Turbine Engine Maintenance Best Practices for Long-Term Performance

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Engine Maintenance Evolution and Objectives

Turbine engine maintenance has evolved significantly since the introduction of the first gas turbine engines in the 1940s. Initially, maintenance was primarily reactive, with engines being serviced only after failure or significant performance degradation. This approach resulted in unpredictable downtime and high operational costs. The 1960s marked a shift toward preventive maintenance, where components were replaced based on fixed time intervals regardless of their condition, improving reliability but often leading to unnecessary part replacements.

The 1970s and 1980s witnessed the emergence of condition-based maintenance, utilizing basic monitoring techniques to assess engine health. This period saw the introduction of borescope inspections and vibration analysis, allowing for more targeted maintenance interventions. By the 1990s, predictive maintenance strategies began to take shape, incorporating advanced diagnostics and prognostics to anticipate failures before they occurred.

Today's turbine engine maintenance landscape is characterized by integrated health management systems that leverage real-time data analytics, machine learning algorithms, and digital twin technology. These sophisticated approaches enable continuous monitoring of engine parameters and performance metrics, facilitating highly optimized maintenance scheduling and significantly extending engine life cycles.

The primary objective of modern turbine engine maintenance is to maximize operational availability while minimizing lifecycle costs. This involves balancing the competing demands of performance optimization, fuel efficiency, emissions reduction, and safety compliance. Maintenance strategies now aim to predict component degradation with increasing accuracy, allowing for just-in-time part replacement and minimizing unnecessary maintenance activities.

Another critical goal is the extension of time-on-wing, enabling engines to remain in service for longer periods without compromising safety or performance. This objective has driven innovations in materials science, coating technologies, and repair methodologies that can restore components to near-original specifications without complete replacement.

Environmental sustainability has emerged as an increasingly important maintenance objective, with programs designed to reduce waste, optimize fuel consumption, and minimize emissions through proper engine tuning and component efficiency. Additionally, regulatory compliance remains a fundamental aim, with maintenance protocols structured to meet stringent airworthiness directives and safety standards across different jurisdictions.

The future trajectory of turbine engine maintenance points toward fully autonomous maintenance systems that can self-diagnose issues and potentially self-heal through advanced materials and embedded technologies. The ultimate goal is to develop maintenance ecosystems that can predict, prevent, and address performance degradation with minimal human intervention, maximizing asset utilization while ensuring optimal performance throughout the engine's operational life.

The 1970s and 1980s witnessed the emergence of condition-based maintenance, utilizing basic monitoring techniques to assess engine health. This period saw the introduction of borescope inspections and vibration analysis, allowing for more targeted maintenance interventions. By the 1990s, predictive maintenance strategies began to take shape, incorporating advanced diagnostics and prognostics to anticipate failures before they occurred.

Today's turbine engine maintenance landscape is characterized by integrated health management systems that leverage real-time data analytics, machine learning algorithms, and digital twin technology. These sophisticated approaches enable continuous monitoring of engine parameters and performance metrics, facilitating highly optimized maintenance scheduling and significantly extending engine life cycles.

The primary objective of modern turbine engine maintenance is to maximize operational availability while minimizing lifecycle costs. This involves balancing the competing demands of performance optimization, fuel efficiency, emissions reduction, and safety compliance. Maintenance strategies now aim to predict component degradation with increasing accuracy, allowing for just-in-time part replacement and minimizing unnecessary maintenance activities.

Another critical goal is the extension of time-on-wing, enabling engines to remain in service for longer periods without compromising safety or performance. This objective has driven innovations in materials science, coating technologies, and repair methodologies that can restore components to near-original specifications without complete replacement.

Environmental sustainability has emerged as an increasingly important maintenance objective, with programs designed to reduce waste, optimize fuel consumption, and minimize emissions through proper engine tuning and component efficiency. Additionally, regulatory compliance remains a fundamental aim, with maintenance protocols structured to meet stringent airworthiness directives and safety standards across different jurisdictions.

