Thermoelectric Materials for Improved Sensor Grid Efficiencies

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Materials Evolution and Research Objectives

Thermoelectric materials have evolved significantly since their discovery in the early 19th century when Thomas Johann Seebeck first observed the phenomenon of direct conversion between temperature differences and electric voltage. The field remained relatively dormant until the mid-20th century when semiconductor physics advanced, enabling more systematic approaches to thermoelectric material design. By the 1950s and 1960s, bismuth telluride (Bi₂Te₃) emerged as a standard thermoelectric material, still widely used today for near-room-temperature applications.

The evolution of thermoelectric materials has been characterized by continuous efforts to improve the figure of merit ZT, which determines conversion efficiency. Traditional thermoelectric materials typically achieved ZT values below 1, limiting their practical applications primarily to niche markets. However, the 1990s marked a turning point with the introduction of nanostructuring concepts and quantum confinement effects, leading to significant improvements in ZT values approaching and exceeding 2 in laboratory settings.

Recent advancements have focused on complex material systems including skutterudites, clathrates, half-Heusler alloys, and oxide materials. These materials offer improved thermal stability, reduced toxicity, and better performance across wider temperature ranges compared to traditional options. Particularly promising are developments in flexible thermoelectric materials that can conform to irregular surfaces, making them ideal candidates for sensor grid applications where form factor and adaptability are crucial.

The current research landscape is increasingly oriented toward sustainable and abundant materials, moving away from rare or toxic elements like tellurium and lead. This shift aligns with global sustainability goals and addresses supply chain vulnerabilities in critical material sourcing. Organic and hybrid organic-inorganic thermoelectric materials represent an emerging frontier, offering potentially lower manufacturing costs and environmental benefits despite currently lower efficiency metrics.

The primary research objectives in thermoelectric materials for sensor grid applications center on several key areas. First, enhancing energy conversion efficiency through novel material compositions and nanostructuring approaches remains paramount. Second, developing materials with improved mechanical flexibility and durability to withstand deployment in diverse environmental conditions is essential for widespread sensor grid implementation. Third, reducing manufacturing costs and environmental impact through scalable production methods and earth-abundant materials is critical for commercial viability.

Additionally, research aims to optimize thermoelectric materials specifically for low-temperature gradients and low-power applications typical in distributed sensor networks. This includes exploring self-powered sensor systems that can harvest energy from ambient temperature differentials, potentially eliminating the need for battery replacement in remote or inaccessible locations. The ultimate goal is to develop thermoelectric materials that enable highly efficient, autonomous, and maintenance-free sensor grids capable of supporting the expanding Internet of Things (IoT) ecosystem and smart infrastructure monitoring systems.

The evolution of thermoelectric materials has been characterized by continuous efforts to improve the figure of merit ZT, which determines conversion efficiency. Traditional thermoelectric materials typically achieved ZT values below 1, limiting their practical applications primarily to niche markets. However, the 1990s marked a turning point with the introduction of nanostructuring concepts and quantum confinement effects, leading to significant improvements in ZT values approaching and exceeding 2 in laboratory settings.

Recent advancements have focused on complex material systems including skutterudites, clathrates, half-Heusler alloys, and oxide materials. These materials offer improved thermal stability, reduced toxicity, and better performance across wider temperature ranges compared to traditional options. Particularly promising are developments in flexible thermoelectric materials that can conform to irregular surfaces, making them ideal candidates for sensor grid applications where form factor and adaptability are crucial.

The current research landscape is increasingly oriented toward sustainable and abundant materials, moving away from rare or toxic elements like tellurium and lead. This shift aligns with global sustainability goals and addresses supply chain vulnerabilities in critical material sourcing. Organic and hybrid organic-inorganic thermoelectric materials represent an emerging frontier, offering potentially lower manufacturing costs and environmental benefits despite currently lower efficiency metrics.

