Thermoelectric Materials: Measuring Thermal Conductivity Precisely

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Materials Background and Research Objectives

Thermoelectric materials have emerged as a promising solution for direct conversion between thermal and electrical energy, with applications spanning waste heat recovery, solid-state refrigeration, and power generation in remote locations. The history of thermoelectric materials dates back to the early 19th century with the discovery of the Seebeck effect in 1821, followed by the Peltier effect in 1834. However, significant advancements in this field only gained momentum in the mid-20th century with the development of semiconductor-based thermoelectric materials.

The evolution of thermoelectric technology has been characterized by three distinct generations. First-generation materials, primarily based on bismuth telluride (Bi₂Te₃) and lead telluride (PbTe), established the foundation for commercial applications but were limited by relatively low efficiency. Second-generation materials introduced nanostructuring techniques to enhance performance through quantum confinement effects. The current third generation explores complex crystal structures and novel material systems including skutterudites, clathrates, and half-Heusler compounds.

A critical parameter determining thermoelectric efficiency is the figure of merit ZT, defined as ZT = S²σT/κ, where S is the Seebeck coefficient, σ is electrical conductivity, T is absolute temperature, and κ is thermal conductivity. Achieving high ZT values requires materials with high electrical conductivity but low thermal conductivity—properties that are typically coupled and difficult to optimize independently. This inherent contradiction represents one of the fundamental challenges in thermoelectric material development.

Precise measurement of thermal conductivity has become increasingly crucial as researchers pursue the "phonon glass, electron crystal" paradigm—materials that conduct electricity like crystals but heat like glasses. Traditional measurement techniques often introduce significant uncertainties, particularly for thin films and nanostructured materials where interface effects dominate. These measurement challenges have hindered accurate material characterization and slowed optimization efforts.

The primary research objectives in this field include developing standardized, high-precision methods for thermal conductivity measurement across different material geometries and temperature ranges. Specifically, researchers aim to achieve measurement accuracy within ±5% for bulk materials and ±10% for thin films and nanostructured systems. Additionally, there is a pressing need for in-situ measurement capabilities that can characterize materials under actual operating conditions.

Recent technological trends indicate growing interest in machine learning approaches to predict thermal properties and accelerate material discovery. Concurrently, advances in microscopy and spectroscopy techniques are enabling unprecedented insights into phonon transport mechanisms at nanoscale dimensions. These developments, coupled with increasing environmental concerns and energy efficiency mandates, have positioned thermoelectric materials research at the intersection of fundamental physics, materials science, and sustainable energy technology.

The evolution of thermoelectric technology has been characterized by three distinct generations. First-generation materials, primarily based on bismuth telluride (Bi₂Te₃) and lead telluride (PbTe), established the foundation for commercial applications but were limited by relatively low efficiency. Second-generation materials introduced nanostructuring techniques to enhance performance through quantum confinement effects. The current third generation explores complex crystal structures and novel material systems including skutterudites, clathrates, and half-Heusler compounds.

A critical parameter determining thermoelectric efficiency is the figure of merit ZT, defined as ZT = S²σT/κ, where S is the Seebeck coefficient, σ is electrical conductivity, T is absolute temperature, and κ is thermal conductivity. Achieving high ZT values requires materials with high electrical conductivity but low thermal conductivity—properties that are typically coupled and difficult to optimize independently. This inherent contradiction represents one of the fundamental challenges in thermoelectric material development.

Precise measurement of thermal conductivity has become increasingly crucial as researchers pursue the "phonon glass, electron crystal" paradigm—materials that conduct electricity like crystals but heat like glasses. Traditional measurement techniques often introduce significant uncertainties, particularly for thin films and nanostructured materials where interface effects dominate. These measurement challenges have hindered accurate material characterization and slowed optimization efforts.

The primary research objectives in this field include developing standardized, high-precision methods for thermal conductivity measurement across different material geometries and temperature ranges. Specifically, researchers aim to achieve measurement accuracy within ±5% for bulk materials and ±10% for thin films and nanostructured systems. Additionally, there is a pressing need for in-situ measurement capabilities that can characterize materials under actual operating conditions.

Recent technological trends indicate growing interest in machine learning approaches to predict thermal properties and accelerate material discovery. Concurrently, advances in microscopy and spectroscopy techniques are enabling unprecedented insights into phonon transport mechanisms at nanoscale dimensions. These developments, coupled with increasing environmental concerns and energy efficiency mandates, have positioned thermoelectric materials research at the intersection of fundamental physics, materials science, and sustainable energy technology.

Market Analysis for Thermoelectric Applications

The thermoelectric materials market has experienced significant growth in recent years, driven by increasing demand for energy-efficient technologies and waste heat recovery systems. The global thermoelectric market was valued at approximately 593 million USD in 2020 and is projected to reach 1,450 million USD by 2027, growing at a CAGR of 13.6% during the forecast period. This growth trajectory underscores the expanding commercial interest in thermoelectric applications across various industries.

