The role of induction motors in steel production facilities

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Induction Motor Evolution in Steel Industry

The evolution of induction motors in the steel industry has been a crucial factor in the advancement of steel production facilities. This journey began in the late 19th century when the first practical induction motor was invented by Nikola Tesla. Initially, these motors were small and inefficient, but they quickly gained traction in industrial applications due to their simplicity and robustness.

In the early 20th century, as steel production began to scale up, induction motors found their place in various processes within steel mills. They were primarily used for driving pumps, fans, and conveyor systems. The 1920s and 1930s saw significant improvements in motor design, including better insulation materials and more efficient cooling systems, which allowed for larger and more powerful motors to be built.

The post-World War II era marked a turning point in the use of induction motors in steel production. The demand for steel skyrocketed, necessitating more efficient and reliable production methods. This period saw the introduction of variable speed drives, which greatly enhanced the control and efficiency of induction motors. These advancements allowed for more precise control of steel rolling processes and improved the quality of the final product.

During the 1970s and 1980s, the focus shifted towards energy efficiency. The oil crises of this period prompted steel manufacturers to seek ways to reduce energy consumption. This led to the development of high-efficiency induction motors, which could operate at higher temperatures and with less energy loss. These motors became integral to the steel industry's efforts to reduce production costs and environmental impact.

The digital revolution of the 1990s and 2000s brought about another significant change in induction motor technology. The integration of advanced control systems and sensors allowed for real-time monitoring and adjustment of motor performance. This not only improved efficiency but also extended the lifespan of motors by enabling predictive maintenance.

In recent years, the evolution of induction motors in the steel industry has been characterized by a focus on sustainability and Industry 4.0 principles. Modern induction motors are designed to be more compact, energy-efficient, and capable of operating in harsh steel mill environments. They are now an essential component of smart manufacturing systems, contributing to the overall optimization of steel production processes.

The latest developments include the use of advanced materials in motor construction, such as high-performance magnetic alloys and innovative insulation systems. These improvements have resulted in motors that can withstand higher temperatures and operate at higher speeds, further enhancing the productivity of steel production facilities.

In the early 20th century, as steel production began to scale up, induction motors found their place in various processes within steel mills. They were primarily used for driving pumps, fans, and conveyor systems. The 1920s and 1930s saw significant improvements in motor design, including better insulation materials and more efficient cooling systems, which allowed for larger and more powerful motors to be built.

The post-World War II era marked a turning point in the use of induction motors in steel production. The demand for steel skyrocketed, necessitating more efficient and reliable production methods. This period saw the introduction of variable speed drives, which greatly enhanced the control and efficiency of induction motors. These advancements allowed for more precise control of steel rolling processes and improved the quality of the final product.

During the 1970s and 1980s, the focus shifted towards energy efficiency. The oil crises of this period prompted steel manufacturers to seek ways to reduce energy consumption. This led to the development of high-efficiency induction motors, which could operate at higher temperatures and with less energy loss. These motors became integral to the steel industry's efforts to reduce production costs and environmental impact.

The digital revolution of the 1990s and 2000s brought about another significant change in induction motor technology. The integration of advanced control systems and sensors allowed for real-time monitoring and adjustment of motor performance. This not only improved efficiency but also extended the lifespan of motors by enabling predictive maintenance.

In recent years, the evolution of induction motors in the steel industry has been characterized by a focus on sustainability and Industry 4.0 principles. Modern induction motors are designed to be more compact, energy-efficient, and capable of operating in harsh steel mill environments. They are now an essential component of smart manufacturing systems, contributing to the overall optimization of steel production processes.

The latest developments include the use of advanced materials in motor construction, such as high-performance magnetic alloys and innovative insulation systems. These improvements have resulted in motors that can withstand higher temperatures and operate at higher speeds, further enhancing the productivity of steel production facilities.