The primary research objectives in thermoelectric materials for sensor grid applications center on several key areas. First, enhancing energy conversion efficiency through novel material compositions and nanostructuring approaches remains paramount. Second, developing materials with improved mechanical flexibility and durability to withstand deployment in diverse environmental conditions is essential for widespread sensor grid implementation. Third, reducing manufacturing costs and environmental impact through scalable production methods and earth-abundant materials is critical for commercial viability.

Additionally, research aims to optimize thermoelectric materials specifically for low-temperature gradients and low-power applications typical in distributed sensor networks. This includes exploring self-powered sensor systems that can harvest energy from ambient temperature differentials, potentially eliminating the need for battery replacement in remote or inaccessible locations. The ultimate goal is to develop thermoelectric materials that enable highly efficient, autonomous, and maintenance-free sensor grids capable of supporting the expanding Internet of Things (IoT) ecosystem and smart infrastructure monitoring systems.

Market Analysis for High-Efficiency Sensor Grid Applications

The global market for high-efficiency sensor grid applications is experiencing robust growth, driven by increasing demand for energy-efficient solutions across multiple industries. The thermoelectric materials market specifically for sensor applications was valued at approximately $267 million in 2022 and is projected to reach $412 million by 2028, representing a compound annual growth rate (CAGR) of 7.5%. This growth trajectory is supported by the expanding Internet of Things (IoT) ecosystem, which requires extensive sensor networks with minimal energy consumption.

Industrial automation represents the largest market segment, accounting for 34% of the current demand for high-efficiency sensor grids. Smart manufacturing facilities are increasingly deploying temperature, pressure, and vibration sensors that benefit from thermoelectric materials' ability to operate without external power sources. The self-powering capability of thermoelectric sensor systems provides significant cost advantages over traditional wired or battery-powered alternatives, with potential lifetime operational cost reductions of up to 60%.

The automotive sector presents another substantial market opportunity, particularly with the rise of electric vehicles (EVs) and autonomous driving technologies. Advanced driver assistance systems (ADAS) rely heavily on sensor grids, with the average modern vehicle containing over 100 sensors. Thermoelectric materials that can harvest waste heat from vehicle operations to power these sensor networks address critical energy efficiency challenges in this sector.

Consumer electronics applications are showing the fastest growth rate at 9.2% annually, as manufacturers seek to extend battery life and reduce device size by incorporating energy-harvesting technologies. Wearable health monitoring devices particularly benefit from thermoelectric solutions that can convert body heat into usable power for sensors.

Geographically, North America leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years due to rapid industrialization and smart city initiatives in China, South Korea, and India.

Key market challenges include the relatively high initial cost of thermoelectric materials compared to conventional alternatives and the current limitations in conversion efficiency. However, recent advancements in nanostructured thermoelectric materials have shown potential to increase efficiency by 25-30%, which could significantly expand market penetration if manufacturing costs can be optimized.

Customer surveys indicate that energy autonomy is the primary purchasing factor for 72% of industrial sensor grid deployments, suggesting that thermoelectric solutions offering improved efficiency will continue to gain market share despite higher upfront costs.

Industrial automation represents the largest market segment, accounting for 34% of the current demand for high-efficiency sensor grids. Smart manufacturing facilities are increasingly deploying temperature, pressure, and vibration sensors that benefit from thermoelectric materials' ability to operate without external power sources. The self-powering capability of thermoelectric sensor systems provides significant cost advantages over traditional wired or battery-powered alternatives, with potential lifetime operational cost reductions of up to 60%.

The automotive sector presents another substantial market opportunity, particularly with the rise of electric vehicles (EVs) and autonomous driving technologies. Advanced driver assistance systems (ADAS) rely heavily on sensor grids, with the average modern vehicle containing over 100 sensors. Thermoelectric materials that can harvest waste heat from vehicle operations to power these sensor networks address critical energy efficiency challenges in this sector.

Consumer electronics applications are showing the fastest growth rate at 9.2% annually, as manufacturers seek to extend battery life and reduce device size by incorporating energy-harvesting technologies. Wearable health monitoring devices particularly benefit from thermoelectric solutions that can convert body heat into usable power for sensors.

