Sustainability Assessments in Ethyl Acetate Utilization

JUN 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate Sustainability Background and Objectives

Ethyl acetate, a versatile organic compound, has gained significant attention in recent years due to its wide range of applications and potential for sustainable utilization. The evolution of ethyl acetate technology has been driven by the growing demand for environmentally friendly solvents and the need to reduce the carbon footprint of industrial processes. As global sustainability concerns continue to rise, the focus on ethyl acetate's sustainable production and use has become increasingly important.

The primary objective of sustainability assessments in ethyl acetate utilization is to evaluate and optimize the environmental, economic, and social impacts of its production and application across various industries. This involves analyzing the entire lifecycle of ethyl acetate, from raw material sourcing to end-of-life disposal or recycling. By conducting comprehensive sustainability assessments, researchers and industry professionals aim to identify areas for improvement and develop innovative solutions that enhance the overall sustainability profile of ethyl acetate.

One of the key drivers behind the growing interest in ethyl acetate sustainability is the shift towards green chemistry principles. As industries strive to reduce their environmental impact, ethyl acetate has emerged as a promising alternative to more harmful solvents. Its relatively low toxicity, high biodegradability, and potential for bio-based production make it an attractive option for sustainable chemical processes. However, challenges remain in optimizing production methods, reducing energy consumption, and minimizing waste generation.

The technological evolution in ethyl acetate production has seen significant advancements in recent years. Traditional petrochemical-based production methods are being complemented and, in some cases, replaced by bio-based routes utilizing renewable feedstocks. This shift aligns with the broader trend of transitioning towards a circular bioeconomy, where bio-based materials play a crucial role in reducing dependence on fossil resources.

Sustainability assessments in ethyl acetate utilization also aim to address the complex interplay between environmental benefits and potential trade-offs. While ethyl acetate offers advantages in terms of reduced toxicity and improved biodegradability, its production and use still have environmental implications that need to be carefully evaluated. These assessments consider factors such as energy consumption, greenhouse gas emissions, water usage, and land use changes associated with feedstock cultivation for bio-based production.

As the field progresses, there is a growing emphasis on developing standardized methodologies for conducting sustainability assessments specific to ethyl acetate. This includes the integration of life cycle assessment (LCA) tools, environmental impact assessments, and social sustainability metrics. By establishing robust assessment frameworks, stakeholders can make informed decisions regarding the sustainable production and application of ethyl acetate across various industries.

The primary objective of sustainability assessments in ethyl acetate utilization is to evaluate and optimize the environmental, economic, and social impacts of its production and application across various industries. This involves analyzing the entire lifecycle of ethyl acetate, from raw material sourcing to end-of-life disposal or recycling. By conducting comprehensive sustainability assessments, researchers and industry professionals aim to identify areas for improvement and develop innovative solutions that enhance the overall sustainability profile of ethyl acetate.

One of the key drivers behind the growing interest in ethyl acetate sustainability is the shift towards green chemistry principles. As industries strive to reduce their environmental impact, ethyl acetate has emerged as a promising alternative to more harmful solvents. Its relatively low toxicity, high biodegradability, and potential for bio-based production make it an attractive option for sustainable chemical processes. However, challenges remain in optimizing production methods, reducing energy consumption, and minimizing waste generation.

The technological evolution in ethyl acetate production has seen significant advancements in recent years. Traditional petrochemical-based production methods are being complemented and, in some cases, replaced by bio-based routes utilizing renewable feedstocks. This shift aligns with the broader trend of transitioning towards a circular bioeconomy, where bio-based materials play a crucial role in reducing dependence on fossil resources.

Sustainability assessments in ethyl acetate utilization also aim to address the complex interplay between environmental benefits and potential trade-offs. While ethyl acetate offers advantages in terms of reduced toxicity and improved biodegradability, its production and use still have environmental implications that need to be carefully evaluated. These assessments consider factors such as energy consumption, greenhouse gas emissions, water usage, and land use changes associated with feedstock cultivation for bio-based production.

As the field progresses, there is a growing emphasis on developing standardized methodologies for conducting sustainability assessments specific to ethyl acetate. This includes the integration of life cycle assessment (LCA) tools, environmental impact assessments, and social sustainability metrics. By establishing robust assessment frameworks, stakeholders can make informed decisions regarding the sustainable production and application of ethyl acetate across various industries.