Automotive and industrial sectors represent the largest market segments for thermoelectric applications, collectively accounting for over 60% of the total market share. In automotive applications, thermoelectric generators (TEGs) are increasingly being integrated into vehicle exhaust systems to convert waste heat into usable electricity, improving fuel efficiency by up to 5%. Major automotive manufacturers including BMW, Ford, and Toyota have active research programs exploring advanced thermoelectric solutions.

Consumer electronics constitutes another rapidly growing segment, with thermoelectric cooling solutions being employed in portable refrigeration, temperature-controlled seats, and specialized electronic components. This segment is expected to grow at a CAGR of 15.2% through 2027, outpacing the overall market growth rate.

Geographically, North America and Asia-Pacific dominate the thermoelectric materials market, together representing approximately 70% of global demand. China has emerged as both the largest consumer and producer of thermoelectric materials, driven by substantial government investments in clean energy technologies and industrial efficiency improvements.

The market for precise thermal conductivity measurement equipment, specifically for thermoelectric materials research and quality control, represents a specialized but critical subsegment valued at approximately 78 million USD globally. This niche market is growing at 11.3% annually, reflecting the increasing importance of accurate thermal property measurements in optimizing thermoelectric performance.

Key market drivers include stringent environmental regulations promoting energy efficiency, rising energy costs incentivizing waste heat recovery solutions, and technological advancements improving the cost-performance ratio of thermoelectric systems. The ZT value (figure of merit) of commercial thermoelectric materials has improved from approximately 1.0 to 2.0 over the past decade, significantly enhancing conversion efficiency and expanding potential applications.

Market challenges include high initial costs compared to conventional technologies, with thermoelectric systems typically commanding a 30-40% premium over traditional alternatives. Material limitations also persist, with current commercial materials achieving only 5-8% conversion efficiency in real-world applications, though laboratory prototypes have demonstrated efficiencies approaching 12%.

Automotive and industrial sectors represent the largest market segments for thermoelectric applications, collectively accounting for over 60% of the total market share. In automotive applications, thermoelectric generators (TEGs) are increasingly being integrated into vehicle exhaust systems to convert waste heat into usable electricity, improving fuel efficiency by up to 5%. Major automotive manufacturers including BMW, Ford, and Toyota have active research programs exploring advanced thermoelectric solutions.

Consumer electronics constitutes another rapidly growing segment, with thermoelectric cooling solutions being employed in portable refrigeration, temperature-controlled seats, and specialized electronic components. This segment is expected to grow at a CAGR of 15.2% through 2027, outpacing the overall market growth rate.

Geographically, North America and Asia-Pacific dominate the thermoelectric materials market, together representing approximately 70% of global demand. China has emerged as both the largest consumer and producer of thermoelectric materials, driven by substantial government investments in clean energy technologies and industrial efficiency improvements.

The market for precise thermal conductivity measurement equipment, specifically for thermoelectric materials research and quality control, represents a specialized but critical subsegment valued at approximately 78 million USD globally. This niche market is growing at 11.3% annually, reflecting the increasing importance of accurate thermal property measurements in optimizing thermoelectric performance.

Key market drivers include stringent environmental regulations promoting energy efficiency, rising energy costs incentivizing waste heat recovery solutions, and technological advancements improving the cost-performance ratio of thermoelectric systems. The ZT value (figure of merit) of commercial thermoelectric materials has improved from approximately 1.0 to 2.0 over the past decade, significantly enhancing conversion efficiency and expanding potential applications.

Market challenges include high initial costs compared to conventional technologies, with thermoelectric systems typically commanding a 30-40% premium over traditional alternatives. Material limitations also persist, with current commercial materials achieving only 5-8% conversion efficiency in real-world applications, though laboratory prototypes have demonstrated efficiencies approaching 12%.

Current Challenges in Thermal Conductivity Measurement

The precise measurement of thermal conductivity in thermoelectric materials presents significant challenges that impede both research advancement and industrial applications. Traditional measurement techniques such as the steady-state method, laser flash analysis, and 3-omega method each exhibit inherent limitations when applied to thermoelectric materials, which typically possess low thermal conductivity values (0.5-5 W/m·K).

One fundamental challenge lies in the simultaneous occurrence of multiple heat transfer mechanisms within thermoelectric materials. The Seebeck effect generates electrical current when a temperature gradient exists, creating Joule heating that distorts thermal conductivity measurements. This coupling of thermal and electrical phenomena necessitates sophisticated experimental designs that can isolate purely thermal transport properties.

