The emergence of V16 engines in distributed power generation systems

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V16 Engine Evolution

The evolution of V16 engines in distributed power generation systems represents a significant technological advancement in the field of energy production. This development can be traced back to the early 20th century when large displacement engines were first introduced for industrial applications. The V16 configuration, characterized by its 16 cylinders arranged in a V-shape, emerged as a solution to the growing demand for higher power output and improved efficiency in stationary power generation.

In the 1930s and 1940s, V16 engines found their initial applications in marine and railway sectors, where their compact design and high power-to-weight ratio proved advantageous. However, it wasn't until the latter half of the 20th century that these engines began to make significant inroads into distributed power generation systems.

The 1970s marked a turning point in the evolution of V16 engines for power generation. With the global energy crisis driving the need for more efficient and flexible power solutions, manufacturers began to adapt V16 designs specifically for stationary power applications. This period saw the introduction of advanced fuel injection systems and improved combustion technologies, which significantly enhanced the performance and reliability of V16 engines.

The 1990s and early 2000s witnessed a rapid acceleration in V16 engine development for distributed power generation. Key innovations during this time included the integration of electronic control systems, which allowed for precise fuel management and optimized engine performance across various load conditions. Additionally, advancements in materials science led to the use of lighter, more durable components, further improving engine efficiency and longevity.

In recent years, the focus of V16 engine evolution has shifted towards meeting increasingly stringent environmental regulations while maintaining high performance. This has led to the development of dual-fuel V16 engines capable of running on both traditional fossil fuels and cleaner alternatives such as natural gas or biogas. Furthermore, the integration of waste heat recovery systems and combined heat and power (CHP) configurations has significantly improved the overall efficiency of V16-based power generation systems.

The latest generation of V16 engines for distributed power generation boasts impressive power outputs, often exceeding 2 MW per unit, while achieving remarkable electrical efficiencies of up to 45%. These engines have become increasingly modular and scalable, allowing for flexible deployment in a wide range of applications, from industrial facilities to remote microgrids.

Looking ahead, the evolution of V16 engines in distributed power generation is likely to continue, with a focus on further improving efficiency, reducing emissions, and increasing fuel flexibility. Emerging technologies such as hydrogen-ready engines and advanced digital control systems are expected to play a crucial role in shaping the future of V16 engines in the power generation landscape.

In the 1930s and 1940s, V16 engines found their initial applications in marine and railway sectors, where their compact design and high power-to-weight ratio proved advantageous. However, it wasn't until the latter half of the 20th century that these engines began to make significant inroads into distributed power generation systems.

The 1970s marked a turning point in the evolution of V16 engines for power generation. With the global energy crisis driving the need for more efficient and flexible power solutions, manufacturers began to adapt V16 designs specifically for stationary power applications. This period saw the introduction of advanced fuel injection systems and improved combustion technologies, which significantly enhanced the performance and reliability of V16 engines.

The 1990s and early 2000s witnessed a rapid acceleration in V16 engine development for distributed power generation. Key innovations during this time included the integration of electronic control systems, which allowed for precise fuel management and optimized engine performance across various load conditions. Additionally, advancements in materials science led to the use of lighter, more durable components, further improving engine efficiency and longevity.

In recent years, the focus of V16 engine evolution has shifted towards meeting increasingly stringent environmental regulations while maintaining high performance. This has led to the development of dual-fuel V16 engines capable of running on both traditional fossil fuels and cleaner alternatives such as natural gas or biogas. Furthermore, the integration of waste heat recovery systems and combined heat and power (CHP) configurations has significantly improved the overall efficiency of V16-based power generation systems.

The latest generation of V16 engines for distributed power generation boasts impressive power outputs, often exceeding 2 MW per unit, while achieving remarkable electrical efficiencies of up to 45%. These engines have become increasingly modular and scalable, allowing for flexible deployment in a wide range of applications, from industrial facilities to remote microgrids.