Geographically, North America leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years due to rapid industrialization and smart city initiatives in China, South Korea, and India.

Key market challenges include the relatively high initial cost of thermoelectric materials compared to conventional alternatives and the current limitations in conversion efficiency. However, recent advancements in nanostructured thermoelectric materials have shown potential to increase efficiency by 25-30%, which could significantly expand market penetration if manufacturing costs can be optimized.

Customer surveys indicate that energy autonomy is the primary purchasing factor for 72% of industrial sensor grid deployments, suggesting that thermoelectric solutions offering improved efficiency will continue to gain market share despite higher upfront costs.

Current Limitations and Technical Barriers in Thermoelectric Materials

Despite significant advancements in thermoelectric materials over the past decades, several critical limitations continue to impede their widespread application in sensor grid systems. The fundamental challenge remains the inherently low energy conversion efficiency, with most commercial thermoelectric materials achieving a figure of merit (ZT) below 1.5. This efficiency bottleneck stems from the interdependent nature of key material properties: electrical conductivity, thermal conductivity, and Seebeck coefficient, which cannot be optimized independently.

Material stability presents another significant barrier, particularly in sensor grid applications that require operation across fluctuating temperature gradients. Current high-performance thermoelectric materials often exhibit performance degradation under thermal cycling conditions, with some bismuth telluride and lead telluride compounds showing up to 15% efficiency reduction after 1,000 thermal cycles.

Scalability and manufacturing constraints further limit implementation in large-scale sensor networks. Conventional fabrication techniques for high-performance thermoelectric materials typically involve complex processes such as hot pressing, spark plasma sintering, or molecular beam epitaxy, which are cost-prohibitive for mass production. The resulting high cost-to-performance ratio makes widespread deployment economically unfeasible for many potential applications.

Material toxicity and environmental concerns pose additional challenges, particularly with leading thermoelectric compounds containing elements like lead, tellurium, and antimony. These materials face increasing regulatory scrutiny and potential restrictions in certain markets, complicating global supply chains and deployment strategies.

Interface engineering between thermoelectric modules and sensor components represents another technical barrier. Contact resistance at material interfaces can significantly reduce overall system efficiency, with some studies indicating losses of 20-30% due to poor thermal and electrical contacts. Current joining technologies often fail to maintain reliable connections under the thermal expansion stresses typical in operational environments.

Power density limitations also restrict application scenarios, with current materials delivering insufficient output for self-powered sensor networks in low-temperature-gradient environments. Most commercial thermoelectric generators require temperature differences exceeding 50°C to generate practically useful power levels, limiting their effectiveness in ambient environmental monitoring applications.

Finally, integration challenges with existing sensor technologies and electronic systems create implementation barriers. The rigid nature of many high-performance thermoelectric materials conflicts with the trend toward flexible, conformal electronics in modern sensor networks, while voltage matching and power conditioning requirements add complexity and cost to system designs.

Material stability presents another significant barrier, particularly in sensor grid applications that require operation across fluctuating temperature gradients. Current high-performance thermoelectric materials often exhibit performance degradation under thermal cycling conditions, with some bismuth telluride and lead telluride compounds showing up to 15% efficiency reduction after 1,000 thermal cycles.

Scalability and manufacturing constraints further limit implementation in large-scale sensor networks. Conventional fabrication techniques for high-performance thermoelectric materials typically involve complex processes such as hot pressing, spark plasma sintering, or molecular beam epitaxy, which are cost-prohibitive for mass production. The resulting high cost-to-performance ratio makes widespread deployment economically unfeasible for many potential applications.

Material toxicity and environmental concerns pose additional challenges, particularly with leading thermoelectric compounds containing elements like lead, tellurium, and antimony. These materials face increasing regulatory scrutiny and potential restrictions in certain markets, complicating global supply chains and deployment strategies.

