The Role of Vacuum Pumps in Advanced Robotics Sensor Technology

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Evolution in Robotics

The evolution of vacuum pumps in robotics has been a critical factor in advancing sensor technology and overall robotic capabilities. Initially, vacuum pumps in robotics were primarily used for basic suction and material handling tasks. However, as robotics technology progressed, the role of vacuum pumps expanded significantly, particularly in the realm of advanced sensor systems.

In the early stages of robotics, vacuum pumps were simple devices used for pick-and-place operations. These pumps created negative pressure to lift and move objects, but their application in sensor technology was limited. As robotics became more sophisticated, the need for precise environmental control in sensor systems became apparent, leading to the development of more advanced vacuum pump technologies.

The introduction of microelectromechanical systems (MEMS) in robotics marked a significant milestone in vacuum pump evolution. MEMS-based sensors required extremely clean and controlled environments to function accurately. This necessitated the development of high-performance vacuum pumps capable of creating and maintaining ultra-low pressure environments. These pumps played a crucial role in enabling the miniaturization of sensor components and improving their sensitivity.

Another key development was the integration of vacuum pumps with advanced materials and coatings. This combination enhanced the pumps' efficiency and durability, making them suitable for long-term operation in challenging robotic applications. The use of corrosion-resistant materials and specialized coatings allowed vacuum pumps to operate in diverse environments, expanding their utility in various robotic sensor applications.

The advent of smart manufacturing and Industry 4.0 concepts further accelerated the evolution of vacuum pumps in robotics. Pumps became equipped with sensors and connectivity features, allowing for real-time monitoring and predictive maintenance. This integration not only improved the reliability of robotic systems but also contributed to the overall intelligence of robotic platforms.

Recent advancements have seen the development of compact, energy-efficient vacuum pumps specifically designed for mobile and collaborative robots. These pumps are crucial in enabling sophisticated sensor arrays in autonomous robots, supporting functions like environmental sensing, object recognition, and navigation. The miniaturization of vacuum pump technology has been particularly impactful in the field of soft robotics, where precise control of air pressure is essential for mimicking biological systems.

Looking forward, the evolution of vacuum pumps in robotics is likely to continue, with a focus on further miniaturization, increased energy efficiency, and enhanced integration with AI and IoT systems. These advancements will play a pivotal role in pushing the boundaries of what's possible in robotic sensor technology, enabling more sophisticated, adaptable, and intelligent robotic systems across various industries.

In the early stages of robotics, vacuum pumps were simple devices used for pick-and-place operations. These pumps created negative pressure to lift and move objects, but their application in sensor technology was limited. As robotics became more sophisticated, the need for precise environmental control in sensor systems became apparent, leading to the development of more advanced vacuum pump technologies.

The introduction of microelectromechanical systems (MEMS) in robotics marked a significant milestone in vacuum pump evolution. MEMS-based sensors required extremely clean and controlled environments to function accurately. This necessitated the development of high-performance vacuum pumps capable of creating and maintaining ultra-low pressure environments. These pumps played a crucial role in enabling the miniaturization of sensor components and improving their sensitivity.

Another key development was the integration of vacuum pumps with advanced materials and coatings. This combination enhanced the pumps' efficiency and durability, making them suitable for long-term operation in challenging robotic applications. The use of corrosion-resistant materials and specialized coatings allowed vacuum pumps to operate in diverse environments, expanding their utility in various robotic sensor applications.

The advent of smart manufacturing and Industry 4.0 concepts further accelerated the evolution of vacuum pumps in robotics. Pumps became equipped with sensors and connectivity features, allowing for real-time monitoring and predictive maintenance. This integration not only improved the reliability of robotic systems but also contributed to the overall intelligence of robotic platforms.

Recent advancements have seen the development of compact, energy-efficient vacuum pumps specifically designed for mobile and collaborative robots. These pumps are crucial in enabling sophisticated sensor arrays in autonomous robots, supporting functions like environmental sensing, object recognition, and navigation. The miniaturization of vacuum pump technology has been particularly impactful in the field of soft robotics, where precise control of air pressure is essential for mimicking biological systems.

