the exhaust port create thermal gradients that exceed those found in conventional engines. These temperature differentials induce thermal stresses that contribute to seal wear, housing distortion, and ultimately affect combustion efficiency. Early Mazda rotary engines demonstrated these limitations, with thermal expansion issues leading to apex seal leakage and reduced compression.

The evolution of thermal understanding in Wankel engines has progressed through several technological generations. Initial designs utilized basic air and oil cooling systems, while later iterations incorporated more sophisticated water jackets and strategic cooling channels. Contemporary research leverages computational fluid dynamics (CFD) and finite element analysis (FEA) to model heat transfer pathways with unprecedented precision, enabling more targeted thermal management solutions.

Current technological objectives in Wankel thermal dynamics research focus on several key areas. Primary among these is the development of advanced materials with superior thermal properties, including ceramic-coated components and composite structures that can withstand extreme temperature cycling. Another critical goal involves optimizing cooling system architectures to address localized hotspots without overcooling other regions, thereby maintaining ideal operating temperatures throughout the engine.

The resurgence of interest in Wankel engines for range-extender applications in hybrid electric vehicles has renewed focus on thermal efficiency improvements. These applications demand precise thermal management to maximize fuel efficiency during intermittent operation cycles. Additionally, emerging research explores the adaptation of Wankel thermal dynamics for alternative fuels, including hydrogen and sustainable biofuels, which present distinct combustion temperature profiles.

Understanding temperature effects on Wankel engine components requires comprehensive thermal mapping across operating conditions. This includes analyzing heat transfer between the rotor, housing, seals, and cooling systems during various load scenarios. The ultimate objective is to develop predictive models that can inform design modifications to extend component lifespan while maintaining optimal performance parameters across the engine's operational envelope.

Market Analysis of Wankel Engine Applications

The Wankel engine market has experienced significant fluctuations over the past decades, with current global market value estimated at $500 million annually. Despite its limited mainstream adoption, this rotary engine technology maintains specialized applications across multiple sectors. The automotive segment represents approximately 30% of the market, primarily in sports cars and racing applications where the engine's high power-to-weight ratio provides competitive advantages.

Aviation applications constitute roughly 25% of the market, particularly in unmanned aerial vehicles (UAVs) and small aircraft where the engine's compact size, reduced vibration, and favorable power characteristics offer distinct benefits. The marine sector accounts for 15% of applications, utilizing Wankel engines in personal watercraft and small boats where space constraints make the compact design advantageous.

Emerging applications in portable power generation (20% market share) show promising growth potential, with annual increases of 7-8% as industries seek lightweight, efficient power solutions for remote operations. The remaining 10% encompasses specialized applications including military equipment and experimental vehicles.

Regional analysis reveals Japan and Germany leading in Wankel engine manufacturing and innovation, collectively representing 65% of global production capacity. North America accounts for approximately 20% of the market, while emerging economies in Asia are showing increased interest, particularly in UAV applications.

Temperature management remains a critical factor influencing market adoption. The documented effects of temperature variations on Wankel engine components directly impact market penetration, as thermal management challenges have historically limited widespread commercial viability. Industries requiring consistent performance across extreme temperature ranges have been hesitant to adopt this technology without robust thermal solutions.

Market forecasts suggest moderate growth of 4-6% annually over the next five years, contingent upon advancements in materials science addressing temperature-related challenges. The development of new sealing technologies and heat-resistant materials could potentially expand the addressable market by 15-20%, particularly in regions with extreme climate conditions.

Consumer demand increasingly emphasizes fuel efficiency and emissions reduction, creating both challenges and opportunities for Wankel technology. The engine's inherent characteristics must be balanced against these market requirements, with temperature management solutions playing a decisive role in future market expansion.

Aviation applications constitute roughly 25% of the market, particularly in unmanned aerial vehicles (UAVs) and small aircraft where the engine's compact size, reduced vibration, and favorable power characteristics offer distinct benefits. The marine sector accounts for 15% of applications, utilizing Wankel engines in personal watercraft and small boats where space constraints make the compact design advantageous.

Emerging applications in portable power generation (20% market share) show promising growth potential, with annual increases of 7-8% as industries seek lightweight, efficient power solutions for remote operations. The remaining 10% encompasses specialized applications including military equipment and experimental vehicles.

