The Impact of Power Steering Fluid on Fuel Economy in Hybrid Cars

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Power Steering Evolution

Power steering technology has undergone significant evolution since its inception in the early 20th century. The journey began with manual steering systems, which required considerable physical effort from drivers, especially when maneuvering vehicles at low speeds or during parking. This limitation led to the development of hydraulic power steering in the 1950s, marking a revolutionary change in automotive design.

Hydraulic power steering systems utilize a hydraulic pump, driven by the engine, to provide assistance to the steering mechanism. This innovation greatly reduced the effort required to steer vehicles, particularly larger ones, and quickly became a standard feature in most automobiles. The system's reliance on engine power, however, resulted in a constant drain on fuel efficiency.

As automotive technology progressed, the focus shifted towards improving fuel economy and reducing environmental impact. This led to the introduction of electric power steering (EPS) systems in the 1990s. EPS eliminates the need for a hydraulic pump and instead uses an electric motor to assist steering. This advancement not only improved fuel efficiency but also allowed for more precise control and integration with other vehicle systems.

The transition to hybrid and electric vehicles in the 21st century has further accelerated the adoption of EPS. These systems are particularly well-suited for hybrid and electric powertrains, as they do not rely on a constantly running engine and can be powered by the vehicle's electrical system. This compatibility has made EPS the preferred choice for modern fuel-efficient vehicles.

Recent developments in power steering technology have focused on enhancing safety and driving experience. Advanced driver assistance systems (ADAS) have been integrated with EPS, enabling features such as lane-keeping assist and automated parking. Additionally, steer-by-wire systems, which completely eliminate the mechanical connection between the steering wheel and the wheels, are being explored for future applications.

The evolution of power steering technology reflects the broader trends in automotive engineering, with a clear trajectory towards electrification, improved efficiency, and enhanced driver assistance. As vehicles continue to become more sophisticated and environmentally conscious, power steering systems are expected to play a crucial role in shaping the future of automotive design and performance.

Hydraulic power steering systems utilize a hydraulic pump, driven by the engine, to provide assistance to the steering mechanism. This innovation greatly reduced the effort required to steer vehicles, particularly larger ones, and quickly became a standard feature in most automobiles. The system's reliance on engine power, however, resulted in a constant drain on fuel efficiency.

As automotive technology progressed, the focus shifted towards improving fuel economy and reducing environmental impact. This led to the introduction of electric power steering (EPS) systems in the 1990s. EPS eliminates the need for a hydraulic pump and instead uses an electric motor to assist steering. This advancement not only improved fuel efficiency but also allowed for more precise control and integration with other vehicle systems.

The transition to hybrid and electric vehicles in the 21st century has further accelerated the adoption of EPS. These systems are particularly well-suited for hybrid and electric powertrains, as they do not rely on a constantly running engine and can be powered by the vehicle's electrical system. This compatibility has made EPS the preferred choice for modern fuel-efficient vehicles.

Recent developments in power steering technology have focused on enhancing safety and driving experience. Advanced driver assistance systems (ADAS) have been integrated with EPS, enabling features such as lane-keeping assist and automated parking. Additionally, steer-by-wire systems, which completely eliminate the mechanical connection between the steering wheel and the wheels, are being explored for future applications.

The evolution of power steering technology reflects the broader trends in automotive engineering, with a clear trajectory towards electrification, improved efficiency, and enhanced driver assistance. As vehicles continue to become more sophisticated and environmentally conscious, power steering systems are expected to play a crucial role in shaping the future of automotive design and performance.

Hybrid Car Market Analysis

The hybrid car market has experienced significant growth and transformation over the past decade, driven by increasing environmental concerns, stricter emissions regulations, and advancements in electric vehicle technology. As of 2023, the global hybrid car market is valued at approximately $200 billion, with projections indicating continued expansion at a compound annual growth rate of 8% through 2028.

Major automotive manufacturers have invested heavily in hybrid technology, recognizing its potential as a transitional solution between traditional internal combustion engines and fully electric vehicles. Toyota, Honda, and Ford have emerged as market leaders, collectively accounting for over 60% of global hybrid vehicle sales. The success of models like the Toyota Prius, Honda Insight, and Ford Fusion Hybrid has paved the way for widespread adoption of hybrid technology across various vehicle segments.

Consumer demand for hybrid vehicles has been steadily increasing, particularly in regions with stringent emissions standards and government incentives for eco-friendly transportation. North America and Europe remain the largest markets for hybrid cars, followed closely by the Asia-Pacific region, where rapid urbanization and growing environmental awareness are driving adoption.

The hybrid car market is characterized by ongoing technological advancements aimed at improving fuel efficiency, reducing emissions, and enhancing overall performance. Innovations in battery technology, regenerative braking systems, and powertrain optimization have contributed to the increased competitiveness of hybrid vehicles compared to their conventional counterparts.