Looking forward, the evolution of vacuum pumps in robotics is likely to continue, with a focus on further miniaturization, increased energy efficiency, and enhanced integration with AI and IoT systems. These advancements will play a pivotal role in pushing the boundaries of what's possible in robotic sensor technology, enabling more sophisticated, adaptable, and intelligent robotic systems across various industries.

Market Demand Analysis

The market demand for vacuum pumps in advanced robotics sensor technology has been experiencing significant growth in recent years. This surge is primarily driven by the increasing adoption of robotics across various industries, including manufacturing, healthcare, and logistics. As robots become more sophisticated and capable of performing complex tasks, the need for advanced sensor technologies has intensified, creating a ripple effect on the demand for high-performance vacuum pumps.

In the manufacturing sector, the integration of robots with advanced sensors has led to improved precision, efficiency, and quality control. Vacuum pumps play a crucial role in maintaining the optimal operating conditions for these sensors, particularly in environments where cleanliness and atmospheric control are paramount. The automotive industry, for instance, has seen a substantial increase in the use of robots equipped with advanced sensors for tasks such as welding, painting, and assembly, driving up the demand for specialized vacuum pump solutions.

The healthcare industry has also emerged as a significant market for vacuum pumps in robotics sensor technology. Surgical robots, equipped with highly sensitive sensors, require precise environmental control to ensure accuracy and safety during procedures. Vacuum pumps are essential in maintaining sterile conditions and supporting the functionality of these advanced sensors. As minimally invasive surgeries become more common, the demand for such robotic systems, and consequently, vacuum pumps, is expected to grow substantially.

In the rapidly expanding field of logistics and warehousing, robots with advanced sensor technologies are being deployed to improve inventory management, order fulfillment, and package handling. These applications often require vacuum pumps for tasks such as pick-and-place operations and maintaining sensor cleanliness in dusty warehouse environments. The e-commerce boom has further accelerated this trend, with major online retailers investing heavily in robotics technology to enhance their operational efficiency.

The semiconductor industry, a key driver of technological advancement, has also contributed significantly to the demand for vacuum pumps in sensor technology. The production of advanced sensors often requires ultra-clean environments and precise pressure control, which can only be achieved through high-performance vacuum systems. As the demand for more sophisticated sensors in robotics continues to grow, so does the need for specialized vacuum pump solutions in semiconductor manufacturing.

Environmental concerns and energy efficiency requirements have also shaped the market demand for vacuum pumps in robotics sensor technology. There is a growing emphasis on developing energy-efficient and environmentally friendly vacuum pump solutions that can support the operation of advanced sensors while minimizing power consumption and environmental impact. This trend has led to innovations in pump design and the adoption of smart control systems, further driving market growth.

In the manufacturing sector, the integration of robots with advanced sensors has led to improved precision, efficiency, and quality control. Vacuum pumps play a crucial role in maintaining the optimal operating conditions for these sensors, particularly in environments where cleanliness and atmospheric control are paramount. The automotive industry, for instance, has seen a substantial increase in the use of robots equipped with advanced sensors for tasks such as welding, painting, and assembly, driving up the demand for specialized vacuum pump solutions.

The healthcare industry has also emerged as a significant market for vacuum pumps in robotics sensor technology. Surgical robots, equipped with highly sensitive sensors, require precise environmental control to ensure accuracy and safety during procedures. Vacuum pumps are essential in maintaining sterile conditions and supporting the functionality of these advanced sensors. As minimally invasive surgeries become more common, the demand for such robotic systems, and consequently, vacuum pumps, is expected to grow substantially.

In the rapidly expanding field of logistics and warehousing, robots with advanced sensor technologies are being deployed to improve inventory management, order fulfillment, and package handling. These applications often require vacuum pumps for tasks such as pick-and-place operations and maintaining sensor cleanliness in dusty warehouse environments. The e-commerce boom has further accelerated this trend, with major online retailers investing heavily in robotics technology to enhance their operational efficiency.

The semiconductor industry, a key driver of technological advancement, has also contributed significantly to the demand for vacuum pumps in sensor technology. The production of advanced sensors often requires ultra-clean environments and precise pressure control, which can only be achieved through high-performance vacuum systems. As the demand for more sophisticated sensors in robotics continues to grow, so does the need for specialized vacuum pump solutions in semiconductor manufacturing.