Steel Production Facility Motor Demand Analysis

The steel production industry heavily relies on induction motors for various critical processes, driving a significant demand for these essential components. The market for induction motors in steel facilities is characterized by a need for robust, high-performance, and energy-efficient solutions capable of withstanding harsh operating conditions. As steel production continues to evolve and modernize, the demand for advanced motor technologies is expected to grow.

Steel production facilities require induction motors for a wide range of applications, including rolling mills, conveyor systems, pumps, fans, and compressors. The market demand is primarily driven by the need for increased productivity, improved energy efficiency, and reduced maintenance costs. Large steel producers are increasingly focusing on upgrading their existing motor systems to meet stringent environmental regulations and reduce operational expenses.

The global steel industry's recovery and expansion, particularly in emerging economies, are key factors influencing the demand for induction motors. Countries like China, India, and Brazil are experiencing rapid industrialization and urbanization, leading to increased steel production capacity and, consequently, a higher demand for motor systems. Additionally, the push for sustainable manufacturing practices is driving the adoption of high-efficiency motors that comply with international energy standards.

Market analysis indicates that the demand for induction motors in steel production facilities is expected to grow at a steady rate over the next five years. This growth is attributed to the ongoing modernization of existing steel plants and the construction of new, state-of-the-art facilities. The replacement market for aging motor systems also contributes significantly to the overall demand, as steel producers seek to improve their operational efficiency and reduce downtime.

The market for induction motors in steel production is segmented based on power rating, with medium and high-power motors dominating the demand. These motors are typically used in critical applications such as rolling mills and large pumps, where reliability and performance are paramount. The demand for low-power motors, while still significant, is primarily driven by auxiliary systems and smaller equipment within the steel production process.

Energy efficiency remains a key consideration in the selection of induction motors for steel facilities. With energy costs representing a substantial portion of operational expenses in steel production, there is a growing trend towards the adoption of premium efficiency and super-premium efficiency motors. This shift is further supported by government regulations and incentives promoting energy-efficient industrial equipment.

Steel production facilities require induction motors for a wide range of applications, including rolling mills, conveyor systems, pumps, fans, and compressors. The market demand is primarily driven by the need for increased productivity, improved energy efficiency, and reduced maintenance costs. Large steel producers are increasingly focusing on upgrading their existing motor systems to meet stringent environmental regulations and reduce operational expenses.

The global steel industry's recovery and expansion, particularly in emerging economies, are key factors influencing the demand for induction motors. Countries like China, India, and Brazil are experiencing rapid industrialization and urbanization, leading to increased steel production capacity and, consequently, a higher demand for motor systems. Additionally, the push for sustainable manufacturing practices is driving the adoption of high-efficiency motors that comply with international energy standards.

Market analysis indicates that the demand for induction motors in steel production facilities is expected to grow at a steady rate over the next five years. This growth is attributed to the ongoing modernization of existing steel plants and the construction of new, state-of-the-art facilities. The replacement market for aging motor systems also contributes significantly to the overall demand, as steel producers seek to improve their operational efficiency and reduce downtime.

The market for induction motors in steel production is segmented based on power rating, with medium and high-power motors dominating the demand. These motors are typically used in critical applications such as rolling mills and large pumps, where reliability and performance are paramount. The demand for low-power motors, while still significant, is primarily driven by auxiliary systems and smaller equipment within the steel production process.

Energy efficiency remains a key consideration in the selection of induction motors for steel facilities. With energy costs representing a substantial portion of operational expenses in steel production, there is a growing trend towards the adoption of premium efficiency and super-premium efficiency motors. This shift is further supported by government regulations and incentives promoting energy-efficient industrial equipment.

Induction Motor Challenges in Steel Manufacturing

Induction motors play a critical role in steel production facilities, serving as the backbone of various processes. However, their operation in this harsh environment presents numerous challenges that demand innovative solutions. The extreme temperatures, corrosive atmospheres, and high-stress conditions inherent in steel manufacturing push these motors to their limits, necessitating specialized designs and robust maintenance strategies.

