Tungsten In 3D Printing: A New Frontier

Tungsten 3D Printing Evolution and Objectives

Tungsten 3D printing has emerged as a groundbreaking technology in the field of advanced manufacturing, offering new possibilities for creating complex and high-performance components. The evolution of this technology can be traced back to the early 2000s when researchers began exploring the potential of using tungsten in additive manufacturing processes.

Initially, the focus was on developing suitable powder materials and understanding the unique challenges posed by tungsten's high melting point and thermal properties. As the technology progressed, researchers and engineers worked on optimizing printing parameters, such as laser power, scanning speed, and layer thickness, to achieve better print quality and material properties.

The mid-2010s saw significant advancements in tungsten 3D printing techniques, with the introduction of more sophisticated printing systems capable of handling high-temperature materials. This period also witnessed the development of specialized post-processing techniques to enhance the mechanical properties and surface finish of printed tungsten parts.

In recent years, the focus has shifted towards expanding the applications of tungsten 3D printing across various industries. The aerospace and defense sectors have shown particular interest in leveraging this technology for creating lightweight yet strong components for aircraft and military equipment. Additionally, the medical industry has begun exploring the use of 3D-printed tungsten for radiation shielding and medical implants.

The primary objectives of tungsten 3D printing research and development are multifaceted. One key goal is to improve the overall print quality and consistency, addressing issues such as porosity, surface roughness, and dimensional accuracy. Researchers are also working on expanding the range of printable tungsten alloys to tailor material properties for specific applications.

Another critical objective is to increase the printing speed and efficiency, making the technology more viable for large-scale production. This involves developing faster printing systems, optimizing powder handling and recycling processes, and improving overall process automation.

Enhancing the mechanical properties of 3D-printed tungsten parts is also a priority. Researchers are exploring various strategies, including heat treatments, hot isostatic pressing, and the incorporation of reinforcing materials to achieve properties comparable to or even superior to traditionally manufactured tungsten components.

Lastly, there is a growing emphasis on sustainability and cost-effectiveness in tungsten 3D printing. Efforts are being made to reduce material waste, improve energy efficiency, and develop more affordable printing systems to broaden the technology's accessibility across industries.

Market Demand for Tungsten 3D Printed Components

The market demand for tungsten 3D printed components has been steadily growing, driven by the unique properties of tungsten and the advantages offered by additive manufacturing. Tungsten's high melting point, excellent thermal and electrical conductivity, and superior radiation shielding capabilities make it an attractive material for various high-performance applications.

In the aerospace and defense sectors, there is a significant demand for tungsten 3D printed components. These industries require lightweight yet strong materials that can withstand extreme temperatures and harsh environments. Tungsten 3D printed parts are being used in rocket nozzles, heat shields, and radiation shielding for spacecraft. The ability to create complex geometries through 3D printing allows for optimized designs that enhance performance while reducing weight.

The medical industry is another key market for tungsten 3D printed components. Tungsten's high density and radiation attenuation properties make it ideal for medical imaging equipment and radiation therapy devices. 3D printing enables the production of customized tungsten collimators and shielding components, improving the precision and effectiveness of cancer treatments.

In the automotive sector, particularly in high-performance and racing applications, tungsten 3D printed components are gaining traction. These parts are used in exhaust systems, turbochargers, and engine components where heat resistance and durability are crucial. The ability to create intricate cooling channels and optimize part geometries through 3D printing enhances the performance of these components.

The energy sector, including nuclear and renewable energy, is also driving demand for tungsten 3D printed parts. In nuclear power plants, tungsten components are used for radiation shielding and in reactor components. The renewable energy sector utilizes tungsten in wind turbine components and solar panel manufacturing equipment.

The electronics industry is exploring the use of tungsten 3D printed components in heat sinks and electrical contacts. The material's excellent thermal management properties and conductivity make it suitable for high-power electronic applications.

While the market for tungsten 3D printed components is growing, it is important to note that the technology is still in its early stages. The high cost of tungsten powder and the complexities associated with 3D printing this material currently limit its widespread adoption. However, as the technology matures and becomes more cost-effective, the market is expected to expand significantly.