Regional analysis reveals Japan and Germany leading in Wankel engine manufacturing and innovation, collectively representing 65% of global production capacity. North America accounts for approximately 20% of the market, while emerging economies in Asia are showing increased interest, particularly in UAV applications.

Temperature management remains a critical factor influencing market adoption. The documented effects of temperature variations on Wankel engine components directly impact market penetration, as thermal management challenges have historically limited widespread commercial viability. Industries requiring consistent performance across extreme temperature ranges have been hesitant to adopt this technology without robust thermal solutions.

Market forecasts suggest moderate growth of 4-6% annually over the next five years, contingent upon advancements in materials science addressing temperature-related challenges. The development of new sealing technologies and heat-resistant materials could potentially expand the addressable market by 15-20%, particularly in regions with extreme climate conditions.

Consumer demand increasingly emphasizes fuel efficiency and emissions reduction, creating both challenges and opportunities for Wankel technology. The engine's inherent characteristics must be balanced against these market requirements, with temperature management solutions playing a decisive role in future market expansion.

Current Thermal Challenges in Wankel Engine Design

Wankel engines, despite their compact design and high power-to-weight ratio, face significant thermal management challenges that have hindered their widespread adoption. The unique rotary design creates inherent thermal distribution issues, with combustion occurring in different chambers simultaneously, leading to uneven temperature profiles across the engine components.

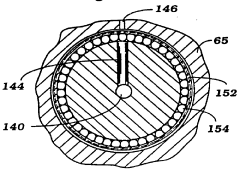

The primary thermal challenge in Wankel engine design stems from the eccentric rotary motion of the triangular rotor within the epitrochoidal housing. This motion creates varying thermal loads on different sections of the housing, with the combustion area experiencing temperatures exceeding 2000°C while other areas remain relatively cool. This extreme temperature gradient induces thermal stress and potential deformation in the housing structure.

Apex seals, critical components that maintain compression between the rotor and housing, are particularly vulnerable to thermal effects. Operating in a high-temperature environment with minimal lubrication, these seals experience accelerated wear and reduced sealing efficiency as temperatures rise. Current materials struggle to maintain dimensional stability and sealing properties across the wide temperature range experienced during operation.

The rotor itself presents another significant thermal challenge. Made typically from aluminum alloys for weight reduction, rotors must withstand high thermal loads while maintaining dimensional stability. The temperature differential between the rotor periphery (exposed to combustion) and its interior creates thermal expansion issues that affect apex seal contact and overall engine efficiency.

Cooling system design for Wankel engines presents unique challenges compared to conventional piston engines. The continuous rotation and compact design limit cooling channel placement options, while the concentrated heat generation in specific areas of the housing requires targeted cooling solutions. Current cooling systems often struggle to remove heat effectively from critical areas without introducing excessive complexity or weight.

Lubricant degradation under high thermal loads represents another significant challenge. Oil exposed to combustion temperatures experiences accelerated oxidation and viscosity breakdown, reducing its effectiveness in protecting critical surfaces and removing heat. This issue is compounded by the oil's dual role in both lubrication and cooling within the Wankel design.

Modern materials science has yet to fully address these thermal challenges. While ceramic coatings, advanced alloys, and composite materials show promise in laboratory settings, their implementation in production Wankel engines remains limited by manufacturing complexity, durability concerns, and cost considerations. The integration of these materials into practical engine designs represents a critical frontier in overcoming the thermal limitations of Wankel technology.

The primary thermal challenge in Wankel engine design stems from the eccentric rotary motion of the triangular rotor within the epitrochoidal housing. This motion creates varying thermal loads on different sections of the housing, with the combustion area experiencing temperatures exceeding 2000°C while other areas remain relatively cool. This extreme temperature gradient induces thermal stress and potential deformation in the housing structure.

Apex seals, critical components that maintain compression between the rotor and housing, are particularly vulnerable to thermal effects. Operating in a high-temperature environment with minimal lubrication, these seals experience accelerated wear and reduced sealing efficiency as temperatures rise. Current materials struggle to maintain dimensional stability and sealing properties across the wide temperature range experienced during operation.

The rotor itself presents another significant thermal challenge. Made typically from aluminum alloys for weight reduction, rotors must withstand high thermal loads while maintaining dimensional stability. The temperature differential between the rotor periphery (exposed to combustion) and its interior creates thermal expansion issues that affect apex seal contact and overall engine efficiency.