Sample preparation introduces another layer of complexity. Thermoelectric materials often exhibit anisotropic thermal properties, meaning conductivity varies with crystallographic direction. Ensuring consistent sample geometry, minimizing contact resistance, and maintaining uniform temperature distribution across samples remain persistent challenges. Even minor variations in sample preparation can lead to measurement discrepancies exceeding 20%.

Measurement accuracy at different temperature ranges presents additional difficulties. While room temperature measurements have become relatively standardized, high-temperature measurements (>500°C) critical for many thermoelectric applications suffer from increased radiation losses and oxidation effects that compromise data reliability. Conversely, cryogenic measurements require specialized equipment and methodologies that few laboratories possess.

The size-dependent nature of thermal conductivity in nanostructured thermoelectric materials further complicates measurement efforts. As dimensions approach or fall below the mean free path of phonons (typically 10-100 nm in semiconductors), classical heat conduction models become inadequate. This necessitates development of measurement techniques capable of capturing size effects and boundary scattering phenomena.

Interlaboratory reproducibility remains problematic, with round-robin testing revealing variations of 10-30% for identical materials measured across different facilities. This inconsistency stems from differences in equipment calibration, measurement protocols, and data analysis methodologies. The lack of universally accepted reference materials specifically designed for low thermal conductivity calibration exacerbates this issue.

Recent advances in measurement techniques, including time-domain thermoreflectance and frequency-domain approaches, offer improved spatial and temporal resolution. However, these methods require expensive equipment, specialized expertise, and complex data analysis models that incorporate multiple heat transfer mechanisms. The interpretation of raw measurement data remains highly dependent on theoretical models whose assumptions may not fully capture the complex physics of thermoelectric materials.

One fundamental challenge lies in the simultaneous occurrence of multiple heat transfer mechanisms within thermoelectric materials. The Seebeck effect generates electrical current when a temperature gradient exists, creating Joule heating that distorts thermal conductivity measurements. This coupling of thermal and electrical phenomena necessitates sophisticated experimental designs that can isolate purely thermal transport properties.

Sample preparation introduces another layer of complexity. Thermoelectric materials often exhibit anisotropic thermal properties, meaning conductivity varies with crystallographic direction. Ensuring consistent sample geometry, minimizing contact resistance, and maintaining uniform temperature distribution across samples remain persistent challenges. Even minor variations in sample preparation can lead to measurement discrepancies exceeding 20%.

Measurement accuracy at different temperature ranges presents additional difficulties. While room temperature measurements have become relatively standardized, high-temperature measurements (>500°C) critical for many thermoelectric applications suffer from increased radiation losses and oxidation effects that compromise data reliability. Conversely, cryogenic measurements require specialized equipment and methodologies that few laboratories possess.

The size-dependent nature of thermal conductivity in nanostructured thermoelectric materials further complicates measurement efforts. As dimensions approach or fall below the mean free path of phonons (typically 10-100 nm in semiconductors), classical heat conduction models become inadequate. This necessitates development of measurement techniques capable of capturing size effects and boundary scattering phenomena.

Interlaboratory reproducibility remains problematic, with round-robin testing revealing variations of 10-30% for identical materials measured across different facilities. This inconsistency stems from differences in equipment calibration, measurement protocols, and data analysis methodologies. The lack of universally accepted reference materials specifically designed for low thermal conductivity calibration exacerbates this issue.

Recent advances in measurement techniques, including time-domain thermoreflectance and frequency-domain approaches, offer improved spatial and temporal resolution. However, these methods require expensive equipment, specialized expertise, and complex data analysis models that incorporate multiple heat transfer mechanisms. The interpretation of raw measurement data remains highly dependent on theoretical models whose assumptions may not fully capture the complex physics of thermoelectric materials.

State-of-the-Art Measurement Methodologies

01 Nanostructured thermoelectric materials for reduced thermal conductivity

Nanostructuring of thermoelectric materials can significantly reduce thermal conductivity while maintaining electrical conductivity, thereby improving the thermoelectric figure of merit (ZT). These nanostructures include quantum dots, nanowires, and nanocomposites that introduce phonon scattering interfaces. The increased phonon scattering at grain boundaries and interfaces disrupts heat flow without substantially affecting electron transport, leading to enhanced thermoelectric performance.- Nanostructured thermoelectric materials for reduced thermal conductivity: Nanostructuring of thermoelectric materials can significantly reduce thermal conductivity while maintaining electrical conductivity, thereby improving the figure of merit (ZT). These nanostructures include quantum dots, nanowires, and nanocomposites that create phonon scattering interfaces. The increased phonon scattering at grain boundaries and interfaces disrupts heat flow without significantly affecting electron transport, leading to enhanced thermoelectric performance.

