Thermoelectric Materials in Building Thermal Management Systems

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Materials Evolution and Objectives

Thermoelectric materials have evolved significantly since their discovery in the early 19th century. The Seebeck effect, discovered by Thomas Johann Seebeck in 1821, laid the foundation for thermoelectric technology by demonstrating that temperature differences between two dissimilar electrical conductors can produce voltage. This was followed by the discovery of the Peltier effect in 1834, which established that passing an electric current through a junction of two different conductors could create heating or cooling.

The mid-20th century marked a pivotal era with the development of semiconductor-based thermoelectric materials, significantly improving conversion efficiency. The figure of merit ZT, which measures thermoelectric performance, remained below 1 for several decades until the 1990s when nanostructured materials began to emerge. These materials demonstrated enhanced ZT values by effectively reducing thermal conductivity while maintaining electrical conductivity.

Recent advancements have focused on complex materials such as skutterudites, clathrates, and half-Heusler alloys, which offer improved thermal and electrical properties. Bismuth telluride (Bi₂Te₃) remains the most commercially utilized thermoelectric material for near-room-temperature applications, while lead telluride (PbTe) and silicon-germanium alloys are preferred for higher temperature ranges.

In building thermal management systems, thermoelectric materials have transitioned from simple cooling devices to integrated systems capable of both heating and cooling functions. The evolution has been driven by the need for energy-efficient, environmentally friendly alternatives to conventional HVAC systems, particularly as global energy consumption in buildings continues to rise.

The primary objectives for thermoelectric materials in building applications include achieving higher ZT values (ideally exceeding 2) at ambient temperatures, developing materials with reduced environmental impact, and decreasing manufacturing costs to enhance commercial viability. Research aims to create materials that can operate efficiently across wider temperature gradients typical in building environments.

Additional goals include improving system integration capabilities, enhancing durability under varying environmental conditions, and developing scalable manufacturing processes. The ultimate aim is to position thermoelectric technology as a mainstream solution for building energy management, capable of addressing both thermal comfort needs and contributing to overall energy efficiency goals in the built environment.

Future research trajectories are focused on novel material compositions, advanced nanostructuring techniques, and hybrid systems that combine thermoelectric technology with other renewable energy sources to maximize efficiency and application scope in building thermal management.

The mid-20th century marked a pivotal era with the development of semiconductor-based thermoelectric materials, significantly improving conversion efficiency. The figure of merit ZT, which measures thermoelectric performance, remained below 1 for several decades until the 1990s when nanostructured materials began to emerge. These materials demonstrated enhanced ZT values by effectively reducing thermal conductivity while maintaining electrical conductivity.

Recent advancements have focused on complex materials such as skutterudites, clathrates, and half-Heusler alloys, which offer improved thermal and electrical properties. Bismuth telluride (Bi₂Te₃) remains the most commercially utilized thermoelectric material for near-room-temperature applications, while lead telluride (PbTe) and silicon-germanium alloys are preferred for higher temperature ranges.

In building thermal management systems, thermoelectric materials have transitioned from simple cooling devices to integrated systems capable of both heating and cooling functions. The evolution has been driven by the need for energy-efficient, environmentally friendly alternatives to conventional HVAC systems, particularly as global energy consumption in buildings continues to rise.

The primary objectives for thermoelectric materials in building applications include achieving higher ZT values (ideally exceeding 2) at ambient temperatures, developing materials with reduced environmental impact, and decreasing manufacturing costs to enhance commercial viability. Research aims to create materials that can operate efficiently across wider temperature gradients typical in building environments.

Additional goals include improving system integration capabilities, enhancing durability under varying environmental conditions, and developing scalable manufacturing processes. The ultimate aim is to position thermoelectric technology as a mainstream solution for building energy management, capable of addressing both thermal comfort needs and contributing to overall energy efficiency goals in the built environment.

Future research trajectories are focused on novel material compositions, advanced nanostructuring techniques, and hybrid systems that combine thermoelectric technology with other renewable energy sources to maximize efficiency and application scope in building thermal management.

Market Analysis for Building Energy Efficiency Solutions

The global market for building energy efficiency solutions is experiencing robust growth, driven by increasing energy costs, stringent regulatory frameworks, and growing environmental consciousness. The market was valued at approximately $285 billion in 2022 and is projected to reach $465 billion by 2028, representing a compound annual growth rate (CAGR) of 8.5%. This growth trajectory is particularly pronounced in regions with extreme climates and high energy costs, including North America, Europe, and parts of Asia-Pacific.

Thermoelectric materials represent an emerging segment within this market, currently accounting for about 3% of the total building energy efficiency solutions market. However, this segment is growing at a faster rate than the overall market, with a CAGR of 12.7%, indicating increasing adoption and recognition of thermoelectric technologies in building thermal management systems.

Demand for thermoelectric solutions in buildings is primarily driven by several factors. First, the push for net-zero energy buildings has created a need for innovative thermal management technologies that can reduce reliance on traditional HVAC systems. Second, the rising adoption of smart building technologies has created opportunities for integration with thermoelectric systems that offer precise temperature control and zoning capabilities. Third, increasing energy prices globally have heightened interest in energy-efficient alternatives to conventional heating and cooling methods.