One of the primary challenges faced by induction motors in steel plants is thermal management. The intense heat generated during steel production processes can lead to rapid degradation of motor components, particularly insulation materials. This thermal stress is exacerbated by the frequent start-stop cycles and variable load conditions typical in steel manufacturing operations. As a result, motor windings are prone to premature failure, leading to unexpected downtime and production losses.

Contamination poses another significant challenge. Steel production environments are characterized by high levels of dust, metal particles, and corrosive gases. These contaminants can infiltrate motor housings, compromising the integrity of bearings, windings, and other critical components. The accumulation of conductive particles can lead to short circuits, while corrosive substances accelerate the deterioration of motor parts, reducing overall reliability and lifespan.

Vibration and mechanical stress present additional hurdles for induction motors in steel facilities. The heavy-duty nature of steel production equipment, coupled with the continuous operation of rolling mills and other machinery, subjects motors to constant vibration and shock loads. This mechanical stress can lead to bearing failures, shaft misalignment, and structural damage to motor housings, necessitating frequent maintenance and replacement.

Power quality issues are also prevalent in steel manufacturing environments. Large electrical loads, such as electric arc furnaces, create significant voltage fluctuations and harmonic distortions in the power supply. These power quality problems can cause motor overheating, reduced efficiency, and increased wear on motor components. Addressing these electrical challenges requires sophisticated power conditioning and motor protection systems.

The demanding nature of steel production processes often requires motors to operate at or near their maximum capacity for extended periods. This continuous high-load operation accelerates wear and tear, potentially leading to premature motor failure. Balancing the need for maximum productivity with motor longevity presents a significant challenge for plant operators and maintenance teams.

Lastly, the integration of induction motors with modern control systems and Industry 4.0 technologies introduces new complexities. While these advancements offer opportunities for improved efficiency and predictive maintenance, they also require specialized knowledge and infrastructure to implement effectively. Bridging the gap between traditional motor technology and smart manufacturing principles remains an ongoing challenge in the steel industry.

One of the primary challenges faced by induction motors in steel plants is thermal management. The intense heat generated during steel production processes can lead to rapid degradation of motor components, particularly insulation materials. This thermal stress is exacerbated by the frequent start-stop cycles and variable load conditions typical in steel manufacturing operations. As a result, motor windings are prone to premature failure, leading to unexpected downtime and production losses.

Contamination poses another significant challenge. Steel production environments are characterized by high levels of dust, metal particles, and corrosive gases. These contaminants can infiltrate motor housings, compromising the integrity of bearings, windings, and other critical components. The accumulation of conductive particles can lead to short circuits, while corrosive substances accelerate the deterioration of motor parts, reducing overall reliability and lifespan.

Vibration and mechanical stress present additional hurdles for induction motors in steel facilities. The heavy-duty nature of steel production equipment, coupled with the continuous operation of rolling mills and other machinery, subjects motors to constant vibration and shock loads. This mechanical stress can lead to bearing failures, shaft misalignment, and structural damage to motor housings, necessitating frequent maintenance and replacement.

Power quality issues are also prevalent in steel manufacturing environments. Large electrical loads, such as electric arc furnaces, create significant voltage fluctuations and harmonic distortions in the power supply. These power quality problems can cause motor overheating, reduced efficiency, and increased wear on motor components. Addressing these electrical challenges requires sophisticated power conditioning and motor protection systems.

The demanding nature of steel production processes often requires motors to operate at or near their maximum capacity for extended periods. This continuous high-load operation accelerates wear and tear, potentially leading to premature motor failure. Balancing the need for maximum productivity with motor longevity presents a significant challenge for plant operators and maintenance teams.

Lastly, the integration of induction motors with modern control systems and Industry 4.0 technologies introduces new complexities. While these advancements offer opportunities for improved efficiency and predictive maintenance, they also require specialized knowledge and infrastructure to implement effectively. Bridging the gap between traditional motor technology and smart manufacturing principles remains an ongoing challenge in the steel industry.