Interface engineering between thermoelectric modules and sensor components represents another technical barrier. Contact resistance at material interfaces can significantly reduce overall system efficiency, with some studies indicating losses of 20-30% due to poor thermal and electrical contacts. Current joining technologies often fail to maintain reliable connections under the thermal expansion stresses typical in operational environments.

Power density limitations also restrict application scenarios, with current materials delivering insufficient output for self-powered sensor networks in low-temperature-gradient environments. Most commercial thermoelectric generators require temperature differences exceeding 50°C to generate practically useful power levels, limiting their effectiveness in ambient environmental monitoring applications.

Finally, integration challenges with existing sensor technologies and electronic systems create implementation barriers. The rigid nature of many high-performance thermoelectric materials conflicts with the trend toward flexible, conformal electronics in modern sensor networks, while voltage matching and power conditioning requirements add complexity and cost to system designs.

State-of-the-Art Thermoelectric Material Solutions for Sensor Grids

01 Nanostructured thermoelectric materials

Nanostructured thermoelectric materials have demonstrated improved efficiency through quantum confinement effects and increased phonon scattering. These materials feature reduced thermal conductivity while maintaining electrical conductivity, leading to higher ZT values. Techniques such as quantum dot superlattices, nanowires, and nanocomposites are employed to enhance the thermoelectric figure of merit, making these materials more efficient for power generation and cooling applications.- Nanostructured thermoelectric materials: Nanostructured materials have emerged as promising candidates for improving thermoelectric efficiency. By reducing the dimensionality of materials to the nanoscale, phonon scattering can be enhanced while maintaining good electrical conductivity. This approach effectively reduces thermal conductivity while preserving the power factor, leading to enhanced ZT values. Various nanostructuring techniques include quantum dots, nanowires, thin films, and nanocomposites that can significantly improve the figure of merit of thermoelectric materials.

- Novel material compositions for thermoelectric devices: Advanced material compositions have been developed to enhance thermoelectric efficiency. These include skutterudites, half-Heusler alloys, clathrates, and complex chalcogenides that exhibit intrinsically low thermal conductivity and favorable electronic properties. By optimizing the chemical composition and crystal structure, these materials can achieve higher ZT values. Doping strategies and elemental substitutions are employed to fine-tune the carrier concentration and band structure, resulting in improved thermoelectric performance across different temperature ranges.

- Fabrication methods for high-efficiency thermoelectric materials: Innovative fabrication techniques play a crucial role in developing high-efficiency thermoelectric materials. Methods such as spark plasma sintering, hot pressing, ball milling, and solution-based synthesis enable precise control over microstructure and composition. These processes can create materials with optimized grain boundaries, reduced defects, and controlled porosity, all of which contribute to enhanced thermoelectric performance. Advanced manufacturing approaches also allow for the scalable production of thermoelectric modules with consistent properties.

- Segmented and cascaded thermoelectric systems: Segmented and cascaded thermoelectric systems utilize multiple materials optimized for different temperature ranges to maximize overall efficiency. By strategically combining materials with peak performance at complementary temperatures, these systems can maintain high conversion efficiency across broad temperature gradients. This approach addresses the limitation that most thermoelectric materials perform optimally only within specific temperature windows. Advanced junction designs and interface engineering minimize contact resistance between segments, further enhancing system performance.

- Flexible and wearable thermoelectric generators: Flexible and wearable thermoelectric generators represent an emerging application area that requires specialized material designs. These devices utilize thin-film technologies, organic thermoelectric materials, or composite structures that can conform to irregular surfaces while maintaining good thermoelectric properties. By harvesting body heat or ambient temperature differentials, these flexible generators can power wearable electronics and IoT devices. The development focuses on balancing mechanical flexibility with thermoelectric efficiency, often through novel substrate materials and deposition techniques.