Environmental concerns and energy efficiency requirements have also shaped the market demand for vacuum pumps in robotics sensor technology. There is a growing emphasis on developing energy-efficient and environmentally friendly vacuum pump solutions that can support the operation of advanced sensors while minimizing power consumption and environmental impact. This trend has led to innovations in pump design and the adoption of smart control systems, further driving market growth.

Current Challenges

The integration of vacuum pumps in advanced robotics sensor technology faces several significant challenges that hinder widespread adoption and optimal performance. One of the primary obstacles is the miniaturization of vacuum pump systems while maintaining high efficiency. As robotic sensors become increasingly compact and sophisticated, the demand for smaller, lighter vacuum pumps grows. However, reducing the size of these pumps often compromises their performance, creating a delicate balance between form factor and functionality.

Another critical challenge lies in power consumption and energy efficiency. Advanced robotic systems, particularly those operating in remote or autonomous environments, require vacuum pumps that consume minimal energy while delivering consistent performance. Achieving this balance is particularly difficult, as maintaining a stable vacuum often necessitates continuous operation, leading to increased power demands and potential heat generation issues.

Durability and reliability present additional hurdles in the implementation of vacuum pumps in robotics sensor technology. Robotic systems are frequently exposed to harsh environments, varying temperatures, and mechanical stresses. Ensuring that vacuum pumps can withstand these conditions while maintaining precise pressure control is crucial for long-term operation and accuracy of sensor readings.

The need for ultra-high vacuum levels in certain advanced sensor applications poses another significant challenge. Some cutting-edge sensors require extremely low pressure environments to function optimally, pushing the limits of current vacuum pump technology. Achieving and maintaining these ultra-high vacuum levels consistently and efficiently remains a complex engineering problem.

Noise and vibration reduction is an often-overlooked but critical challenge in integrating vacuum pumps with robotic sensors. The operational noise and vibrations generated by vacuum pumps can interfere with sensitive sensor readings and overall robot performance. Developing quieter, low-vibration pump solutions without sacrificing efficiency is a key area of focus for researchers and engineers.

Cost-effectiveness and scalability also present significant hurdles. While high-performance vacuum pumps are available, their cost often prohibits widespread adoption in commercial robotic applications. Developing more affordable solutions that can be mass-produced without compromising on quality and performance is essential for broader implementation across various robotics sectors.

Lastly, the integration of vacuum pump systems with existing robotic architectures and control systems poses a challenge. Ensuring seamless communication and coordination between the pump system and other robotic components is crucial for optimal performance. This integration must be robust enough to handle various operational scenarios and adapt to changing environmental conditions, adding another layer of complexity to the design and implementation process.

Another critical challenge lies in power consumption and energy efficiency. Advanced robotic systems, particularly those operating in remote or autonomous environments, require vacuum pumps that consume minimal energy while delivering consistent performance. Achieving this balance is particularly difficult, as maintaining a stable vacuum often necessitates continuous operation, leading to increased power demands and potential heat generation issues.

Durability and reliability present additional hurdles in the implementation of vacuum pumps in robotics sensor technology. Robotic systems are frequently exposed to harsh environments, varying temperatures, and mechanical stresses. Ensuring that vacuum pumps can withstand these conditions while maintaining precise pressure control is crucial for long-term operation and accuracy of sensor readings.

The need for ultra-high vacuum levels in certain advanced sensor applications poses another significant challenge. Some cutting-edge sensors require extremely low pressure environments to function optimally, pushing the limits of current vacuum pump technology. Achieving and maintaining these ultra-high vacuum levels consistently and efficiently remains a complex engineering problem.

Noise and vibration reduction is an often-overlooked but critical challenge in integrating vacuum pumps with robotic sensors. The operational noise and vibrations generated by vacuum pumps can interfere with sensitive sensor readings and overall robot performance. Developing quieter, low-vibration pump solutions without sacrificing efficiency is a key area of focus for researchers and engineers.