Current Induction Motor Solutions for Steel Plants

01 Design and construction of induction motors

This category covers the fundamental design and construction aspects of induction motors, including rotor and stator configurations, winding arrangements, and core materials. Innovations in these areas aim to improve efficiency, power output, and overall performance of the motors.- Design and construction of induction motors: This category covers the fundamental design and construction aspects of induction motors, including rotor and stator configurations, winding arrangements, and core materials. Innovations in these areas aim to improve motor efficiency, power output, and overall performance.

- Control systems for induction motors: This point focuses on the development of control systems and methods for induction motors. It includes advancements in speed control, torque regulation, and power factor correction. These control systems aim to enhance motor performance, energy efficiency, and adaptability to various operating conditions.

- Efficiency improvements in induction motors: This category encompasses innovations aimed at improving the energy efficiency of induction motors. It includes techniques for reducing losses, optimizing magnetic circuits, and enhancing thermal management. These advancements contribute to lower operating costs and reduced environmental impact.

- Specialized applications of induction motors: This point covers the adaptation and optimization of induction motors for specific applications. It includes designs for high-speed operations, heavy-duty industrial use, and integration with renewable energy systems. These specialized motors are tailored to meet the unique requirements of various industries and operating environments.

- Manufacturing and assembly techniques for induction motors: This category focuses on innovative manufacturing and assembly methods for induction motors. It includes advancements in automated production, precision assembly techniques, and quality control processes. These innovations aim to improve production efficiency, reduce costs, and enhance the overall quality and reliability of induction motors.

02 Control systems for induction motors

Control systems play a crucial role in regulating the speed, torque, and efficiency of induction motors. This category includes advancements in motor drives, frequency converters, and intelligent control algorithms that enhance the motor's performance and adaptability to various operating conditions.Expand Specific Solutions03 Energy efficiency improvements

This category focuses on innovations aimed at increasing the energy efficiency of induction motors. It includes techniques for reducing losses, optimizing magnetic circuits, and implementing advanced materials to minimize energy consumption while maintaining or improving motor performance.Expand Specific Solutions04 Specialized applications of induction motors

Induction motors are used in various specialized applications, each with unique requirements. This category covers modifications and adaptations of induction motors for specific industries or purposes, such as high-speed operations, submersible pumps, or extreme environmental conditions.Expand Specific Solutions05 Manufacturing and assembly techniques

This category encompasses innovations in the manufacturing and assembly processes of induction motors. It includes advancements in production methods, automated assembly techniques, and quality control measures that improve the reliability, consistency, and cost-effectiveness of motor production.Expand Specific Solutions

Key Induction Motor Manufacturers for Steel Sector

The induction motor market in steel production facilities is in a mature stage, with a substantial global market size driven by the industry's continuous demand for reliable and efficient motor solutions. The technology is well-established, with major players like Hitachi Ltd., ABB AB, and Danieli Automation SpA offering advanced induction motor systems tailored for steel production. These companies, along with others such as JFE Steel Corp. and Nippon Steel Corp., have developed sophisticated motor control technologies and energy-efficient solutions to meet the specific requirements of steel manufacturing processes. The competitive landscape is characterized by ongoing innovations in motor design, efficiency improvements, and integration with smart manufacturing systems.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL has implemented advanced induction motor systems in their steel production facilities to improve energy efficiency and process control. They utilize high-voltage induction motors with variable frequency drives (VFDs) for large-scale applications such as rolling mills and blast furnace blowers[4]. These motors are designed to withstand the extreme conditions in steel plants, including high temperatures and dust. NIPPON STEEL has also developed a proprietary motor control system that optimizes the performance of induction motors based on real-time production data, resulting in energy savings of up to 15% in some processes[5].

Strengths: Customized solutions for steel industry, integration with advanced control systems. Weaknesses: Potentially limited applicability outside the steel industry, high implementation costs.

