The Role of Vacuum Pumps in Novel Thermoplastic Elastomers

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TPE Vacuum Pump Tech Background and Objectives

Thermoplastic elastomers (TPEs) have emerged as a revolutionary class of materials in the polymer industry, combining the elasticity of rubber with the processability of thermoplastics. The integration of vacuum pumps in TPE production and processing has become a critical factor in enhancing the quality and efficiency of these novel materials. This technological synergy aims to address the growing demand for high-performance, sustainable, and cost-effective elastomeric products across various industries.

The evolution of TPE technology can be traced back to the 1960s, with significant advancements occurring in the past few decades. The incorporation of vacuum pumps in TPE processing represents a more recent development, driven by the need for improved material properties and manufacturing efficiency. This integration seeks to overcome challenges such as air entrapment, moisture contamination, and inconsistent material distribution, which have historically plagued TPE production.

The primary objective of utilizing vacuum pumps in TPE technology is to achieve superior material characteristics and processing capabilities. By creating a controlled low-pressure environment, vacuum pumps facilitate the removal of volatile compounds, air bubbles, and moisture from the TPE melt during extrusion or molding processes. This results in enhanced material homogeneity, reduced porosity, and improved surface finish of the final products.

Furthermore, the application of vacuum technology in TPE processing aims to expand the range of achievable material properties. By manipulating pressure conditions, manufacturers can fine-tune the molecular structure of TPEs, potentially leading to novel compositions with unique mechanical, thermal, and chemical properties. This opens up new possibilities for TPE applications in demanding sectors such as automotive, medical, and consumer electronics.

Another key goal is to optimize the energy efficiency and sustainability of TPE production. Vacuum-assisted processing can potentially reduce cycle times, lower processing temperatures, and minimize material waste. These improvements not only contribute to cost reduction but also align with the growing emphasis on environmentally friendly manufacturing practices in the polymer industry.

As the TPE market continues to expand, driven by the increasing demand for lightweight, durable, and recyclable materials, the role of vacuum pumps is expected to become increasingly pivotal. The technology aims to enable the development of next-generation TPEs with enhanced performance characteristics, broader application scope, and improved environmental profiles. This technological integration represents a significant step towards meeting the evolving needs of various industries and addressing global sustainability challenges.

The evolution of TPE technology can be traced back to the 1960s, with significant advancements occurring in the past few decades. The incorporation of vacuum pumps in TPE processing represents a more recent development, driven by the need for improved material properties and manufacturing efficiency. This integration seeks to overcome challenges such as air entrapment, moisture contamination, and inconsistent material distribution, which have historically plagued TPE production.

The primary objective of utilizing vacuum pumps in TPE technology is to achieve superior material characteristics and processing capabilities. By creating a controlled low-pressure environment, vacuum pumps facilitate the removal of volatile compounds, air bubbles, and moisture from the TPE melt during extrusion or molding processes. This results in enhanced material homogeneity, reduced porosity, and improved surface finish of the final products.

Furthermore, the application of vacuum technology in TPE processing aims to expand the range of achievable material properties. By manipulating pressure conditions, manufacturers can fine-tune the molecular structure of TPEs, potentially leading to novel compositions with unique mechanical, thermal, and chemical properties. This opens up new possibilities for TPE applications in demanding sectors such as automotive, medical, and consumer electronics.

Another key goal is to optimize the energy efficiency and sustainability of TPE production. Vacuum-assisted processing can potentially reduce cycle times, lower processing temperatures, and minimize material waste. These improvements not only contribute to cost reduction but also align with the growing emphasis on environmentally friendly manufacturing practices in the polymer industry.

As the TPE market continues to expand, driven by the increasing demand for lightweight, durable, and recyclable materials, the role of vacuum pumps is expected to become increasingly pivotal. The technology aims to enable the development of next-generation TPEs with enhanced performance characteristics, broader application scope, and improved environmental profiles. This technological integration represents a significant step towards meeting the evolving needs of various industries and addressing global sustainability challenges.

Market Analysis for TPE Vacuum Pump Applications

The market for thermoplastic elastomers (TPEs) in vacuum pump applications has been experiencing significant growth in recent years. This expansion is driven by the increasing demand for lightweight, durable, and cost-effective materials in various industries, including automotive, medical, and industrial manufacturing. TPEs offer a unique combination of elastomeric properties and thermoplastic processability, making them ideal for use in vacuum pump components such as seals, gaskets, and diaphragms.