Market trends indicate a shift towards plug-in hybrid electric vehicles (PHEVs), which offer extended electric-only driving ranges and greater fuel savings. This segment is expected to grow at a faster rate than traditional hybrid vehicles, as consumers seek more versatile and environmentally friendly transportation options.

The impact of power steering fluid on fuel economy in hybrid cars is an emerging area of interest within the market. As manufacturers strive to maximize efficiency in every aspect of vehicle design, even minor improvements in auxiliary systems can contribute to overall fuel economy gains. This has led to increased research and development efforts focused on optimizing power steering systems and their associated fluids to minimize energy consumption and enhance vehicle performance.

In conclusion, the hybrid car market continues to evolve rapidly, driven by technological innovation, changing consumer preferences, and regulatory pressures. The ongoing focus on improving fuel economy and reducing emissions ensures that every aspect of hybrid vehicle design, including power steering systems, remains subject to scrutiny and optimization efforts.

Major automotive manufacturers have invested heavily in hybrid technology, recognizing its potential as a transitional solution between traditional internal combustion engines and fully electric vehicles. Toyota, Honda, and Ford have emerged as market leaders, collectively accounting for over 60% of global hybrid vehicle sales. The success of models like the Toyota Prius, Honda Insight, and Ford Fusion Hybrid has paved the way for widespread adoption of hybrid technology across various vehicle segments.

Consumer demand for hybrid vehicles has been steadily increasing, particularly in regions with stringent emissions standards and government incentives for eco-friendly transportation. North America and Europe remain the largest markets for hybrid cars, followed closely by the Asia-Pacific region, where rapid urbanization and growing environmental awareness are driving adoption.

The hybrid car market is characterized by ongoing technological advancements aimed at improving fuel efficiency, reducing emissions, and enhancing overall performance. Innovations in battery technology, regenerative braking systems, and powertrain optimization have contributed to the increased competitiveness of hybrid vehicles compared to their conventional counterparts.

Market trends indicate a shift towards plug-in hybrid electric vehicles (PHEVs), which offer extended electric-only driving ranges and greater fuel savings. This segment is expected to grow at a faster rate than traditional hybrid vehicles, as consumers seek more versatile and environmentally friendly transportation options.

The impact of power steering fluid on fuel economy in hybrid cars is an emerging area of interest within the market. As manufacturers strive to maximize efficiency in every aspect of vehicle design, even minor improvements in auxiliary systems can contribute to overall fuel economy gains. This has led to increased research and development efforts focused on optimizing power steering systems and their associated fluids to minimize energy consumption and enhance vehicle performance.

In conclusion, the hybrid car market continues to evolve rapidly, driven by technological innovation, changing consumer preferences, and regulatory pressures. The ongoing focus on improving fuel economy and reducing emissions ensures that every aspect of hybrid vehicle design, including power steering systems, remains subject to scrutiny and optimization efforts.

Fluid-Economy Challenges

The integration of power steering fluid systems in hybrid vehicles presents unique challenges at the intersection of hydraulic efficiency and fuel economy. As hybrid cars strive to maximize energy conservation, the power steering system's impact on overall vehicle efficiency becomes a critical consideration. Traditional power steering systems, which rely on engine-driven hydraulic pumps, can create a constant parasitic load on the engine, potentially reducing fuel efficiency.

In hybrid vehicles, where the internal combustion engine may not be running continuously, the power steering system must adapt to intermittent power sources. This necessitates the development of more sophisticated fluid management systems that can operate efficiently under varying conditions. The challenge lies in maintaining optimal steering assistance while minimizing energy consumption, particularly during electric-only operation modes.

One of the primary fluid-economy challenges is the need for power steering systems that can rapidly transition between different power sources without compromising performance or efficiency. This requires advanced fluid control mechanisms and potentially the integration of electric assist systems to supplement or replace traditional hydraulic systems during certain driving conditions.

Another significant challenge is the thermal management of power steering fluid in hybrid vehicles. The intermittent nature of hybrid powertrains can lead to inconsistent fluid temperatures, affecting viscosity and system efficiency. Developing fluids and systems that maintain optimal performance across a wide temperature range without excessive energy input for heating or cooling is crucial for maximizing fuel economy.

The weight of the power steering system, including the fluid reservoir and associated components, also plays a role in the overall efficiency equation. Hybrid vehicle designers must balance the need for adequate steering assistance with the imperative to minimize vehicle weight to enhance fuel economy. This may lead to the exploration of alternative fluid formulations or reduced fluid volume systems that can deliver the required performance with less mass.

Furthermore, the interaction between regenerative braking systems and power steering fluid dynamics presents another layer of complexity. The challenge lies in designing systems that can seamlessly integrate these two functions without compromising the energy recovery potential of regenerative braking or the responsiveness of the steering system.