ABB AB

Technical Solution: ABB has developed advanced induction motor solutions specifically for steel production facilities. Their ACS880 industrial drives with Direct Torque Control (DTC) technology provide precise speed and torque control for induction motors in steel mills[1]. These drives can operate in harsh environments with temperatures up to 60°C without derating. ABB's induction motors feature IE4 super premium efficiency levels, reducing energy consumption by up to 40% compared to standard motors[2]. For critical applications in steel production, ABB offers water-cooled induction motors that can deliver high power output in compact designs, ideal for rolling mills and continuous casting machines[3].

Strengths: High efficiency, precise control, and robust design for harsh environments. Weaknesses: Higher initial cost compared to standard motors, may require specialized maintenance.

Innovative Motor Designs for Harsh Environments

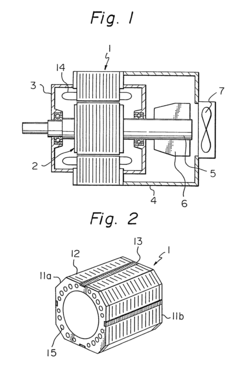

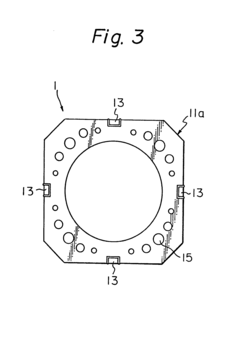

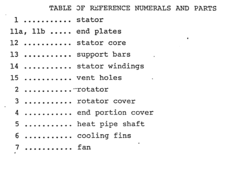

Induction motor

PatentInactiveEP0063162A1

Innovation

- The use of nonmagnetic metal support bars, such as stainless steel, welded along the external surface of the stator core, reduces the magnetic flux leakage and subsequent current flow, minimizing power loss.

Induction motor

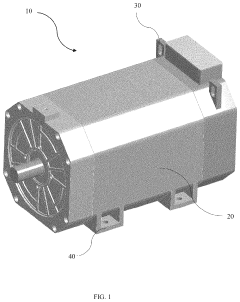

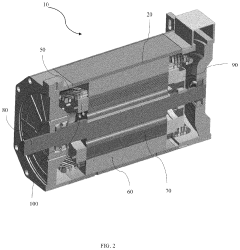

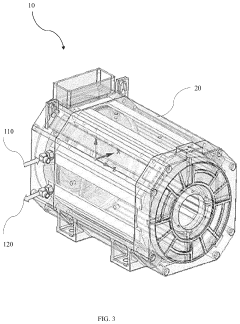

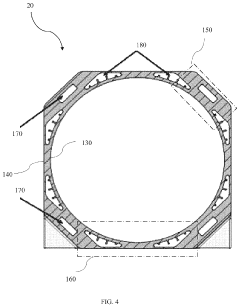

PatentPendingUS20240063684A1

Innovation

- An induction motor with an irregular octagonal motor casing housing a cooling system of interconnected cooling channels and air ducts, featuring a hollow cylindrical stator and rotor stacks with specific slots and notches for efficient component alignment and cooling, along with a fan for air inflow assistance.

Energy Efficiency Regulations for Industrial Motors

Energy efficiency regulations for industrial motors have become increasingly stringent in recent years, driven by the need to reduce energy consumption and greenhouse gas emissions in the steel production sector. These regulations primarily focus on induction motors, which are widely used in steel manufacturing facilities due to their robustness and reliability.

The European Union has been at the forefront of implementing energy efficiency standards for industrial motors. The EU's Ecodesign Directive, specifically regulation (EC) No 640/2009, sets minimum energy performance standards for electric motors. This regulation has been updated over time, with the latest version (EU) 2019/1781 coming into effect in July 2021. It mandates that most induction motors with a rated output between 0.75 kW and 1000 kW must meet IE3 (Premium Efficiency) or higher efficiency levels.

In the United States, the Department of Energy (DOE) has established similar regulations. The Energy Independence and Security Act of 2007 set minimum efficiency standards for electric motors, which have been periodically updated. The current standards, effective since June 2016, require most induction motors between 1 and 500 horsepower to meet NEMA Premium efficiency levels, equivalent to IE3.