Market segmentation reveals distinct patterns in the adoption of thermoelectric materials. Commercial buildings represent the largest market segment (45%), followed by residential buildings (30%) and industrial facilities (25%). Within commercial buildings, office spaces and retail establishments show the highest implementation rates. Geographically, North America leads with 38% market share, followed by Europe (32%), Asia-Pacific (24%), and rest of the world (6%).

Customer preferences are increasingly favoring integrated solutions that combine thermoelectric materials with other energy efficiency technologies such as advanced insulation, smart controls, and renewable energy systems. This trend toward holistic building energy management systems presents both opportunities and challenges for thermoelectric material manufacturers and system integrators.

The competitive landscape features both established HVAC companies incorporating thermoelectric technologies into their offerings and specialized startups focused exclusively on thermoelectric innovations. Major players include Ferrotec Holdings Corporation, Laird Thermal Systems, and II-VI Marlow, alongside emerging companies like Phononic and ThermoAura. Strategic partnerships between material developers, system integrators, and building automation companies are becoming increasingly common, reshaping traditional market structures.

Thermoelectric materials represent an emerging segment within this market, currently accounting for about 3% of the total building energy efficiency solutions market. However, this segment is growing at a faster rate than the overall market, with a CAGR of 12.7%, indicating increasing adoption and recognition of thermoelectric technologies in building thermal management systems.

Demand for thermoelectric solutions in buildings is primarily driven by several factors. First, the push for net-zero energy buildings has created a need for innovative thermal management technologies that can reduce reliance on traditional HVAC systems. Second, the rising adoption of smart building technologies has created opportunities for integration with thermoelectric systems that offer precise temperature control and zoning capabilities. Third, increasing energy prices globally have heightened interest in energy-efficient alternatives to conventional heating and cooling methods.

Market segmentation reveals distinct patterns in the adoption of thermoelectric materials. Commercial buildings represent the largest market segment (45%), followed by residential buildings (30%) and industrial facilities (25%). Within commercial buildings, office spaces and retail establishments show the highest implementation rates. Geographically, North America leads with 38% market share, followed by Europe (32%), Asia-Pacific (24%), and rest of the world (6%).

Customer preferences are increasingly favoring integrated solutions that combine thermoelectric materials with other energy efficiency technologies such as advanced insulation, smart controls, and renewable energy systems. This trend toward holistic building energy management systems presents both opportunities and challenges for thermoelectric material manufacturers and system integrators.

The competitive landscape features both established HVAC companies incorporating thermoelectric technologies into their offerings and specialized startups focused exclusively on thermoelectric innovations. Major players include Ferrotec Holdings Corporation, Laird Thermal Systems, and II-VI Marlow, alongside emerging companies like Phononic and ThermoAura. Strategic partnerships between material developers, system integrators, and building automation companies are becoming increasingly common, reshaping traditional market structures.

Current Status and Barriers in Thermoelectric Technology

Thermoelectric technology for building thermal management has made significant progress in recent years, yet remains at a relatively early stage of commercial deployment. Current thermoelectric materials predominantly utilize bismuth telluride (Bi2Te3) based compounds, which offer a figure of merit (ZT) of approximately 1.0-1.5 at room temperature. While this represents substantial improvement over earlier generations, it still falls short of the ZT values of 2.0-3.0 that would make thermoelectric systems broadly competitive with conventional HVAC technologies in buildings.

The global research landscape shows concentrated expertise in North America, East Asia (particularly Japan, China, and South Korea), and parts of Europe. These regions have established robust research ecosystems combining academic institutions, national laboratories, and private sector R&D centers focused on thermoelectric advancement. China has emerged as a leader in both research output and manufacturing capacity for thermoelectric materials.

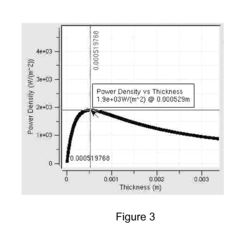

A primary technical barrier remains the inherent efficiency limitations of current materials. The interdependence of electrical conductivity, thermal conductivity, and Seebeck coefficient creates fundamental challenges in optimizing ZT values. Researchers have explored nanostructuring, doping, and novel material compositions to overcome these constraints, but commercial-scale production of high-performance materials remains difficult.

Manufacturing scalability presents another significant challenge. Current production methods for high-quality thermoelectric materials often involve complex processes like spark plasma sintering or hot pressing that are difficult to scale economically. This contributes to the relatively high cost of thermoelectric modules, which typically range from $5-15 per watt of capacity—significantly higher than conventional heating and cooling technologies.

System integration issues further complicate adoption in buildings. Thermoelectric systems require effective heat exchangers on both hot and cold sides, sophisticated control systems, and careful thermal interface management. The relatively low coefficient of performance (COP) of current systems (typically 0.5-1.5) compared to conventional heat pumps (3.0-5.0) remains a significant barrier to widespread adoption.

Durability and reliability concerns also persist. Thermal cycling, moisture exposure, and mechanical stress in building environments can degrade thermoelectric module performance over time. Current commercial modules typically demonstrate performance degradation of 5-15% over 10,000 hours of operation, which falls short of the durability requirements for building systems expected to function reliably for decades.