The future trajectory of turbine engine maintenance points toward fully autonomous maintenance systems that can self-diagnose issues and potentially self-heal through advanced materials and embedded technologies. The ultimate goal is to develop maintenance ecosystems that can predict, prevent, and address performance degradation with minimal human intervention, maximizing asset utilization while ensuring optimal performance throughout the engine's operational life.

Market Demand Analysis for Advanced Maintenance Solutions

The global market for advanced turbine engine maintenance solutions is experiencing robust growth, driven by increasing demand for efficient power generation and the aging fleet of turbine engines across various industries. The market size for turbine maintenance services was valued at approximately $25 billion in 2022, with projections indicating growth at a compound annual rate of 8.3% through 2030. This expansion is particularly evident in regions with established power generation infrastructure, including North America, Europe, and parts of Asia.

Aviation and power generation sectors represent the largest market segments, collectively accounting for over 70% of the total demand. The commercial aviation industry, despite temporary setbacks during global disruptions, continues to expand its fleet, creating sustained demand for sophisticated maintenance solutions that can extend engine life while ensuring optimal performance. Similarly, power generation companies are increasingly focused on maximizing the operational lifespan of their turbine assets while minimizing downtime.

Market research indicates a significant shift in customer preferences toward predictive and condition-based maintenance approaches. End-users are demonstrating willingness to invest in advanced solutions that offer demonstrable return on investment through reduced unplanned downtime and extended component life. A recent industry survey revealed that 78% of turbine operators consider predictive maintenance capabilities as "very important" or "critical" in their procurement decisions for maintenance services.

The demand landscape is further shaped by regulatory pressures and sustainability initiatives. Environmental regulations are becoming increasingly stringent, requiring operators to maintain engines at peak efficiency to minimize emissions. This regulatory environment has created a premium market segment for maintenance solutions that can simultaneously address compliance requirements and operational efficiency.

Regional analysis shows varying market maturity and growth potential. While North America and Western Europe represent mature markets with emphasis on technology upgrades, emerging economies in Asia-Pacific and Middle East regions show the highest growth potential, driven by rapid industrialization and power infrastructure development. These regions are projected to grow at rates exceeding 10% annually through 2028.

Customer segmentation reveals distinct needs across different industries. Aviation customers prioritize reliability and minimized ground time, while power generation operators focus on efficiency optimization and emissions control. Industrial applications typically emphasize cost-effectiveness and extended maintenance intervals. This segmentation presents opportunities for specialized maintenance solution providers to develop targeted offerings addressing specific industry requirements.

The market is also witnessing increased demand for integrated service packages that combine traditional maintenance with digital monitoring solutions, creating opportunities for comprehensive service providers who can offer end-to-end maintenance ecosystems rather than standalone services.

Aviation and power generation sectors represent the largest market segments, collectively accounting for over 70% of the total demand. The commercial aviation industry, despite temporary setbacks during global disruptions, continues to expand its fleet, creating sustained demand for sophisticated maintenance solutions that can extend engine life while ensuring optimal performance. Similarly, power generation companies are increasingly focused on maximizing the operational lifespan of their turbine assets while minimizing downtime.

Market research indicates a significant shift in customer preferences toward predictive and condition-based maintenance approaches. End-users are demonstrating willingness to invest in advanced solutions that offer demonstrable return on investment through reduced unplanned downtime and extended component life. A recent industry survey revealed that 78% of turbine operators consider predictive maintenance capabilities as "very important" or "critical" in their procurement decisions for maintenance services.

The demand landscape is further shaped by regulatory pressures and sustainability initiatives. Environmental regulations are becoming increasingly stringent, requiring operators to maintain engines at peak efficiency to minimize emissions. This regulatory environment has created a premium market segment for maintenance solutions that can simultaneously address compliance requirements and operational efficiency.