Looking ahead, the evolution of V16 engines in distributed power generation is likely to continue, with a focus on further improving efficiency, reducing emissions, and increasing fuel flexibility. Emerging technologies such as hydrogen-ready engines and advanced digital control systems are expected to play a crucial role in shaping the future of V16 engines in the power generation landscape.

Power Gen Market Demand

The distributed power generation market has witnessed significant growth in recent years, driven by increasing energy demand, grid reliability concerns, and the push for cleaner energy solutions. The emergence of V16 engines in this sector represents a response to the evolving needs of the market, particularly in terms of power output and efficiency.

Market analysis indicates a robust demand for distributed power generation systems, with a projected compound annual growth rate (CAGR) of 11.4% from 2021 to 2028. This growth is fueled by factors such as rapid industrialization in developing economies, the need for reliable backup power in critical infrastructure, and the integration of renewable energy sources into existing power grids.

The adoption of V16 engines in distributed power generation systems is primarily driven by their ability to deliver high power output in a relatively compact footprint. This characteristic makes them particularly attractive for applications where space is at a premium, such as urban environments or industrial facilities with limited real estate for power generation equipment.

Furthermore, the market demand for V16 engines is influenced by their versatility in fuel consumption. These engines can be designed to run on various fuel types, including natural gas, diesel, and biofuels, aligning with the growing emphasis on fuel flexibility and reduced environmental impact in the power generation sector.

The industrial sector represents a significant portion of the demand for V16 engine-based distributed power systems. Manufacturing facilities, data centers, and other industrial operations require reliable, high-capacity power sources to maintain continuous operations. The ability of V16 engines to provide both baseload and peak load power makes them an attractive option for these applications.

In the commercial sector, there is a growing demand for combined heat and power (CHP) systems utilizing V16 engines. These systems offer improved energy efficiency by capturing and utilizing waste heat, making them particularly appealing for large commercial buildings, hospitals, and educational institutions seeking to optimize their energy consumption and reduce operational costs.

The emergence of microgrids and smart grid technologies has also contributed to the increased demand for V16 engines in distributed power generation. These engines can serve as anchor generators in microgrid systems, providing the necessary power capacity and flexibility to integrate with renewable energy sources and energy storage systems.

Geographically, the demand for V16 engines in distributed power generation is particularly strong in regions with unreliable grid infrastructure or those experiencing rapid industrial growth. Developing economies in Asia-Pacific and Africa are showing significant interest in these systems as they seek to address power shortages and support economic development.

Market analysis indicates a robust demand for distributed power generation systems, with a projected compound annual growth rate (CAGR) of 11.4% from 2021 to 2028. This growth is fueled by factors such as rapid industrialization in developing economies, the need for reliable backup power in critical infrastructure, and the integration of renewable energy sources into existing power grids.

The adoption of V16 engines in distributed power generation systems is primarily driven by their ability to deliver high power output in a relatively compact footprint. This characteristic makes them particularly attractive for applications where space is at a premium, such as urban environments or industrial facilities with limited real estate for power generation equipment.

Furthermore, the market demand for V16 engines is influenced by their versatility in fuel consumption. These engines can be designed to run on various fuel types, including natural gas, diesel, and biofuels, aligning with the growing emphasis on fuel flexibility and reduced environmental impact in the power generation sector.

The industrial sector represents a significant portion of the demand for V16 engine-based distributed power systems. Manufacturing facilities, data centers, and other industrial operations require reliable, high-capacity power sources to maintain continuous operations. The ability of V16 engines to provide both baseload and peak load power makes them an attractive option for these applications.

In the commercial sector, there is a growing demand for combined heat and power (CHP) systems utilizing V16 engines. These systems offer improved energy efficiency by capturing and utilizing waste heat, making them particularly appealing for large commercial buildings, hospitals, and educational institutions seeking to optimize their energy consumption and reduce operational costs.

The emergence of microgrids and smart grid technologies has also contributed to the increased demand for V16 engines in distributed power generation. These engines can serve as anchor generators in microgrid systems, providing the necessary power capacity and flexibility to integrate with renewable energy sources and energy storage systems.