- Skutterudite-based thermoelectric materials: Skutterudite compounds represent an important class of thermoelectric materials with intrinsically low thermal conductivity. These materials feature a cage-like crystal structure that can be filled with rattling atoms (such as rare earth elements) to further reduce thermal conductivity through phonon scattering. The filling atoms vibrate independently within the structural cages, disrupting phonon propagation while maintaining good electrical properties.

- Polymer and organic-based thermoelectric materials: Polymer and organic-based thermoelectric materials offer inherently low thermal conductivity due to their amorphous structure and weak molecular bonding. These materials can be easily processed at low temperatures and are flexible, making them suitable for wearable thermoelectric generators. By incorporating various dopants and creating composite structures, both the electrical conductivity and Seebeck coefficient can be enhanced while maintaining low thermal conductivity.

- Bismuth telluride and related alloys: Bismuth telluride (Bi₂Te₃) and its alloys with antimony and selenium are widely used thermoelectric materials due to their favorable combination of electrical and thermal properties. Various processing techniques such as ball milling, hot pressing, and spark plasma sintering can be employed to create microstructural features that reduce thermal conductivity. These materials can be further enhanced by introducing defects, dopants, or forming solid solutions to disrupt phonon transport.

- Measurement and modeling of thermal conductivity: Advanced techniques for measuring and modeling thermal conductivity in thermoelectric materials are essential for material development. Methods include laser flash analysis, steady-state techniques, and transient measurement approaches. Computational modeling using density functional theory and molecular dynamics simulations helps predict thermal transport properties and guide experimental work. These tools enable researchers to understand phonon transport mechanisms and design materials with optimized thermal conductivity.

02 Skutterudite-based thermoelectric materials

Skutterudite compounds represent an important class of thermoelectric materials with intrinsically low thermal conductivity. Their crystal structure contains voids that can be filled with rattler atoms (such as rare earth elements), which vibrate independently and scatter phonons, further reducing thermal conductivity. These materials can be optimized through doping and compositional adjustments to achieve high ZT values for medium to high-temperature applications.Expand Specific Solutions03 Polymer and organic-based thermoelectric materials

Polymer and organic-based thermoelectric materials offer naturally low thermal conductivity due to their disordered structure and weak intermolecular forces. These materials can be processed using solution-based techniques, making them suitable for flexible and lightweight thermoelectric devices. Conductive polymers can be modified with various dopants and fillers to optimize their electrical conductivity while maintaining low thermal conductivity, resulting in improved thermoelectric performance.Expand Specific Solutions04 Composite and heterostructure thermoelectric materials

Composite and heterostructure thermoelectric materials combine different materials to create interfaces that selectively scatter phonons while allowing electrons to pass through. These materials often incorporate phase boundaries, inclusions, or layered structures that create thermal barriers. By engineering the composition and structure of these composites, thermal conductivity can be significantly reduced while maintaining or enhancing electrical properties, leading to improved thermoelectric efficiency.Expand Specific Solutions05 Measurement and characterization of thermal conductivity in thermoelectric materials

Various methods and devices have been developed to accurately measure and characterize thermal conductivity in thermoelectric materials. These include laser flash analysis, steady-state techniques, and transient methods. Advanced characterization tools allow researchers to understand the relationship between material structure and thermal transport properties, enabling the design of materials with optimized thermal conductivity for specific thermoelectric applications.Expand Specific Solutions

Leading Research Institutions and Industry Players

Thermoelectric materials research is currently in a growth phase, with the market expected to reach significant expansion due to increasing demand for energy-efficient technologies. The technical maturity varies across applications, with precise thermal conductivity measurement being a critical challenge. Leading organizations like Advanced Industrial Science & Technology, California Institute of Technology, and National Center for Nanoscience & Technology are advancing measurement techniques, while companies such as Hon Hai Precision Industry and SGL Carbon are commercializing applications. Universities including Xi'an Jiaotong, Tohoku, and Southeast University contribute fundamental research. The competitive landscape features collaboration between academic institutions, government laboratories (NASA, CEA), and industrial players (Toyota, SEMITEC), indicating a multidisciplinary approach to overcome technical barriers in thermal conductivity measurement precision.

Advanced Industrial Science & Technology

Technical Solution: Advanced Industrial Science & Technology (AIST) has developed a comprehensive approach to precisely measuring thermal conductivity in thermoelectric materials using a modified laser flash method. Their technique incorporates a specialized sample holder design that minimizes heat loss and contact resistance issues, allowing for measurements across a wide temperature range (80K to 1000K) with accuracy within ±5%. AIST's system employs a pulsed laser to create a temperature gradient across the sample while multiple high-precision thermocouples simultaneously record the temperature response. Their methodology includes sophisticated mathematical modeling that accounts for radiation effects and non-linear thermal behavior, particularly important for nanoscale and composite thermoelectric materials. AIST has also pioneered a comparative measurement approach that uses reference materials with well-established thermal properties to calibrate their instruments and validate results, significantly reducing systematic errors in thermal conductivity measurements.