Cost-effectiveness and scalability also present significant hurdles. While high-performance vacuum pumps are available, their cost often prohibits widespread adoption in commercial robotic applications. Developing more affordable solutions that can be mass-produced without compromising on quality and performance is essential for broader implementation across various robotics sectors.

Lastly, the integration of vacuum pump systems with existing robotic architectures and control systems poses a challenge. Ensuring seamless communication and coordination between the pump system and other robotic components is crucial for optimal performance. This integration must be robust enough to handle various operational scenarios and adapt to changing environmental conditions, adding another layer of complexity to the design and implementation process.

Existing Vacuum Solutions

01 Improvements in vacuum pump design

Various advancements in vacuum pump design have been made to enhance efficiency and performance. These improvements include modifications to pump components, optimized fluid flow paths, and innovative sealing mechanisms. Such enhancements contribute to increased pumping capacity, reduced power consumption, and improved reliability in vacuum systems.- Improvements in vacuum pump design: Various advancements in vacuum pump design have been made to enhance efficiency and performance. These improvements include modifications to pump components, optimized fluid flow paths, and innovative sealing mechanisms. Such enhancements contribute to increased pumping speed, better vacuum levels, and improved overall reliability of the vacuum systems.

- Specialized vacuum pumps for semiconductor manufacturing: Vacuum pumps tailored for semiconductor manufacturing processes have been developed to meet the stringent requirements of the industry. These pumps are designed to handle corrosive gases, maintain high cleanliness levels, and provide stable vacuum conditions. Features may include corrosion-resistant materials, advanced filtration systems, and precise pressure control mechanisms.

- Energy-efficient vacuum pump systems: Innovations in vacuum pump technology have focused on improving energy efficiency. These developments include the use of variable speed drives, optimized motor designs, and intelligent control systems. Such advancements result in reduced power consumption, lower operating costs, and improved environmental sustainability of vacuum pump operations.

- Multi-stage vacuum pump configurations: Multi-stage vacuum pump designs have been created to achieve higher vacuum levels and improved pumping efficiency. These configurations typically combine different pump types or stages to optimize performance across a wide pressure range. Such arrangements can provide better ultimate vacuum, faster pump-down times, and enhanced handling of various gas loads.

- Vacuum pump monitoring and control systems: Advanced monitoring and control systems have been developed for vacuum pumps to enhance their performance and reliability. These systems may include sensors for real-time monitoring of pump parameters, predictive maintenance algorithms, and remote control capabilities. Such features enable optimized pump operation, early detection of potential issues, and improved overall system management.

02 Specialized vacuum pumps for semiconductor manufacturing

Vacuum pumps tailored for semiconductor manufacturing processes have been developed to meet the stringent requirements of the industry. These pumps are designed to handle corrosive gases, maintain high vacuum levels, and operate in clean room environments. Features may include corrosion-resistant materials, advanced filtration systems, and precise pressure control mechanisms.Expand Specific Solutions03 Historical developments in vacuum pump technology

The evolution of vacuum pump technology spans several decades, with numerous innovations contributing to improved performance and functionality. Historical patents showcase early designs and concepts that laid the foundation for modern vacuum pumps, including advancements in rotary, reciprocating, and diffusion pump technologies.Expand Specific Solutions04 Integration of vacuum pumps in automotive systems

Vacuum pumps have found applications in various automotive systems, including brake boosters, engine management, and emissions control. Specialized designs have been developed to meet the specific requirements of automotive applications, such as compact size, durability under harsh conditions, and integration with other vehicle components.Expand Specific Solutions05 Energy-efficient vacuum pump solutions

Recent innovations in vacuum pump technology have focused on improving energy efficiency and reducing environmental impact. These developments include the use of advanced materials, optimized motor designs, and intelligent control systems to minimize power consumption while maintaining high performance. Some solutions also incorporate heat recovery mechanisms to further enhance overall system efficiency.Expand Specific Solutions

Key Industry Players

The vacuum pump market in advanced robotics sensor technology is in a growth phase, driven by increasing demand for precision and efficiency in robotics applications. The market size is expanding, with major players like Edwards Ltd., Pfeiffer Vacuum Technology AG, and Atlas Copco Airpower NV competing for market share. These companies are investing heavily in R&D to improve vacuum pump technology, focusing on miniaturization, energy efficiency, and integration with smart systems. The technology is maturing rapidly, with innovations in dry vacuum pumps and hermetically sealed designs from companies like SKY Technology Development Co., Ltd. CAS and Ateliers Busch SA. As the market evolves, we're seeing a trend towards customized solutions for specific robotics applications, indicating a shift towards more specialized and advanced vacuum pump technologies.