The global TPE market for vacuum pump applications is projected to grow at a steady rate over the next five years. This growth is attributed to the rising adoption of TPEs in place of traditional materials like rubber and metal in vacuum pump systems. The automotive sector, in particular, has been a major contributor to this market expansion, as manufacturers seek to improve fuel efficiency and reduce vehicle weight through the use of advanced materials.

In the medical industry, the demand for TPEs in vacuum pump applications has surged due to the increasing use of portable medical devices and diagnostic equipment. TPEs offer excellent chemical resistance and biocompatibility, making them suitable for use in medical-grade vacuum pumps used in various healthcare settings.

The industrial manufacturing sector has also shown a growing interest in TPE-based vacuum pump components. The ability of TPEs to withstand harsh operating conditions, including exposure to chemicals and high temperatures, has made them a preferred choice for industrial vacuum systems used in processes such as material handling, packaging, and waste management.

Geographically, North America and Europe currently dominate the market for TPE vacuum pump applications, owing to the presence of established automotive and medical device industries in these regions. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization and increasing investments in healthcare infrastructure.

Key market players in the TPE vacuum pump application segment include major polymer manufacturers and specialized TPE producers. These companies are focusing on developing innovative TPE formulations tailored specifically for vacuum pump applications, aiming to enhance performance characteristics such as wear resistance, temperature stability, and chemical compatibility.

The market is also witnessing a trend towards the development of sustainable TPE solutions, in response to growing environmental concerns and stringent regulations. Manufacturers are investing in research and development to create bio-based TPEs and improve the recyclability of their products, which is expected to open up new opportunities in the vacuum pump application market.

The global TPE market for vacuum pump applications is projected to grow at a steady rate over the next five years. This growth is attributed to the rising adoption of TPEs in place of traditional materials like rubber and metal in vacuum pump systems. The automotive sector, in particular, has been a major contributor to this market expansion, as manufacturers seek to improve fuel efficiency and reduce vehicle weight through the use of advanced materials.

In the medical industry, the demand for TPEs in vacuum pump applications has surged due to the increasing use of portable medical devices and diagnostic equipment. TPEs offer excellent chemical resistance and biocompatibility, making them suitable for use in medical-grade vacuum pumps used in various healthcare settings.

The industrial manufacturing sector has also shown a growing interest in TPE-based vacuum pump components. The ability of TPEs to withstand harsh operating conditions, including exposure to chemicals and high temperatures, has made them a preferred choice for industrial vacuum systems used in processes such as material handling, packaging, and waste management.

Geographically, North America and Europe currently dominate the market for TPE vacuum pump applications, owing to the presence of established automotive and medical device industries in these regions. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization and increasing investments in healthcare infrastructure.

Key market players in the TPE vacuum pump application segment include major polymer manufacturers and specialized TPE producers. These companies are focusing on developing innovative TPE formulations tailored specifically for vacuum pump applications, aiming to enhance performance characteristics such as wear resistance, temperature stability, and chemical compatibility.

The market is also witnessing a trend towards the development of sustainable TPE solutions, in response to growing environmental concerns and stringent regulations. Manufacturers are investing in research and development to create bio-based TPEs and improve the recyclability of their products, which is expected to open up new opportunities in the vacuum pump application market.

Current Challenges in TPE Vacuum Pump Technology

The vacuum pump technology in thermoplastic elastomers (TPEs) faces several significant challenges that hinder its widespread adoption and optimal performance. One of the primary issues is the difficulty in achieving consistent and uniform vacuum levels across the entire TPE processing system. This inconsistency can lead to variations in material properties and product quality, which is particularly problematic in industries requiring high precision, such as medical devices and automotive components.

Another major challenge lies in the energy efficiency of vacuum pumps used in TPE processing. Current systems often consume substantial amounts of energy, contributing to increased production costs and environmental concerns. The development of more energy-efficient vacuum pump technologies that maintain or improve performance is a critical area of focus for manufacturers and researchers alike.

The handling of volatile organic compounds (VOCs) released during TPE processing presents another significant challenge. Vacuum pumps must effectively remove these compounds without compromising their own functionality or the quality of the final product. This requires advanced filtration and exhaust systems, which add complexity and cost to the overall production setup.

Maintenance and reliability of vacuum pumps in TPE applications also pose ongoing challenges. The aggressive nature of some TPE materials and the presence of particulates can lead to accelerated wear and tear on pump components. This necessitates frequent maintenance and replacement, resulting in increased downtime and operational costs.