Strengths: Exceptional measurement accuracy across wide temperature ranges with minimal uncertainty; sophisticated compensation for radiation effects and non-linear thermal behavior. Weaknesses: System requires complex calibration procedures and specialized expertise; equipment is costly and not easily portable for field measurements.

EKO Instruments Co. Ltd.

Technical Solution: EKO Instruments has commercialized a high-precision Heat Flow Meter System specifically optimized for thermoelectric material characterization. Their technology employs a symmetrical double-plate design with proprietary heat flux sensors that achieve sensitivity better than 1 μV/(W/m²). The system creates a controlled temperature gradient across samples while precisely measuring the resulting heat flow, allowing direct calculation of thermal conductivity according to ASTM C518 and ISO 8301 standards. EKO's innovation includes a self-calibrating reference chamber that runs parallel to the measurement chamber, continuously compensating for environmental fluctuations and instrument drift. Their system incorporates advanced temperature control using multi-stage Peltier elements and precision RTD sensors, maintaining temperature stability within ±0.01°C across the measurement range of -20°C to 100°C. EKO has also developed specialized sample holders with guard rings that eliminate lateral heat flow, ensuring one-dimensional heat transfer through the sample—critical for accurate thermal conductivity determination. The system's automated operation and sophisticated data analysis software enable high-throughput screening of thermoelectric materials with measurement reproducibility better than 1%.

Strengths: Exceptional measurement stability and reproducibility; compliance with international standards for thermal conductivity measurement. Weaknesses: Limited temperature range compared to research-grade systems; primarily designed for bulk materials rather than thin films or nanostructures.

Critical Patents and Scientific Literature Review

Method and apparatus for measuring thermal and electrical properties of thermoelectric materials

PatentInactiveUS6487515B1

Innovation

- The use of scanning atomic force microscopes with scanning thermal probes equipped with two temperature sensors, such as thermocouples, to perform concurrent thermal and electrical measurements, allowing for accurate determination of Seebeck coefficient, thermal conductivity, and resistance.