Geographically, the demand for V16 engines in distributed power generation is particularly strong in regions with unreliable grid infrastructure or those experiencing rapid industrial growth. Developing economies in Asia-Pacific and Africa are showing significant interest in these systems as they seek to address power shortages and support economic development.

V16 Tech Challenges

The emergence of V16 engines in distributed power generation systems presents several significant technical challenges. One of the primary issues is the complexity of the engine design itself. With 16 cylinders arranged in a V-configuration, these engines require intricate balancing mechanisms to mitigate vibrations and ensure smooth operation. The increased number of moving parts also raises concerns about reliability and maintenance requirements, potentially impacting the overall system uptime.

Thermal management poses another substantial challenge for V16 engines in distributed power generation. The high power output generates considerable heat, necessitating advanced cooling systems to maintain optimal operating temperatures. This becomes particularly crucial in compact installations where space for cooling infrastructure is limited. Engineers must develop innovative solutions to efficiently dissipate heat without compromising the engine's performance or the surrounding equipment.

Fuel efficiency and emissions control represent ongoing challenges for V16 engines. As environmental regulations become increasingly stringent, power generation systems must meet strict emission standards while maintaining high efficiency. This requires sophisticated fuel injection systems, advanced combustion chamber designs, and state-of-the-art exhaust aftertreatment technologies. Balancing these requirements with the need for high power output and reliability adds complexity to the engine development process.

Integration of V16 engines into distributed power generation systems presents its own set of challenges. The large size and weight of these engines can make installation and transportation difficult, especially in urban or remote areas with limited access. Additionally, synchronizing multiple V16 units in a distributed network requires advanced control systems to ensure stable power output and load sharing among units.

Noise reduction is another critical challenge, particularly in residential or noise-sensitive areas. The sheer size and power of V16 engines can result in significant noise pollution if not properly addressed. Engineers must develop effective sound insulation and vibration dampening techniques without compromising the engine's performance or increasing the overall system footprint excessively.

Lastly, the cost-effectiveness of V16 engines in distributed power generation remains a challenge. While these engines offer high power density, their complexity and specialized components can lead to higher initial and maintenance costs compared to smaller engine configurations. Balancing the benefits of high power output with economic considerations is crucial for widespread adoption in distributed power generation applications.

Thermal management poses another substantial challenge for V16 engines in distributed power generation. The high power output generates considerable heat, necessitating advanced cooling systems to maintain optimal operating temperatures. This becomes particularly crucial in compact installations where space for cooling infrastructure is limited. Engineers must develop innovative solutions to efficiently dissipate heat without compromising the engine's performance or the surrounding equipment.

Fuel efficiency and emissions control represent ongoing challenges for V16 engines. As environmental regulations become increasingly stringent, power generation systems must meet strict emission standards while maintaining high efficiency. This requires sophisticated fuel injection systems, advanced combustion chamber designs, and state-of-the-art exhaust aftertreatment technologies. Balancing these requirements with the need for high power output and reliability adds complexity to the engine development process.

Integration of V16 engines into distributed power generation systems presents its own set of challenges. The large size and weight of these engines can make installation and transportation difficult, especially in urban or remote areas with limited access. Additionally, synchronizing multiple V16 units in a distributed network requires advanced control systems to ensure stable power output and load sharing among units.

Noise reduction is another critical challenge, particularly in residential or noise-sensitive areas. The sheer size and power of V16 engines can result in significant noise pollution if not properly addressed. Engineers must develop effective sound insulation and vibration dampening techniques without compromising the engine's performance or increasing the overall system footprint excessively.

Lastly, the cost-effectiveness of V16 engines in distributed power generation remains a challenge. While these engines offer high power density, their complexity and specialized components can lead to higher initial and maintenance costs compared to smaller engine configurations. Balancing the benefits of high power output with economic considerations is crucial for widespread adoption in distributed power generation applications.