Furthermore, the scalability of vacuum pump systems for different TPE production volumes remains a challenge. Manufacturers struggle to find solutions that are equally efficient and cost-effective for both small-batch specialty products and large-scale production runs. This lack of flexibility can limit the adoption of vacuum pump technology across various segments of the TPE industry.

Lastly, the integration of vacuum pump systems with other TPE processing equipment and Industry 4.0 technologies presents a significant hurdle. There is a growing need for smart, interconnected systems that can provide real-time data on vacuum performance and adjust parameters automatically. However, the development of such integrated systems requires overcoming compatibility issues and investing in advanced control and monitoring technologies.

Another major challenge lies in the energy efficiency of vacuum pumps used in TPE processing. Current systems often consume substantial amounts of energy, contributing to increased production costs and environmental concerns. The development of more energy-efficient vacuum pump technologies that maintain or improve performance is a critical area of focus for manufacturers and researchers alike.

The handling of volatile organic compounds (VOCs) released during TPE processing presents another significant challenge. Vacuum pumps must effectively remove these compounds without compromising their own functionality or the quality of the final product. This requires advanced filtration and exhaust systems, which add complexity and cost to the overall production setup.

Maintenance and reliability of vacuum pumps in TPE applications also pose ongoing challenges. The aggressive nature of some TPE materials and the presence of particulates can lead to accelerated wear and tear on pump components. This necessitates frequent maintenance and replacement, resulting in increased downtime and operational costs.

Furthermore, the scalability of vacuum pump systems for different TPE production volumes remains a challenge. Manufacturers struggle to find solutions that are equally efficient and cost-effective for both small-batch specialty products and large-scale production runs. This lack of flexibility can limit the adoption of vacuum pump technology across various segments of the TPE industry.

Lastly, the integration of vacuum pump systems with other TPE processing equipment and Industry 4.0 technologies presents a significant hurdle. There is a growing need for smart, interconnected systems that can provide real-time data on vacuum performance and adjust parameters automatically. However, the development of such integrated systems requires overcoming compatibility issues and investing in advanced control and monitoring technologies.

Existing TPE Vacuum Pump Solutions

01 Improvements in vacuum pump design

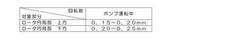

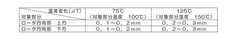

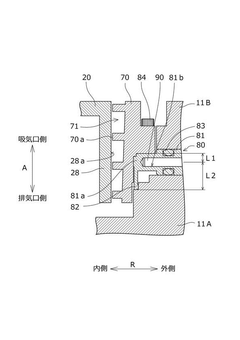

Various advancements in vacuum pump design have been made to enhance efficiency and performance. These improvements include modifications to pump components, optimized fluid flow paths, and innovative sealing mechanisms. Such enhancements contribute to increased pumping speed, better vacuum levels, and improved overall reliability.- Rotary vacuum pump designs: Various designs of rotary vacuum pumps have been developed to improve efficiency and performance. These include innovations in rotor configurations, sealing mechanisms, and chamber designs to enhance suction power and reduce friction. Some designs focus on compact arrangements for specific applications, while others aim to optimize flow dynamics within the pump.

- Vacuum pump control systems: Advanced control systems have been implemented in vacuum pumps to regulate pressure, flow rate, and energy consumption. These systems may incorporate sensors, microprocessors, and variable speed drives to adjust pump operation based on demand. Some designs feature intelligent algorithms for predictive maintenance and optimal performance across different operating conditions.

- Specialized vacuum pumps for semiconductor manufacturing: Vacuum pumps tailored for semiconductor manufacturing processes have been developed to meet the stringent requirements of clean room environments. These pumps often feature corrosion-resistant materials, particle-free operation, and high pumping speeds for specific gases used in semiconductor fabrication. Some designs incorporate multiple stages or hybrid technologies to achieve ultra-high vacuum levels.

- Improvements in vacuum pump sealing and lubrication: Advancements in sealing technologies and lubrication systems have been made to enhance vacuum pump performance and longevity. These improvements include novel seal designs, dry-running capabilities, and specialized lubricants that can withstand high temperatures and vacuum conditions. Some innovations focus on reducing oil contamination in the pumped medium for applications requiring high purity.

- Integration of vacuum pumps in larger systems: Vacuum pumps have been integrated into larger systems and processes to improve overall efficiency and functionality. This includes designs for coupling vacuum pumps with other equipment, such as compressors or turbines, as well as innovations in packaging and mounting for specific industrial applications. Some integrations focus on energy recovery or multi-functional capabilities within a single unit.