Regional analysis shows varying market maturity and growth potential. While North America and Western Europe represent mature markets with emphasis on technology upgrades, emerging economies in Asia-Pacific and Middle East regions show the highest growth potential, driven by rapid industrialization and power infrastructure development. These regions are projected to grow at rates exceeding 10% annually through 2028.

Customer segmentation reveals distinct needs across different industries. Aviation customers prioritize reliability and minimized ground time, while power generation operators focus on efficiency optimization and emissions control. Industrial applications typically emphasize cost-effectiveness and extended maintenance intervals. This segmentation presents opportunities for specialized maintenance solution providers to develop targeted offerings addressing specific industry requirements.

The market is also witnessing increased demand for integrated service packages that combine traditional maintenance with digital monitoring solutions, creating opportunities for comprehensive service providers who can offer end-to-end maintenance ecosystems rather than standalone services.

Current Maintenance Challenges and Technical Limitations

Despite significant advancements in turbine engine technology, maintenance practices continue to face substantial challenges that limit operational efficiency and long-term performance. One of the most pressing issues is the difficulty in accurately predicting component failure. Current predictive maintenance models often rely on historical data that may not adequately account for unique operational conditions or emerging failure modes, resulting in either premature component replacement or unexpected failures.

Material degradation presents another significant challenge, particularly in high-temperature environments where turbine blades and combustion components operate. Advanced alloys and thermal barrier coatings have extended component life, but degradation mechanisms such as oxidation, hot corrosion, and thermal fatigue continue to accelerate wear rates beyond predicted models. This discrepancy between theoretical and actual material performance creates maintenance planning uncertainties.

Access limitations within engine architecture represent a substantial technical constraint. Modern turbine engines are increasingly compact and complex, making physical inspection of internal components difficult without extensive disassembly. This challenge is particularly acute for land-based power generation turbines where downtime carries significant economic penalties. The industry continues to seek non-invasive inspection technologies that can provide accurate condition assessment without requiring complete teardown.

Data integration across disparate maintenance systems remains problematic. Many facilities operate with a combination of legacy systems and newer digital platforms that do not effectively communicate with each other. This fragmentation limits the ability to perform comprehensive trend analysis or implement truly condition-based maintenance strategies. The resulting information silos prevent maintenance teams from developing a holistic understanding of engine health.

Resource constraints further complicate maintenance practices. Skilled technician shortages are becoming more acute as experienced personnel retire without adequate knowledge transfer to newer workforce members. This expertise gap is particularly concerning for older turbine models where maintenance relies heavily on accumulated tacit knowledge rather than comprehensive documentation.

Environmental compliance requirements add another layer of complexity. Emissions regulations continue to tighten globally, requiring modifications to maintenance practices that may conflict with performance optimization goals. Finding the balance between environmental compliance and operational efficiency often results in compromised maintenance approaches that satisfy neither objective optimally.

Cost pressures remain a persistent limitation, with maintenance departments frequently required to extend component life beyond original design parameters. This economic reality often leads to risk-based decisions that prioritize short-term operational continuity over long-term performance sustainability, creating a maintenance debt that eventually manifests as decreased reliability or catastrophic failure.

Material degradation presents another significant challenge, particularly in high-temperature environments where turbine blades and combustion components operate. Advanced alloys and thermal barrier coatings have extended component life, but degradation mechanisms such as oxidation, hot corrosion, and thermal fatigue continue to accelerate wear rates beyond predicted models. This discrepancy between theoretical and actual material performance creates maintenance planning uncertainties.

Access limitations within engine architecture represent a substantial technical constraint. Modern turbine engines are increasingly compact and complex, making physical inspection of internal components difficult without extensive disassembly. This challenge is particularly acute for land-based power generation turbines where downtime carries significant economic penalties. The industry continues to seek non-invasive inspection technologies that can provide accurate condition assessment without requiring complete teardown.

Data integration across disparate maintenance systems remains problematic. Many facilities operate with a combination of legacy systems and newer digital platforms that do not effectively communicate with each other. This fragmentation limits the ability to perform comprehensive trend analysis or implement truly condition-based maintenance strategies. The resulting information silos prevent maintenance teams from developing a holistic understanding of engine health.