China, a major player in the steel industry, has also implemented energy efficiency regulations for industrial motors. The GB 18613-2012 standard sets minimum energy performance requirements for small and medium three-phase asynchronous motors, which are widely used in steel production facilities. This standard has been revised and updated to align more closely with international efficiency classifications.

These regulations have significant implications for steel production facilities. Manufacturers are required to upgrade or replace older, less efficient motors with newer, high-efficiency models. While this may involve substantial upfront costs, the long-term benefits in terms of energy savings and reduced operational expenses are considerable.

The impact of these regulations extends beyond individual steel plants. Motor manufacturers have been compelled to innovate and develop more efficient motor designs, leading to advancements in materials and manufacturing techniques. This has resulted in the introduction of super-premium efficiency (IE4) and ultra-premium efficiency (IE5) motors, which offer even greater energy savings.

As energy efficiency regulations continue to evolve, steel production facilities must stay informed and proactive in their approach to motor management. This includes conducting regular energy audits, implementing predictive maintenance strategies, and considering the total cost of ownership when selecting new motors. By embracing these regulations and adopting high-efficiency induction motors, steel producers can significantly reduce their energy consumption, lower operating costs, and contribute to global efforts in combating climate change.

The European Union has been at the forefront of implementing energy efficiency standards for industrial motors. The EU's Ecodesign Directive, specifically regulation (EC) No 640/2009, sets minimum energy performance standards for electric motors. This regulation has been updated over time, with the latest version (EU) 2019/1781 coming into effect in July 2021. It mandates that most induction motors with a rated output between 0.75 kW and 1000 kW must meet IE3 (Premium Efficiency) or higher efficiency levels.

In the United States, the Department of Energy (DOE) has established similar regulations. The Energy Independence and Security Act of 2007 set minimum efficiency standards for electric motors, which have been periodically updated. The current standards, effective since June 2016, require most induction motors between 1 and 500 horsepower to meet NEMA Premium efficiency levels, equivalent to IE3.

China, a major player in the steel industry, has also implemented energy efficiency regulations for industrial motors. The GB 18613-2012 standard sets minimum energy performance requirements for small and medium three-phase asynchronous motors, which are widely used in steel production facilities. This standard has been revised and updated to align more closely with international efficiency classifications.

These regulations have significant implications for steel production facilities. Manufacturers are required to upgrade or replace older, less efficient motors with newer, high-efficiency models. While this may involve substantial upfront costs, the long-term benefits in terms of energy savings and reduced operational expenses are considerable.

The impact of these regulations extends beyond individual steel plants. Motor manufacturers have been compelled to innovate and develop more efficient motor designs, leading to advancements in materials and manufacturing techniques. This has resulted in the introduction of super-premium efficiency (IE4) and ultra-premium efficiency (IE5) motors, which offer even greater energy savings.

As energy efficiency regulations continue to evolve, steel production facilities must stay informed and proactive in their approach to motor management. This includes conducting regular energy audits, implementing predictive maintenance strategies, and considering the total cost of ownership when selecting new motors. By embracing these regulations and adopting high-efficiency induction motors, steel producers can significantly reduce their energy consumption, lower operating costs, and contribute to global efforts in combating climate change.

Cost-Benefit Analysis of Motor Upgrades in Steel Mills

The cost-benefit analysis of motor upgrades in steel mills is a critical consideration for facility managers and decision-makers in the steel production industry. Upgrading induction motors can lead to significant improvements in energy efficiency, productivity, and overall operational performance. However, these upgrades also require substantial initial investments, making it essential to carefully evaluate the potential returns.

One of the primary benefits of upgrading induction motors is the reduction in energy consumption. Modern, high-efficiency motors can reduce energy losses by up to 30% compared to older, standard-efficiency models. In steel mills, where motors often operate continuously under heavy loads, this translates to substantial energy savings over time. For example, a 500 horsepower motor running at 75% load for 8,000 hours per year could save approximately $20,000 annually in electricity costs when upgraded to a premium efficiency model.