Current Challenges in Tungsten 3D Printing

Despite the promising potential of tungsten in 3D printing, several significant challenges currently hinder its widespread adoption and application. One of the primary obstacles is the high melting point of tungsten, which reaches approximately 3422°C. This extreme temperature requirement poses difficulties for conventional 3D printing systems, necessitating specialized equipment and processes capable of handling such high temperatures.

The inherent brittleness of tungsten presents another major challenge. The material's lack of ductility makes it prone to cracking during the printing process, particularly as layers cool and contract. This characteristic complicates the production of complex geometries and can lead to structural weaknesses in the final printed parts.

Oxidation is a significant concern when working with tungsten at high temperatures. The material readily oxidizes when exposed to air at elevated temperatures, forming volatile oxides that can compromise the integrity and properties of the printed components. This necessitates the use of inert atmospheres or vacuum conditions during the printing process, adding complexity and cost to the manufacturing setup.

The high density of tungsten, while beneficial in many applications, presents challenges in powder-based 3D printing methods. The material's weight can cause uneven distribution in powder beds, leading to inconsistencies in layer formation and potential defects in the final product. This issue is particularly pronounced in larger parts or those with intricate internal structures.

Another significant hurdle is the limited availability of high-quality tungsten powders suitable for additive manufacturing. The production of fine, spherical tungsten particles with consistent size distribution and minimal impurities is technically challenging and costly. This scarcity of appropriate raw materials can impact the quality and repeatability of 3D printed tungsten components.

The post-processing of 3D printed tungsten parts also presents challenges. The material's hardness and high melting point make traditional machining and finishing techniques difficult and time-consuming. This can limit the achievable surface quality and dimensional accuracy of printed components, potentially restricting their use in high-precision applications.

Lastly, the lack of comprehensive understanding and standardization in tungsten 3D printing processes poses a significant challenge. The complex interactions between material properties, printing parameters, and final part characteristics are not yet fully mapped out. This knowledge gap hampers the development of reliable, repeatable manufacturing processes and slows down the adoption of tungsten 3D printing in industrial applications.

Existing Tungsten 3D Printing Methodologies

01 Tungsten deposition and film formation

Various methods and processes for depositing tungsten and forming tungsten films on substrates. This includes techniques such as chemical vapor deposition (CVD), atomic layer deposition (ALD), and physical vapor deposition (PVD) to create thin, uniform tungsten layers for semiconductor applications.- Tungsten deposition methods: Various methods for depositing tungsten on substrates, including chemical vapor deposition (CVD) and atomic layer deposition (ALD). These techniques are used to create thin films of tungsten for applications in semiconductor manufacturing and other industries.

- Tungsten-based alloys and composites: Development of tungsten-based alloys and composite materials with enhanced properties, such as improved strength, hardness, and thermal stability. These materials find applications in aerospace, defense, and high-temperature industrial processes.

- Tungsten in semiconductor devices: Utilization of tungsten in semiconductor devices, including its use as interconnects, gate electrodes, and diffusion barriers. Tungsten's low resistivity and high melting point make it suitable for various semiconductor applications.

- Tungsten processing and recycling: Methods for processing tungsten ores, refining tungsten, and recycling tungsten-containing materials. These processes aim to improve the efficiency of tungsten production and reduce environmental impact.

- Tungsten in lighting and electronics: Applications of tungsten in lighting technologies, such as incandescent bulbs and fluorescent lamps, as well as in electronic components like filaments and electrodes. Tungsten's high melting point and durability make it ideal for these applications.

02 Tungsten etching and patterning

Techniques for etching and patterning tungsten layers in semiconductor manufacturing. This involves selective removal of tungsten using various etchants and processes to create desired structures and patterns for integrated circuits and other electronic devices.Expand Specific Solutions03 Tungsten-based alloys and composites

Development and production of tungsten-based alloys and composite materials. These materials combine tungsten with other elements or compounds to enhance specific properties such as strength, conductivity, or thermal resistance for various industrial applications.Expand Specific Solutions04 Tungsten in electronic components

Use of tungsten in the fabrication of electronic components and devices. This includes applications in interconnects, contacts, and electrodes for semiconductor devices, as well as in the production of filaments for lighting and display technologies.Expand Specific Solutions05 Tungsten processing and recycling