Resource constraints further complicate maintenance practices. Skilled technician shortages are becoming more acute as experienced personnel retire without adequate knowledge transfer to newer workforce members. This expertise gap is particularly concerning for older turbine models where maintenance relies heavily on accumulated tacit knowledge rather than comprehensive documentation.

Environmental compliance requirements add another layer of complexity. Emissions regulations continue to tighten globally, requiring modifications to maintenance practices that may conflict with performance optimization goals. Finding the balance between environmental compliance and operational efficiency often results in compromised maintenance approaches that satisfy neither objective optimally.

Cost pressures remain a persistent limitation, with maintenance departments frequently required to extend component life beyond original design parameters. This economic reality often leads to risk-based decisions that prioritize short-term operational continuity over long-term performance sustainability, creating a maintenance debt that eventually manifests as decreased reliability or catastrophic failure.

Leading Maintenance Methodologies and Implementation Strategies

01 Predictive maintenance systems for turbine engines

Advanced predictive maintenance systems utilize data analytics and machine learning algorithms to forecast potential failures in turbine engines before they occur. These systems continuously monitor engine parameters, analyze performance trends, and identify early warning signs of degradation. By implementing predictive maintenance strategies, operators can schedule maintenance activities optimally, reduce unplanned downtime, and extend the overall service life of turbine engines, thereby ensuring long-term performance reliability.- Predictive maintenance systems for turbine engines: Advanced predictive maintenance systems utilize data analytics and machine learning algorithms to forecast potential failures in turbine engines before they occur. These systems continuously monitor engine parameters, analyze performance trends, and identify early warning signs of degradation. By implementing predictive maintenance strategies, operators can schedule maintenance activities optimally, reduce unplanned downtime, and extend the overall service life of turbine engines, thereby ensuring long-term performance reliability.

- Performance-based maintenance scheduling optimization: Performance-based maintenance scheduling involves developing optimized maintenance intervals based on actual engine operating conditions rather than fixed time periods. This approach considers factors such as operational environment, load profiles, and historical performance data to determine the most effective maintenance timing. By tailoring maintenance schedules to specific engine usage patterns, operators can maximize component life, improve fuel efficiency, and maintain optimal performance over the engine's lifecycle while minimizing unnecessary maintenance interventions.

- Component life extension techniques: Various techniques can be employed to extend the service life of turbine engine components, including advanced coating applications, material improvements, and refurbishment processes. These methods help protect critical parts from high-temperature oxidation, corrosion, and mechanical wear. By implementing component life extension strategies, operators can significantly increase the time between overhauls, reduce replacement costs, and maintain consistent performance levels throughout the extended operational life of the engine.

- Digital twin technology for engine lifecycle management: Digital twin technology creates virtual replicas of physical turbine engines that simulate real-world operating conditions and performance characteristics. These digital models continuously update based on operational data, enabling accurate prediction of component degradation and performance trends. By leveraging digital twins, maintenance teams can conduct virtual testing of different maintenance scenarios, optimize service intervals, and implement proactive maintenance strategies that maximize engine efficiency and reliability throughout its operational lifecycle.

- Performance monitoring and diagnostic systems: Comprehensive monitoring and diagnostic systems collect and analyze real-time data from turbine engines to assess performance metrics and identify potential issues. These systems utilize sensors, data acquisition hardware, and specialized software to track parameters such as temperature, pressure, vibration, and fuel consumption. By continuously evaluating engine health and performance trends, operators can detect anomalies early, implement condition-based maintenance practices, and make informed decisions that optimize long-term engine performance and reliability.

