The balance of form and function in V16 engine layouts

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V16 Engine Evolution

The V16 engine layout has undergone significant evolution since its inception in the early 20th century. Initially developed for high-performance applications in aviation and racing, the V16 configuration has seen various iterations and improvements over time, each striving to balance form and function in unique ways.

In the 1930s, Auto Union introduced the Type A race car, featuring a V16 engine designed by Ferdinand Porsche. This marked a pivotal moment in V16 engine evolution, showcasing the potential for immense power output in a relatively compact package. The engine's layout allowed for a lower center of gravity, improving vehicle handling and aerodynamics.

The 1930s also saw Cadillac experimenting with V16 engines for luxury automobiles. Their approach focused on smooth operation and refined power delivery, emphasizing the importance of balancing performance with comfort in high-end consumer applications. This era demonstrated the versatility of the V16 configuration across different automotive segments.

Post-World War II, the focus shifted towards more practical engine configurations for mass-market vehicles. However, the V16 layout continued to evolve in specialized applications. In the 1960s, BRM (British Racing Motors) developed a V16 Formula One engine, pushing the boundaries of power-to-weight ratios in motorsport.

The late 20th century saw a resurgence of interest in V16 engines for concept cars and limited-production vehicles. Manufacturers like Cizeta-Moroder with the V16T supercar in the 1990s showcased how modern engineering could address previous challenges in packaging and weight distribution associated with the V16 layout.

In recent years, the evolution of V16 engines has been largely conceptual, with various automakers exploring the configuration for its potential in ultra-luxury and high-performance applications. These modern interpretations often focus on integrating advanced materials and technologies to optimize power output, efficiency, and packaging.

The ongoing evolution of V16 engines reflects a constant pursuit of balancing form and function. Engineers continue to explore ways to harness the power potential of 16 cylinders while addressing challenges related to weight, size, and complexity. This evolution has led to innovations in areas such as cylinder deactivation, variable valve timing, and advanced cooling systems, all aimed at enhancing the V16's performance and efficiency.

As environmental concerns become increasingly prominent, the future evolution of V16 engines may involve integration with hybrid or electric powertrains, potentially allowing this iconic configuration to adapt to changing automotive landscapes while maintaining its status as a pinnacle of engineering prowess.

In the 1930s, Auto Union introduced the Type A race car, featuring a V16 engine designed by Ferdinand Porsche. This marked a pivotal moment in V16 engine evolution, showcasing the potential for immense power output in a relatively compact package. The engine's layout allowed for a lower center of gravity, improving vehicle handling and aerodynamics.

The 1930s also saw Cadillac experimenting with V16 engines for luxury automobiles. Their approach focused on smooth operation and refined power delivery, emphasizing the importance of balancing performance with comfort in high-end consumer applications. This era demonstrated the versatility of the V16 configuration across different automotive segments.

Post-World War II, the focus shifted towards more practical engine configurations for mass-market vehicles. However, the V16 layout continued to evolve in specialized applications. In the 1960s, BRM (British Racing Motors) developed a V16 Formula One engine, pushing the boundaries of power-to-weight ratios in motorsport.

The late 20th century saw a resurgence of interest in V16 engines for concept cars and limited-production vehicles. Manufacturers like Cizeta-Moroder with the V16T supercar in the 1990s showcased how modern engineering could address previous challenges in packaging and weight distribution associated with the V16 layout.

In recent years, the evolution of V16 engines has been largely conceptual, with various automakers exploring the configuration for its potential in ultra-luxury and high-performance applications. These modern interpretations often focus on integrating advanced materials and technologies to optimize power output, efficiency, and packaging.

The ongoing evolution of V16 engines reflects a constant pursuit of balancing form and function. Engineers continue to explore ways to harness the power potential of 16 cylinders while addressing challenges related to weight, size, and complexity. This evolution has led to innovations in areas such as cylinder deactivation, variable valve timing, and advanced cooling systems, all aimed at enhancing the V16's performance and efficiency.

As environmental concerns become increasingly prominent, the future evolution of V16 engines may involve integration with hybrid or electric powertrains, potentially allowing this iconic configuration to adapt to changing automotive landscapes while maintaining its status as a pinnacle of engineering prowess.