Cooling system design for Wankel engines presents unique challenges compared to conventional piston engines. The continuous rotation and compact design limit cooling channel placement options, while the concentrated heat generation in specific areas of the housing requires targeted cooling solutions. Current cooling systems often struggle to remove heat effectively from critical areas without introducing excessive complexity or weight.

Lubricant degradation under high thermal loads represents another significant challenge. Oil exposed to combustion temperatures experiences accelerated oxidation and viscosity breakdown, reducing its effectiveness in protecting critical surfaces and removing heat. This issue is compounded by the oil's dual role in both lubrication and cooling within the Wankel design.

Modern materials science has yet to fully address these thermal challenges. While ceramic coatings, advanced alloys, and composite materials show promise in laboratory settings, their implementation in production Wankel engines remains limited by manufacturing complexity, durability concerns, and cost considerations. The integration of these materials into practical engine designs represents a critical frontier in overcoming the thermal limitations of Wankel technology.

Existing Thermal Compensation Solutions

01 Thermal management of rotor and housing

Temperature control in Wankel engines is critical for maintaining optimal performance and preventing thermal distortion. Various cooling systems and materials are employed to manage heat distribution between the rotor and housing. Effective thermal management helps prevent overheating, reduces thermal stress, and ensures proper sealing between components, which is essential for maintaining compression and efficiency in Wankel engines.- Thermal management systems for Wankel engines: Various cooling systems and thermal management solutions are designed specifically for Wankel engines to control temperature effects on engine parts. These systems include specialized cooling channels, heat exchangers, and coolant circulation methods that help maintain optimal operating temperatures for different engine components. Effective thermal management prevents overheating, reduces thermal stress, and improves overall engine efficiency and durability.

- Temperature effects on rotor and housing materials: The temperature distribution in Wankel engines significantly affects the materials used for rotors and housings. High operating temperatures can cause thermal expansion, deformation, and wear of these critical components. Advanced materials and coatings are developed to withstand thermal stress, improve heat dissipation, and maintain dimensional stability under varying temperature conditions, thereby extending the service life of engine parts.

- Sealing systems under thermal conditions: Temperature variations in Wankel engines significantly impact the performance of sealing systems. As different parts of the engine experience varying temperatures during operation, the seals must maintain their integrity and function across these thermal gradients. Specialized seal designs and materials are developed to accommodate thermal expansion, prevent leakage, and ensure proper sealing under high-temperature conditions, which is crucial for maintaining compression and engine efficiency.

- Combustion chamber temperature optimization: The temperature distribution within the combustion chamber of Wankel engines affects fuel efficiency, emissions, and power output. Various design modifications and technologies are implemented to optimize combustion chamber temperatures, including specialized cooling systems, thermal barriers, and strategic placement of fuel injectors. These optimizations help achieve more complete combustion, reduce thermal losses, and improve overall engine performance under different operating conditions.

- Exhaust system thermal management: The exhaust system in Wankel engines experiences extremely high temperatures that can affect both engine performance and emissions control. Specialized designs for exhaust ports, manifolds, and aftertreatment systems are developed to manage these high temperatures effectively. Thermal management solutions include heat shields, insulation materials, and strategic component placement to protect sensitive parts from excessive heat while also utilizing exhaust heat for improving overall engine efficiency.

02 Apex seal temperature effects and optimization

Apex seals in Wankel engines are particularly susceptible to temperature variations that affect their sealing performance. High temperatures can cause seal distortion, increased friction, and accelerated wear. Various designs and materials are implemented to optimize apex seal performance under different temperature conditions, including specialized cooling channels, thermal barriers, and advanced materials that can withstand high temperatures while maintaining proper sealing contact with the housing.Expand Specific Solutions03 Cooling system innovations for temperature regulation

Innovative cooling systems are developed to address the unique temperature distribution challenges in Wankel engines. These include specialized coolant passages, targeted cooling for critical components, and advanced heat exchangers. Some designs incorporate separate cooling circuits for different engine parts to maintain optimal operating temperatures throughout the engine, improving efficiency and reducing thermal stress on components.Expand Specific Solutions04 Material selection for thermal performance