As hybrid vehicles continue to evolve, addressing these fluid-economy challenges will be crucial for optimizing overall vehicle efficiency. Innovations in fluid technology, system design, and control algorithms will be necessary to overcome these hurdles and ensure that power steering systems contribute positively to the fuel economy goals of hybrid vehicles.

In hybrid vehicles, where the internal combustion engine may not be running continuously, the power steering system must adapt to intermittent power sources. This necessitates the development of more sophisticated fluid management systems that can operate efficiently under varying conditions. The challenge lies in maintaining optimal steering assistance while minimizing energy consumption, particularly during electric-only operation modes.

One of the primary fluid-economy challenges is the need for power steering systems that can rapidly transition between different power sources without compromising performance or efficiency. This requires advanced fluid control mechanisms and potentially the integration of electric assist systems to supplement or replace traditional hydraulic systems during certain driving conditions.

Another significant challenge is the thermal management of power steering fluid in hybrid vehicles. The intermittent nature of hybrid powertrains can lead to inconsistent fluid temperatures, affecting viscosity and system efficiency. Developing fluids and systems that maintain optimal performance across a wide temperature range without excessive energy input for heating or cooling is crucial for maximizing fuel economy.

The weight of the power steering system, including the fluid reservoir and associated components, also plays a role in the overall efficiency equation. Hybrid vehicle designers must balance the need for adequate steering assistance with the imperative to minimize vehicle weight to enhance fuel economy. This may lead to the exploration of alternative fluid formulations or reduced fluid volume systems that can deliver the required performance with less mass.

Furthermore, the interaction between regenerative braking systems and power steering fluid dynamics presents another layer of complexity. The challenge lies in designing systems that can seamlessly integrate these two functions without compromising the energy recovery potential of regenerative braking or the responsiveness of the steering system.

As hybrid vehicles continue to evolve, addressing these fluid-economy challenges will be crucial for optimizing overall vehicle efficiency. Innovations in fluid technology, system design, and control algorithms will be necessary to overcome these hurdles and ensure that power steering systems contribute positively to the fuel economy goals of hybrid vehicles.

Current Fluid Solutions

01 Power steering fluid composition optimization

Improving the composition of power steering fluid can enhance fuel economy. This involves developing fluids with lower viscosity and better friction-reducing properties, which can reduce energy losses in the power steering system and contribute to overall vehicle efficiency.- Power steering fluid composition optimization: Improving the composition of power steering fluid can enhance fuel economy. This involves developing fluids with lower viscosity and better friction-reducing properties, which can reduce energy losses in the power steering system. Advanced additives and base oils are used to maintain system protection while improving efficiency.

- Electric power steering systems: Implementing electric power steering systems can significantly improve fuel economy compared to traditional hydraulic systems. These systems use an electric motor to assist steering, eliminating the need for a hydraulic pump driven by the engine, thus reducing parasitic losses and improving overall vehicle efficiency.

- Adaptive power steering control: Developing adaptive control algorithms for power steering systems can optimize power consumption based on driving conditions. These systems adjust the level of steering assistance according to vehicle speed, driver input, and road conditions, minimizing unnecessary power usage and improving fuel economy.

- Integration with start-stop systems: Integrating power steering systems with start-stop technology can contribute to fuel savings. This involves designing power steering systems that can operate efficiently during engine shut-off periods, maintaining steering assistance without compromising fuel economy benefits of the start-stop system.

- Hydraulic system optimization: For vehicles still using hydraulic power steering, optimizing the hydraulic system can improve fuel economy. This includes developing more efficient pumps, reducing system pressure when full assistance is not needed, and implementing variable-flow pumps that adjust output based on steering demand.

02 Electric power steering systems

Implementing electric power steering systems instead of traditional hydraulic systems can significantly improve fuel economy. These systems use an electric motor to assist steering, eliminating the need for a hydraulic pump and reducing the load on the engine.Expand Specific Solutions03 Adaptive power steering control

Developing adaptive control algorithms for power steering systems can optimize power consumption based on driving conditions. This approach adjusts the level of steering assistance dynamically, reducing unnecessary power usage and improving fuel efficiency.Expand Specific Solutions04 Integration with vehicle energy management systems

Integrating power steering systems with overall vehicle energy management can lead to improved fuel economy. This involves coordinating power steering operation with other vehicle systems to optimize energy usage across the entire vehicle.Expand Specific Solutions05 Regenerative power steering systems

Developing regenerative power steering systems that can recover and store energy during steering operations can contribute to improved fuel economy. These systems capture energy that would otherwise be lost and use it to assist in future steering operations or power other vehicle systems.Expand Specific Solutions

Key Automotive Players

The impact of power steering fluid on fuel economy in hybrid cars represents a niche area within the evolving automotive industry. The market is in a growth phase, driven by increasing demand for fuel-efficient vehicles and stricter environmental regulations. While the market size is relatively small, it's expected to expand as hybrid car adoption rises. Technologically, the field is moderately mature, with established players like Ford Global Technologies LLC and GM Global Technology Operations LLC leading research and development efforts. However, emerging companies such as Chery Automobile Co., Ltd. and Zhejiang Geely Holding Group Co., Ltd. are also making significant contributions, particularly in the Asian market. The competition is intensifying as automakers strive to optimize power steering systems for improved fuel efficiency in hybrid vehicles.