Market Demand Analysis

The market demand for V16 engine layouts has been relatively niche but persistent, primarily driven by luxury and high-performance vehicle segments. Historically, V16 engines have been associated with prestige, power, and exclusivity, appealing to a select group of automotive enthusiasts and ultra-luxury car manufacturers.

In recent years, there has been a resurgence of interest in V16 engines, particularly in the hypercar and concept car markets. This renewed demand is fueled by the desire for unique, high-performance powertrains that can differentiate vehicles in an increasingly competitive luxury automotive landscape. Manufacturers are exploring V16 layouts as a way to showcase engineering prowess and create halo products that generate buzz and enhance brand image.

The market for V16 engines is closely tied to the broader trends in the automotive industry, including the shift towards electrification and increased focus on environmental sustainability. While this might seem contradictory to the development of large displacement engines, there is a growing demand for hybrid powertrains that incorporate V16 engines alongside electric motors. This combination allows for the retention of the prestigious V16 configuration while addressing efficiency concerns.

From a geographical perspective, the demand for V16 engines is primarily concentrated in mature automotive markets with high disposable incomes, such as North America, Western Europe, and parts of Asia. These regions have a strong culture of automotive enthusiasm and a customer base willing to invest in exclusive, high-performance vehicles.

The potential market size for V16 engines remains limited due to their specialized nature and high production costs. However, the value proposition of V16 engines extends beyond direct sales, as they serve as technological showcases and marketing tools for automotive brands. The development and production of V16 engines can lead to technological advancements that trickle down to more mainstream engine configurations.

Looking ahead, the market demand for V16 engines is expected to evolve in response to regulatory pressures and changing consumer preferences. While traditional applications in internal combustion engines may face challenges, there is potential for V16 layouts to find new relevance in emerging powertrain technologies, such as hydrogen fuel cells or advanced hybrid systems.

In conclusion, while the market for V16 engines remains specialized, there is a persistent demand driven by the pursuit of automotive excellence and the desire for distinctive, high-performance powertrains. The balance between form and function in V16 layouts continues to captivate a segment of the automotive market, ensuring ongoing interest and development in this unique engine configuration.

In recent years, there has been a resurgence of interest in V16 engines, particularly in the hypercar and concept car markets. This renewed demand is fueled by the desire for unique, high-performance powertrains that can differentiate vehicles in an increasingly competitive luxury automotive landscape. Manufacturers are exploring V16 layouts as a way to showcase engineering prowess and create halo products that generate buzz and enhance brand image.

The market for V16 engines is closely tied to the broader trends in the automotive industry, including the shift towards electrification and increased focus on environmental sustainability. While this might seem contradictory to the development of large displacement engines, there is a growing demand for hybrid powertrains that incorporate V16 engines alongside electric motors. This combination allows for the retention of the prestigious V16 configuration while addressing efficiency concerns.

From a geographical perspective, the demand for V16 engines is primarily concentrated in mature automotive markets with high disposable incomes, such as North America, Western Europe, and parts of Asia. These regions have a strong culture of automotive enthusiasm and a customer base willing to invest in exclusive, high-performance vehicles.

The potential market size for V16 engines remains limited due to their specialized nature and high production costs. However, the value proposition of V16 engines extends beyond direct sales, as they serve as technological showcases and marketing tools for automotive brands. The development and production of V16 engines can lead to technological advancements that trickle down to more mainstream engine configurations.

Looking ahead, the market demand for V16 engines is expected to evolve in response to regulatory pressures and changing consumer preferences. While traditional applications in internal combustion engines may face challenges, there is potential for V16 layouts to find new relevance in emerging powertrain technologies, such as hydrogen fuel cells or advanced hybrid systems.

In conclusion, while the market for V16 engines remains specialized, there is a persistent demand driven by the pursuit of automotive excellence and the desire for distinctive, high-performance powertrains. The balance between form and function in V16 layouts continues to captivate a segment of the automotive market, ensuring ongoing interest and development in this unique engine configuration.