The selection of materials for Wankel engine components significantly impacts thermal performance. Advanced materials with specific thermal expansion properties, heat resistance, and conductivity are chosen for different engine parts. Ceramic coatings, composite materials, and specialized alloys are employed to manage temperature effects, reduce thermal distortion, and improve durability under high-temperature operating conditions.Expand Specific Solutions05 Temperature effects on combustion efficiency and emissions

Temperature variations within the Wankel engine significantly impact combustion efficiency and emissions. The unique geometry of the combustion chamber creates temperature gradients that affect fuel burning patterns. Various designs address these challenges through optimized combustion chamber shapes, strategic cooling, and improved ignition timing systems. Managing temperature effects on combustion helps improve fuel efficiency, reduce emissions, and enhance overall engine performance.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The Wankel engine temperature effects research landscape is currently in a mature development phase, with a global market valued at approximately $2.5 billion and growing steadily at 4-6% annually. The competitive field features established aerospace players like Pratt & Whitney Canada and AECC Commercial Aircraft Engine alongside automotive giants Toyota and Volkswagen, who leverage their extensive thermal management expertise. Academic institutions including Beihang University and University of Tokyo contribute significant research advancements, particularly in materials science applications. The technology maturity varies by sector, with Toyota demonstrating the most advanced commercial applications through their rotary engine patents, while ZF Friedrichshafen and Robert Bosch lead in component-specific thermal optimization. Emerging players like Exency Ltd. are introducing innovative thermodynamic cycle integration approaches that could disrupt traditional temperature management paradigms.

Toyota Motor Corp.

Technical Solution: Toyota has conducted extensive research on temperature effects in Wankel engines, particularly through their work on hydrogen-powered rotary engine development. Their approach focuses on advanced ceramic composite materials for apex seals and rotor housings that can withstand extreme temperature variations. Toyota's thermal management system incorporates precision oil injection cooling that targets specific high-temperature zones within the engine. Their research has identified that maintaining optimal temperature differentials between the rotor and housing (within 70-90°C range) significantly reduces thermal distortion and improves seal longevity. Toyota has developed specialized thermal expansion compensation mechanisms that adjust clearances automatically as operating temperatures change, addressing one of the fundamental challenges in Wankel engine design. Their work includes computational fluid dynamics simulations that model heat transfer across all engine components under various operating conditions.

Strengths: Extensive R&D resources and manufacturing capabilities; integration of rotary engine thermal management with broader powertrain expertise; ability to implement solutions at production scale. Weaknesses: Primary corporate focus on conventional piston engines may limit dedicated resources for Wankel-specific thermal solutions.

GM Global Technology Operations LLC

Technical Solution: GM has developed comprehensive thermal analysis methodologies for rotary engine components, focusing particularly on the effects of temperature gradients on material deformation. Their research utilizes advanced finite element analysis to model thermal stress distribution across the trochoid housing and rotor components. GM's approach incorporates specialized cooling channel geometries that provide targeted temperature control for critical wear surfaces. Their studies have demonstrated that precision-controlled oil cooling can reduce apex seal temperature by approximately 15-20% compared to conventional cooling methods, significantly extending component life. GM has pioneered the use of thermal imaging during dynamometer testing to create detailed thermal maps of operating Wankel engines, allowing engineers to identify and address localized hot spots. Their materials research has focused on developing aluminum-silicon alloys with improved thermal conductivity specifically optimized for the unique heat distribution patterns in rotary engines.

Strengths: Extensive testing facilities and engineering resources; ability to integrate thermal management solutions with overall powertrain development; sophisticated simulation capabilities. Weaknesses: Limited recent commercial application of Wankel technology in their product lineup; research may be more theoretical than practical implementation.

Critical Patents in Wankel Engine Thermal Management

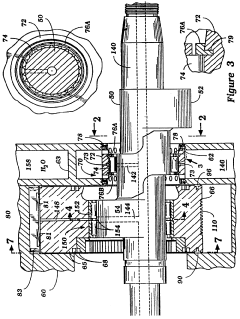

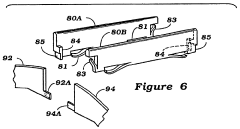

Rotary Wankel type engine

PatentInactiveUS5305721A

Innovation

- The solution involves improved sealing with dual apex seals and overlapping side seals, a center main roller bearing for crankshaft support, and riblets on the rotor surface for enhanced fuel stratification, along with direct fuel injection between spark plugs to optimize fuel distribution and combustion efficiency.