Ford Global Technologies LLC

Technical Solution: Ford has developed a dual-mode power steering system for hybrid vehicles that switches between hydraulic and electric assistance based on driving conditions. This system uses a low-viscosity, energy-efficient fluid that reduces pumping losses by up to 30% compared to traditional fluids[2]. Ford's technology incorporates an intelligent fluid circulation system that minimizes fluid flow when full power assist isn't required, such as during straight-line driving or at higher speeds. They've also implemented an advanced filtration system that extends fluid life, reducing the need for frequent replacements and improving long-term efficiency[4]. Furthermore, Ford has integrated their power steering system with the vehicle's hybrid powertrain management, optimizing power distribution between steering assistance and propulsion for maximum fuel economy[6].

Strengths: Dual-mode flexibility, energy-efficient fluid, and integrated powertrain management enhance fuel economy. Weaknesses: Potential for increased maintenance complexity due to dual systems.

Zhejiang Geely Holding Group Co., Ltd.

Technical Solution: Geely has developed a hybrid-specific electro-hydraulic power steering (EHPS) system that combines the benefits of both electric and hydraulic steering assistance. Their system uses a compact electric pump to pressurize a high-performance, low-viscosity steering fluid, reducing parasitic losses compared to traditional belt-driven pumps[10]. Geely's EHPS incorporates a variable-flow control valve that adjusts fluid pressure based on steering demand and vehicle speed, minimizing energy consumption during low-load conditions. They've also implemented an advanced thermal management system that rapidly brings the steering fluid to optimal operating temperature, reducing cold-start inefficiencies[11]. Furthermore, Geely has integrated their EHPS with the vehicle's start-stop system, ensuring seamless steering assistance even when the engine is temporarily shut off for fuel savings[12].

Strengths: Combines benefits of electric and hydraulic systems, variable pressure control, and integration with start-stop technology improve fuel economy. Weaknesses: Still relies on fluid, which may require periodic maintenance and replacement.