Technical Challenges

The development of V16 engine layouts presents a complex set of technical challenges that engineers must navigate to achieve an optimal balance between form and function. One of the primary hurdles is managing the increased length and weight of the engine block, which can significantly impact vehicle design and performance. The extended crankshaft required for a V16 configuration is particularly susceptible to torsional vibrations, necessitating advanced damping systems and precise balancing techniques.

Thermal management poses another significant challenge in V16 engines. The increased number of cylinders generates substantial heat, requiring sophisticated cooling systems to maintain optimal operating temperatures across the entire engine. This often involves intricate coolant passages and potentially multiple radiators, adding complexity to the overall engine design and vehicle packaging.

Fuel delivery and air intake systems must be meticulously engineered to ensure uniform distribution across all 16 cylinders. This challenge is compounded by the need for precise timing and control of multiple fuel injectors and valves, demanding advanced engine management systems and high-precision manufacturing techniques.

The complexity of the exhaust system in V16 engines presents its own set of challenges. Engineers must design a system that efficiently evacuates exhaust gases from all cylinders while minimizing back pressure and meeting stringent emissions standards. This often results in intricate exhaust manifolds and potentially multiple catalytic converters, further complicating the engine's packaging within the vehicle.

Lubrication is another critical area of concern in V16 engines. The extended crankshaft and increased number of moving parts require a robust oil circulation system to ensure adequate lubrication throughout the engine. This may involve multiple oil pumps and carefully designed oil galleries to maintain proper oil pressure and flow across all components.

Manufacturing and assembly processes for V16 engines present their own unique challenges. The increased number of components and tighter tolerances require highly specialized tooling and assembly techniques. Quality control becomes even more critical, as the complexity of the engine amplifies the potential for manufacturing defects or assembly errors.

Lastly, the integration of V16 engines into vehicle platforms poses significant challenges in terms of weight distribution, center of gravity, and overall vehicle dynamics. Engineers must carefully consider the impact of the engine's size and weight on vehicle handling, stability, and performance, often requiring extensive chassis and suspension tuning to achieve optimal results.

Thermal management poses another significant challenge in V16 engines. The increased number of cylinders generates substantial heat, requiring sophisticated cooling systems to maintain optimal operating temperatures across the entire engine. This often involves intricate coolant passages and potentially multiple radiators, adding complexity to the overall engine design and vehicle packaging.

Fuel delivery and air intake systems must be meticulously engineered to ensure uniform distribution across all 16 cylinders. This challenge is compounded by the need for precise timing and control of multiple fuel injectors and valves, demanding advanced engine management systems and high-precision manufacturing techniques.

The complexity of the exhaust system in V16 engines presents its own set of challenges. Engineers must design a system that efficiently evacuates exhaust gases from all cylinders while minimizing back pressure and meeting stringent emissions standards. This often results in intricate exhaust manifolds and potentially multiple catalytic converters, further complicating the engine's packaging within the vehicle.

Lubrication is another critical area of concern in V16 engines. The extended crankshaft and increased number of moving parts require a robust oil circulation system to ensure adequate lubrication throughout the engine. This may involve multiple oil pumps and carefully designed oil galleries to maintain proper oil pressure and flow across all components.

Manufacturing and assembly processes for V16 engines present their own unique challenges. The increased number of components and tighter tolerances require highly specialized tooling and assembly techniques. Quality control becomes even more critical, as the complexity of the engine amplifies the potential for manufacturing defects or assembly errors.

Lastly, the integration of V16 engines into vehicle platforms poses significant challenges in terms of weight distribution, center of gravity, and overall vehicle dynamics. Engineers must carefully consider the impact of the engine's size and weight on vehicle handling, stability, and performance, often requiring extensive chassis and suspension tuning to achieve optimal results.