Current V16 Solutions

01 V16 engine design and configuration

V16 engines are large, powerful internal combustion engines with 16 cylinders arranged in a V-shape. These engines are typically used in high-performance vehicles, marine applications, and industrial machinery. The V-configuration allows for a more compact design compared to inline engines with the same number of cylinders, while still providing significant power output.- V16 engine design and configuration: V16 engines are large, powerful internal combustion engines with 16 cylinders arranged in a V-shape. This configuration allows for increased power output while maintaining a relatively compact design compared to inline engines. V16 engines are often used in high-performance vehicles, marine applications, and industrial machinery.

- V16 engine applications in vehicles: V16 engines are utilized in various types of vehicles, including luxury cars, sports cars, and heavy-duty trucks. These engines provide exceptional power and torque, making them suitable for high-performance applications and heavy load-bearing vehicles. The implementation of V16 engines in vehicles often requires specialized design considerations for cooling, lubrication, and exhaust systems.

- Historical development of V16 engines: The development of V16 engines dates back to the early 20th century, with various iterations and improvements made over time. Early designs focused on aircraft and marine applications, while later developments expanded to automotive use. The evolution of V16 engines has been driven by the need for increased power output and efficiency in various industries.

- V16 engine control systems: Modern V16 engines incorporate advanced control systems to optimize performance, fuel efficiency, and emissions. These systems may include electronic fuel injection, variable valve timing, and engine management computers. The complexity of V16 engines requires sophisticated control mechanisms to ensure proper operation and synchronization of all 16 cylinders.

- V16 engine cooling and lubrication: Due to their size and power output, V16 engines require specialized cooling and lubrication systems. These systems are designed to manage the high heat generation and ensure proper lubrication of all moving parts. Innovations in cooling and lubrication technologies have contributed to improved reliability and performance of V16 engines in various applications.

02 V16 engine applications in vehicles

V16 engines are often employed in luxury and high-performance automobiles, as well as in some specialized vehicles such as racing cars and concept vehicles. These engines provide exceptional power and torque, making them suitable for vehicles that require outstanding performance characteristics.Expand Specific Solutions03 Historical development of V16 engines

The development of V16 engines dates back to the early 20th century, with various designs and improvements made over the years. Early applications included aircraft engines and luxury automobiles. The evolution of V16 engines has led to increased efficiency, power output, and reliability in modern designs.Expand Specific Solutions04 V16 engine control systems and optimization

Modern V16 engines incorporate advanced control systems and optimization techniques to improve performance, fuel efficiency, and emissions. These may include electronic fuel injection, variable valve timing, and sophisticated engine management systems that monitor and adjust various parameters in real-time.Expand Specific Solutions05 V16 engine manufacturing and assembly

The production of V16 engines involves complex manufacturing processes and assembly techniques. This includes precision machining of components, advanced materials selection, and specialized assembly procedures to ensure proper alignment and balance of the engine's many moving parts.Expand Specific Solutions

Key V16 Manufacturers

The emergence of V16 engines in distributed power generation systems represents a nascent market with significant growth potential. The industry is in its early development stage, characterized by technological innovation and increasing market adoption. While the market size is currently modest, it is expected to expand rapidly as demand for efficient and powerful distributed energy solutions grows. Companies like Rolls-Royce Plc and GE Energy Power Conversion Technology Ltd. are at the forefront of this technology, leveraging their expertise in power systems to develop advanced V16 engine solutions. Other players such as Enphase Energy, Inc. and Ansaldo Energia SpA are also contributing to the ecosystem, focusing on complementary technologies that enhance the overall efficiency and integration of V16 engines in distributed power systems.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has developed the Bergen B36:45 V16 gas engine for distributed power generation. This engine produces up to 11.8 MW of power with an electrical efficiency of over 50%[4]. The B36:45 incorporates lean-burn combustion technology and advanced engine control systems to optimize performance and reduce emissions[5]. Rolls-Royce's V16 engine design also features a compact footprint and low vibration levels, making it suitable for a wide range of distributed power applications, including combined heat and power (CHP) systems[6].