Edwards Ltd.

Technical Solution: Edwards Ltd. has made significant strides in vacuum technology for robotics applications. Their nEXT turbomolecular pumps feature advanced rotor designs and bearing systems, providing high pumping speeds and low vibration levels crucial for sensitive robotic sensors[7]. Edwards has also developed the iXH dry pump series, which offers high reliability and low maintenance requirements, making them ideal for continuous operation in robotic systems[8]. The company's Vacuum Management System (VMS) allows for intelligent control and monitoring of multiple vacuum pumps, optimizing performance and energy efficiency in complex robotic setups[9].

Strengths: Robust and reliable vacuum solutions, advanced control systems, global service network. Weaknesses: Some products may be overspecified for simpler robotic applications, potentially leading to higher costs.

Pfeiffer Vacuum Technology AG

Technical Solution: Pfeiffer Vacuum Technology AG has developed advanced vacuum pumps specifically designed for robotics sensor applications. Their HiPace turbomolecular pumps utilize magnetic levitation technology to achieve ultra-high vacuum levels with minimal vibration, crucial for sensitive robotic sensors[1]. The company's multi-stage roots pumps offer high pumping speeds and low power consumption, ideal for mobile robotics platforms[2]. Pfeiffer has also introduced smart vacuum solutions with integrated sensors and control systems, allowing real-time monitoring and adjustment of vacuum conditions to optimize sensor performance in varying environments[3].

Strengths: Industry-leading vacuum technology, wide range of specialized pumps for different robotic applications, smart control systems. Weaknesses: Higher cost compared to conventional pumps, may require specialized maintenance.

Innovative Pump Designs

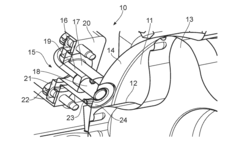

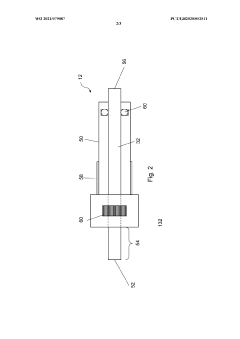

Pump comprising a proximity sensor

PatentActiveUS20180238328A1

Innovation

- A sensor system mounted on the stator, connected to a processing circuit, measures the absolute distance between the rotor and stator surfaces in real time, allowing for accurate clearance determination and monitoring of wear or vibrations, with outputs for display, storage, and warning indications to optimize pump performance and predict maintenance needs.

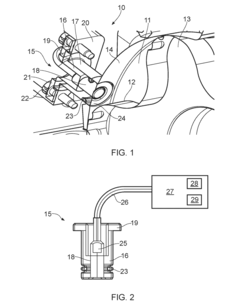

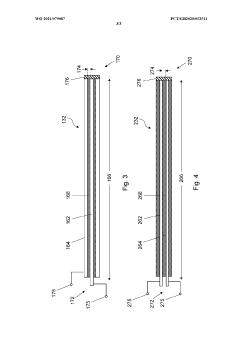

Sensor assembly

PatentWO2021079087A1

Innovation

- A sensor assembly with a probe forming an incomplete circuit that completes only when engaged by a moving part, producing a signal to activate a shut-down process or alert, reducing data output and allowing for reduced supervision and maintenance, featuring a low-volume data output and cost-effective design.

Sensor Integration Strategies

Sensor integration strategies play a crucial role in the development of advanced robotics systems that utilize vacuum pump technology. These strategies focus on seamlessly incorporating various sensors into robotic platforms to enhance their perception, decision-making, and overall performance.