Current V16 Designs

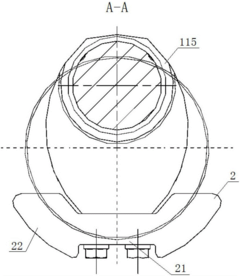

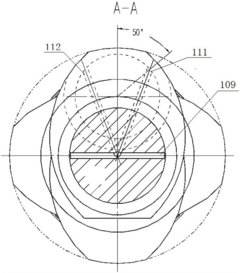

01 Cylinder arrangement and crankshaft design

V16 engines balance form and function through innovative cylinder arrangements and crankshaft designs. These configurations optimize power output while maintaining a compact form factor. The arrangement of cylinders in a V-shape allows for better weight distribution and reduced engine length compared to inline configurations.- Cylinder arrangement and crankshaft design: V16 engines balance form and function through innovative cylinder arrangements and crankshaft designs. These configurations optimize power output while maintaining a compact form factor. The arrangement of cylinders in a V-shape allows for better weight distribution and reduced engine length compared to inline configurations.

- Vibration reduction and balancing mechanisms: To achieve balance in V16 engines, various vibration reduction and balancing mechanisms are employed. These include counterweights, balance shafts, and advanced mounting systems. These components work together to minimize engine vibrations and ensure smooth operation, enhancing both performance and comfort.

- Intake and exhaust system optimization: The balance of form and function in V16 engines is further improved through optimized intake and exhaust systems. Advanced designs for air intake manifolds and exhaust headers contribute to enhanced engine breathing, power output, and efficiency while maintaining a compact overall package.

- Cooling system integration: Efficient cooling system integration is crucial for balancing the form and function of V16 engines. Innovative cooling designs, including advanced radiator configurations and targeted coolant flow, help manage the high heat output of these powerful engines while maintaining a sleek and compact engine bay layout.

- Materials and manufacturing techniques: The use of advanced materials and manufacturing techniques contributes to the balance of form and function in V16 engines. Lightweight alloys, precision machining, and innovative casting methods allow for the creation of complex engine components that optimize performance while reducing overall engine weight and size.

02 Vibration reduction and balancing mechanisms

To achieve balance in V16 engines, various vibration reduction and balancing mechanisms are employed. These include counterweights, balance shafts, and advanced mounting systems. Such features help minimize engine vibrations, enhancing overall performance and longevity while improving driver comfort.Expand Specific Solutions03 Fuel efficiency and emissions control

V16 engines incorporate advanced technologies to balance power output with fuel efficiency and emissions control. This includes optimized fuel injection systems, variable valve timing, and exhaust gas recirculation. These innovations help meet stringent environmental regulations while maintaining high performance.Expand Specific Solutions04 Cooling and lubrication systems

Effective cooling and lubrication systems are crucial for balancing the form and function of V16 engines. Advanced cooling techniques, such as precision coolant flow management and oil jet piston cooling, help maintain optimal operating temperatures. Efficient lubrication systems ensure proper oil distribution throughout the engine, reducing wear and enhancing performance.Expand Specific Solutions05 Materials and manufacturing techniques

The use of advanced materials and manufacturing techniques contributes to the balance of form and function in V16 engines. Lightweight alloys, composite materials, and precision manufacturing processes allow for the creation of engines with improved power-to-weight ratios and enhanced durability. These innovations enable the development of high-performance V16 engines suitable for various applications.Expand Specific Solutions

Key V16 Manufacturers

The V16 engine layout represents a niche market within the automotive and marine industries, currently in a mature stage of development. The market size for V16 engines is relatively small, primarily catering to high-end luxury vehicles, marine applications, and specialized industrial uses. Technologically, V16 engines are well-established but continue to evolve, with companies like Mercedes-Benz Group AG and BMW (Bayerische Motoren Werke AG) leading innovation in this space. These manufacturers, along with others like Volkswagen AG and Yamaha Motor Co., Ltd., focus on balancing the impressive power output of V16 engines with increasing demands for efficiency and environmental compliance. The complexity and cost of V16 engines limit their widespread adoption, positioning them as premium offerings in select markets.

Honda Motor Co., Ltd.

Technical Solution: Honda's approach to V16 engine design focuses on achieving a balance between high performance and practical application. While Honda has not produced a production V16 engine, their concept explores the potential of such a configuration for high-end sports and luxury vehicles. The design incorporates Honda's VTEC (Variable Valve Timing and Lift Electronic Control) system, adapted for the V16 layout to optimize performance across the entire RPM range[9]. To address the inherent challenges of a V16 configuration, Honda employs advanced materials such as titanium for valves and connecting rods to reduce reciprocating mass. The engine concept also features a dry-sump lubrication system to ensure consistent oil pressure and allow for a lower engine placement, improving the vehicle's center of gravity[10].