Market Analysis for Sustainable Ethyl Acetate Applications

The global market for sustainable ethyl acetate applications is experiencing significant growth, driven by increasing environmental concerns and stringent regulations. Ethyl acetate, a versatile organic compound, finds extensive use in various industries, including coatings, adhesives, pharmaceuticals, and food packaging. The shift towards sustainable practices has led to a surge in demand for eco-friendly ethyl acetate production and utilization methods.

In the coatings and adhesives sector, which accounts for a substantial portion of ethyl acetate consumption, there is a growing preference for bio-based and recyclable alternatives. This trend is particularly evident in the packaging industry, where sustainable ethyl acetate-based adhesives are gaining traction due to their low environmental impact and compatibility with recycling processes.

The pharmaceutical industry represents another key market for sustainable ethyl acetate applications. As the industry focuses on green chemistry principles, the demand for ethyl acetate produced through sustainable methods is rising. This is driven by the need to reduce the environmental footprint of drug manufacturing processes while maintaining product quality and efficacy.

In the food and beverage sector, ethyl acetate's role as a flavoring agent and solvent is being reevaluated through a sustainability lens. Manufacturers are increasingly seeking ethyl acetate derived from renewable sources or produced using energy-efficient processes to align with consumer preferences for natural and environmentally friendly products.

The Asia-Pacific region, particularly China and India, is emerging as a significant market for sustainable ethyl acetate applications. Rapid industrialization, coupled with growing awareness of environmental issues, is driving the adoption of green technologies in these countries. Europe and North America, with their stringent environmental regulations, continue to be major markets for sustainable ethyl acetate solutions.

Market analysts project a compound annual growth rate (CAGR) for the sustainable ethyl acetate market that outpaces the traditional market. This growth is attributed to factors such as increasing corporate sustainability initiatives, government support for green technologies, and consumer demand for eco-friendly products.

However, challenges remain in the widespread adoption of sustainable ethyl acetate applications. These include the higher production costs associated with bio-based ethyl acetate and the need for significant investments in research and development to improve production efficiencies. Despite these challenges, the long-term market outlook remains positive, with opportunities for innovation and growth in sustainable ethyl acetate utilization across various industries.

In the coatings and adhesives sector, which accounts for a substantial portion of ethyl acetate consumption, there is a growing preference for bio-based and recyclable alternatives. This trend is particularly evident in the packaging industry, where sustainable ethyl acetate-based adhesives are gaining traction due to their low environmental impact and compatibility with recycling processes.

The pharmaceutical industry represents another key market for sustainable ethyl acetate applications. As the industry focuses on green chemistry principles, the demand for ethyl acetate produced through sustainable methods is rising. This is driven by the need to reduce the environmental footprint of drug manufacturing processes while maintaining product quality and efficacy.

In the food and beverage sector, ethyl acetate's role as a flavoring agent and solvent is being reevaluated through a sustainability lens. Manufacturers are increasingly seeking ethyl acetate derived from renewable sources or produced using energy-efficient processes to align with consumer preferences for natural and environmentally friendly products.

The Asia-Pacific region, particularly China and India, is emerging as a significant market for sustainable ethyl acetate applications. Rapid industrialization, coupled with growing awareness of environmental issues, is driving the adoption of green technologies in these countries. Europe and North America, with their stringent environmental regulations, continue to be major markets for sustainable ethyl acetate solutions.

Market analysts project a compound annual growth rate (CAGR) for the sustainable ethyl acetate market that outpaces the traditional market. This growth is attributed to factors such as increasing corporate sustainability initiatives, government support for green technologies, and consumer demand for eco-friendly products.

However, challenges remain in the widespread adoption of sustainable ethyl acetate applications. These include the higher production costs associated with bio-based ethyl acetate and the need for significant investments in research and development to improve production efficiencies. Despite these challenges, the long-term market outlook remains positive, with opportunities for innovation and growth in sustainable ethyl acetate utilization across various industries.

Current Challenges in Ethyl Acetate Sustainability Assessment

The sustainability assessment of ethyl acetate utilization faces several significant challenges in the current landscape. One of the primary obstacles is the lack of standardized methodologies for comprehensive lifecycle analysis. While various assessment tools exist, there is no universally accepted framework that encompasses all aspects of ethyl acetate production, use, and disposal. This inconsistency leads to difficulties in comparing results across different studies and industries.