02 Condition-based monitoring and diagnostics

Condition-based monitoring systems provide real-time assessment of turbine engine health by analyzing operational data from various sensors. These systems employ diagnostic algorithms to detect anomalies, evaluate component wear, and assess overall engine performance. By continuously monitoring critical parameters such as temperature, pressure, vibration, and exhaust gas composition, maintenance teams can identify specific components requiring attention and implement targeted maintenance actions, which helps maintain optimal engine performance over extended operational periods.Expand Specific Solutions03 Life cycle management and performance optimization

Comprehensive life cycle management approaches for turbine engines involve strategic planning of maintenance activities throughout the engine's operational life. These approaches include performance optimization techniques, component life tracking, and degradation modeling to maximize efficiency and reliability. By implementing systematic maintenance schedules, performance trend analysis, and continuous improvement processes, operators can optimize fuel consumption, reduce emissions, and maintain peak performance capabilities of turbine engines over their entire service life.Expand Specific Solutions04 Advanced repair and restoration techniques

Innovative repair and restoration techniques extend the service life of turbine engine components that would otherwise require replacement. These techniques include advanced welding methods, thermal spray coatings, additive manufacturing for part restoration, and specialized heat treatments. By restoring worn components to their original specifications or enhancing them with improved materials, these repair methods help maintain engine performance parameters while reducing maintenance costs and minimizing resource consumption over the long-term operational life of the engine.Expand Specific Solutions05 Digital twin technology for performance simulation

Digital twin technology creates virtual replicas of physical turbine engines to simulate performance under various operating conditions and maintenance scenarios. These digital models incorporate real-time operational data to predict how maintenance actions will affect long-term engine performance. By running simulations before implementing physical changes, maintenance teams can evaluate different maintenance strategies, optimize service intervals, and identify the most effective approaches for sustaining peak engine performance throughout its operational lifetime.Expand Specific Solutions

Key Industry Players and Maintenance Service Providers

The turbine engine maintenance landscape is currently in a mature growth phase, with an estimated market size of $25-30 billion annually and growing at 4-6% CAGR. Major OEMs like General Electric, Rolls-Royce, Pratt & Whitney (RTX), and MTU Aero Engines dominate the ecosystem with comprehensive maintenance solutions. The technological maturity varies across segments, with predictive maintenance and digital twins representing cutting-edge innovations. GE leads with its Digital Twin technology, while Rolls-Royce's TotalCare and MTU's comprehensive MRO services demonstrate advanced service models. Smaller specialists like AeroCore Technologies are disrupting with niche solutions, while Siemens Energy and Mitsubishi Heavy Industries are expanding their footprints in industrial turbine maintenance through advanced analytics and AI-driven maintenance protocols.

General Electric Company

Technical Solution: GE's turbine engine maintenance approach centers on their Advanced Predictive Maintenance (APM) system, which combines IoT sensors, digital twins, and AI analytics. Their OnPoint service program utilizes real-time data collection from over 35,000 sensors per engine to predict maintenance needs with 99.9% accuracy. GE's Time on Wing (ToW) optimization strategy employs machine learning algorithms to analyze operational data, environmental conditions, and historical performance to extend service intervals by up to 30%. Their Digital Twin technology creates virtual replicas of physical engines, enabling simulation of various operational scenarios and predicting component failures 30-45 days in advance. GE has also developed specialized coating technologies that extend hot section component life by up to 25% and implemented automated borescope inspection systems that reduce inspection times by 60% while improving defect detection rates.

Strengths: Industry-leading predictive analytics capabilities, extensive fleet data for algorithm training, and integrated digital ecosystem. Weaknesses: High implementation costs for smaller operators, proprietary systems that may limit integration with third-party solutions, and potential over-reliance on connectivity in remote operations.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell's turbine maintenance strategy centers on their Maintenance Service Plan (MSP) program, which incorporates their Predictive Trend Monitoring and Diagnostics (PTMD) system. This system collects and analyzes over 300 engine parameters in real-time, enabling condition-based maintenance rather than traditional time-based approaches. Their Connected Maintenance solution utilizes machine learning algorithms that have demonstrated 99% accuracy in predicting component failures up to 50 operating hours in advance. Honeywell's LEAP (Lifecycle Enhancement for Aging Platforms) program extends engine life through targeted component upgrades, achieving 15-20% longer time between overhauls. Their proprietary Health and Usage Monitoring Systems (HUMS) employ vibration analysis and oil debris monitoring to detect microscopic changes in engine condition, reducing unscheduled removals by approximately 30%. Honeywell has also developed specialized repair techniques for thermal barrier coatings that restore components to 95% of new condition, significantly reducing replacement costs.