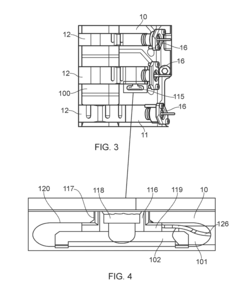

One key aspect of sensor integration in vacuum pump-based robotics is the selection of appropriate sensor types. Pressure sensors are essential for monitoring the vacuum levels within the system, ensuring optimal pump operation. Temperature sensors are often integrated to prevent overheating and maintain efficient performance. Additionally, flow sensors can be employed to measure and control the air or gas flow through the vacuum pump system.

The placement of sensors is another critical consideration in the integration process. Sensors must be strategically positioned to provide accurate and reliable data without interfering with the robot's mechanical components or the vacuum pump's operation. This may involve embedding sensors directly into pump housings or placing them at key points along the vacuum lines.

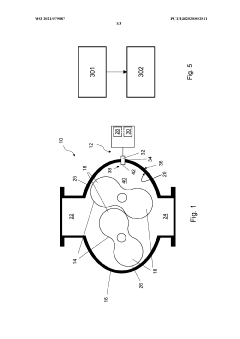

Data fusion techniques are employed to combine information from multiple sensors, creating a more comprehensive understanding of the robot's environment and internal state. This approach allows for more robust decision-making and improved adaptability to changing conditions. For instance, combining data from pressure sensors and flow sensors can provide insights into the efficiency of the vacuum system and detect potential leaks or blockages.

Miniaturization of sensors is a growing trend in advanced robotics, particularly in applications where space is at a premium. Compact, high-performance sensors are being developed to integrate seamlessly into smaller robotic platforms without compromising functionality. This trend aligns well with the need for efficient vacuum pump systems in compact robotic designs.

Real-time processing of sensor data is crucial for responsive and adaptive robotic systems. Advanced signal processing algorithms and dedicated microcontrollers are often integrated to handle the continuous stream of sensor data, enabling rapid adjustments to vacuum pump operation based on changing environmental conditions or task requirements.

Wireless sensor networks are increasingly being utilized in robotic systems, allowing for greater flexibility in sensor placement and easier system reconfiguration. This approach can be particularly beneficial in complex robotic applications where traditional wired connections may be impractical or limiting.

As robotics technology continues to advance, the integration of artificial intelligence and machine learning algorithms with sensor systems is becoming more prevalent. These technologies enable robots to learn from sensor data over time, improving their performance and adaptability in various tasks that rely on vacuum pump technology.

One key aspect of sensor integration in vacuum pump-based robotics is the selection of appropriate sensor types. Pressure sensors are essential for monitoring the vacuum levels within the system, ensuring optimal pump operation. Temperature sensors are often integrated to prevent overheating and maintain efficient performance. Additionally, flow sensors can be employed to measure and control the air or gas flow through the vacuum pump system.

The placement of sensors is another critical consideration in the integration process. Sensors must be strategically positioned to provide accurate and reliable data without interfering with the robot's mechanical components or the vacuum pump's operation. This may involve embedding sensors directly into pump housings or placing them at key points along the vacuum lines.

Data fusion techniques are employed to combine information from multiple sensors, creating a more comprehensive understanding of the robot's environment and internal state. This approach allows for more robust decision-making and improved adaptability to changing conditions. For instance, combining data from pressure sensors and flow sensors can provide insights into the efficiency of the vacuum system and detect potential leaks or blockages.

Miniaturization of sensors is a growing trend in advanced robotics, particularly in applications where space is at a premium. Compact, high-performance sensors are being developed to integrate seamlessly into smaller robotic platforms without compromising functionality. This trend aligns well with the need for efficient vacuum pump systems in compact robotic designs.

Real-time processing of sensor data is crucial for responsive and adaptive robotic systems. Advanced signal processing algorithms and dedicated microcontrollers are often integrated to handle the continuous stream of sensor data, enabling rapid adjustments to vacuum pump operation based on changing environmental conditions or task requirements.

Wireless sensor networks are increasingly being utilized in robotic systems, allowing for greater flexibility in sensor placement and easier system reconfiguration. This approach can be particularly beneficial in complex robotic applications where traditional wired connections may be impractical or limiting.