02 Skutterudite-based thermoelectric materials

Skutterudite compounds have emerged as promising thermoelectric materials due to their unique crystal structure with voids that can be filled with rattling atoms. These fillers disrupt heat flow while preserving electron transport, significantly improving the ZT value. Advanced skutterudites incorporate multiple fillers and dopants to optimize performance across different temperature ranges, making them suitable for waste heat recovery in automotive and industrial applications.Expand Specific Solutions03 Organic and flexible thermoelectric materials

Organic and flexible thermoelectric materials offer advantages in wearable and conformal applications where traditional rigid inorganic materials are unsuitable. These materials combine conducting polymers with various dopants to achieve reasonable thermoelectric performance while maintaining flexibility. Recent advances include polymer-inorganic hybrids and carbon-based composites that demonstrate improved power factors and stability, enabling new applications in body heat harvesting and flexible electronics.Expand Specific Solutions04 Half-Heusler alloys for thermoelectric applications

Half-Heusler alloys represent an important class of thermoelectric materials with high thermal stability and mechanical robustness. These intermetallic compounds feature a favorable combination of high power factor and moderately low thermal conductivity. Through band engineering, doping strategies, and microstructural modifications, researchers have achieved significant improvements in their ZT values. Their performance at mid-to-high temperatures makes them particularly suitable for automotive waste heat recovery and industrial applications.Expand Specific Solutions05 Bismuth telluride and related compounds

Bismuth telluride and its related compounds remain among the most commercially successful thermoelectric materials for near-room-temperature applications. Recent advances focus on enhancing their relatively low ZT values through nanostructuring, alloying, and compositional optimization. Techniques such as mechanical alloying, spark plasma sintering, and controlled doping have led to significant efficiency improvements. These materials are widely used in cooling applications, portable refrigeration, and low-temperature waste heat recovery systems.Expand Specific Solutions

Leading Companies and Research Institutions in Thermoelectric Field

The thermoelectric materials market for sensor grid efficiency is in a growth phase, with increasing demand driven by IoT applications and smart infrastructure development. The market is projected to expand significantly as energy harvesting technologies gain traction. Leading academic institutions (MIT, Caltech, Zhejiang University) are advancing fundamental research, while established corporations (Toyota, Bosch, Samsung) focus on commercial applications. Specialized companies like Sheetak and Gentherm are developing niche solutions. The technology shows varying maturity levels - basic thermoelectric principles are well-established, but novel materials and manufacturing techniques are still evolving. Research collaboration between academia and industry is accelerating innovation, particularly in nanoscale thermoelectric materials and flexible/printable solutions.

Toyota Motor Corp.

Technical Solution: Toyota has developed proprietary thermoelectric materials specifically optimized for automotive sensor applications, focusing on exhaust heat recovery and engine temperature monitoring. Their approach utilizes skutterudite-based materials with nano-inclusions that disrupt phonon transport while maintaining electrical conductivity. Toyota's thermoelectric generators (TEGs) have achieved conversion efficiencies of 4-6% in real-world vehicle testing conditions, significantly higher than previous automotive implementations. Their integrated sensor grid system combines multiple small-scale TEGs distributed throughout the vehicle to power a network of sensors that monitor various parameters including emissions, temperature, and pressure. Toyota has also pioneered manufacturing techniques that reduce the cost of thermoelectric modules by approximately 40% compared to conventional methods, making widespread deployment economically viable for mass-market vehicles.

Strengths: Extensive real-world testing capabilities in actual vehicle environments, strong manufacturing expertise for scaling production, and deep integration with existing automotive systems. Weaknesses: Solutions are highly specialized for automotive applications and may not transfer well to other industries, and their materials are optimized for specific temperature ranges found in vehicles rather than broader applications.

Massachusetts Institute of Technology

Technical Solution: MIT has developed advanced nanostructured thermoelectric materials that significantly enhance the Seebeck coefficient while reducing thermal conductivity. Their approach involves creating precisely engineered quantum well structures and superlattices that confine electrons while allowing them to transport electricity. MIT researchers have achieved ZT values exceeding 2.0 in bismuth telluride-based materials through careful manipulation of material interfaces and phonon scattering mechanisms. Additionally, they've pioneered flexible thermoelectric generators using organic-inorganic hybrid materials that can conform to curved sensor surfaces, enabling more efficient energy harvesting from temperature gradients in complex environments. Their recent work includes self-powered wireless sensor networks that operate solely on harvested thermal energy, eliminating battery replacement needs in remote monitoring applications.