02 Specialized vacuum pumps for semiconductor manufacturing

Vacuum pumps tailored for semiconductor manufacturing processes have been developed to meet the stringent requirements of the industry. These pumps are designed to handle corrosive gases, maintain high cleanliness levels, and provide stable vacuum conditions. Features may include corrosion-resistant materials, advanced filtration systems, and precise pressure control mechanisms.Expand Specific Solutions03 Energy-efficient vacuum pump systems

Innovations in vacuum pump technology have focused on improving energy efficiency. These developments include the use of variable speed drives, optimized motor designs, and intelligent control systems. Such advancements result in reduced power consumption, lower operating costs, and improved environmental sustainability.Expand Specific Solutions04 Multi-stage vacuum pump configurations

Multi-stage vacuum pump designs have been created to achieve higher vacuum levels and improved pumping performance. These configurations typically combine different pump types or multiple pumping stages in series. This approach allows for more efficient gas removal across a wide pressure range and can result in faster pump-down times and lower ultimate pressures.Expand Specific Solutions05 Vacuum pump maintenance and monitoring systems

Advanced maintenance and monitoring systems have been developed for vacuum pumps to ensure optimal performance and longevity. These systems may include sensors for real-time condition monitoring, predictive maintenance algorithms, and remote diagnostics capabilities. Such features help prevent unexpected downtime, optimize maintenance schedules, and extend pump lifespan.Expand Specific Solutions

Key Players in TPE and Vacuum Pump Industries

The vacuum pump market for novel thermoplastic elastomers is in a growth phase, driven by increasing demand in semiconductor, display, and advanced materials industries. The market size is expanding, with projections indicating significant growth potential. Technologically, the field is advancing rapidly, with companies like Edwards Ltd., Pfeiffer Vacuum GmbH, and LEYBOLD AG leading innovation in vacuum pump technology. These firms are developing more efficient, compact, and specialized pumps to meet the evolving needs of thermoplastic elastomer processing. Emerging players such as Nantong Pengshu Vacuum Equipment Manufacturing Co., Ltd. are also contributing to market competitiveness, particularly in regional markets.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed advanced vacuum pump technologies specifically tailored for the production of novel thermoplastic elastomers (TPEs). Their innovative approach involves the use of dry screw vacuum pumps with variable speed drives, which allow for precise control of the vacuum levels during the TPE manufacturing process[1]. These pumps are designed to handle the volatile organic compounds (VOCs) often released during TPE production, ensuring a clean and efficient process. Edwards' vacuum systems incorporate intelligent control algorithms that optimize pump performance based on the specific requirements of different TPE formulations, resulting in improved product quality and consistency[3]. The company has also introduced a new line of chemical-resistant vacuum pumps that can withstand the aggressive chemicals sometimes used in TPE synthesis, extending pump life and reducing maintenance costs for manufacturers[5].

Strengths: Highly specialized vacuum solutions for TPE production, advanced control systems for process optimization, and chemical-resistant designs. Weaknesses: Potentially higher initial investment costs compared to generic vacuum systems, and may require specialized training for operators.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil Chemical Patents, Inc. has developed a novel approach to TPE production that heavily relies on advanced vacuum technology. Their patented process utilizes a series of vacuum chambers to precisely control the polymerization and blending stages of TPE manufacturing[2]. The company's vacuum-assisted reactive extrusion technique allows for the creation of TPEs with highly tailored properties, such as improved elasticity and thermal stability[4]. ExxonMobil's system incorporates multi-stage vacuum pumps that can achieve ultra-low pressures, enabling the removal of residual monomers and volatile byproducts, resulting in purer end products with enhanced performance characteristics[6]. The vacuum technology also plays a crucial role in their solvent-free TPE production methods, significantly reducing environmental impact and production costs[8].

Strengths: Innovative vacuum-assisted TPE production techniques, ability to create highly specialized TPE formulations, and environmentally friendly processes. Weaknesses: Complex system that may require significant capital investment and specialized expertise to operate effectively.

Core Innovations in TPE Vacuum Pump Technology

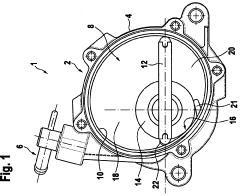

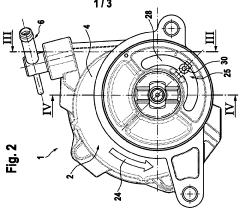

Vacuum pump

PatentWO2010145633A2

Innovation

- Incorporating a plastic layer, specifically an elastomeric plastic material, on metal parts such as valve springs and holders to enhance sealing and damping properties, reducing noise and wear by applying the plastic layer to contact surfaces or inside the metal parts.