As robotics technology continues to advance, the integration of artificial intelligence and machine learning algorithms with sensor systems is becoming more prevalent. These technologies enable robots to learn from sensor data over time, improving their performance and adaptability in various tasks that rely on vacuum pump technology.

Energy Efficiency Considerations

Energy efficiency is a critical consideration in the development and implementation of vacuum pumps for advanced robotics sensor technology. As robotics systems become increasingly sophisticated and autonomous, the demand for efficient and reliable sensor technologies grows. Vacuum pumps play a crucial role in maintaining the precise environmental conditions required for many advanced sensors, particularly in applications such as MEMS (Micro-Electro-Mechanical Systems) devices and high-precision optical sensors.

The energy consumption of vacuum pumps can significantly impact the overall power budget of robotic systems, especially in mobile or battery-powered applications. Therefore, optimizing the energy efficiency of these pumps is essential for extending operational time, reducing heat generation, and minimizing the environmental footprint of robotic systems. Recent advancements in pump design and materials have led to substantial improvements in energy efficiency.

One key area of focus is the development of variable-speed pumps that can adjust their operation based on the specific vacuum requirements of the sensor system. This adaptive approach allows for significant energy savings during periods of lower demand, as opposed to traditional fixed-speed pumps that operate at full capacity regardless of the actual needs of the system.

Another important consideration is the integration of advanced control systems and algorithms that optimize pump operation in real-time. These systems can monitor various parameters such as pressure, temperature, and power consumption to ensure that the pump operates at its most efficient point while still meeting the required vacuum levels for sensor functionality.

Material innovations have also contributed to improved energy efficiency in vacuum pumps. The use of lightweight, low-friction materials in pump components reduces mechanical losses and heat generation, leading to better overall efficiency. Additionally, advancements in bearing technology and lubrication systems have further reduced energy losses due to friction.

The miniaturization of vacuum pump technology is another trend that has significant implications for energy efficiency in robotics applications. Smaller, more compact pumps not only reduce the overall weight and size of robotic systems but can also lead to reduced power consumption. This is particularly important in applications such as micro-robotics or drone-based systems where weight and power constraints are critical.

As the field of robotics continues to evolve, the demand for more energy-efficient vacuum pump solutions will likely drive further innovations. Future developments may include the integration of energy harvesting technologies to supplement pump power requirements or the use of novel materials and designs that push the boundaries of pump efficiency even further.

The energy consumption of vacuum pumps can significantly impact the overall power budget of robotic systems, especially in mobile or battery-powered applications. Therefore, optimizing the energy efficiency of these pumps is essential for extending operational time, reducing heat generation, and minimizing the environmental footprint of robotic systems. Recent advancements in pump design and materials have led to substantial improvements in energy efficiency.

One key area of focus is the development of variable-speed pumps that can adjust their operation based on the specific vacuum requirements of the sensor system. This adaptive approach allows for significant energy savings during periods of lower demand, as opposed to traditional fixed-speed pumps that operate at full capacity regardless of the actual needs of the system.

Another important consideration is the integration of advanced control systems and algorithms that optimize pump operation in real-time. These systems can monitor various parameters such as pressure, temperature, and power consumption to ensure that the pump operates at its most efficient point while still meeting the required vacuum levels for sensor functionality.

Material innovations have also contributed to improved energy efficiency in vacuum pumps. The use of lightweight, low-friction materials in pump components reduces mechanical losses and heat generation, leading to better overall efficiency. Additionally, advancements in bearing technology and lubrication systems have further reduced energy losses due to friction.

The miniaturization of vacuum pump technology is another trend that has significant implications for energy efficiency in robotics applications. Smaller, more compact pumps not only reduce the overall weight and size of robotic systems but can also lead to reduced power consumption. This is particularly important in applications such as micro-robotics or drone-based systems where weight and power constraints are critical.

As the field of robotics continues to evolve, the demand for more energy-efficient vacuum pump solutions will likely drive further innovations. Future developments may include the integration of energy harvesting technologies to supplement pump power requirements or the use of novel materials and designs that push the boundaries of pump efficiency even further.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!