Strengths: High power output, excellent efficiency, and compact design. Weaknesses: Limited track record in some markets compared to more established competitors.

Ansaldo Energia SpA

Technical Solution: Ansaldo Energia has developed the AE64.3A gas turbine, which, while not a V16 engine, represents their approach to distributed power generation. This turbine can produce up to 75 MW of power with high efficiency and flexibility[13]. Ansaldo's technology focuses on rapid start-up times and load-following capabilities, which are essential for distributed power systems that need to respond quickly to changes in demand[14]. The company has also invested in digital solutions for remote monitoring and predictive maintenance, enhancing the reliability and performance of their power generation systems[15].

Strengths: High power output, excellent operational flexibility, and advanced digital integration. Weaknesses: Not specifically a V16 engine technology, which may limit direct comparison with other V16 solutions in certain applications.

V16 Core Innovations

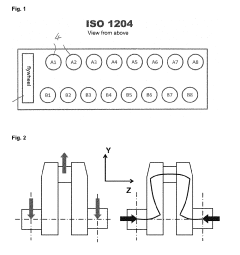

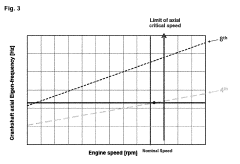

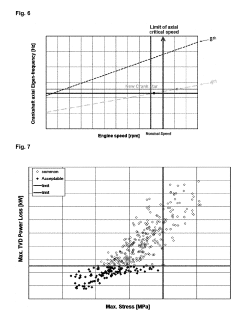

V16 crankstar and firing sequences

PatentActiveUS20190249598A1

Innovation

- The implementation of specific firing sequences and crankshaft designs with lengthwise symmetric or quasi-symmetric crank stars, combined with a torsional vibration damper, to optimize the angular sequence of crank throws and firing intervals, reducing axial and torsional vibrations and enhancing dynamic behavior.

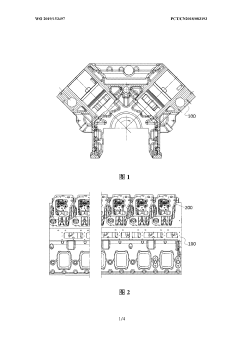

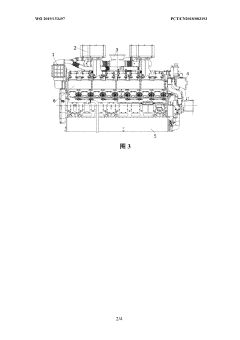

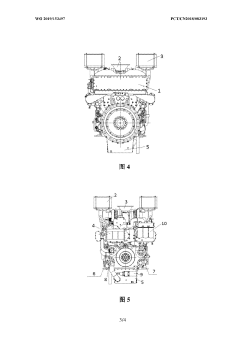

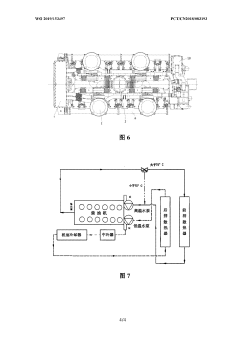

High power v-shaped 16-cylinder diesel engine

PatentWO2019153497A1

Innovation

- A high-power V-type 16-cylinder diesel engine is designed, using a V-shaped cylinder block and 16 single cylinder heads, equipped with four turbochargers and an intercooler, using a high and low temperature water separate cooling system, combined with a W combustion chamber and The internally cooled piston improves air density and combustion efficiency and reduces heat energy loss.

Emissions Regulations

The emergence of V16 engines in distributed power generation systems has brought significant challenges in meeting increasingly stringent emissions regulations. These regulations, primarily aimed at reducing harmful pollutants and greenhouse gas emissions, have become a critical factor in the development and deployment of power generation technologies.

In recent years, environmental protection agencies worldwide have implemented more rigorous standards for emissions from stationary power sources. These regulations typically focus on limiting the release of nitrogen oxides (NOx), carbon monoxide (CO), particulate matter (PM), and sulfur dioxide (SO2). For V16 engines used in distributed power generation, compliance with these standards has become a key consideration in their design and operation.