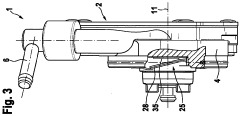

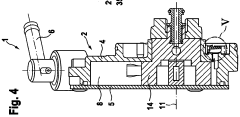

Vacuum pump

PatentWO2017086135A1

Innovation

- A vacuum pump design featuring a heat-insulating spacer and a heating mechanism that maintains the stator at a controlled temperature, with a distance between the rotor and stator set to absorb centrifugal forces and prevent excessive heat transfer, using a cylindrical spacer with a lower expansion coefficient to restrict stator deformation and maintain a stable gas flow path.

Environmental Impact of TPE Vacuum Pump Processes

The environmental impact of TPE vacuum pump processes is a critical consideration in the production of novel thermoplastic elastomers. These processes, while essential for creating high-quality materials, can have significant ecological implications if not managed properly.

Vacuum pumps used in TPE production consume substantial amounts of energy, contributing to the overall carbon footprint of the manufacturing process. The energy intensity varies depending on the specific type of vacuum pump employed, with oil-sealed rotary vane pumps generally being less energy-efficient compared to dry pumps. As the industry moves towards more sustainable practices, there is a growing trend to adopt energy-efficient vacuum pump technologies, such as variable speed drives and heat recovery systems, to reduce power consumption and minimize environmental impact.

Water usage is another environmental concern in TPE vacuum pump processes. Some vacuum pump systems require water for cooling, which can lead to significant water consumption and potential contamination if not properly treated. Closed-loop cooling systems and water recycling technologies are being implemented to address this issue, reducing both water usage and the risk of releasing pollutants into local water systems.

The use of lubricants in certain vacuum pump types poses potential environmental risks. Oil-sealed pumps, while common in TPE production, can lead to oil contamination if not properly maintained. This contamination can result in hazardous waste that requires specialized disposal methods. Dry pump technologies are gaining popularity as they eliminate the need for oil, reducing the risk of contamination and simplifying waste management processes.

Emissions from vacuum pump processes in TPE production are another area of environmental concern. Volatile organic compounds (VOCs) and other potentially harmful gases can be released during the evacuation process. To mitigate this impact, manufacturers are increasingly implementing advanced filtration systems and gas scrubbers to capture and treat emissions before they are released into the atmosphere.

The lifecycle of vacuum pump equipment also factors into the environmental impact assessment. The production, transportation, and eventual disposal of these pumps contribute to their overall ecological footprint. Manufacturers are addressing this by designing pumps with longer lifespans, using recyclable materials, and implementing take-back programs for end-of-life equipment.

As the TPE industry continues to evolve, there is a growing focus on developing more environmentally friendly vacuum pump processes. This includes research into alternative vacuum technologies, such as those based on ionic liquids or advanced membrane systems, which promise reduced energy consumption and minimal environmental impact. Additionally, the integration of smart monitoring systems and predictive maintenance algorithms is helping to optimize pump performance, further reducing unnecessary energy consumption and potential environmental risks.

Vacuum pumps used in TPE production consume substantial amounts of energy, contributing to the overall carbon footprint of the manufacturing process. The energy intensity varies depending on the specific type of vacuum pump employed, with oil-sealed rotary vane pumps generally being less energy-efficient compared to dry pumps. As the industry moves towards more sustainable practices, there is a growing trend to adopt energy-efficient vacuum pump technologies, such as variable speed drives and heat recovery systems, to reduce power consumption and minimize environmental impact.

Water usage is another environmental concern in TPE vacuum pump processes. Some vacuum pump systems require water for cooling, which can lead to significant water consumption and potential contamination if not properly treated. Closed-loop cooling systems and water recycling technologies are being implemented to address this issue, reducing both water usage and the risk of releasing pollutants into local water systems.

The use of lubricants in certain vacuum pump types poses potential environmental risks. Oil-sealed pumps, while common in TPE production, can lead to oil contamination if not properly maintained. This contamination can result in hazardous waste that requires specialized disposal methods. Dry pump technologies are gaining popularity as they eliminate the need for oil, reducing the risk of contamination and simplifying waste management processes.

Emissions from vacuum pump processes in TPE production are another area of environmental concern. Volatile organic compounds (VOCs) and other potentially harmful gases can be released during the evacuation process. To mitigate this impact, manufacturers are increasingly implementing advanced filtration systems and gas scrubbers to capture and treat emissions before they are released into the atmosphere.