Fluid Efficiency Patents

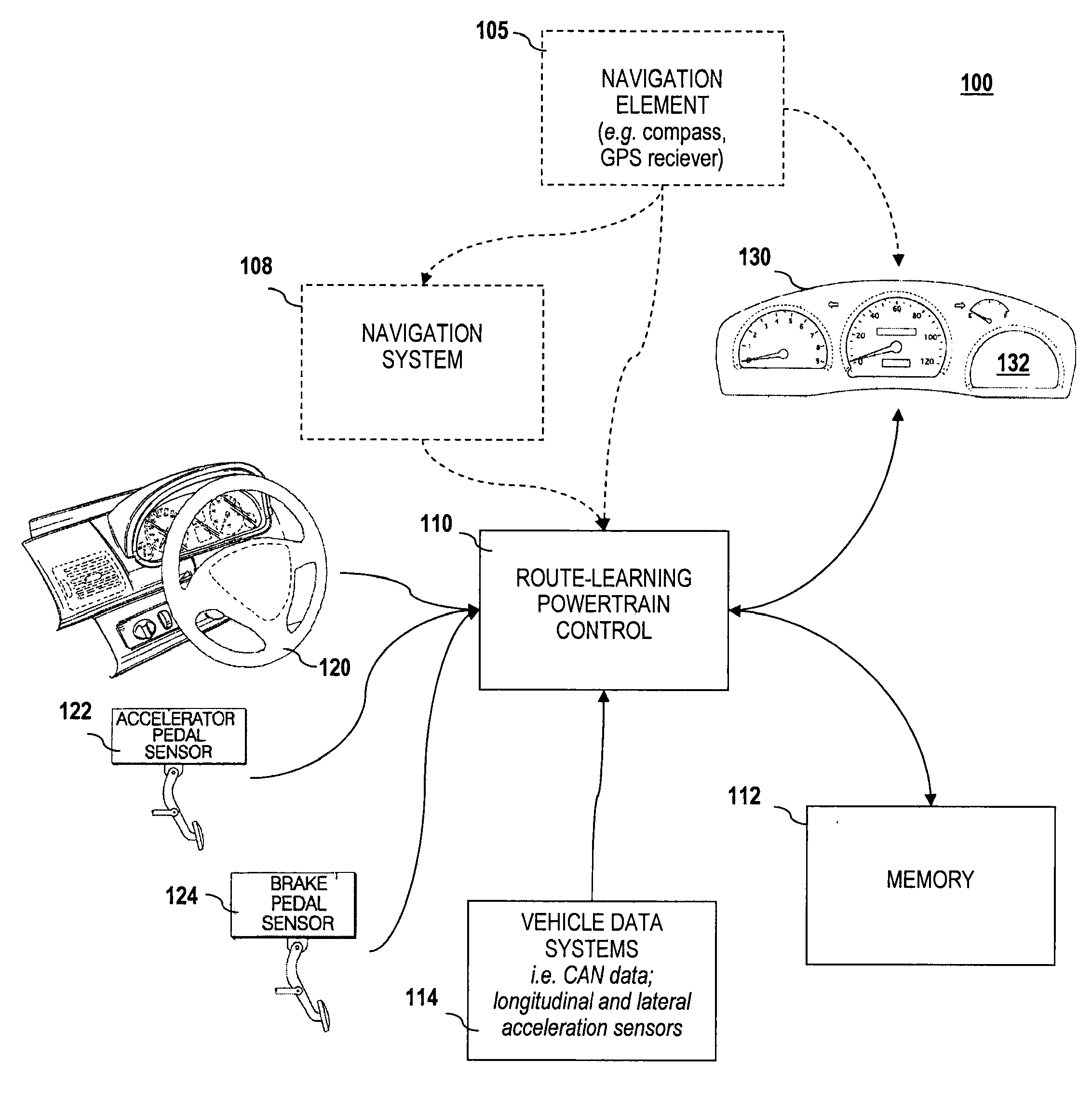

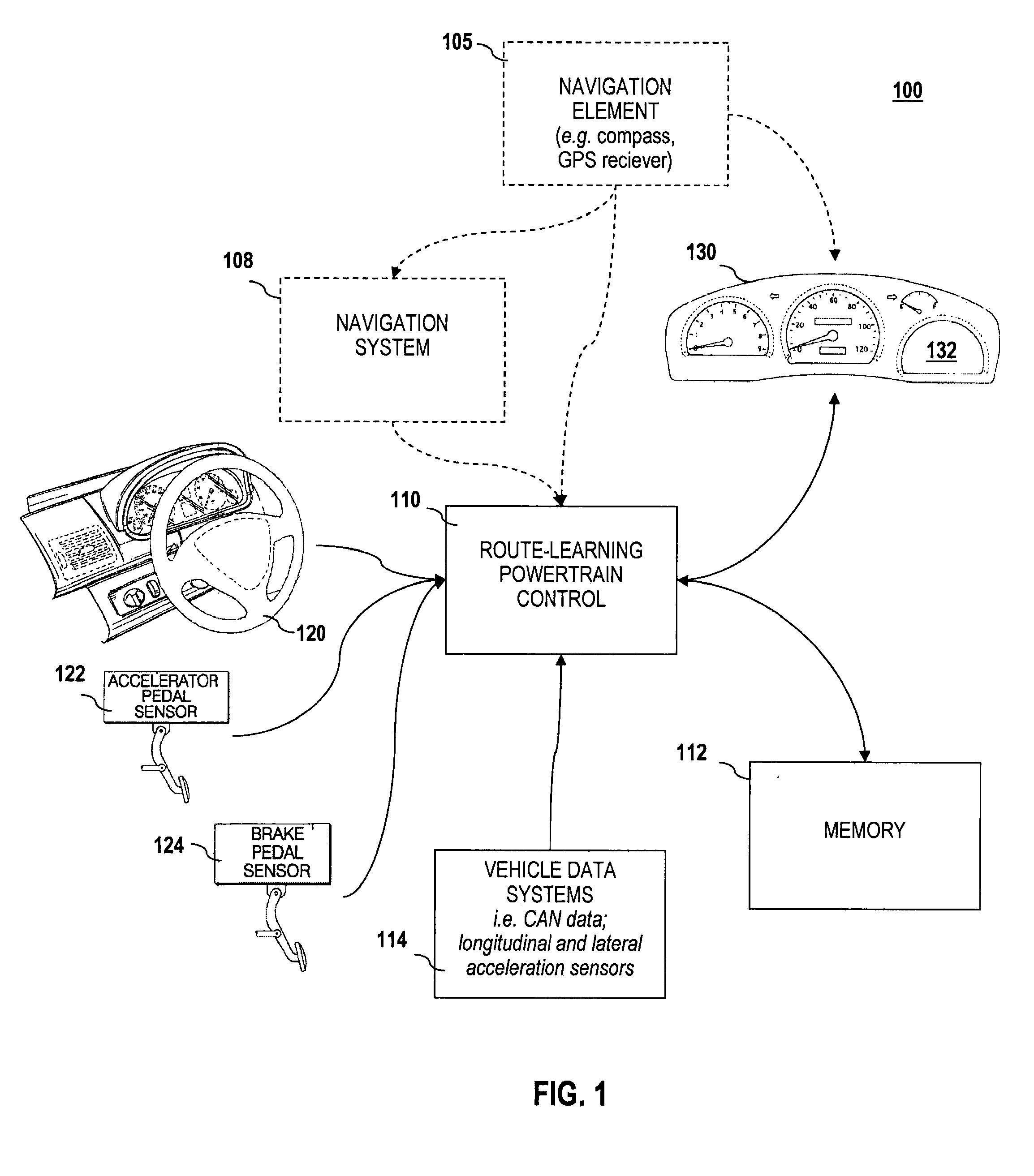

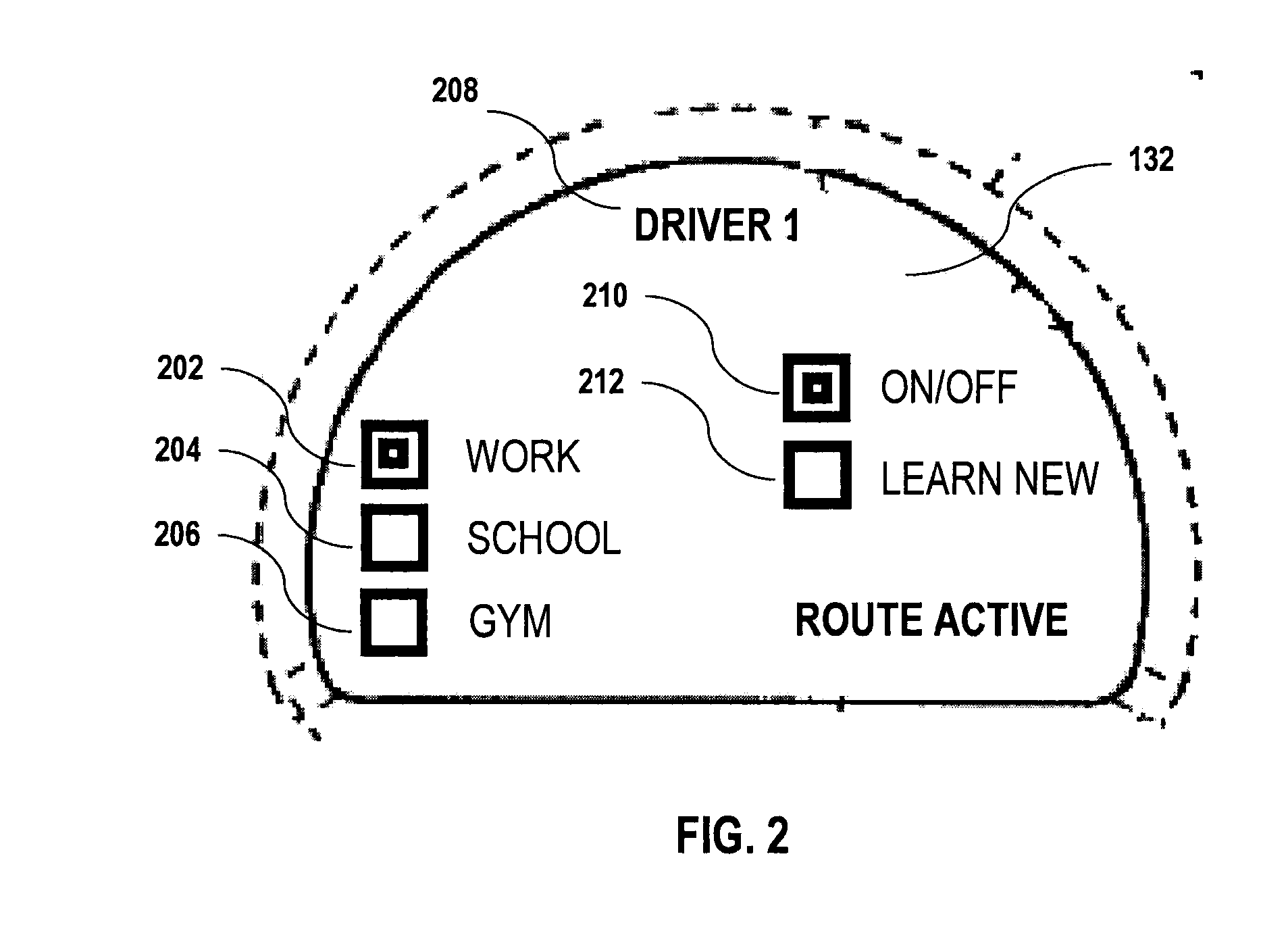

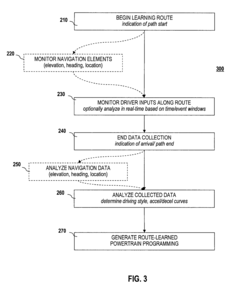

Optimized powertrain with route-learning feature

PatentActiveUS20110153127A1

Innovation

- A route-learning powertrain control system that utilizes feedback from acceleration and brake sensors, steering wheel angle, and on-board navigation data to optimize powertrain operations such as transmission shifting, regenerative braking, and start/stop functionality based on learned driver preferences, allowing customization of the driving experience.