Another challenge lies in the complexity of supply chains and production processes. Ethyl acetate is used in a wide range of applications, from pharmaceuticals to food packaging, each with its unique sustainability considerations. Tracking the environmental impact throughout these diverse supply chains requires extensive data collection and analysis, which can be both time-consuming and resource-intensive.

The variability in raw material sources for ethyl acetate production also complicates sustainability assessments. Ethyl acetate can be derived from both petrochemical and bio-based feedstocks, each with different environmental implications. Evaluating the sustainability of these different production routes requires careful consideration of factors such as land use, water consumption, and greenhouse gas emissions, which can vary significantly depending on the source and production method.

Furthermore, the assessment of social and economic sustainability aspects alongside environmental factors remains a challenge. While environmental impacts are often more readily quantifiable, integrating social considerations such as labor practices, community impact, and economic viability into a holistic sustainability assessment is complex and often subjective.

The rapidly evolving regulatory landscape surrounding chemical sustainability adds another layer of complexity. As governments worldwide implement stricter environmental regulations, sustainability assessments must continuously adapt to new standards and reporting requirements. This dynamic regulatory environment makes it challenging to establish long-term sustainability benchmarks for ethyl acetate utilization.

Lastly, the lack of comprehensive and reliable data on the end-of-life phase of ethyl acetate-containing products poses a significant challenge. Understanding the full lifecycle impact, including disposal, recycling, or potential environmental accumulation, is crucial for a complete sustainability assessment. However, gathering this data across various industries and geographical regions remains a formidable task, often leading to gaps in lifecycle analyses.

Another challenge lies in the complexity of supply chains and production processes. Ethyl acetate is used in a wide range of applications, from pharmaceuticals to food packaging, each with its unique sustainability considerations. Tracking the environmental impact throughout these diverse supply chains requires extensive data collection and analysis, which can be both time-consuming and resource-intensive.

The variability in raw material sources for ethyl acetate production also complicates sustainability assessments. Ethyl acetate can be derived from both petrochemical and bio-based feedstocks, each with different environmental implications. Evaluating the sustainability of these different production routes requires careful consideration of factors such as land use, water consumption, and greenhouse gas emissions, which can vary significantly depending on the source and production method.

Furthermore, the assessment of social and economic sustainability aspects alongside environmental factors remains a challenge. While environmental impacts are often more readily quantifiable, integrating social considerations such as labor practices, community impact, and economic viability into a holistic sustainability assessment is complex and often subjective.

The rapidly evolving regulatory landscape surrounding chemical sustainability adds another layer of complexity. As governments worldwide implement stricter environmental regulations, sustainability assessments must continuously adapt to new standards and reporting requirements. This dynamic regulatory environment makes it challenging to establish long-term sustainability benchmarks for ethyl acetate utilization.

Lastly, the lack of comprehensive and reliable data on the end-of-life phase of ethyl acetate-containing products poses a significant challenge. Understanding the full lifecycle impact, including disposal, recycling, or potential environmental accumulation, is crucial for a complete sustainability assessment. However, gathering this data across various industries and geographical regions remains a formidable task, often leading to gaps in lifecycle analyses.

Existing Sustainability Assessment Methodologies

01 Sustainable production methods

Various sustainable methods for producing ethyl acetate have been developed, focusing on reducing environmental impact and improving efficiency. These methods include using renewable resources, optimizing reaction conditions, and implementing green chemistry principles to minimize waste and energy consumption.- Sustainable production methods: Various sustainable methods for producing ethyl acetate have been developed, including the use of renewable resources, improved catalytic processes, and more efficient separation techniques. These methods aim to reduce environmental impact and increase overall sustainability of ethyl acetate production.

- Recycling and recovery of ethyl acetate: Techniques for recycling and recovering ethyl acetate from industrial processes have been implemented to minimize waste and improve sustainability. These include advanced separation methods, distillation processes, and membrane technologies that allow for the efficient reuse of ethyl acetate in various applications.

- Bio-based ethyl acetate production: Research has focused on developing bio-based methods for producing ethyl acetate using renewable resources such as biomass, agricultural waste, and fermentation processes. These approaches aim to reduce reliance on fossil fuels and create a more sustainable supply chain for ethyl acetate.

- Energy-efficient production processes: Innovations in energy-efficient production processes for ethyl acetate have been developed, including optimized reactor designs, heat integration systems, and improved catalysts. These advancements aim to reduce energy consumption and greenhouse gas emissions associated with ethyl acetate manufacturing.