Methods for processing raw tungsten ore, refining tungsten, and recycling tungsten-containing materials. This includes extraction techniques, purification processes, and strategies for recovering tungsten from scrap or waste materials to support sustainable use of this valuable metal.Expand Specific Solutions

Key Players in Tungsten 3D Printing Industry

The integration of tungsten in 3D printing represents an emerging frontier in advanced manufacturing, currently in its early development stage. The market for tungsten 3D printing is relatively small but growing, driven by increasing demand in aerospace, defense, and medical industries. The technology's maturity varies among key players. Companies like Stratasys Ltd. and Carbon, Inc. are at the forefront, leveraging their expertise in additive manufacturing to develop tungsten-based solutions. Academic institutions such as the University of Science & Technology Beijing and Central South University are conducting fundamental research to advance the technology. Industrial giants like Applied Materials, Inc. and Lam Research Corp. are exploring potential applications in semiconductor manufacturing. The technology's complexity and high material costs present challenges, but ongoing research and development efforts by these players are steadily improving its viability and expanding potential applications.

Stratasys Ltd.

Carbon, Inc.

Innovative Approaches in Tungsten 3D Printing

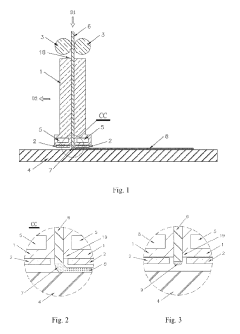

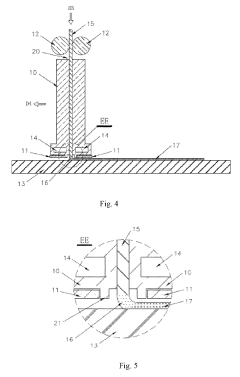

- A method and apparatus utilizing electromagnetic induction heating to generate molten raw materials, where a solid raw material is heated to a molten state within a guiding device, allowing for precise control of the molten segment's position and avoiding contact with heating devices or containers, enabling the use of conductive materials with ultrahigh melting points.

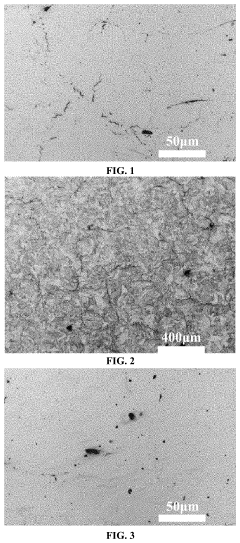

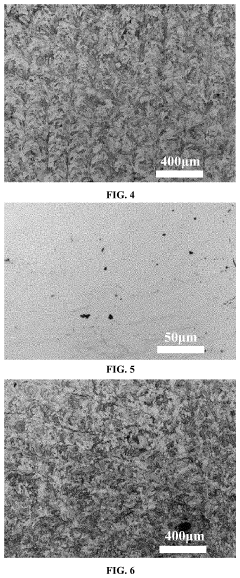

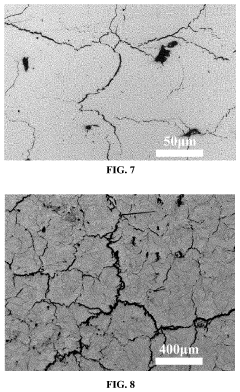

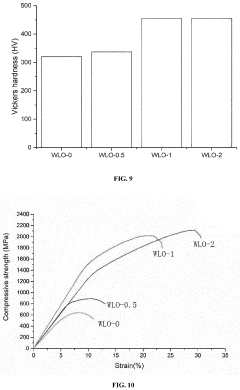

- A nano-lanthanum oxide reinforced tungsten-based composite material is created by mixing pure tungsten powder with nano-lanthanum oxide powder and 3D printing in an argon atmosphere, with optimized parameters to reduce defects and enhance mechanical properties.

Material Properties and Characterization

Tungsten, with its exceptional properties, presents both opportunities and challenges in the realm of 3D printing. The material's high melting point, approximately 3422°C, makes it particularly suitable for high-temperature applications. This characteristic, combined with tungsten's excellent thermal and electrical conductivity, opens up new possibilities for creating components that can withstand extreme conditions.