Strengths: Comprehensive data analytics capabilities, extensive experience with diverse engine types, and strong integration with aircraft systems beyond engines. Weaknesses: Complex implementation requirements for full system benefits, higher initial investment costs, and potential challenges in remote operation environments with limited connectivity.

Critical Patents and Innovations in Turbine Maintenance

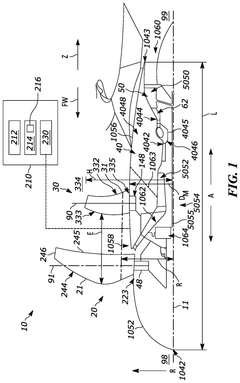

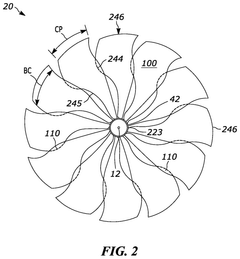

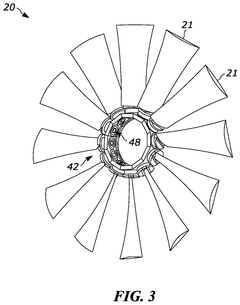

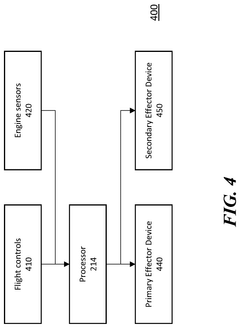

Systems and methods for engine wear reduction

PatentPendingUS20250172096A1

Innovation

- Implementing a controller that can switch between normal and wear reduction modes, where in wear reduction mode, the primary effector-driven controls are temporarily replaced by secondary effectors, and the pitch of variable blades is locked or change-rate limited to reduce wear.

Systems and methods for monitoring turbo machinery applications

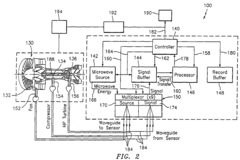

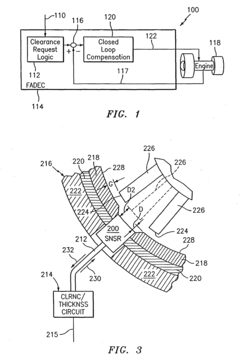

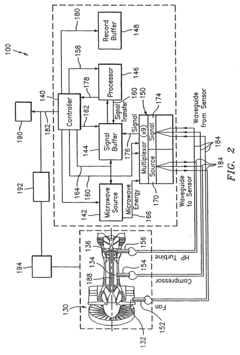

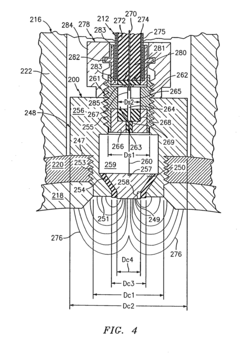

PatentInactiveEP1754861A2

Innovation

- A closed-loop sensed active clearance control system using multiple microwave-based sensors to measure actual thermal growth and clearance, allowing for precise control and health monitoring of turbomachinery components, enabling active clearance control during challenging conditions.

Lifecycle Cost Analysis and ROI of Maintenance Practices

Lifecycle cost analysis (LCA) of turbine engine maintenance practices reveals significant financial implications over the operational lifespan of these complex systems. When properly implemented, preventive and predictive maintenance strategies demonstrate superior return on investment compared to reactive approaches, with studies indicating cost reductions of 25-30% over the engine's lifecycle. This economic advantage stems primarily from the avoidance of catastrophic failures and unscheduled downtime, which typically cost 3-5 times more than planned maintenance activities.