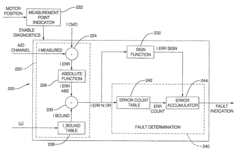

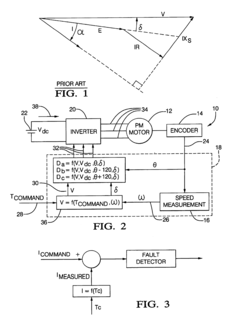

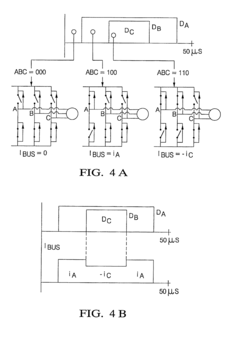

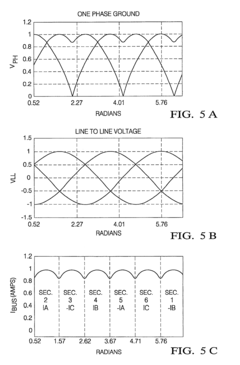

Current determination in a permanent magnet electric machine

PatentInactiveUS7042227B2

Innovation

- A method and apparatus for determining torque current in a PM motor using voltage mode control without current feedback, employing a position encoder and inverter to control motor torque based on motor parameters and speed, allowing for diagnostic monitoring and reducing the impact of unidentified faults.

Environmental Regulations

Environmental regulations play a crucial role in shaping the development and adoption of hybrid car technologies, including the use of power steering fluid and its impact on fuel economy. These regulations are designed to reduce greenhouse gas emissions, improve air quality, and promote energy efficiency in the automotive sector.

In the United States, the Corporate Average Fuel Economy (CAFE) standards set by the National Highway Traffic Safety Administration (NHTSA) and the Environmental Protection Agency (EPA) have been instrumental in driving improvements in fuel efficiency. These standards require automakers to achieve specific fleet-wide average fuel economy targets, which has led to increased investment in hybrid and electric vehicle technologies.

The European Union has implemented similar regulations through its CO2 emissions standards for new passenger cars and light commercial vehicles. These standards set increasingly stringent targets for reducing CO2 emissions, indirectly influencing the development of more fuel-efficient power steering systems in hybrid vehicles.

China, the world's largest automotive market, has also introduced strict fuel consumption regulations and incentives for new energy vehicles, including hybrids. These policies have accelerated the adoption of advanced power steering technologies that contribute to overall vehicle efficiency.

The impact of power steering fluid on fuel economy in hybrid cars is subject to these environmental regulations. Manufacturers are required to consider the energy consumption of all vehicle systems, including power steering, to meet the prescribed efficiency standards. This has led to innovations in power steering fluid formulations and system designs to minimize energy losses and maximize fuel economy.

Regulatory bodies are increasingly focusing on the lifecycle environmental impact of automotive fluids, including power steering fluid. This has prompted research into biodegradable and low-toxicity alternatives that maintain performance while reducing environmental risks. Some jurisdictions have implemented regulations on the disposal and recycling of automotive fluids, encouraging manufacturers to develop more sustainable power steering fluid options.

The push for electrification in the automotive industry, driven by environmental regulations, is also influencing power steering technology. Electric power steering systems, which do not require traditional hydraulic fluid, are becoming more prevalent in hybrid vehicles. This shift is partly due to their potential for improved energy efficiency and reduced environmental impact.

As environmental regulations continue to evolve, the automotive industry is likely to see further innovations in power steering technologies for hybrid vehicles. These may include advanced fluid formulations, more efficient hydraulic systems, or entirely new approaches to steering assistance that prioritize fuel economy and environmental sustainability.

In the United States, the Corporate Average Fuel Economy (CAFE) standards set by the National Highway Traffic Safety Administration (NHTSA) and the Environmental Protection Agency (EPA) have been instrumental in driving improvements in fuel efficiency. These standards require automakers to achieve specific fleet-wide average fuel economy targets, which has led to increased investment in hybrid and electric vehicle technologies.

The European Union has implemented similar regulations through its CO2 emissions standards for new passenger cars and light commercial vehicles. These standards set increasingly stringent targets for reducing CO2 emissions, indirectly influencing the development of more fuel-efficient power steering systems in hybrid vehicles.

China, the world's largest automotive market, has also introduced strict fuel consumption regulations and incentives for new energy vehicles, including hybrids. These policies have accelerated the adoption of advanced power steering technologies that contribute to overall vehicle efficiency.