The lifecycle of vacuum pump equipment also factors into the environmental impact assessment. The production, transportation, and eventual disposal of these pumps contribute to their overall ecological footprint. Manufacturers are addressing this by designing pumps with longer lifespans, using recyclable materials, and implementing take-back programs for end-of-life equipment.

As the TPE industry continues to evolve, there is a growing focus on developing more environmentally friendly vacuum pump processes. This includes research into alternative vacuum technologies, such as those based on ionic liquids or advanced membrane systems, which promise reduced energy consumption and minimal environmental impact. Additionally, the integration of smart monitoring systems and predictive maintenance algorithms is helping to optimize pump performance, further reducing unnecessary energy consumption and potential environmental risks.

Cost-Benefit Analysis of TPE Vacuum Pump Integration

The integration of vacuum pumps in the production of novel thermoplastic elastomers (TPEs) presents a complex cost-benefit scenario that warrants careful analysis. Initial investment in vacuum pump technology can be substantial, with high-quality industrial pumps ranging from $5,000 to $50,000 depending on capacity and specifications. However, this upfront cost must be weighed against the potential long-term benefits and efficiency gains in TPE manufacturing processes.

One of the primary advantages of incorporating vacuum pumps is the significant improvement in product quality. By removing air bubbles and volatile compounds during the extrusion or molding process, vacuum systems can enhance the mechanical properties and surface finish of TPEs. This quality improvement can lead to reduced scrap rates, potentially saving 5-10% in material costs over time. Additionally, higher-quality products may command premium prices in the market, potentially increasing profit margins by 3-7%.

Energy efficiency is another crucial factor to consider. While vacuum pumps consume electricity, their integration often results in overall energy savings in the production line. By optimizing the curing and cooling processes, manufacturers can reduce cycle times by up to 15-20%, leading to decreased energy consumption per unit produced. Over the course of a year, this could translate to energy cost savings of 8-12% for a medium-sized TPE production facility.

Maintenance costs and operational reliability must also be factored into the analysis. High-quality vacuum pumps typically require less frequent maintenance compared to other production equipment, with service intervals often extending beyond 10,000 operating hours. This reduced downtime can increase overall equipment effectiveness (OEE) by 2-4%, contributing to improved production efficiency and cost savings.

The environmental impact of vacuum pump integration should not be overlooked. By enabling more efficient use of raw materials and energy, these systems can help reduce the carbon footprint of TPE production. This aligns with growing consumer and regulatory demands for sustainable manufacturing practices, potentially opening up new market opportunities and enhancing brand value.

Lastly, the scalability and flexibility offered by vacuum pump systems can provide long-term strategic advantages. As production needs evolve, these systems can often be adapted or upgraded more easily than other core manufacturing equipment, allowing for more agile responses to market demands and technological advancements in TPE formulations.

One of the primary advantages of incorporating vacuum pumps is the significant improvement in product quality. By removing air bubbles and volatile compounds during the extrusion or molding process, vacuum systems can enhance the mechanical properties and surface finish of TPEs. This quality improvement can lead to reduced scrap rates, potentially saving 5-10% in material costs over time. Additionally, higher-quality products may command premium prices in the market, potentially increasing profit margins by 3-7%.

Energy efficiency is another crucial factor to consider. While vacuum pumps consume electricity, their integration often results in overall energy savings in the production line. By optimizing the curing and cooling processes, manufacturers can reduce cycle times by up to 15-20%, leading to decreased energy consumption per unit produced. Over the course of a year, this could translate to energy cost savings of 8-12% for a medium-sized TPE production facility.

Maintenance costs and operational reliability must also be factored into the analysis. High-quality vacuum pumps typically require less frequent maintenance compared to other production equipment, with service intervals often extending beyond 10,000 operating hours. This reduced downtime can increase overall equipment effectiveness (OEE) by 2-4%, contributing to improved production efficiency and cost savings.

The environmental impact of vacuum pump integration should not be overlooked. By enabling more efficient use of raw materials and energy, these systems can help reduce the carbon footprint of TPE production. This aligns with growing consumer and regulatory demands for sustainable manufacturing practices, potentially opening up new market opportunities and enhancing brand value.

Lastly, the scalability and flexibility offered by vacuum pump systems can provide long-term strategic advantages. As production needs evolve, these systems can often be adapted or upgraded more easily than other core manufacturing equipment, allowing for more agile responses to market demands and technological advancements in TPE formulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!