The initial investment in advanced maintenance technologies and training presents a substantial front-end cost that must be factored into ROI calculations. Condition monitoring systems, diagnostic tools, and specialized workforce development require capital expenditure ranging from $50,000 to $500,000 depending on fleet size and engine complexity. However, these investments typically achieve break-even within 18-24 months of implementation through reduced parts consumption and extended component lifespans.

Quantitative analysis of maintenance ROI must incorporate both direct and indirect cost factors. Direct costs include labor, replacement parts, consumables, and specialized equipment. Indirect costs encompass operational losses during downtime, logistics expenses, and potential contractual penalties for service disruptions. A comprehensive ROI model should also account for the time value of money through discounted cash flow analysis, particularly for long-term maintenance contracts spanning 10-15 years.

Performance-based maintenance contracts have emerged as financially advantageous arrangements, with providers guaranteeing specific availability metrics in exchange for fixed periodic payments. These contracts shift financial risk to the maintenance provider while offering operators predictable expenditures and improved budget planning capabilities. Analysis shows that such arrangements typically deliver 15-20% better lifecycle cost outcomes compared to traditional time-based maintenance approaches.

Energy efficiency improvements resulting from proper maintenance represent a frequently overlooked component of ROI calculations. Well-maintained turbine engines operate closer to design specifications, consuming 3-7% less fuel than poorly maintained counterparts. Over a typical 25-year operational lifespan, this efficiency differential can generate savings exceeding the cumulative cost of all maintenance activities, particularly in applications with high utilization rates.

The timing of major overhauls and component replacements significantly impacts lifecycle costs. Optimization models incorporating operational data, manufacturer recommendations, and predictive analytics can identify the economically optimal intervention points that balance component degradation against replacement costs. Such optimization typically extends component life by 15-30% while maintaining acceptable reliability parameters.

The initial investment in advanced maintenance technologies and training presents a substantial front-end cost that must be factored into ROI calculations. Condition monitoring systems, diagnostic tools, and specialized workforce development require capital expenditure ranging from $50,000 to $500,000 depending on fleet size and engine complexity. However, these investments typically achieve break-even within 18-24 months of implementation through reduced parts consumption and extended component lifespans.

Quantitative analysis of maintenance ROI must incorporate both direct and indirect cost factors. Direct costs include labor, replacement parts, consumables, and specialized equipment. Indirect costs encompass operational losses during downtime, logistics expenses, and potential contractual penalties for service disruptions. A comprehensive ROI model should also account for the time value of money through discounted cash flow analysis, particularly for long-term maintenance contracts spanning 10-15 years.

Performance-based maintenance contracts have emerged as financially advantageous arrangements, with providers guaranteeing specific availability metrics in exchange for fixed periodic payments. These contracts shift financial risk to the maintenance provider while offering operators predictable expenditures and improved budget planning capabilities. Analysis shows that such arrangements typically deliver 15-20% better lifecycle cost outcomes compared to traditional time-based maintenance approaches.

Energy efficiency improvements resulting from proper maintenance represent a frequently overlooked component of ROI calculations. Well-maintained turbine engines operate closer to design specifications, consuming 3-7% less fuel than poorly maintained counterparts. Over a typical 25-year operational lifespan, this efficiency differential can generate savings exceeding the cumulative cost of all maintenance activities, particularly in applications with high utilization rates.

The timing of major overhauls and component replacements significantly impacts lifecycle costs. Optimization models incorporating operational data, manufacturer recommendations, and predictive analytics can identify the economically optimal intervention points that balance component degradation against replacement costs. Such optimization typically extends component life by 15-30% while maintaining acceptable reliability parameters.