The impact of power steering fluid on fuel economy in hybrid cars is subject to these environmental regulations. Manufacturers are required to consider the energy consumption of all vehicle systems, including power steering, to meet the prescribed efficiency standards. This has led to innovations in power steering fluid formulations and system designs to minimize energy losses and maximize fuel economy.

Regulatory bodies are increasingly focusing on the lifecycle environmental impact of automotive fluids, including power steering fluid. This has prompted research into biodegradable and low-toxicity alternatives that maintain performance while reducing environmental risks. Some jurisdictions have implemented regulations on the disposal and recycling of automotive fluids, encouraging manufacturers to develop more sustainable power steering fluid options.

The push for electrification in the automotive industry, driven by environmental regulations, is also influencing power steering technology. Electric power steering systems, which do not require traditional hydraulic fluid, are becoming more prevalent in hybrid vehicles. This shift is partly due to their potential for improved energy efficiency and reduced environmental impact.

As environmental regulations continue to evolve, the automotive industry is likely to see further innovations in power steering technologies for hybrid vehicles. These may include advanced fluid formulations, more efficient hydraulic systems, or entirely new approaches to steering assistance that prioritize fuel economy and environmental sustainability.

Energy Recovery Potential

The energy recovery potential in hybrid cars' power steering systems presents a promising avenue for improving fuel economy. By harnessing the energy typically dissipated as heat in conventional power steering systems, hybrid vehicles can redirect this energy to supplement their electric power sources. This approach aligns with the broader trend of maximizing energy efficiency in hybrid and electric vehicles.

One of the primary methods for energy recovery in power steering systems involves the implementation of electric power steering (EPS) technology. EPS systems replace traditional hydraulic components with electric motors, eliminating the need for power steering fluid altogether. This transition not only reduces the overall weight of the vehicle but also allows for more precise control over the steering assistance provided.

In the context of hybrid vehicles, EPS systems can be integrated with regenerative braking systems to capture and store energy during deceleration and steering maneuvers. This synergy between different vehicle systems enhances the overall energy recovery potential, contributing to improved fuel economy.

Another innovative approach to energy recovery in power steering systems involves the use of electro-hydraulic power steering (EHPS). This hybrid technology combines the benefits of traditional hydraulic systems with the efficiency of electric control. EHPS systems can potentially recover energy by utilizing a variable displacement pump that adjusts its output based on steering demand, reducing unnecessary power consumption.

Furthermore, advanced control algorithms and sensors can optimize the power steering system's operation, ensuring that energy is only expended when necessary. By fine-tuning the assistance provided based on factors such as vehicle speed, steering angle, and driver input, these systems can minimize energy waste and maximize recovery potential.

The integration of power steering energy recovery with the hybrid vehicle's battery management system is crucial for realizing the full benefits of this technology. By efficiently storing and distributing recovered energy, the vehicle can reduce its reliance on the internal combustion engine, thereby improving overall fuel economy.

As research in this area progresses, we can expect to see further innovations in materials and designs that enhance the energy recovery capabilities of power steering systems in hybrid vehicles. These advancements may include the development of more efficient electric motors, improved energy storage solutions, and sophisticated control systems that can predict and adapt to driving conditions in real-time.

One of the primary methods for energy recovery in power steering systems involves the implementation of electric power steering (EPS) technology. EPS systems replace traditional hydraulic components with electric motors, eliminating the need for power steering fluid altogether. This transition not only reduces the overall weight of the vehicle but also allows for more precise control over the steering assistance provided.

In the context of hybrid vehicles, EPS systems can be integrated with regenerative braking systems to capture and store energy during deceleration and steering maneuvers. This synergy between different vehicle systems enhances the overall energy recovery potential, contributing to improved fuel economy.

Another innovative approach to energy recovery in power steering systems involves the use of electro-hydraulic power steering (EHPS). This hybrid technology combines the benefits of traditional hydraulic systems with the efficiency of electric control. EHPS systems can potentially recover energy by utilizing a variable displacement pump that adjusts its output based on steering demand, reducing unnecessary power consumption.

Furthermore, advanced control algorithms and sensors can optimize the power steering system's operation, ensuring that energy is only expended when necessary. By fine-tuning the assistance provided based on factors such as vehicle speed, steering angle, and driver input, these systems can minimize energy waste and maximize recovery potential.

The integration of power steering energy recovery with the hybrid vehicle's battery management system is crucial for realizing the full benefits of this technology. By efficiently storing and distributing recovered energy, the vehicle can reduce its reliance on the internal combustion engine, thereby improving overall fuel economy.

As research in this area progresses, we can expect to see further innovations in materials and designs that enhance the energy recovery capabilities of power steering systems in hybrid vehicles. These advancements may include the development of more efficient electric motors, improved energy storage solutions, and sophisticated control systems that can predict and adapt to driving conditions in real-time.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!