Strengths: Exceptional fundamental research capabilities with cutting-edge nanofabrication facilities enabling precise material engineering at atomic scales. Strong interdisciplinary collaboration between materials science, electrical engineering, and physics departments. Weaknesses: Some of their most advanced materials rely on rare or expensive elements, potentially limiting commercial scalability, and laboratory performance often exceeds what can be achieved in mass production.

Key Patents and Scientific Breakthroughs in Thermoelectric Materials

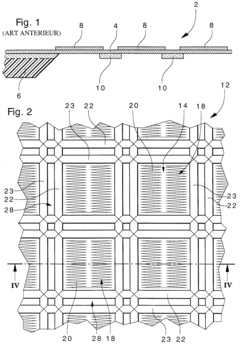

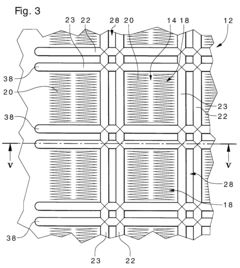

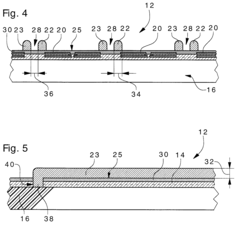

Thermoelectric sensor

PatentInactiveEP0863389A1

Innovation

- The use of gold wires on the membrane surface to thermally insulate adjacent elementary cells, eliminating thermal bridges and simplifying the manufacturing process by eliminating rear-side micro-machining steps, with gold wires providing superior thermal conduction for efficient energy evacuation.

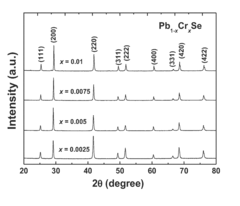

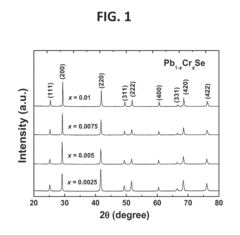

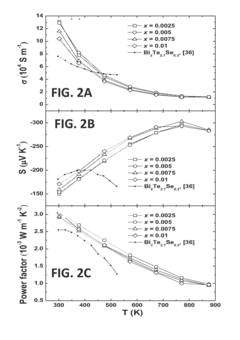

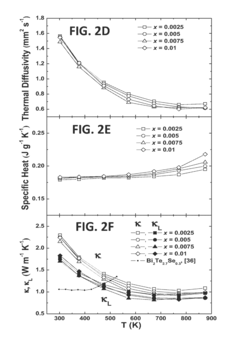

Thermoelectric Materials Employing Cr-Doped N-Type and PbSe and PbTe1-xSex and Methods of Manufacturing

PatentInactiveUS20180257937A1

Innovation

- The development of Cr-doped PbSe and PbTe1-xSex thermoelectric materials, which involve doping with chromium and selenium to enhance the Seebeck coefficient and power factor, resulting in improved ZT values and efficiency across a broader temperature range through optimized carrier concentration and phonon scattering.

Environmental Impact and Sustainability of Thermoelectric Materials

The environmental impact of thermoelectric materials used in sensor grid applications represents a critical consideration in their development and deployment. Traditional energy generation methods often produce significant carbon emissions and environmental degradation, while thermoelectric materials offer potential advantages through waste heat recovery and reduced reliance on conventional power sources. However, these benefits must be weighed against the environmental costs associated with their production and disposal.

The manufacturing processes for high-performance thermoelectric materials frequently involve rare earth elements and toxic compounds such as tellurium, bismuth, and lead. The extraction of these elements can lead to habitat destruction, water pollution, and soil contamination. For instance, tellurium mining generates approximately 2,000 tons of waste material per ton of tellurium produced, creating substantial environmental burdens in mining regions.