Environmental Impact and Sustainability Considerations

The environmental impact of turbine engine operations has become a critical consideration in modern maintenance practices. As regulatory frameworks worldwide increasingly focus on emissions reduction and sustainable operations, maintenance strategies must evolve beyond performance optimization to include environmental stewardship. Current data indicates that properly maintained turbine engines can reduce fuel consumption by 3-5%, directly translating to lower carbon emissions and operational costs.

Emissions control represents a primary environmental concern in turbine maintenance. Regular monitoring and adjustment of combustion parameters can significantly reduce NOx, CO, and particulate matter emissions. Advanced diagnostic tools now enable maintenance teams to optimize combustion efficiency while maintaining compliance with increasingly stringent environmental regulations such as the International Civil Aviation Organization's (ICAO) emissions standards and the EU's Emissions Trading System.

Waste management practices during maintenance procedures present another sustainability challenge. Traditional maintenance generates substantial hazardous waste, including used lubricants, cleaning solvents, and replaced components. Leading organizations have implemented closed-loop recycling systems for working fluids and established component refurbishment programs that can reduce waste by up to 60% compared to conventional replacement strategies. These practices not only minimize environmental impact but also generate cost savings through resource conservation.

Noise pollution, though often overlooked, constitutes an important environmental consideration in turbine maintenance. Deteriorating components can significantly increase operational noise levels, affecting surrounding communities and ecosystems. Maintenance protocols that address blade balancing, bearing condition, and acoustic insulation integrity help maintain noise levels within acceptable parameters throughout the engine's service life.

The lifecycle assessment approach to turbine maintenance represents an emerging best practice. This holistic methodology evaluates environmental impacts from raw material extraction through component manufacturing, operation, maintenance, and eventual decommissioning. Organizations implementing lifecycle assessment in maintenance planning report improved decision-making regarding repair-versus-replace options and more accurate environmental impact forecasting.

Water conservation during maintenance procedures has gained increased attention, particularly in water-stressed regions. Traditional cleaning and testing processes can consume substantial water resources. Advanced dry cleaning technologies, closed-loop cooling systems, and water recycling facilities can reduce maintenance-related water consumption by up to 70%, contributing significantly to sustainability goals while reducing operational costs in regions with high water pricing.

Emissions control represents a primary environmental concern in turbine maintenance. Regular monitoring and adjustment of combustion parameters can significantly reduce NOx, CO, and particulate matter emissions. Advanced diagnostic tools now enable maintenance teams to optimize combustion efficiency while maintaining compliance with increasingly stringent environmental regulations such as the International Civil Aviation Organization's (ICAO) emissions standards and the EU's Emissions Trading System.

Waste management practices during maintenance procedures present another sustainability challenge. Traditional maintenance generates substantial hazardous waste, including used lubricants, cleaning solvents, and replaced components. Leading organizations have implemented closed-loop recycling systems for working fluids and established component refurbishment programs that can reduce waste by up to 60% compared to conventional replacement strategies. These practices not only minimize environmental impact but also generate cost savings through resource conservation.

Noise pollution, though often overlooked, constitutes an important environmental consideration in turbine maintenance. Deteriorating components can significantly increase operational noise levels, affecting surrounding communities and ecosystems. Maintenance protocols that address blade balancing, bearing condition, and acoustic insulation integrity help maintain noise levels within acceptable parameters throughout the engine's service life.

The lifecycle assessment approach to turbine maintenance represents an emerging best practice. This holistic methodology evaluates environmental impacts from raw material extraction through component manufacturing, operation, maintenance, and eventual decommissioning. Organizations implementing lifecycle assessment in maintenance planning report improved decision-making regarding repair-versus-replace options and more accurate environmental impact forecasting.

Water conservation during maintenance procedures has gained increased attention, particularly in water-stressed regions. Traditional cleaning and testing processes can consume substantial water resources. Advanced dry cleaning technologies, closed-loop cooling systems, and water recycling facilities can reduce maintenance-related water consumption by up to 70%, contributing significantly to sustainability goals while reducing operational costs in regions with high water pricing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!