Strengths: Potential for extremely high power output, application of proven VTEC technology, and Honda's reputation for reliability. Weaknesses: Limited practical applications, high development and production costs, and challenges in meeting fuel efficiency standards.

Volkswagen AG

Technical Solution: Volkswagen's approach to V16 engine design emphasizes efficiency and modularity. Their V16 concept is based on a modular design philosophy, allowing for shared components with smaller engine configurations to reduce production costs[7]. The engine features a 72-degree V-angle, balancing compactness with optimal firing intervals. VW incorporates their advanced FSI (Fuel Stratified Injection) technology, adapted for the V16 layout to ensure precise fuel delivery and improved combustion efficiency. To address the challenges of weight and size, Volkswagen utilizes lightweight materials and compact accessory drives. The company has also developed a sophisticated thermal management system to maintain optimal operating temperatures across the large number of cylinders, crucial for efficiency and longevity[8].

Strengths: Modular design for cost-effective production, advanced fuel injection technology, and potential for high-end luxury applications. Weaknesses: Complexity in emissions control, high fuel consumption, and limited market demand for V16 engines.

Core V16 Innovations

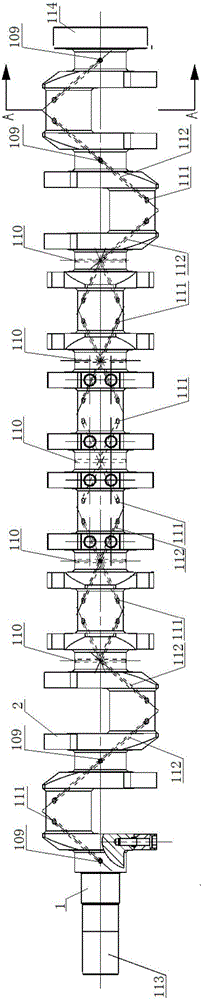

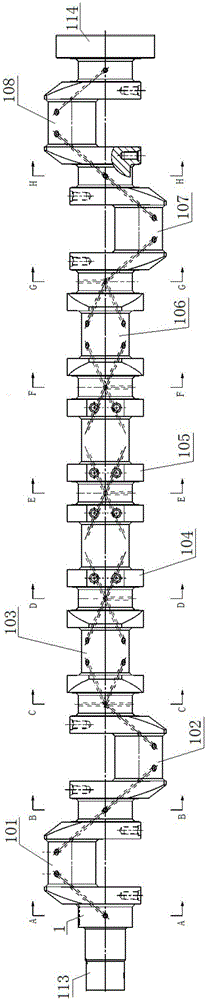

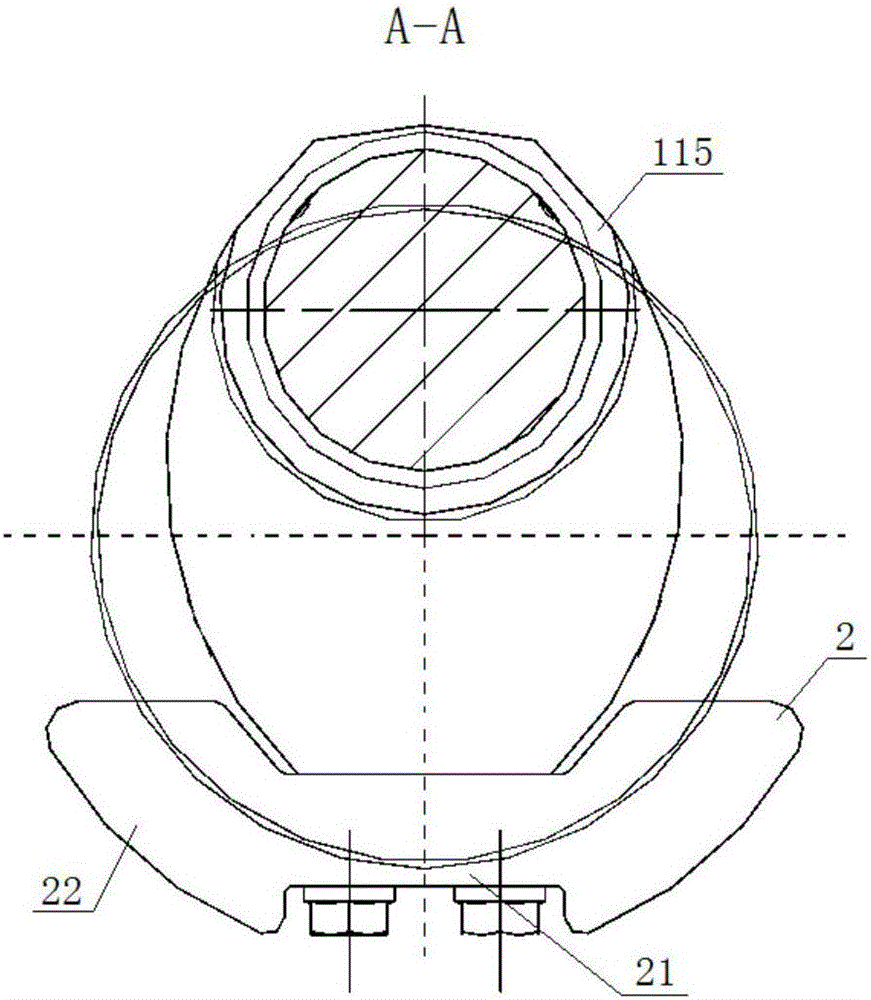

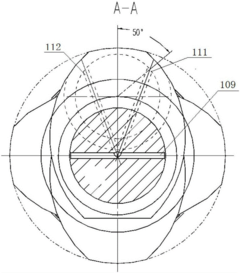

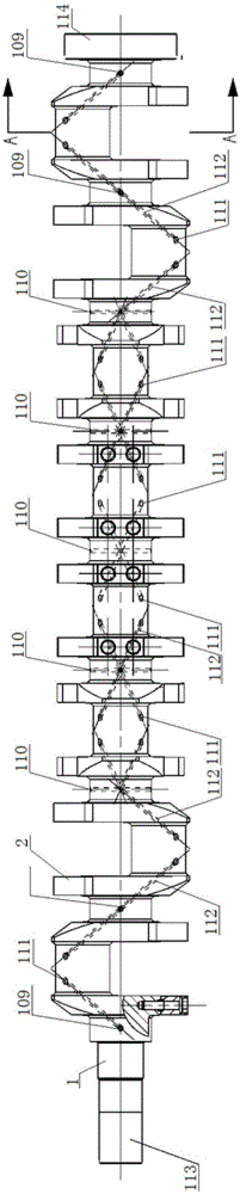

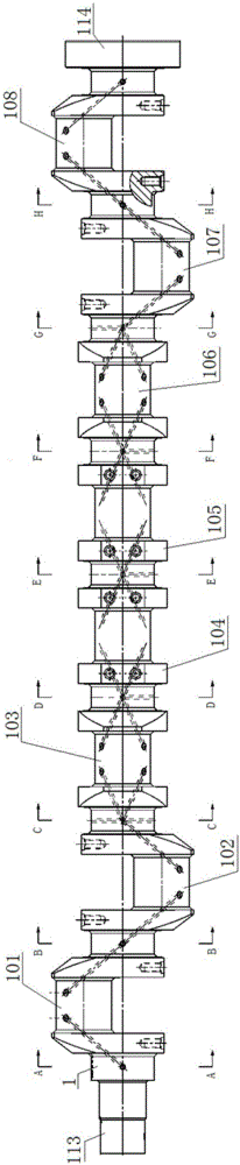

Crankshaft structure of V-shaped 16-cylinder engine

PatentInactiveCN106089974A

Innovation

- A V-shaped 16-cylinder engine crankshaft structure is designed, using horizontal and vertical oil passage arrangements on multiple cranks and connecting rod journals, combined with symmetrical crank arms and counterweights, to optimize the oil passage arrangement and firing sequence. , enhanced lubrication effect and dynamic balance.