Life cycle assessments of thermoelectric sensor grids reveal that their environmental footprint is heavily influenced by material selection and manufacturing techniques. Advanced bismuth telluride-based materials, while offering superior performance, present greater environmental challenges than alternatives like silicon-germanium alloys. Recent research indicates that the carbon footprint of producing high-efficiency thermoelectric modules can be reduced by up to 40% through optimized manufacturing processes and material recycling initiatives.

Sustainability considerations are driving innovation in thermoelectric material development. Emerging research focuses on abundant, non-toxic alternatives such as organic thermoelectric materials and oxide-based compounds. These materials, while currently less efficient than conventional options, offer significant environmental advantages and reduced supply chain vulnerabilities. Silicon-based thermoelectric materials, for example, utilize earth-abundant elements and can be manufactured using established semiconductor processing techniques, potentially reducing environmental impact by 60-70% compared to telluride-based alternatives.

End-of-life management presents another environmental challenge. The complex composition of thermoelectric materials complicates recycling efforts, with current recovery rates for critical elements remaining below 15%. Developing effective recycling technologies and implementing design-for-disassembly principles could significantly improve the sustainability profile of thermoelectric sensor systems.

The transition to more sustainable thermoelectric materials must balance performance requirements with environmental considerations. While some performance trade-offs may be necessary in the near term, the long-term benefits of developing environmentally benign materials include reduced regulatory risks, improved public perception, and alignment with global sustainability goals. Companies investing in sustainable thermoelectric technologies may gain competitive advantages as environmental regulations tighten and consumers increasingly prioritize eco-friendly products.

The manufacturing processes for high-performance thermoelectric materials frequently involve rare earth elements and toxic compounds such as tellurium, bismuth, and lead. The extraction of these elements can lead to habitat destruction, water pollution, and soil contamination. For instance, tellurium mining generates approximately 2,000 tons of waste material per ton of tellurium produced, creating substantial environmental burdens in mining regions.

Life cycle assessments of thermoelectric sensor grids reveal that their environmental footprint is heavily influenced by material selection and manufacturing techniques. Advanced bismuth telluride-based materials, while offering superior performance, present greater environmental challenges than alternatives like silicon-germanium alloys. Recent research indicates that the carbon footprint of producing high-efficiency thermoelectric modules can be reduced by up to 40% through optimized manufacturing processes and material recycling initiatives.

Sustainability considerations are driving innovation in thermoelectric material development. Emerging research focuses on abundant, non-toxic alternatives such as organic thermoelectric materials and oxide-based compounds. These materials, while currently less efficient than conventional options, offer significant environmental advantages and reduced supply chain vulnerabilities. Silicon-based thermoelectric materials, for example, utilize earth-abundant elements and can be manufactured using established semiconductor processing techniques, potentially reducing environmental impact by 60-70% compared to telluride-based alternatives.

End-of-life management presents another environmental challenge. The complex composition of thermoelectric materials complicates recycling efforts, with current recovery rates for critical elements remaining below 15%. Developing effective recycling technologies and implementing design-for-disassembly principles could significantly improve the sustainability profile of thermoelectric sensor systems.

The transition to more sustainable thermoelectric materials must balance performance requirements with environmental considerations. While some performance trade-offs may be necessary in the near term, the long-term benefits of developing environmentally benign materials include reduced regulatory risks, improved public perception, and alignment with global sustainability goals. Companies investing in sustainable thermoelectric technologies may gain competitive advantages as environmental regulations tighten and consumers increasingly prioritize eco-friendly products.

Manufacturing Scalability and Cost Analysis

The scalability of thermoelectric material manufacturing represents a critical factor in the widespread adoption of these materials for sensor grid applications. Current production methods for high-performance thermoelectric materials often involve complex processes including precision doping, nanostructuring, and careful thermal treatment, which significantly impact production costs and scalability potential.