The density of tungsten, at 19.3 g/cm³, is another crucial property that influences its behavior in 3D printing processes. This high density contributes to the material's strength and wear resistance, making it ideal for applications in aerospace, defense, and nuclear industries. However, it also presents challenges in terms of material handling and equipment requirements during the printing process.

Tungsten's hardness and brittleness are significant factors that affect its printability. The material's high hardness (7.5-9.5 on the Mohs scale) contributes to its wear resistance but can lead to difficulties in post-processing and finishing of printed parts. The brittleness of tungsten can result in cracking or delamination during the printing process, necessitating careful control of printing parameters and post-processing techniques.

The thermal expansion coefficient of tungsten is relatively low compared to other metals, which can be advantageous in maintaining dimensional stability during the heating and cooling cycles of the 3D printing process. This property is particularly beneficial when printing complex geometries or parts that require high precision.

Characterization of tungsten powder for 3D printing involves several key aspects. Particle size distribution is crucial, as it affects the flowability and packing density of the powder, which in turn influences the quality of the printed parts. Typically, powder particles ranging from 15 to 45 microns are used in most metal 3D printing processes.

The morphology of tungsten particles also plays a significant role in the printing process. Spherical particles are generally preferred for their improved flowability and packing density. However, the production of spherical tungsten particles can be challenging and costly, often requiring specialized techniques such as plasma spheroidization.

Surface chemistry and oxidation state of tungsten powder are critical factors that affect the printing process and the final properties of the printed parts. Tungsten is prone to oxidation, which can lead to defects in the printed parts and affect the material's properties. Therefore, careful handling and storage of tungsten powder are essential to minimize oxidation.

Understanding these material properties and characterization techniques is crucial for developing effective 3D printing processes for tungsten. It enables the optimization of printing parameters, the design of suitable support structures, and the development of post-processing techniques to achieve the desired properties in the final printed components.

Environmental Impact and Sustainability

The integration of tungsten in 3D printing processes brings both opportunities and challenges from an environmental and sustainability perspective. As this new frontier in additive manufacturing expands, it is crucial to assess its ecological footprint and long-term viability.

Tungsten's high melting point and density make it an attractive material for 3D printing applications in aerospace, automotive, and medical industries. However, these same properties also contribute to increased energy consumption during the printing process. The high temperatures required for melting tungsten result in significant energy expenditure, potentially leading to a larger carbon footprint compared to traditional manufacturing methods or the 3D printing of other metals.

The extraction and processing of tungsten ore also raise environmental concerns. Mining operations can lead to habitat destruction, soil erosion, and water pollution if not managed responsibly. Additionally, the refining process to produce tungsten powder suitable for 3D printing involves chemical treatments that may generate hazardous waste. Proper disposal and recycling protocols must be established to mitigate these environmental risks.

On the positive side, 3D printing with tungsten can contribute to sustainability through material efficiency. Additive manufacturing processes typically produce less waste compared to subtractive methods, as they only use the material necessary for the final product. This reduction in material waste is particularly significant for tungsten, given its scarcity and the environmental impact of its extraction.

The durability and longevity of tungsten products created through 3D printing also contribute to sustainability. Tungsten's resistance to wear and corrosion means that parts and components can have extended lifespans, reducing the need for frequent replacements and, consequently, lowering the overall environmental impact over time.

Recycling and reuse of tungsten in 3D printing present both challenges and opportunities. While tungsten powder that is not used in the printing process can be easily recycled, the recycling of printed tungsten parts is more complex due to potential contamination and the need for specialized processes to break down the material. Developing efficient recycling methods for 3D-printed tungsten products will be crucial for improving the overall sustainability of this technology.

As the adoption of tungsten in 3D printing grows, it is essential to conduct comprehensive life cycle assessments to fully understand its environmental impact. These assessments should consider factors such as energy consumption, material efficiency, product lifespan, and end-of-life recycling potential. By identifying areas for improvement, researchers and industry professionals can work towards optimizing the sustainability of tungsten-based 3D printing processes.