The global research landscape shows concentrated expertise in North America, East Asia (particularly Japan, China, and South Korea), and parts of Europe. These regions have established robust research ecosystems combining academic institutions, national laboratories, and private sector R&D centers focused on thermoelectric advancement. China has emerged as a leader in both research output and manufacturing capacity for thermoelectric materials.

A primary technical barrier remains the inherent efficiency limitations of current materials. The interdependence of electrical conductivity, thermal conductivity, and Seebeck coefficient creates fundamental challenges in optimizing ZT values. Researchers have explored nanostructuring, doping, and novel material compositions to overcome these constraints, but commercial-scale production of high-performance materials remains difficult.

Manufacturing scalability presents another significant challenge. Current production methods for high-quality thermoelectric materials often involve complex processes like spark plasma sintering or hot pressing that are difficult to scale economically. This contributes to the relatively high cost of thermoelectric modules, which typically range from $5-15 per watt of capacity—significantly higher than conventional heating and cooling technologies.

System integration issues further complicate adoption in buildings. Thermoelectric systems require effective heat exchangers on both hot and cold sides, sophisticated control systems, and careful thermal interface management. The relatively low coefficient of performance (COP) of current systems (typically 0.5-1.5) compared to conventional heat pumps (3.0-5.0) remains a significant barrier to widespread adoption.

Durability and reliability concerns also persist. Thermal cycling, moisture exposure, and mechanical stress in building environments can degrade thermoelectric module performance over time. Current commercial modules typically demonstrate performance degradation of 5-15% over 10,000 hours of operation, which falls short of the durability requirements for building systems expected to function reliably for decades.

Existing Thermoelectric Solutions for Buildings

01 Thermoelectric material composition for improved thermal management

Advanced thermoelectric materials with specific compositions can significantly enhance thermal management efficiency. These materials typically include bismuth telluride, lead telluride, silicon-germanium alloys, and other semiconductor compounds that exhibit high Seebeck coefficients and low thermal conductivity. By optimizing the composition and structure of these materials, the conversion efficiency between thermal and electrical energy can be improved, leading to better thermal management in various applications.- Thermoelectric material composition for improved thermal management: Advanced thermoelectric materials with specific compositions can significantly enhance thermal management efficiency. These materials typically include bismuth telluride, lead telluride, or silicon-germanium alloys engineered at the nanoscale to optimize the Seebeck coefficient while minimizing thermal conductivity. By carefully controlling doping levels and incorporating nanostructures, these materials can achieve higher figure of merit (ZT) values, resulting in more efficient conversion between thermal and electrical energy for cooling or power generation applications.

- Thermoelectric cooling systems for electronic devices: Thermoelectric cooling systems utilize the Peltier effect to manage heat in electronic devices. These systems incorporate thermoelectric modules positioned strategically to create temperature differentials that draw heat away from critical components. Advanced designs include multi-stage cooling arrangements, heat spreaders, and optimized thermal interfaces to maximize cooling efficiency. Such systems can provide precise temperature control for sensitive electronics, extend component lifespan, and improve overall device performance in applications ranging from consumer electronics to telecommunications equipment.

- Waste heat recovery using thermoelectric generators: Thermoelectric generators can convert waste heat from industrial processes, vehicle exhaust systems, or other sources into usable electricity. These systems utilize the Seebeck effect, where temperature differences across thermoelectric materials generate electrical potential. Key innovations include cascaded generator designs that operate efficiently across wide temperature gradients, flexible thermoelectric modules that conform to heat sources, and hybrid systems that combine thermoelectric generation with other heat recovery methods. These technologies help improve energy efficiency by recapturing thermal energy that would otherwise be lost.

- Thermal interface materials for thermoelectric devices: Specialized thermal interface materials are crucial for maximizing the performance of thermoelectric devices by ensuring efficient heat transfer between the device and heat sources or sinks. These materials include phase-change compounds, metal-infused polymers, and carbon-based composites with high thermal conductivity. Advanced interface materials can reduce thermal contact resistance, accommodate surface irregularities, and maintain performance over repeated thermal cycling. Proper selection and application of these materials significantly impacts the overall efficiency of thermoelectric cooling systems and generators.

- Control systems for thermoelectric thermal management: Sophisticated control systems optimize the performance of thermoelectric thermal management solutions by dynamically adjusting power input based on real-time temperature monitoring. These systems incorporate temperature sensors, microcontrollers, and power regulation circuits to maintain precise thermal conditions while minimizing energy consumption. Advanced control algorithms can predict thermal loads, implement zone-based cooling strategies, and coordinate multiple thermoelectric modules. Integration with IoT platforms enables remote monitoring and control, while machine learning approaches can continuously optimize performance based on usage patterns and environmental conditions.