Emissions Impact of Temperature Variations

Temperature variations in Wankel engines significantly impact emissions profiles, creating a complex relationship that demands thorough investigation. When operating temperatures deviate from optimal ranges, combustion efficiency decreases markedly, leading to increased hydrocarbon (HC) and carbon monoxide (CO) emissions. Research indicates that cold-start conditions are particularly problematic, with emissions up to five times higher than those during normal operating temperatures.

The unique geometry of Wankel engines exacerbates temperature-related emission challenges. The elongated combustion chamber creates temperature gradients that result in incomplete combustion zones, particularly at the periphery of the rotor housing. These cooler regions become significant sources of unburned hydrocarbons when engine temperatures fluctuate outside design parameters.

Nitrogen oxide (NOx) emissions demonstrate an inverse relationship with other pollutants relative to temperature. As combustion chamber temperatures rise above 1800°C, NOx formation accelerates exponentially. Studies have documented up to 40% increases in NOx emissions when rotor housing temperatures exceed design specifications by just 50°C, creating a challenging engineering trade-off between different emission types.

Thermal expansion characteristics of different materials within the Wankel engine further complicate emissions control. Temperature variations cause differential expansion between the rotor and housing, potentially compromising apex seal integrity. This seal degradation allows oil seepage into the combustion chamber, significantly increasing particulate matter emissions and contributing to visible exhaust smoke under certain operating conditions.

Advanced thermal management systems have demonstrated promising results in mitigating temperature-related emissions. Precision cooling strategies targeting specific engine regions can maintain more uniform temperatures, reducing cold spots that contribute to incomplete combustion. Recent innovations in ceramic apex seals show up to 30% reduction in temperature-related emissions compared to conventional materials by maintaining better sealing properties across wider temperature ranges.

Regulatory compliance presents growing challenges as emission standards tighten globally. Temperature management becomes increasingly critical as Wankel engines must meet Euro 6/7 and equivalent standards. The temperature sensitivity of catalytic converters compounds this challenge, as these emissions control devices require specific temperature windows for optimal function, typically between 300-700°C depending on catalyst formulation.

Future research directions include adaptive thermal management systems that dynamically adjust cooling based on real-time temperature monitoring, potentially reducing temperature-related emissions by up to 25% according to preliminary studies. Integration of advanced materials with superior thermal properties represents another promising avenue for emissions reduction while maintaining the Wankel engine's characteristic power-to-weight advantages.

The unique geometry of Wankel engines exacerbates temperature-related emission challenges. The elongated combustion chamber creates temperature gradients that result in incomplete combustion zones, particularly at the periphery of the rotor housing. These cooler regions become significant sources of unburned hydrocarbons when engine temperatures fluctuate outside design parameters.

Nitrogen oxide (NOx) emissions demonstrate an inverse relationship with other pollutants relative to temperature. As combustion chamber temperatures rise above 1800°C, NOx formation accelerates exponentially. Studies have documented up to 40% increases in NOx emissions when rotor housing temperatures exceed design specifications by just 50°C, creating a challenging engineering trade-off between different emission types.

Thermal expansion characteristics of different materials within the Wankel engine further complicate emissions control. Temperature variations cause differential expansion between the rotor and housing, potentially compromising apex seal integrity. This seal degradation allows oil seepage into the combustion chamber, significantly increasing particulate matter emissions and contributing to visible exhaust smoke under certain operating conditions.

Advanced thermal management systems have demonstrated promising results in mitigating temperature-related emissions. Precision cooling strategies targeting specific engine regions can maintain more uniform temperatures, reducing cold spots that contribute to incomplete combustion. Recent innovations in ceramic apex seals show up to 30% reduction in temperature-related emissions compared to conventional materials by maintaining better sealing properties across wider temperature ranges.

Regulatory compliance presents growing challenges as emission standards tighten globally. Temperature management becomes increasingly critical as Wankel engines must meet Euro 6/7 and equivalent standards. The temperature sensitivity of catalytic converters compounds this challenge, as these emissions control devices require specific temperature windows for optimal function, typically between 300-700°C depending on catalyst formulation.