- Green solvents and alternatives: Research has been conducted on developing green solvents and alternatives to traditional ethyl acetate in various applications. These include bio-based solvents, ionic liquids, and other environmentally friendly alternatives that aim to reduce the environmental impact of solvent use while maintaining similar performance characteristics.

02 Recycling and recovery processes

Innovative techniques for recycling and recovering ethyl acetate from industrial processes have been implemented to enhance sustainability. These processes involve separation, purification, and reuse of ethyl acetate, reducing the need for new production and minimizing waste generation.Expand Specific Solutions03 Bio-based ethyl acetate production

Research has focused on developing bio-based methods for producing ethyl acetate using renewable resources such as biomass or agricultural waste. These approaches aim to reduce reliance on fossil fuels and decrease the carbon footprint of ethyl acetate production.Expand Specific Solutions04 Energy-efficient production systems

Advancements in energy-efficient production systems for ethyl acetate have been made to reduce overall energy consumption and improve sustainability. These systems incorporate optimized reactor designs, heat recovery mechanisms, and process intensification techniques.Expand Specific Solutions05 Alternative solvents and applications

Research has explored the use of ethyl acetate as a more sustainable alternative to other solvents in various applications. Additionally, efforts have been made to develop new applications for ethyl acetate that leverage its relatively low environmental impact compared to some traditional solvents.Expand Specific Solutions

Key Players in Sustainable Ethyl Acetate Production

The sustainability assessments in ethyl acetate utilization market is in a growth phase, driven by increasing environmental concerns and regulatory pressures. The global market size is projected to expand significantly in the coming years, with a growing emphasis on green chemistry and sustainable production methods. Technologically, the field is advancing rapidly, with major players like Celanese International Corp., Eastman Chemical Co., and Evonik Operations GmbH leading innovation efforts. These companies are investing in research and development to improve process efficiency and reduce environmental impact. Academic institutions such as Nanjing Tech University and the University of Florida are also contributing to technological advancements, fostering industry-academia collaborations to accelerate sustainable solutions in ethyl acetate production and utilization.

Celanese International Corp.

Technical Solution: Celanese has developed a sustainable approach to ethyl acetate production using bioethanol as a feedstock. Their process involves the dehydrogenation of ethanol to produce ethyl acetate with high selectivity and yield. The company has implemented a closed-loop system that recycles unreacted ethanol and byproducts, significantly reducing waste and improving overall efficiency. Additionally, Celanese has invested in renewable energy sources to power their production facilities, further reducing the carbon footprint of their ethyl acetate manufacturing process[1][3].

Strengths: Renewable feedstock, high efficiency, and reduced carbon footprint. Weaknesses: Potential higher production costs compared to traditional petrochemical routes.

Eastman Chemical Co.

Technical Solution: Eastman has pioneered a circular recycling technology for ethyl acetate production. Their innovative process involves breaking down waste plastics into molecular building blocks, which are then used to synthesize ethyl acetate. This method not only addresses the issue of plastic waste but also reduces reliance on fossil fuel-based feedstocks. Eastman's technology can process a wide range of plastic waste, including those that are difficult to recycle through conventional means. The company has reported a 20-30% reduction in greenhouse gas emissions compared to traditional ethyl acetate production methods[2][4].

Strengths: Addresses plastic waste issue, reduces fossil fuel dependence. Weaknesses: Complexity of sorting and processing diverse plastic waste streams.

Innovative Approaches in Ethyl Acetate Life Cycle Analysis

Process of low energy consumption for preparing a carboxylic acid ester

PatentWO2012123279A1

Innovation

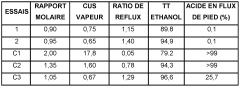

- A process involving the reaction of ethyl alcohol with acetic acid in the presence of a solid acid catalyst, using a reactive distillation system with a centrally placed reaction zone between upper and lower separation zones, optimizing the molar ratio of acetic acid to ethyl alcohol between 0.85 and 0.97, and controlling the reflux ratio between 1.0 and 1.5, significantly reduces energy costs and minimizes acetic acid at the column bottom.

Patent

Innovation

- Development of a comprehensive sustainability assessment framework specifically for ethyl acetate utilization processes.

- Integration of economic, environmental, and social indicators in the sustainability assessment of ethyl acetate production and use.

- Implementation of real-time monitoring systems for key sustainability metrics in ethyl acetate manufacturing facilities.