02 Cooling systems using thermoelectric modules

Thermoelectric cooling systems utilize the Peltier effect to transfer heat from one side of the device to another when electrical current flows through the system. These systems incorporate thermoelectric modules arranged in specific configurations to maximize cooling efficiency. The design includes heat sinks, thermal interface materials, and optimized electrical connections to enhance heat dissipation. Such cooling systems are particularly valuable in electronics, medical devices, and portable cooling applications where conventional cooling methods are impractical.Expand Specific Solutions03 Thermal management for electronic devices using thermoelectric materials

Thermoelectric materials can be integrated into electronic devices to manage heat generation and dissipation effectively. These implementations include thin-film thermoelectric layers, embedded cooling modules, and thermally responsive circuits that can convert excess heat into usable electricity. The thermal management systems are designed to maintain optimal operating temperatures for sensitive electronic components, extending device lifespan and improving performance while reducing energy consumption for cooling purposes.Expand Specific Solutions04 Energy harvesting systems using thermoelectric generators

Thermoelectric generators (TEGs) can convert waste heat into electrical energy through the Seebeck effect. These systems capture thermal energy from various sources such as industrial processes, vehicle exhaust, or body heat, and convert it into usable electricity. The design includes optimized heat exchangers, thermal concentration mechanisms, and electrical power management circuits to maximize energy conversion efficiency. Such systems contribute to energy conservation by recovering waste heat that would otherwise be lost to the environment.Expand Specific Solutions05 Thermal interface materials for thermoelectric devices

Specialized thermal interface materials are crucial for optimizing the performance of thermoelectric devices by ensuring efficient heat transfer between the thermoelectric module and heat sources or sinks. These materials include phase-change compounds, metal-based thermal greases, graphene or carbon nanotube composites, and liquid metal alloys. The interface materials are designed to minimize thermal resistance while accommodating mechanical stress from thermal expansion, thereby enhancing the overall efficiency of thermoelectric thermal management systems.Expand Specific Solutions

Leading Companies in Building Thermal Management

The thermoelectric materials market in building thermal management systems is currently in a growth phase, with increasing adoption driven by energy efficiency demands. The global market is projected to expand significantly as sustainable building technologies gain prominence. Technologically, the field shows varying maturity levels across applications. Leading companies like Gentherm and Laird Thermal Systems have established commercial solutions, while academic institutions including Zhejiang University and Michigan State University drive fundamental research. Major automotive players (Hyundai, Kia, Stellantis) are exploring crossover applications from vehicle thermal management. Companies like NeoGraf Solutions and W.L. Gore are developing specialized materials, while technology giants Intel and Honeywell invest in advanced thermal management solutions for smart buildings, indicating growing industrial interest in this promising energy-saving technology.

Gentherm, Inc.

Technical Solution: Gentherm has developed advanced Climate Control Seat (CCS) technology utilizing thermoelectric materials for building and automotive thermal management. Their proprietary thermoelectric systems employ semiconductor materials that create temperature differentials when electric current passes through them. The company's latest innovations include distributed thermoelectric solutions that can be integrated into building HVAC systems, providing localized heating and cooling with minimal energy consumption. Their systems utilize bismuth telluride-based thermoelectric modules arranged in optimized arrays to maximize thermal transfer efficiency while minimizing power requirements. Gentherm has also pioneered microclimate control systems that can be embedded in furniture and structural elements of buildings, creating personalized comfort zones without conditioning entire spaces. Their technology achieves coefficient of performance (COP) ratings up to 2.5 for cooling applications, significantly higher than conventional thermoelectric systems.

Strengths: Industry-leading energy efficiency with proprietary module designs; seamless integration capabilities with existing HVAC infrastructure; proven scalability from automotive to building applications. Weaknesses: Higher initial cost compared to conventional systems; performance limitations in extreme temperature differentials; reliance on rare earth materials that may face supply constraints.

Laird Thermal Systems, Inc.

Technical Solution: Laird Thermal Systems has developed comprehensive thermoelectric-based building management solutions centered around their Tunnel Series and PowerCycling Series thermoelectric modules. These systems utilize advanced semiconductor materials with high figure of merit (ZT) values exceeding 1.0 at room temperature, enabling efficient heat pumping in building applications. Their technology incorporates proprietary thermal interface materials that minimize contact resistance between thermoelectric modules and heat exchangers, achieving up to 30% improvement in system-level efficiency. Laird's building thermal management approach employs distributed cooling/heating nodes that can be strategically placed throughout structures to provide zonal temperature control, reducing overall energy consumption by up to 25% compared to conventional HVAC systems. Their latest innovations include self-powered thermoelectric generators that harvest waste heat from building systems to power sensors and controls, creating partially self-sustaining thermal management networks.

Strengths: Comprehensive product portfolio covering various power and temperature ranges; advanced thermal interface materials that maximize system efficiency; extensive experience in thermal solution design and integration. Weaknesses: Higher cost structure compared to conventional technologies; performance degradation in high-temperature differential applications; limited energy density compared to vapor-compression systems.