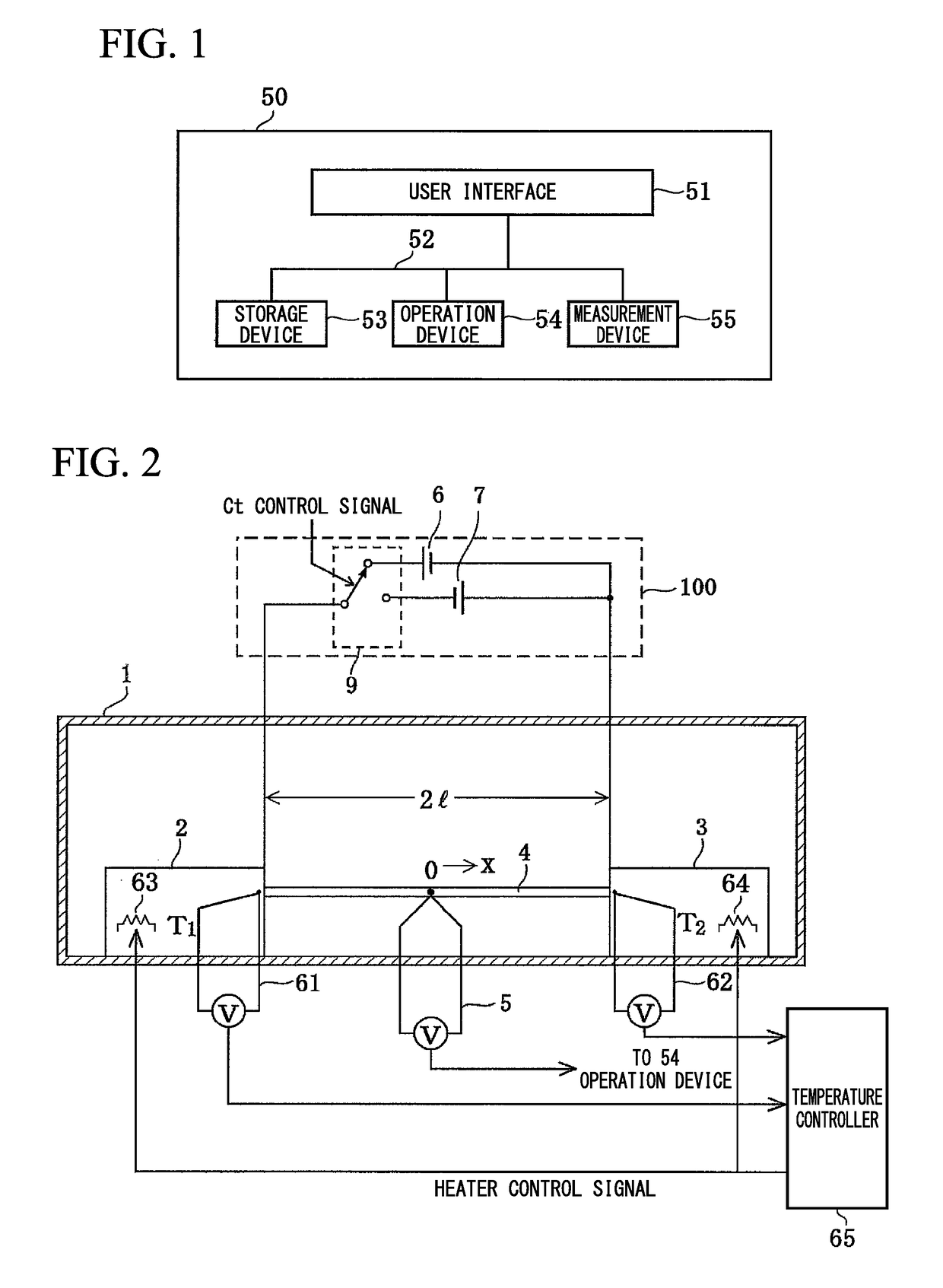

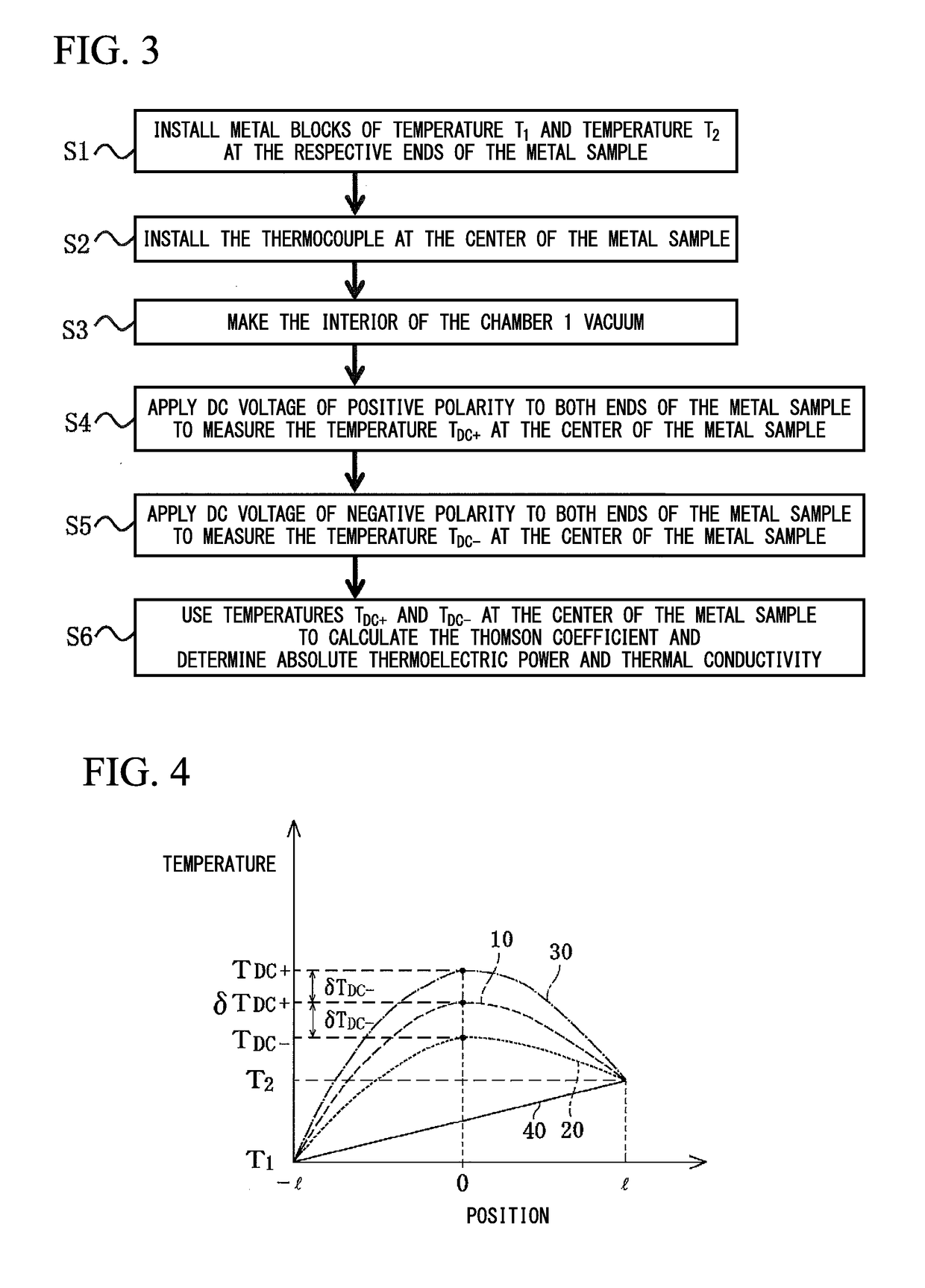

Thermophysical property measurement method and thermophysical property measurement apparatus