Crankshaft structure for V-type 16 cylinder engine

PatentInactiveCN106089975A

Innovation

- A V-shaped 16-cylinder engine crankshaft structure was designed, using a symmetrical crank arm and counterweight design to optimize the firing sequence, and set up horizontal and vertical oil passages on the crankshaft journal to form an inclined oil passage to improve the lubrication effect.

Environmental Impact

The environmental impact of V16 engine layouts is a critical consideration in the balance between form and function. These powerful engines, while offering impressive performance, have significant implications for fuel consumption and emissions. V16 engines typically consume more fuel than smaller configurations, leading to increased carbon dioxide emissions. This higher fuel consumption is primarily due to the larger displacement and greater number of cylinders, which require more energy to operate.

Emissions from V16 engines are also a concern. These engines often produce higher levels of nitrogen oxides (NOx) and particulate matter due to their high-performance nature and the combustion characteristics of larger engines. The increased emissions contribute to air pollution and can have negative effects on both human health and the environment. As a result, manufacturers must invest heavily in advanced emission control technologies to meet increasingly stringent environmental regulations.

The production and disposal of V16 engines also have environmental implications. The manufacturing process requires more raw materials and energy compared to smaller engines, leading to a larger carbon footprint. Additionally, the complexity of these engines can make them more challenging to recycle at the end of their life cycle, potentially increasing waste and environmental impact.

However, it's important to note that advancements in engine technology have led to improvements in the environmental performance of V16 engines. Modern V16 designs often incorporate features such as direct fuel injection, variable valve timing, and cylinder deactivation, which can help improve fuel efficiency and reduce emissions. Some manufacturers are also exploring hybrid V16 configurations, combining the power of the V16 with electric motors to achieve better environmental performance.

The use of lightweight materials in V16 engine construction, such as aluminum alloys and carbon fiber components, can help offset some of the environmental impact by reducing overall vehicle weight and improving fuel efficiency. Additionally, the development of more efficient lubricants and cooling systems can further enhance the environmental performance of these engines.

In conclusion, while V16 engines present significant environmental challenges due to their size and power output, ongoing technological advancements are helping to mitigate their impact. The balance between form and function in V16 layouts continues to evolve, with manufacturers striving to meet performance demands while addressing environmental concerns through innovative engineering solutions.

Emissions from V16 engines are also a concern. These engines often produce higher levels of nitrogen oxides (NOx) and particulate matter due to their high-performance nature and the combustion characteristics of larger engines. The increased emissions contribute to air pollution and can have negative effects on both human health and the environment. As a result, manufacturers must invest heavily in advanced emission control technologies to meet increasingly stringent environmental regulations.

The production and disposal of V16 engines also have environmental implications. The manufacturing process requires more raw materials and energy compared to smaller engines, leading to a larger carbon footprint. Additionally, the complexity of these engines can make them more challenging to recycle at the end of their life cycle, potentially increasing waste and environmental impact.

However, it's important to note that advancements in engine technology have led to improvements in the environmental performance of V16 engines. Modern V16 designs often incorporate features such as direct fuel injection, variable valve timing, and cylinder deactivation, which can help improve fuel efficiency and reduce emissions. Some manufacturers are also exploring hybrid V16 configurations, combining the power of the V16 with electric motors to achieve better environmental performance.

The use of lightweight materials in V16 engine construction, such as aluminum alloys and carbon fiber components, can help offset some of the environmental impact by reducing overall vehicle weight and improving fuel efficiency. Additionally, the development of more efficient lubricants and cooling systems can further enhance the environmental performance of these engines.

In conclusion, while V16 engines present significant environmental challenges due to their size and power output, ongoing technological advancements are helping to mitigate their impact. The balance between form and function in V16 layouts continues to evolve, with manufacturers striving to meet performance demands while addressing environmental concerns through innovative engineering solutions.