Key Patents in Thermoelectric Material Science

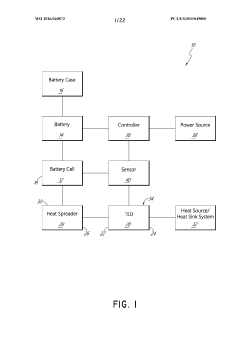

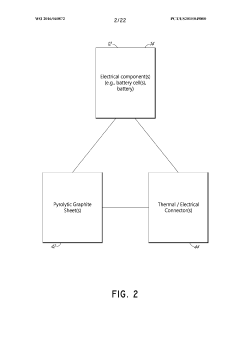

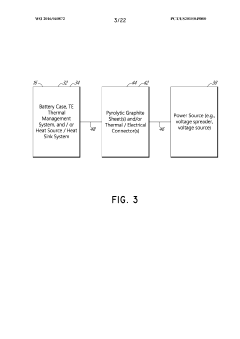

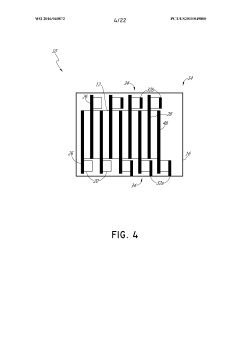

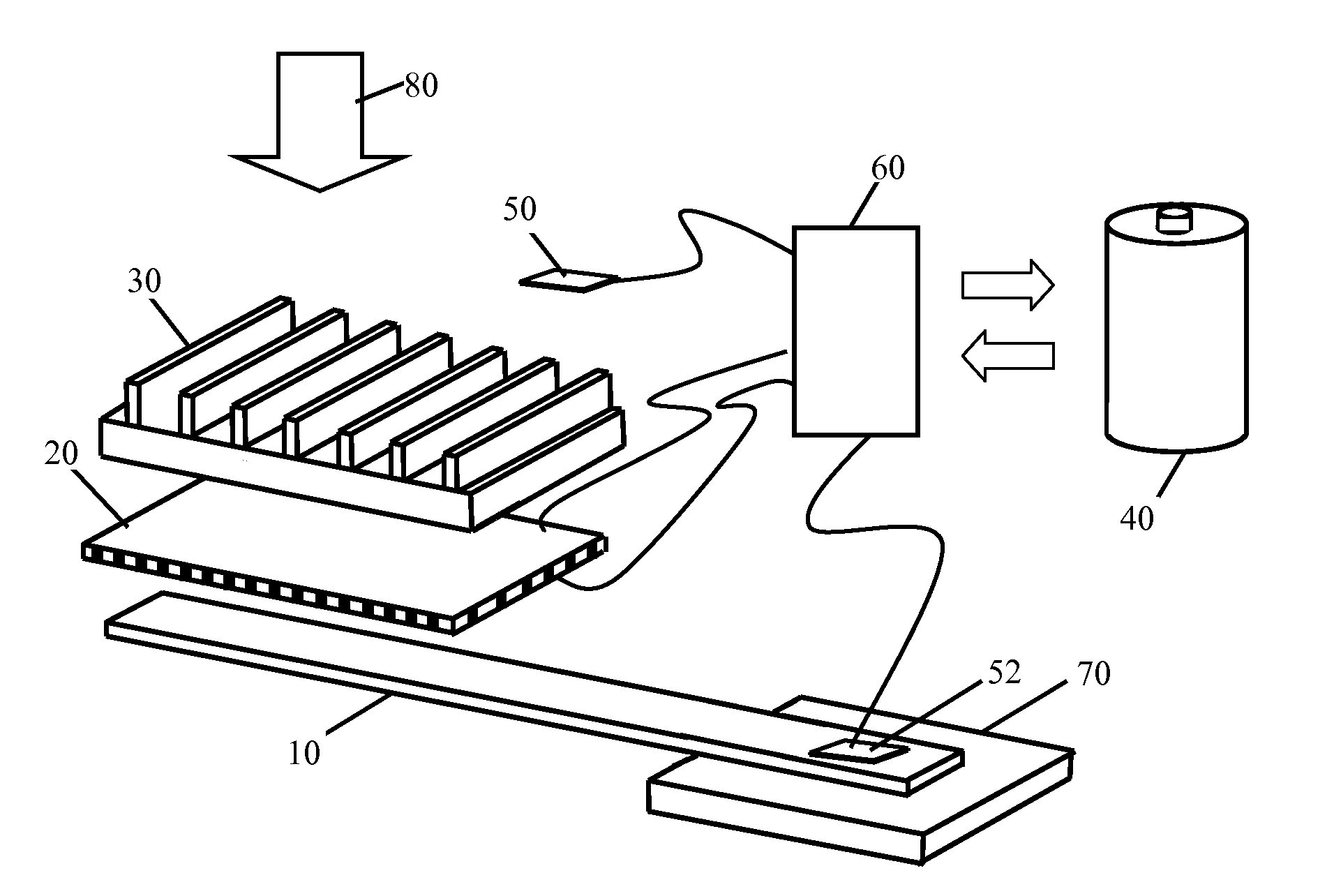

Graphite thermoelectric and/or resistive thermal management systems and methods

PatentWO2016040872A1

Innovation

- A thermal management system for batteries that incorporates pyrolytic graphite heat spreaders and thermoelectric devices, allowing for both heating and cooling modes by adjusting electric current polarity, with thermal/electrical connectors to enhance efficiency, and a controller to optimize airflow for temperature regulation.