Improved reliability is another significant advantage of motor upgrades. Newer motors are designed with advanced materials and manufacturing techniques, resulting in longer lifespans and reduced maintenance requirements. This leads to decreased downtime and lower maintenance costs, which can have a substantial impact on the overall productivity of a steel mill. The reduction in unexpected failures can prevent costly production interruptions and improve the consistency of output quality.

However, the initial costs of motor upgrades can be substantial. Premium efficiency motors typically cost 15-30% more than standard models, and installation costs must also be considered. For large steel mill operations, a comprehensive motor upgrade program could require millions of dollars in upfront investment. This significant capital expenditure necessitates a thorough analysis of the expected payback period and return on investment (ROI).

The payback period for motor upgrades can vary widely depending on factors such as motor size, operating hours, electricity rates, and the efficiency gain achieved. In many cases, the payback period for upgrading to premium efficiency motors ranges from 2 to 5 years. After this period, the ongoing energy savings continue to provide financial benefits for the remainder of the motor's operational life, which can extend to 20 years or more.

Additional factors to consider in the cost-benefit analysis include potential incentives or rebates offered by utility companies or government agencies for energy-efficient upgrades. These programs can significantly offset the initial investment costs and improve the overall financial attractiveness of the upgrade project. Furthermore, the environmental benefits of reduced energy consumption, while not directly quantifiable in monetary terms, can contribute to a company's sustainability goals and public image.

In conclusion, while the upfront costs of motor upgrades in steel mills can be substantial, the long-term benefits in terms of energy savings, improved reliability, and reduced maintenance costs often justify the investment. A comprehensive cost-benefit analysis should consider not only the direct financial impacts but also the broader operational and environmental benefits to make an informed decision on motor upgrade initiatives.

One of the primary benefits of upgrading induction motors is the reduction in energy consumption. Modern, high-efficiency motors can reduce energy losses by up to 30% compared to older, standard-efficiency models. In steel mills, where motors often operate continuously under heavy loads, this translates to substantial energy savings over time. For example, a 500 horsepower motor running at 75% load for 8,000 hours per year could save approximately $20,000 annually in electricity costs when upgraded to a premium efficiency model.

Improved reliability is another significant advantage of motor upgrades. Newer motors are designed with advanced materials and manufacturing techniques, resulting in longer lifespans and reduced maintenance requirements. This leads to decreased downtime and lower maintenance costs, which can have a substantial impact on the overall productivity of a steel mill. The reduction in unexpected failures can prevent costly production interruptions and improve the consistency of output quality.

However, the initial costs of motor upgrades can be substantial. Premium efficiency motors typically cost 15-30% more than standard models, and installation costs must also be considered. For large steel mill operations, a comprehensive motor upgrade program could require millions of dollars in upfront investment. This significant capital expenditure necessitates a thorough analysis of the expected payback period and return on investment (ROI).

The payback period for motor upgrades can vary widely depending on factors such as motor size, operating hours, electricity rates, and the efficiency gain achieved. In many cases, the payback period for upgrading to premium efficiency motors ranges from 2 to 5 years. After this period, the ongoing energy savings continue to provide financial benefits for the remainder of the motor's operational life, which can extend to 20 years or more.

Additional factors to consider in the cost-benefit analysis include potential incentives or rebates offered by utility companies or government agencies for energy-efficient upgrades. These programs can significantly offset the initial investment costs and improve the overall financial attractiveness of the upgrade project. Furthermore, the environmental benefits of reduced energy consumption, while not directly quantifiable in monetary terms, can contribute to a company's sustainability goals and public image.

In conclusion, while the upfront costs of motor upgrades in steel mills can be substantial, the long-term benefits in terms of energy savings, improved reliability, and reduced maintenance costs often justify the investment. A comprehensive cost-benefit analysis should consider not only the direct financial impacts but also the broader operational and environmental benefits to make an informed decision on motor upgrade initiatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!