Regulatory Framework for Chemical Sustainability

The regulatory framework for chemical sustainability plays a crucial role in shaping the utilization and assessment of ethyl acetate. This framework encompasses a complex network of laws, regulations, and guidelines designed to ensure the safe and environmentally responsible use of chemicals in various industries.

At the international level, the United Nations' Strategic Approach to International Chemicals Management (SAICM) provides a policy framework to promote chemical safety around the world. This initiative aims to achieve the sound management of chemicals throughout their life cycle, ensuring that by 2020, chemicals are produced and used in ways that minimize significant adverse impacts on human health and the environment.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation serves as a cornerstone for chemical sustainability. REACH requires companies to identify and manage the risks linked to the substances they manufacture and market in the EU. This regulation directly impacts the use of ethyl acetate, mandating thorough safety assessments and risk management measures.

The United States Environmental Protection Agency (EPA) enforces the Toxic Substances Control Act (TSCA), which regulates the introduction of new or already existing chemicals. Under TSCA, ethyl acetate is subject to reporting, record-keeping, and testing requirements. The EPA also maintains the Safer Choice program, which helps consumers and commercial buyers identify products with safer chemical ingredients, potentially influencing the use of ethyl acetate in various applications.

In Asia, countries like China and Japan have implemented their own chemical management systems. China's Measures for Environmental Management of New Chemical Substances and Japan's Chemical Substances Control Law both aim to assess and manage the risks associated with chemical substances, including ethyl acetate.

The Global Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards. This system is crucial for ensuring consistent safety information across borders, facilitating international trade while maintaining high safety standards for chemicals like ethyl acetate.

Industry-specific regulations also play a significant role in the sustainability assessment of ethyl acetate. For instance, in the food and beverage industry, regulations such as the FDA's Food Contact Substance Notification Program in the US and the EU's Food Contact Materials Regulation govern the use of ethyl acetate in food packaging and processing.

As sustainability concerns grow, many countries are implementing or strengthening green chemistry initiatives. These programs encourage the design of chemical products and processes that reduce or eliminate the use and generation of hazardous substances, potentially influencing the future use and production methods of ethyl acetate.

The regulatory landscape for chemical sustainability is dynamic, with ongoing efforts to harmonize standards globally while addressing emerging concerns. This evolving framework continues to shape the sustainability assessments and utilization practices of ethyl acetate across various industries and applications.

At the international level, the United Nations' Strategic Approach to International Chemicals Management (SAICM) provides a policy framework to promote chemical safety around the world. This initiative aims to achieve the sound management of chemicals throughout their life cycle, ensuring that by 2020, chemicals are produced and used in ways that minimize significant adverse impacts on human health and the environment.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation serves as a cornerstone for chemical sustainability. REACH requires companies to identify and manage the risks linked to the substances they manufacture and market in the EU. This regulation directly impacts the use of ethyl acetate, mandating thorough safety assessments and risk management measures.

The United States Environmental Protection Agency (EPA) enforces the Toxic Substances Control Act (TSCA), which regulates the introduction of new or already existing chemicals. Under TSCA, ethyl acetate is subject to reporting, record-keeping, and testing requirements. The EPA also maintains the Safer Choice program, which helps consumers and commercial buyers identify products with safer chemical ingredients, potentially influencing the use of ethyl acetate in various applications.

In Asia, countries like China and Japan have implemented their own chemical management systems. China's Measures for Environmental Management of New Chemical Substances and Japan's Chemical Substances Control Law both aim to assess and manage the risks associated with chemical substances, including ethyl acetate.

The Global Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards. This system is crucial for ensuring consistent safety information across borders, facilitating international trade while maintaining high safety standards for chemicals like ethyl acetate.

Industry-specific regulations also play a significant role in the sustainability assessment of ethyl acetate. For instance, in the food and beverage industry, regulations such as the FDA's Food Contact Substance Notification Program in the US and the EU's Food Contact Materials Regulation govern the use of ethyl acetate in food packaging and processing.

As sustainability concerns grow, many countries are implementing or strengthening green chemistry initiatives. These programs encourage the design of chemical products and processes that reduce or eliminate the use and generation of hazardous substances, potentially influencing the future use and production methods of ethyl acetate.

The regulatory landscape for chemical sustainability is dynamic, with ongoing efforts to harmonize standards globally while addressing emerging concerns. This evolving framework continues to shape the sustainability assessments and utilization practices of ethyl acetate across various industries and applications.