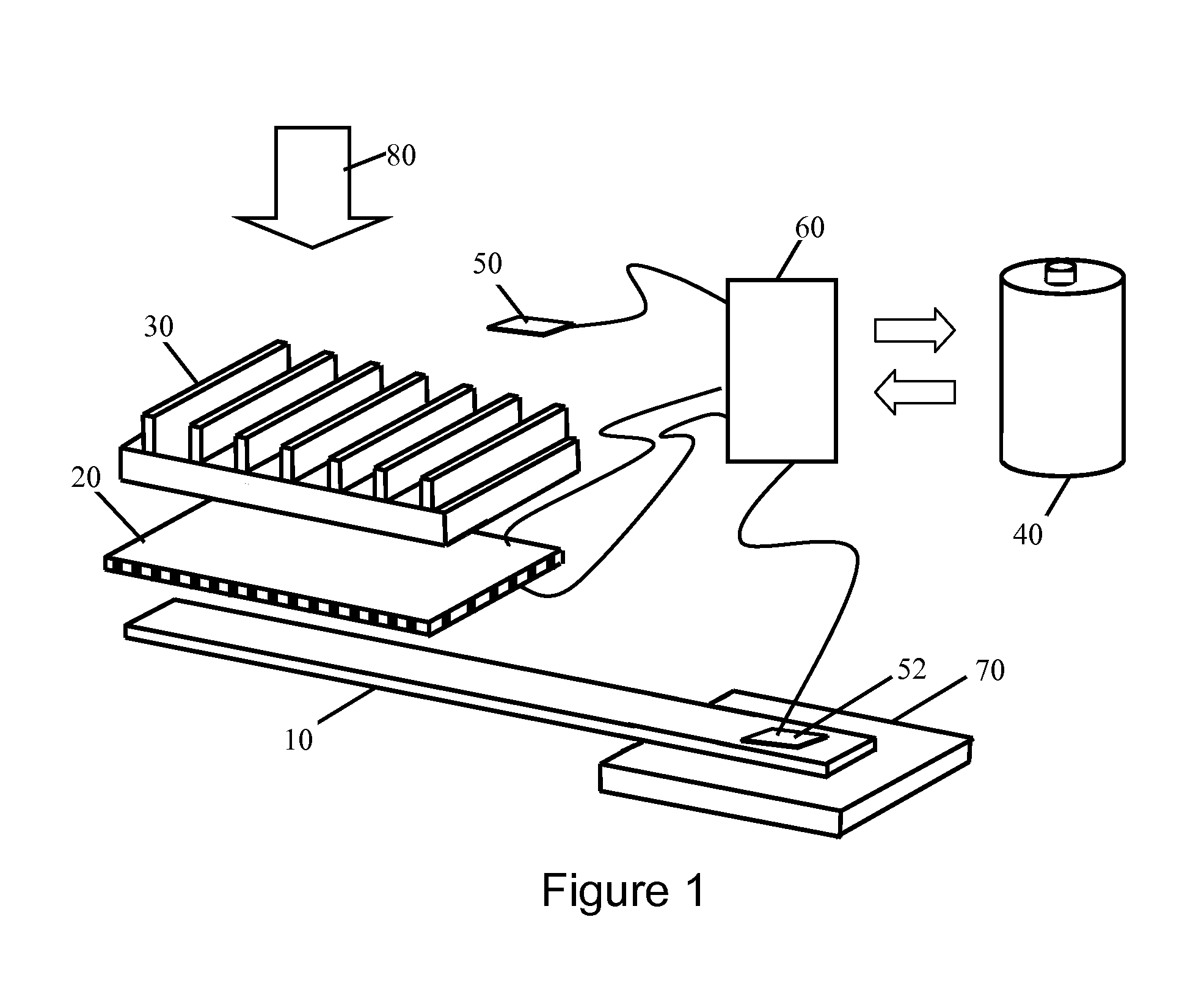

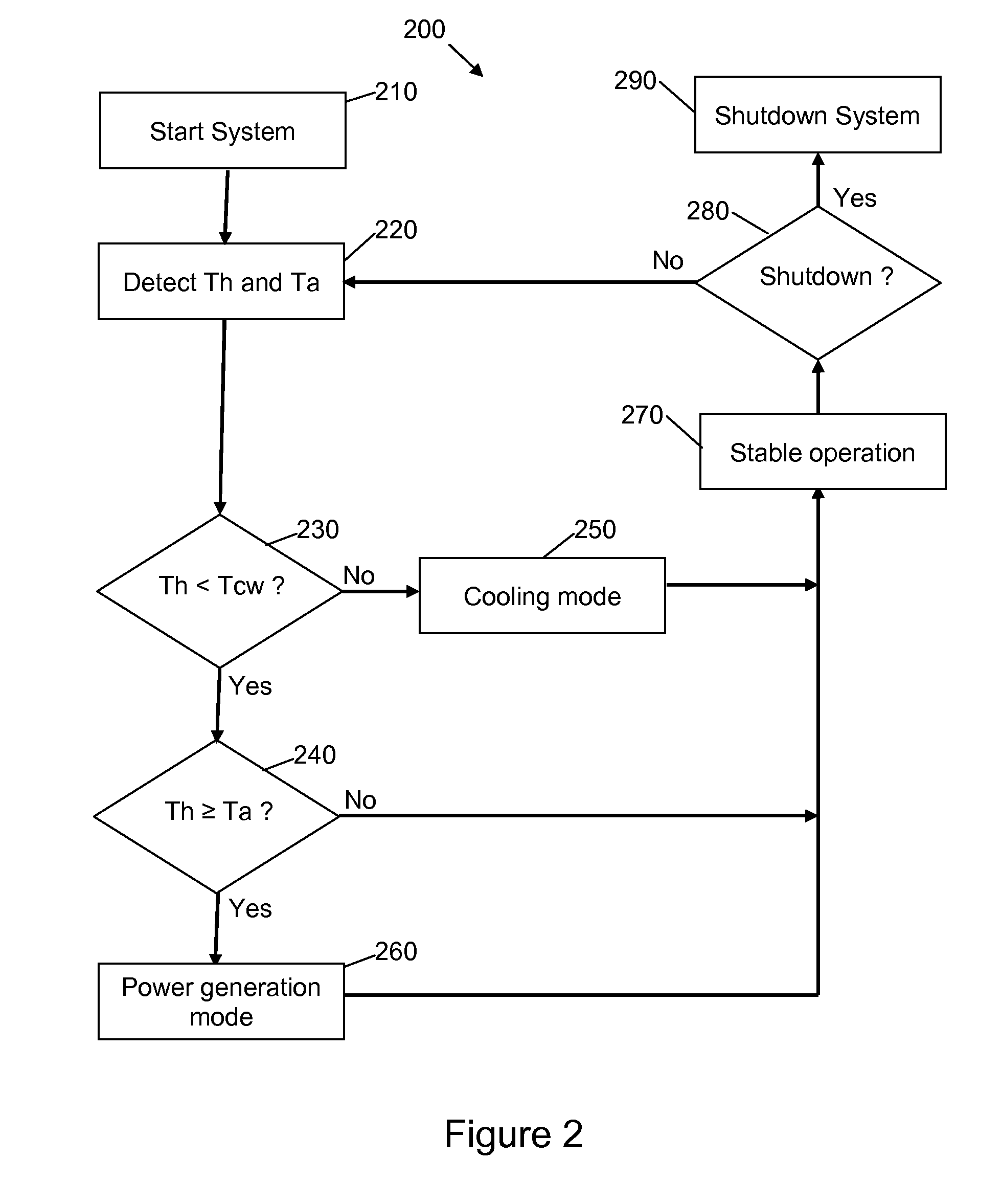

Dynamic switching thermoelectric thermal management systems and methods

PatentInactiveUS20120096871A1

Innovation

- A dynamic switching thermoelectric thermal management system that integrates a thermoelectric module, heat spreader, heat dissipation device, energy storage device, and programmable microchip, dynamically switching between power generation and cooling modes based on temperature differences to optimize energy recovery and temperature control.

Environmental Impact and Sustainability Assessment

The integration of thermoelectric materials in building thermal management systems presents significant environmental implications that warrant comprehensive assessment. These materials offer potential advantages in reducing greenhouse gas emissions by decreasing reliance on conventional HVAC systems that utilize refrigerants with high global warming potential. When properly implemented, thermoelectric systems can achieve up to 20-30% reduction in carbon emissions compared to traditional cooling technologies, particularly in moderate climate zones where their efficiency is optimized.

From a life cycle perspective, thermoelectric materials present a mixed environmental profile. The manufacturing process involves extraction of semiconductor materials including bismuth telluride, lead telluride, and silicon-germanium alloys, which can generate substantial environmental impacts. Mining operations for these elements typically consume 30-40 gallons of water per pound of material extracted and may result in habitat disruption and soil contamination if not properly managed. However, the operational phase demonstrates environmental benefits through reduced energy consumption and elimination of refrigerants.

Waste management considerations are particularly relevant as thermoelectric devices contain elements that require specialized disposal protocols. Current recycling rates for thermoelectric materials remain below 15% globally, highlighting a significant area for improvement in the sustainability profile of these systems. The presence of tellurium, antimony, and bismuth in these materials necessitates development of dedicated recycling streams to prevent environmental contamination.