The United States Environmental Protection Agency (EPA) and the European Union's Industrial Emissions Directive (IED) have been at the forefront of establishing emissions limits for stationary engines. These regulations often set specific targets for different engine sizes and fuel types, with more stringent requirements for larger engines and those operating in densely populated areas.

To meet these regulatory challenges, manufacturers of V16 engines have had to implement various technological solutions. Advanced combustion control systems, such as lean-burn technology and precise fuel injection timing, have been developed to reduce NOx formation. Exhaust gas recirculation (EGR) systems have also been employed to lower combustion temperatures and further reduce NOx emissions.

Post-combustion treatment technologies have become increasingly important in achieving compliance. Selective catalytic reduction (SCR) systems, which use a catalyst and a reducing agent like urea to convert NOx into nitrogen and water, have been widely adopted. For particulate matter control, diesel particulate filters (DPF) have been integrated into the exhaust systems of diesel-powered V16 engines.

The push for lower carbon emissions has also led to increased interest in alternative fuels for V16 engines. Natural gas, biogas, and hydrogen-enriched fuels are being explored as cleaner alternatives to traditional diesel fuel. These alternative fuels often require modifications to the engine design and fuel delivery systems but can offer significant reductions in both criteria pollutants and greenhouse gas emissions.

Emissions regulations have also driven the development of advanced monitoring and control systems for V16 engines. Continuous emissions monitoring systems (CEMS) are now commonly required to ensure ongoing compliance with emissions limits. These systems provide real-time data on engine performance and emissions, allowing operators to optimize engine settings and quickly address any deviations from regulatory standards.

As emissions regulations continue to evolve, the future of V16 engines in distributed power generation will depend on their ability to meet increasingly stringent standards while maintaining efficiency and reliability. This regulatory landscape is driving ongoing research and development efforts to further improve emissions control technologies and explore new approaches to clean power generation.

In recent years, environmental protection agencies worldwide have implemented more rigorous standards for emissions from stationary power sources. These regulations typically focus on limiting the release of nitrogen oxides (NOx), carbon monoxide (CO), particulate matter (PM), and sulfur dioxide (SO2). For V16 engines used in distributed power generation, compliance with these standards has become a key consideration in their design and operation.

The United States Environmental Protection Agency (EPA) and the European Union's Industrial Emissions Directive (IED) have been at the forefront of establishing emissions limits for stationary engines. These regulations often set specific targets for different engine sizes and fuel types, with more stringent requirements for larger engines and those operating in densely populated areas.

To meet these regulatory challenges, manufacturers of V16 engines have had to implement various technological solutions. Advanced combustion control systems, such as lean-burn technology and precise fuel injection timing, have been developed to reduce NOx formation. Exhaust gas recirculation (EGR) systems have also been employed to lower combustion temperatures and further reduce NOx emissions.

Post-combustion treatment technologies have become increasingly important in achieving compliance. Selective catalytic reduction (SCR) systems, which use a catalyst and a reducing agent like urea to convert NOx into nitrogen and water, have been widely adopted. For particulate matter control, diesel particulate filters (DPF) have been integrated into the exhaust systems of diesel-powered V16 engines.

The push for lower carbon emissions has also led to increased interest in alternative fuels for V16 engines. Natural gas, biogas, and hydrogen-enriched fuels are being explored as cleaner alternatives to traditional diesel fuel. These alternative fuels often require modifications to the engine design and fuel delivery systems but can offer significant reductions in both criteria pollutants and greenhouse gas emissions.

Emissions regulations have also driven the development of advanced monitoring and control systems for V16 engines. Continuous emissions monitoring systems (CEMS) are now commonly required to ensure ongoing compliance with emissions limits. These systems provide real-time data on engine performance and emissions, allowing operators to optimize engine settings and quickly address any deviations from regulatory standards.