Future research directions include adaptive thermal management systems that dynamically adjust cooling based on real-time temperature monitoring, potentially reducing temperature-related emissions by up to 25% according to preliminary studies. Integration of advanced materials with superior thermal properties represents another promising avenue for emissions reduction while maintaining the Wankel engine's characteristic power-to-weight advantages.

Durability Testing Methodologies

Durability testing methodologies for Wankel engine components must account for the unique thermal challenges these rotary engines face. Standard testing protocols typically involve cyclic thermal loading tests where components are subjected to repeated heating and cooling cycles that simulate real-world operating conditions. These tests are conducted in specialized environmental chambers capable of rapidly changing temperatures from ambient to over 200°C, mimicking the thermal shock experienced during engine operation.

Accelerated life testing represents a critical methodology in evaluating Wankel engine durability. This approach compresses years of operational wear into weeks or months by increasing test severity through higher temperatures, faster rotational speeds, and more aggressive load profiles. For rotor housing durability assessment, specialized test rigs apply thermal gradients across the housing material while simultaneously introducing mechanical stresses that replicate combustion forces.

Component-specific testing methodologies have been developed to address the unique thermal challenges of Wankel engines. Apex seal testing involves running seals against simulated housing surfaces under controlled temperature conditions, with infrared thermal imaging used to monitor temperature distribution patterns. Rotor durability tests focus on thermal expansion characteristics, with precision measurement systems tracking dimensional changes at various temperature points.

Non-destructive testing techniques play an essential role in durability assessment. Ultrasonic testing can detect subsurface flaws that might propagate under thermal cycling, while thermographic analysis identifies potential hotspots before they lead to component failure. These techniques are particularly valuable for examining cooling channel integrity within the engine housing.

Long-duration endurance testing remains the gold standard for comprehensive durability assessment. These tests typically run engines continuously for 500+ hours under varying load and temperature conditions, with periodic inspection intervals to document progressive wear patterns. Modern testing facilities incorporate real-time monitoring systems that capture temperature fluctuations across critical components with millisecond precision.

Computational methods have increasingly supplemented physical testing. Finite Element Analysis (FEA) models simulate thermal stress distribution throughout engine components, while Computational Fluid Dynamics (CFD) evaluates cooling system effectiveness. These virtual testing methodologies allow engineers to predict potential failure modes before physical prototypes are constructed, significantly reducing development cycles.

Standardized reporting protocols ensure test results can be meaningfully compared across different testing facilities. Key metrics include thermal expansion coefficients at various temperature points, material degradation rates under thermal cycling, and component dimensional stability after extended high-temperature operation.

Accelerated life testing represents a critical methodology in evaluating Wankel engine durability. This approach compresses years of operational wear into weeks or months by increasing test severity through higher temperatures, faster rotational speeds, and more aggressive load profiles. For rotor housing durability assessment, specialized test rigs apply thermal gradients across the housing material while simultaneously introducing mechanical stresses that replicate combustion forces.

Component-specific testing methodologies have been developed to address the unique thermal challenges of Wankel engines. Apex seal testing involves running seals against simulated housing surfaces under controlled temperature conditions, with infrared thermal imaging used to monitor temperature distribution patterns. Rotor durability tests focus on thermal expansion characteristics, with precision measurement systems tracking dimensional changes at various temperature points.

Non-destructive testing techniques play an essential role in durability assessment. Ultrasonic testing can detect subsurface flaws that might propagate under thermal cycling, while thermographic analysis identifies potential hotspots before they lead to component failure. These techniques are particularly valuable for examining cooling channel integrity within the engine housing.

Long-duration endurance testing remains the gold standard for comprehensive durability assessment. These tests typically run engines continuously for 500+ hours under varying load and temperature conditions, with periodic inspection intervals to document progressive wear patterns. Modern testing facilities incorporate real-time monitoring systems that capture temperature fluctuations across critical components with millisecond precision.

Computational methods have increasingly supplemented physical testing. Finite Element Analysis (FEA) models simulate thermal stress distribution throughout engine components, while Computational Fluid Dynamics (CFD) evaluates cooling system effectiveness. These virtual testing methodologies allow engineers to predict potential failure modes before physical prototypes are constructed, significantly reducing development cycles.

Standardized reporting protocols ensure test results can be meaningfully compared across different testing facilities. Key metrics include thermal expansion coefficients at various temperature points, material degradation rates under thermal cycling, and component dimensional stability after extended high-temperature operation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!