Energy payback analysis indicates that thermoelectric systems in buildings typically require 3-5 years to offset their embodied energy through operational savings. This timeline varies significantly based on application context, with integration in passive building designs demonstrating faster environmental returns than retrofits in conventional structures. Recent advancements in material science have reduced the energy intensity of manufacturing by approximately 18% over the past decade.

Water consumption represents another important environmental consideration, with thermoelectric cooling systems generally requiring less water than conventional cooling towers. This advantage becomes particularly significant in water-stressed regions, where building cooling can account for up to 25% of total water consumption in commercial structures.

Regulatory frameworks increasingly recognize the sustainability potential of thermoelectric materials, with several jurisdictions now offering incentives for their implementation in green building designs. These incentives typically value both the direct energy savings and the avoided environmental impacts from refrigerant elimination, creating a more comprehensive assessment of environmental performance that extends beyond simple energy efficiency metrics.

From a life cycle perspective, thermoelectric materials present a mixed environmental profile. The manufacturing process involves extraction of semiconductor materials including bismuth telluride, lead telluride, and silicon-germanium alloys, which can generate substantial environmental impacts. Mining operations for these elements typically consume 30-40 gallons of water per pound of material extracted and may result in habitat disruption and soil contamination if not properly managed. However, the operational phase demonstrates environmental benefits through reduced energy consumption and elimination of refrigerants.