Traditional bulk manufacturing techniques for thermoelectric materials such as Bi2Te3, PbTe, and SiGe alloys typically require high-temperature processing (800-1000°C) and precise compositional control. These requirements translate to energy-intensive production lines with specialized equipment, resulting in production costs ranging from $200-500 per kilogram for semiconductor-grade materials. For sensor grid applications requiring thousands of nodes, this cost structure presents a substantial barrier to implementation.

Recent advancements in solution-based processing methods offer promising alternatives for large-scale production. Techniques such as screen printing, inkjet printing, and roll-to-roll processing of thermoelectric materials have demonstrated potential for reducing manufacturing costs by 40-60% compared to conventional methods. These approaches enable deposition on flexible substrates and facilitate integration with existing electronic manufacturing infrastructure, potentially reducing capital expenditure requirements.

Economic analysis indicates that material costs currently constitute approximately 35-45% of total sensor node production expenses. Scaling production volumes from laboratory (1-10 kg/year) to industrial scale (>1000 kg/year) could potentially reduce unit costs by 50-70% through economies of scale, process optimization, and yield improvements. However, this transition requires significant initial investment in specialized equipment and process development.

Supply chain considerations also impact manufacturing scalability. Critical raw materials for high-performance thermoelectric devices include tellurium, bismuth, and rare earth elements, which face supply constraints and price volatility. Diversification of material compositions to incorporate more abundant elements represents an important research direction for improving manufacturing scalability.

Environmental and regulatory factors further influence production economics. Energy-intensive processing methods face increasing scrutiny under carbon pricing mechanisms, while waste management for materials containing heavy metals incurs additional compliance costs. Life cycle assessment studies suggest that next-generation thermoelectric materials with reduced toxic element content could decrease end-of-life management costs by 25-30%.

For sensor grid applications specifically, miniaturization presents both challenges and opportunities. While smaller devices reduce material requirements, they also demand more precise manufacturing controls. Cost modeling indicates that optimizing device dimensions for specific applications rather than pursuing maximum miniaturization may yield the most favorable economics for large-scale deployment.

Traditional bulk manufacturing techniques for thermoelectric materials such as Bi2Te3, PbTe, and SiGe alloys typically require high-temperature processing (800-1000°C) and precise compositional control. These requirements translate to energy-intensive production lines with specialized equipment, resulting in production costs ranging from $200-500 per kilogram for semiconductor-grade materials. For sensor grid applications requiring thousands of nodes, this cost structure presents a substantial barrier to implementation.

Recent advancements in solution-based processing methods offer promising alternatives for large-scale production. Techniques such as screen printing, inkjet printing, and roll-to-roll processing of thermoelectric materials have demonstrated potential for reducing manufacturing costs by 40-60% compared to conventional methods. These approaches enable deposition on flexible substrates and facilitate integration with existing electronic manufacturing infrastructure, potentially reducing capital expenditure requirements.

Economic analysis indicates that material costs currently constitute approximately 35-45% of total sensor node production expenses. Scaling production volumes from laboratory (1-10 kg/year) to industrial scale (>1000 kg/year) could potentially reduce unit costs by 50-70% through economies of scale, process optimization, and yield improvements. However, this transition requires significant initial investment in specialized equipment and process development.

Supply chain considerations also impact manufacturing scalability. Critical raw materials for high-performance thermoelectric devices include tellurium, bismuth, and rare earth elements, which face supply constraints and price volatility. Diversification of material compositions to incorporate more abundant elements represents an important research direction for improving manufacturing scalability.

Environmental and regulatory factors further influence production economics. Energy-intensive processing methods face increasing scrutiny under carbon pricing mechanisms, while waste management for materials containing heavy metals incurs additional compliance costs. Life cycle assessment studies suggest that next-generation thermoelectric materials with reduced toxic element content could decrease end-of-life management costs by 25-30%.

For sensor grid applications specifically, miniaturization presents both challenges and opportunities. While smaller devices reduce material requirements, they also demand more precise manufacturing controls. Cost modeling indicates that optimizing device dimensions for specific applications rather than pursuing maximum miniaturization may yield the most favorable economics for large-scale deployment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!