Performance Benchmarks

Performance benchmarks for V16 engine layouts provide crucial insights into the delicate balance between form and function in these complex powerplants. When evaluating V16 engines, several key metrics are typically considered to assess their overall performance and efficiency.

Horsepower output is a primary benchmark, with modern V16 engines capable of producing over 1,000 horsepower. The Bugatti Chiron's 8.0-liter quad-turbocharged W16 engine, for instance, generates an impressive 1,479 horsepower. Torque figures are equally important, with V16 engines often delivering massive amounts of low-end torque, enhancing acceleration and towing capabilities.

Fuel efficiency, while not typically a priority in V16 applications, is still measured and compared. Advanced technologies such as direct injection, variable valve timing, and cylinder deactivation have improved fuel economy in recent V16 designs. However, these engines generally consume significantly more fuel than their smaller counterparts.

Acceleration times, particularly 0-60 mph and quarter-mile times, are standard performance benchmarks. V16-powered vehicles often achieve exceptional acceleration due to their high power output and torque characteristics. Top speed is another crucial metric, with some V16-equipped supercars capable of reaching speeds over 250 mph.

Thermal efficiency is a critical benchmark that measures how effectively the engine converts fuel energy into mechanical power. Modern V16 engines employ advanced cooling systems and materials to manage heat dissipation and maintain optimal operating temperatures.

Power-to-weight ratio is particularly relevant for V16 engines, as their size and complexity often result in significant weight. Engineers strive to optimize this ratio through the use of lightweight materials and compact designs. The packaging efficiency of V16 layouts is also benchmarked, considering how well the engine integrates into the vehicle's overall design.

Emissions performance is increasingly important, with V16 engines facing stringent regulations. Advanced exhaust aftertreatment systems and combustion optimization techniques are employed to meet emissions standards while maintaining high performance levels.

Durability and reliability metrics, such as mean time between failures and service intervals, are crucial for assessing the long-term viability of V16 engines. These complex powerplants must demonstrate robustness despite their intricate designs and high-stress operating conditions.

By analyzing these performance benchmarks, engineers and designers can fine-tune the balance between form and function in V16 engine layouts, creating powerplants that deliver exceptional performance while meeting practical requirements for modern vehicles.

Horsepower output is a primary benchmark, with modern V16 engines capable of producing over 1,000 horsepower. The Bugatti Chiron's 8.0-liter quad-turbocharged W16 engine, for instance, generates an impressive 1,479 horsepower. Torque figures are equally important, with V16 engines often delivering massive amounts of low-end torque, enhancing acceleration and towing capabilities.

Fuel efficiency, while not typically a priority in V16 applications, is still measured and compared. Advanced technologies such as direct injection, variable valve timing, and cylinder deactivation have improved fuel economy in recent V16 designs. However, these engines generally consume significantly more fuel than their smaller counterparts.

Acceleration times, particularly 0-60 mph and quarter-mile times, are standard performance benchmarks. V16-powered vehicles often achieve exceptional acceleration due to their high power output and torque characteristics. Top speed is another crucial metric, with some V16-equipped supercars capable of reaching speeds over 250 mph.

Thermal efficiency is a critical benchmark that measures how effectively the engine converts fuel energy into mechanical power. Modern V16 engines employ advanced cooling systems and materials to manage heat dissipation and maintain optimal operating temperatures.

Power-to-weight ratio is particularly relevant for V16 engines, as their size and complexity often result in significant weight. Engineers strive to optimize this ratio through the use of lightweight materials and compact designs. The packaging efficiency of V16 layouts is also benchmarked, considering how well the engine integrates into the vehicle's overall design.

Emissions performance is increasingly important, with V16 engines facing stringent regulations. Advanced exhaust aftertreatment systems and combustion optimization techniques are employed to meet emissions standards while maintaining high performance levels.

Durability and reliability metrics, such as mean time between failures and service intervals, are crucial for assessing the long-term viability of V16 engines. These complex powerplants must demonstrate robustness despite their intricate designs and high-stress operating conditions.

By analyzing these performance benchmarks, engineers and designers can fine-tune the balance between form and function in V16 engine layouts, creating powerplants that deliver exceptional performance while meeting practical requirements for modern vehicles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!