As emissions regulations continue to evolve, the future of V16 engines in distributed power generation will depend on their ability to meet increasingly stringent standards while maintaining efficiency and reliability. This regulatory landscape is driving ongoing research and development efforts to further improve emissions control technologies and explore new approaches to clean power generation.

V16 Efficiency Analysis

The efficiency analysis of V16 engines in distributed power generation systems reveals significant advancements in performance and fuel economy. These engines, characterized by their 16-cylinder V-configuration, have demonstrated remarkable improvements in thermal efficiency, reaching levels of up to 50% in some advanced designs. This high efficiency is attributed to several factors, including optimized combustion processes, advanced turbocharging systems, and sophisticated engine management technologies.

One of the key contributors to the enhanced efficiency of V16 engines is their ability to maintain optimal combustion temperatures across a wide range of operating conditions. This is achieved through precise control of fuel injection timing and duration, coupled with variable valve timing systems that adjust to different load requirements. The result is a more complete fuel burn, reducing waste and maximizing energy extraction from each combustion cycle.

Turbocharging plays a crucial role in boosting the efficiency of V16 engines. Modern turbocharging systems, often featuring variable geometry turbines, allow for better matching of air supply to engine demand across the entire operating range. This not only improves power output but also contributes to better fuel economy, especially at partial load conditions commonly encountered in distributed power generation applications.

Heat recovery systems have been integrated into many V16 engine designs, further enhancing overall system efficiency. Waste heat from exhaust gases and cooling systems is captured and utilized for additional power generation or for heating purposes in combined heat and power (CHP) installations. This approach significantly increases the total energy utilization, with some systems achieving overall efficiencies of up to 90% when both electrical and thermal outputs are considered.

The modular nature of V16 engines allows for flexible power output scaling, making them suitable for a wide range of distributed generation applications. This scalability, combined with their high efficiency, positions V16 engines as a competitive option in scenarios where rapid response to load changes and high reliability are required. The ability to quickly ramp up or down in response to demand fluctuations contributes to grid stability and reduces the need for spinning reserves.

Advancements in materials science have also played a role in improving V16 engine efficiency. The use of lightweight, high-strength materials in engine components has reduced internal friction and allowed for higher operating pressures, both of which contribute to improved thermal efficiency. Additionally, advanced coatings and surface treatments have enhanced wear resistance and reduced heat losses, further optimizing engine performance.

One of the key contributors to the enhanced efficiency of V16 engines is their ability to maintain optimal combustion temperatures across a wide range of operating conditions. This is achieved through precise control of fuel injection timing and duration, coupled with variable valve timing systems that adjust to different load requirements. The result is a more complete fuel burn, reducing waste and maximizing energy extraction from each combustion cycle.

Turbocharging plays a crucial role in boosting the efficiency of V16 engines. Modern turbocharging systems, often featuring variable geometry turbines, allow for better matching of air supply to engine demand across the entire operating range. This not only improves power output but also contributes to better fuel economy, especially at partial load conditions commonly encountered in distributed power generation applications.

Heat recovery systems have been integrated into many V16 engine designs, further enhancing overall system efficiency. Waste heat from exhaust gases and cooling systems is captured and utilized for additional power generation or for heating purposes in combined heat and power (CHP) installations. This approach significantly increases the total energy utilization, with some systems achieving overall efficiencies of up to 90% when both electrical and thermal outputs are considered.

The modular nature of V16 engines allows for flexible power output scaling, making them suitable for a wide range of distributed generation applications. This scalability, combined with their high efficiency, positions V16 engines as a competitive option in scenarios where rapid response to load changes and high reliability are required. The ability to quickly ramp up or down in response to demand fluctuations contributes to grid stability and reduces the need for spinning reserves.

Advancements in materials science have also played a role in improving V16 engine efficiency. The use of lightweight, high-strength materials in engine components has reduced internal friction and allowed for higher operating pressures, both of which contribute to improved thermal efficiency. Additionally, advanced coatings and surface treatments have enhanced wear resistance and reduced heat losses, further optimizing engine performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!