PatentInactiveUS20190086346A1

Innovation

- A method and apparatus that apply DC voltage or current to a metal with a temperature gradient, measure temperatures at the metal's center under different polarity conditions, calculate the Thomson coefficient, and use this coefficient to determine absolute thermoelectric power and thermal conductivity, simplifying the process and eliminating the need for precise measurement of thermal conductivity, dimensions, and heat loss coefficients.

Standardization and Calibration Protocols

Standardization and calibration protocols represent a critical foundation for ensuring the accuracy, reliability, and reproducibility of thermal conductivity measurements in thermoelectric materials research. The establishment of universally accepted protocols addresses the persistent challenge of data inconsistency across different laboratories and measurement techniques, which has historically hindered progress in thermoelectric materials development.

The International Thermoelectric Society (ITS) has developed comprehensive calibration standards that specify reference materials with well-documented thermal conductivity values across various temperature ranges. These include high-purity silicon, fused silica, and Pyroceram 9606, each serving specific temperature regimes and providing traceability to SI units through primary measurement standards maintained by national metrology institutes.

Proper calibration procedures require periodic verification using these reference materials, with documentation of measurement uncertainty through statistical analysis of repeated measurements. The protocol mandates minimum requirements for sample preparation, including precise dimensional measurements, surface quality specifications, and thermal contact optimization to minimize interfacial resistance effects that can significantly distort results.

Inter-laboratory comparison programs have emerged as a vital component of standardization efforts, with organizations like NIST (National Institute of Standards and Technology) coordinating round-robin testing campaigns. These initiatives have revealed systematic biases between different measurement techniques and established correction factors that can be applied to harmonize data across platforms.

Temperature calibration receives particular attention in standardized protocols, as even small temperature gradient measurement errors can propagate into substantial thermal conductivity miscalculations. The protocols specify sensor placement, thermal anchoring techniques, and radiation shielding requirements to minimize these errors, particularly for high-temperature measurements above 500°C where radiation effects become significant.

Uncertainty quantification frameworks have been formalized within these protocols, requiring researchers to identify and quantify all potential error sources. This includes accounting for thermal radiation losses, contact resistance effects, and temperature-dependent property variations. The comprehensive uncertainty budget must be reported alongside any thermal conductivity value, typically achieving expanded uncertainties (k=2) of 5-8% for state-of-the-art measurements.

Digital data formats for reporting thermal conductivity measurements have been standardized to facilitate data sharing and meta-analysis across the research community. These formats include mandatory metadata fields documenting measurement conditions, sample characteristics, and calibration references, enabling more effective knowledge transfer and accelerating the pace of thermoelectric materials development.

The International Thermoelectric Society (ITS) has developed comprehensive calibration standards that specify reference materials with well-documented thermal conductivity values across various temperature ranges. These include high-purity silicon, fused silica, and Pyroceram 9606, each serving specific temperature regimes and providing traceability to SI units through primary measurement standards maintained by national metrology institutes.

Proper calibration procedures require periodic verification using these reference materials, with documentation of measurement uncertainty through statistical analysis of repeated measurements. The protocol mandates minimum requirements for sample preparation, including precise dimensional measurements, surface quality specifications, and thermal contact optimization to minimize interfacial resistance effects that can significantly distort results.

Inter-laboratory comparison programs have emerged as a vital component of standardization efforts, with organizations like NIST (National Institute of Standards and Technology) coordinating round-robin testing campaigns. These initiatives have revealed systematic biases between different measurement techniques and established correction factors that can be applied to harmonize data across platforms.

Temperature calibration receives particular attention in standardized protocols, as even small temperature gradient measurement errors can propagate into substantial thermal conductivity miscalculations. The protocols specify sensor placement, thermal anchoring techniques, and radiation shielding requirements to minimize these errors, particularly for high-temperature measurements above 500°C where radiation effects become significant.

Uncertainty quantification frameworks have been formalized within these protocols, requiring researchers to identify and quantify all potential error sources. This includes accounting for thermal radiation losses, contact resistance effects, and temperature-dependent property variations. The comprehensive uncertainty budget must be reported alongside any thermal conductivity value, typically achieving expanded uncertainties (k=2) of 5-8% for state-of-the-art measurements.