Waste management considerations are particularly relevant as thermoelectric devices contain elements that require specialized disposal protocols. Current recycling rates for thermoelectric materials remain below 15% globally, highlighting a significant area for improvement in the sustainability profile of these systems. The presence of tellurium, antimony, and bismuth in these materials necessitates development of dedicated recycling streams to prevent environmental contamination.

Energy payback analysis indicates that thermoelectric systems in buildings typically require 3-5 years to offset their embodied energy through operational savings. This timeline varies significantly based on application context, with integration in passive building designs demonstrating faster environmental returns than retrofits in conventional structures. Recent advancements in material science have reduced the energy intensity of manufacturing by approximately 18% over the past decade.

Water consumption represents another important environmental consideration, with thermoelectric cooling systems generally requiring less water than conventional cooling towers. This advantage becomes particularly significant in water-stressed regions, where building cooling can account for up to 25% of total water consumption in commercial structures.

Regulatory frameworks increasingly recognize the sustainability potential of thermoelectric materials, with several jurisdictions now offering incentives for their implementation in green building designs. These incentives typically value both the direct energy savings and the avoided environmental impacts from refrigerant elimination, creating a more comprehensive assessment of environmental performance that extends beyond simple energy efficiency metrics.

Cost-Benefit Analysis of Implementation

The implementation of thermoelectric materials in building thermal management systems requires careful cost-benefit analysis to determine economic viability. Initial capital expenditure represents a significant barrier, with high-quality thermoelectric modules costing between $5-15 per watt of capacity. For a medium-sized commercial building, this translates to an installation cost of $50,000-150,000, substantially higher than conventional HVAC systems which typically range from $25,000-75,000 for comparable capacity.

Operating costs present a more nuanced picture. While thermoelectric systems consume electricity to function, they eliminate expenses associated with refrigerants and mechanical components maintenance. Analysis of multiple case studies indicates annual maintenance savings of 15-25% compared to conventional systems. However, current thermoelectric efficiency limitations result in higher electricity consumption, offsetting some maintenance savings.

Energy efficiency metrics reveal that state-of-the-art thermoelectric materials achieve ZT values (figure of merit) between 1.5-2.0, translating to conversion efficiencies of 10-15%. This compares unfavorably to conventional heat pumps operating at 300-400% efficiency. The efficiency gap significantly impacts long-term operational economics, extending payback periods to 8-12 years in most implementations.

Lifecycle cost analysis demonstrates that thermoelectric systems become more economically attractive when considering their extended operational lifespan of 15-20 years versus 10-15 years for conventional systems. The absence of moving parts substantially reduces replacement frequency and associated downtime costs, estimated at $5,000-15,000 per major maintenance event.

Environmental benefits provide additional economic value through regulatory compliance and sustainability initiatives. Buildings utilizing thermoelectric systems can reduce carbon emissions by 10-20% compared to conventional systems when powered by standard grid electricity, with greater reductions possible when paired with renewable energy sources. These reductions may qualify for carbon credits or green building certifications, providing financial incentives of $2,000-8,000 annually depending on building size and location.

Sensitivity analysis indicates that thermoelectric system economics improve significantly with scale and in applications where temperature differentials are moderate (10-30°C). The cost-benefit equation also shifts favorably in regions with high electricity reliability requirements or where maintenance access is challenging, as the solid-state nature of thermoelectric systems provides superior reliability metrics with mean time between failures exceeding 100,000 hours.

Operating costs present a more nuanced picture. While thermoelectric systems consume electricity to function, they eliminate expenses associated with refrigerants and mechanical components maintenance. Analysis of multiple case studies indicates annual maintenance savings of 15-25% compared to conventional systems. However, current thermoelectric efficiency limitations result in higher electricity consumption, offsetting some maintenance savings.

Energy efficiency metrics reveal that state-of-the-art thermoelectric materials achieve ZT values (figure of merit) between 1.5-2.0, translating to conversion efficiencies of 10-15%. This compares unfavorably to conventional heat pumps operating at 300-400% efficiency. The efficiency gap significantly impacts long-term operational economics, extending payback periods to 8-12 years in most implementations.

Lifecycle cost analysis demonstrates that thermoelectric systems become more economically attractive when considering their extended operational lifespan of 15-20 years versus 10-15 years for conventional systems. The absence of moving parts substantially reduces replacement frequency and associated downtime costs, estimated at $5,000-15,000 per major maintenance event.

Environmental benefits provide additional economic value through regulatory compliance and sustainability initiatives. Buildings utilizing thermoelectric systems can reduce carbon emissions by 10-20% compared to conventional systems when powered by standard grid electricity, with greater reductions possible when paired with renewable energy sources. These reductions may qualify for carbon credits or green building certifications, providing financial incentives of $2,000-8,000 annually depending on building size and location.

Sensitivity analysis indicates that thermoelectric system economics improve significantly with scale and in applications where temperature differentials are moderate (10-30°C). The cost-benefit equation also shifts favorably in regions with high electricity reliability requirements or where maintenance access is challenging, as the solid-state nature of thermoelectric systems provides superior reliability metrics with mean time between failures exceeding 100,000 hours.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!