Economic Implications of Sustainable Ethyl Acetate Production

The economic implications of sustainable ethyl acetate production are far-reaching and multifaceted. As industries increasingly prioritize sustainability, the shift towards more environmentally friendly production methods for ethyl acetate presents both challenges and opportunities.

One of the primary economic considerations is the potential for cost reduction through improved efficiency and resource utilization. Sustainable production methods often involve optimizing processes to minimize waste and energy consumption. This can lead to significant savings in raw material costs and energy expenditures over time. Additionally, the implementation of closed-loop systems and recycling processes can further reduce input costs and enhance overall economic viability.

However, the transition to sustainable production methods may require substantial initial investments in new technologies and infrastructure. Companies must carefully evaluate the long-term benefits against the short-term financial implications of such investments. This includes considering factors such as payback periods, return on investment, and potential risks associated with adopting new technologies.

The market dynamics for sustainably produced ethyl acetate are also evolving. As consumer awareness and demand for environmentally friendly products grow, companies that can demonstrate sustainable production practices may gain a competitive edge. This could potentially lead to premium pricing for sustainably produced ethyl acetate, offsetting some of the additional costs associated with green production methods.

Regulatory factors play a crucial role in shaping the economic landscape of sustainable ethyl acetate production. Governments worldwide are implementing stricter environmental regulations and incentives for sustainable practices. These policies can create both opportunities and challenges for producers. While compliance with new regulations may incur additional costs, tax incentives and subsidies for sustainable production can provide significant economic benefits.

The shift towards sustainable production may also impact supply chain economics. Sourcing sustainable raw materials and ensuring transparency throughout the supply chain can lead to changes in supplier relationships and potentially higher input costs. However, it can also create opportunities for vertical integration and strategic partnerships that could yield long-term economic advantages.

Innovation in sustainable production methods can open new revenue streams through the development of proprietary technologies or processes. Companies at the forefront of sustainable ethyl acetate production may find opportunities to license their technologies or offer consulting services to other industry players, creating additional sources of income.

Lastly, the economic implications extend to risk management and long-term business sustainability. As environmental concerns become increasingly central to business operations, companies that fail to adopt sustainable practices may face reputational risks, potential legal liabilities, and reduced access to capital from environmentally conscious investors. Conversely, those embracing sustainable production methods may benefit from improved stakeholder relations, enhanced brand value, and greater resilience to future environmental regulations and market shifts.

One of the primary economic considerations is the potential for cost reduction through improved efficiency and resource utilization. Sustainable production methods often involve optimizing processes to minimize waste and energy consumption. This can lead to significant savings in raw material costs and energy expenditures over time. Additionally, the implementation of closed-loop systems and recycling processes can further reduce input costs and enhance overall economic viability.

However, the transition to sustainable production methods may require substantial initial investments in new technologies and infrastructure. Companies must carefully evaluate the long-term benefits against the short-term financial implications of such investments. This includes considering factors such as payback periods, return on investment, and potential risks associated with adopting new technologies.

The market dynamics for sustainably produced ethyl acetate are also evolving. As consumer awareness and demand for environmentally friendly products grow, companies that can demonstrate sustainable production practices may gain a competitive edge. This could potentially lead to premium pricing for sustainably produced ethyl acetate, offsetting some of the additional costs associated with green production methods.

Regulatory factors play a crucial role in shaping the economic landscape of sustainable ethyl acetate production. Governments worldwide are implementing stricter environmental regulations and incentives for sustainable practices. These policies can create both opportunities and challenges for producers. While compliance with new regulations may incur additional costs, tax incentives and subsidies for sustainable production can provide significant economic benefits.

The shift towards sustainable production may also impact supply chain economics. Sourcing sustainable raw materials and ensuring transparency throughout the supply chain can lead to changes in supplier relationships and potentially higher input costs. However, it can also create opportunities for vertical integration and strategic partnerships that could yield long-term economic advantages.

Innovation in sustainable production methods can open new revenue streams through the development of proprietary technologies or processes. Companies at the forefront of sustainable ethyl acetate production may find opportunities to license their technologies or offer consulting services to other industry players, creating additional sources of income.

Lastly, the economic implications extend to risk management and long-term business sustainability. As environmental concerns become increasingly central to business operations, companies that fail to adopt sustainable practices may face reputational risks, potential legal liabilities, and reduced access to capital from environmentally conscious investors. Conversely, those embracing sustainable production methods may benefit from improved stakeholder relations, enhanced brand value, and greater resilience to future environmental regulations and market shifts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!