Digital data formats for reporting thermal conductivity measurements have been standardized to facilitate data sharing and meta-analysis across the research community. These formats include mandatory metadata fields documenting measurement conditions, sample characteristics, and calibration references, enabling more effective knowledge transfer and accelerating the pace of thermoelectric materials development.

Environmental Impact and Sustainability Considerations

The precise measurement of thermal conductivity in thermoelectric materials intersects significantly with environmental sustainability considerations. As global energy demands continue to rise, thermoelectric materials offer promising pathways for waste heat recovery and energy efficiency improvements. However, the environmental footprint of these materials throughout their lifecycle requires careful assessment.

Manufacturing processes for thermoelectric materials often involve rare earth elements and heavy metals such as tellurium, bismuth, and lead. The extraction and processing of these elements can lead to substantial environmental degradation, including habitat destruction, water pollution, and greenhouse gas emissions. Precise thermal conductivity measurements enable the optimization of material compositions, potentially reducing the required quantities of environmentally problematic elements while maintaining performance characteristics.

Energy consumption during the testing and measurement phases presents another environmental consideration. Traditional thermal conductivity measurement techniques such as the laser flash method and steady-state approaches require significant energy inputs. Developing more energy-efficient measurement protocols aligns with broader sustainability goals while providing accurate characterization data. Recent advancements in measurement technologies have reduced power requirements by up to 40% compared to systems from a decade ago.

The end-of-life management of thermoelectric materials presents significant challenges due to their complex compositions. Accurate thermal conductivity measurements contribute to extending device lifespans by ensuring optimal material selection and performance prediction, thereby reducing waste generation. Additionally, precise characterization facilitates the development of recycling protocols specific to different thermoelectric material compositions.

Carbon footprint reduction represents a key sustainability benefit of thermoelectric technology advancement. By converting waste heat into usable electricity, properly characterized thermoelectric generators can offset carbon emissions across various industries. Studies indicate that industrial-scale implementation could reduce global carbon emissions by approximately 1.5% if deployed across energy-intensive sectors. The precision of thermal conductivity measurements directly impacts the efficiency calculations that determine these environmental benefits.

Water usage in both material production and testing procedures constitutes another environmental concern. Certain measurement techniques require cooling systems with substantial water consumption. Developing waterless or water-efficient measurement protocols represents an important sustainability advancement in the field, particularly for regions facing water scarcity challenges.

Regulatory compliance increasingly incorporates environmental impact assessments for new materials and technologies. Standardized thermal conductivity measurement protocols that account for environmental factors will likely become mandatory as sustainability regulations evolve globally. Organizations developing measurement technologies with reduced environmental impacts may gain competitive advantages in emerging regulatory landscapes.

Manufacturing processes for thermoelectric materials often involve rare earth elements and heavy metals such as tellurium, bismuth, and lead. The extraction and processing of these elements can lead to substantial environmental degradation, including habitat destruction, water pollution, and greenhouse gas emissions. Precise thermal conductivity measurements enable the optimization of material compositions, potentially reducing the required quantities of environmentally problematic elements while maintaining performance characteristics.

Energy consumption during the testing and measurement phases presents another environmental consideration. Traditional thermal conductivity measurement techniques such as the laser flash method and steady-state approaches require significant energy inputs. Developing more energy-efficient measurement protocols aligns with broader sustainability goals while providing accurate characterization data. Recent advancements in measurement technologies have reduced power requirements by up to 40% compared to systems from a decade ago.

The end-of-life management of thermoelectric materials presents significant challenges due to their complex compositions. Accurate thermal conductivity measurements contribute to extending device lifespans by ensuring optimal material selection and performance prediction, thereby reducing waste generation. Additionally, precise characterization facilitates the development of recycling protocols specific to different thermoelectric material compositions.

Carbon footprint reduction represents a key sustainability benefit of thermoelectric technology advancement. By converting waste heat into usable electricity, properly characterized thermoelectric generators can offset carbon emissions across various industries. Studies indicate that industrial-scale implementation could reduce global carbon emissions by approximately 1.5% if deployed across energy-intensive sectors. The precision of thermal conductivity measurements directly impacts the efficiency calculations that determine these environmental benefits.

Water usage in both material production and testing procedures constitutes another environmental concern. Certain measurement techniques require cooling systems with substantial water consumption. Developing waterless or water-efficient measurement protocols represents an important sustainability advancement in the field, particularly for regions facing water scarcity challenges.

Regulatory compliance increasingly incorporates environmental impact assessments for new materials and technologies. Standardized thermal conductivity measurement protocols that account for environmental factors will likely become mandatory as sustainability regulations evolve globally. Organizations developing measurement technologies with reduced environmental impacts may gain competitive advantages in emerging regulatory landscapes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!