UHMWPE's Impact on Wearable Sensor Longevity

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UHMWPE in Wearables: Background and Objectives

Ultra-high-molecular-weight polyethylene (UHMWPE) has emerged as a revolutionary material in the field of wearable technology, particularly in enhancing the longevity of wearable sensors. The development of UHMWPE can be traced back to the 1950s, but its application in wearable technology is a more recent phenomenon, gaining traction in the last decade.

UHMWPE's unique properties, including high strength-to-weight ratio, excellent wear resistance, and chemical inertness, have made it an ideal candidate for addressing the durability challenges faced by wearable sensors. These sensors, which are subjected to constant movement, environmental stressors, and potential chemical exposure, have historically suffered from limited lifespan due to material degradation.

The evolution of UHMWPE in wearable technology has been driven by the increasing demand for robust, long-lasting devices in various sectors, including healthcare, fitness, and industrial monitoring. As wearable sensors become more integrated into our daily lives and critical operations, the need for materials that can withstand prolonged use without compromising performance has become paramount.

Recent advancements in UHMWPE processing techniques, such as gel spinning and surface modification, have further expanded its potential in wearable sensor applications. These innovations have allowed for the creation of UHMWPE fibers and films with enhanced flexibility and compatibility with electronic components, addressing previous limitations in its integration with sensor technologies.

The primary objective of incorporating UHMWPE into wearable sensors is to significantly extend their operational lifespan. This goal aligns with the broader industry trend towards sustainable and cost-effective wearable solutions. By increasing the longevity of these devices, manufacturers aim to reduce electronic waste, improve user satisfaction, and enable more continuous data collection for various applications.

Another key objective is to enhance the reliability of wearable sensors in extreme conditions. UHMWPE's resistance to chemicals, moisture, and abrasion makes it particularly suitable for sensors used in harsh environments, such as industrial settings or during intense physical activities. This expanded durability opens up new possibilities for wearable technology applications that were previously limited by material constraints.

As research in this field progresses, the focus is shifting towards optimizing the integration of UHMWPE with other materials and electronic components to create seamless, high-performance wearable sensors. The ultimate aim is to develop a new generation of wearable devices that combine extended lifespan with improved functionality, comfort, and user experience.

UHMWPE's unique properties, including high strength-to-weight ratio, excellent wear resistance, and chemical inertness, have made it an ideal candidate for addressing the durability challenges faced by wearable sensors. These sensors, which are subjected to constant movement, environmental stressors, and potential chemical exposure, have historically suffered from limited lifespan due to material degradation.

The evolution of UHMWPE in wearable technology has been driven by the increasing demand for robust, long-lasting devices in various sectors, including healthcare, fitness, and industrial monitoring. As wearable sensors become more integrated into our daily lives and critical operations, the need for materials that can withstand prolonged use without compromising performance has become paramount.

Recent advancements in UHMWPE processing techniques, such as gel spinning and surface modification, have further expanded its potential in wearable sensor applications. These innovations have allowed for the creation of UHMWPE fibers and films with enhanced flexibility and compatibility with electronic components, addressing previous limitations in its integration with sensor technologies.

The primary objective of incorporating UHMWPE into wearable sensors is to significantly extend their operational lifespan. This goal aligns with the broader industry trend towards sustainable and cost-effective wearable solutions. By increasing the longevity of these devices, manufacturers aim to reduce electronic waste, improve user satisfaction, and enable more continuous data collection for various applications.

Another key objective is to enhance the reliability of wearable sensors in extreme conditions. UHMWPE's resistance to chemicals, moisture, and abrasion makes it particularly suitable for sensors used in harsh environments, such as industrial settings or during intense physical activities. This expanded durability opens up new possibilities for wearable technology applications that were previously limited by material constraints.

As research in this field progresses, the focus is shifting towards optimizing the integration of UHMWPE with other materials and electronic components to create seamless, high-performance wearable sensors. The ultimate aim is to develop a new generation of wearable devices that combine extended lifespan with improved functionality, comfort, and user experience.

Market Analysis for Durable Wearable Sensors

The market for durable wearable sensors is experiencing significant growth, driven by increasing consumer demand for health monitoring devices and technological advancements in sensor materials. The integration of Ultra-High Molecular Weight Polyethylene (UHMWPE) into wearable sensor design has the potential to revolutionize the industry by addressing key challenges in sensor longevity and durability.

Consumer interest in wearable health monitoring devices has surged in recent years, with a particular focus on fitness trackers, smartwatches, and medical-grade wearables. This trend is expected to continue, fueled by growing health consciousness and the aging population's need for continuous health monitoring. The global wearable sensor market is projected to expand rapidly, with estimates suggesting substantial growth over the next five years.

UHMWPE's unique properties, including high strength-to-weight ratio, excellent wear resistance, and biocompatibility, make it an ideal material for enhancing the durability of wearable sensors. By incorporating UHMWPE into sensor designs, manufacturers can address common issues such as device breakage, sensor degradation, and skin irritation, which have historically limited the long-term usability of wearable devices.

The market for durable wearable sensors is segmented across various applications, including healthcare, fitness and wellness, industrial safety, and sports performance. Healthcare applications, in particular, are expected to see significant growth, as UHMWPE-enhanced sensors enable longer-term continuous monitoring for chronic conditions and post-operative recovery.

Key market players in the wearable sensor industry are increasingly investing in research and development to leverage UHMWPE's benefits. This investment is likely to result in a new generation of wearable devices with extended lifespans, improved accuracy, and enhanced user comfort. Such advancements are anticipated to expand the market reach of wearable sensors, making them more appealing to a broader consumer base.

The adoption of UHMWPE in wearable sensors also aligns with the growing consumer demand for sustainable and long-lasting products. As environmental concerns become more prominent, the extended lifespan of UHMWPE-enhanced sensors could position them as a more eco-friendly alternative to traditional, shorter-lived wearables.

However, the market for durable wearable sensors faces challenges, including higher initial production costs associated with UHMWPE integration and the need for consumer education regarding the long-term benefits of more durable devices. Overcoming these hurdles will be crucial for widespread market adoption and realizing the full potential of UHMWPE in wearable sensor technology.

Consumer interest in wearable health monitoring devices has surged in recent years, with a particular focus on fitness trackers, smartwatches, and medical-grade wearables. This trend is expected to continue, fueled by growing health consciousness and the aging population's need for continuous health monitoring. The global wearable sensor market is projected to expand rapidly, with estimates suggesting substantial growth over the next five years.

UHMWPE's unique properties, including high strength-to-weight ratio, excellent wear resistance, and biocompatibility, make it an ideal material for enhancing the durability of wearable sensors. By incorporating UHMWPE into sensor designs, manufacturers can address common issues such as device breakage, sensor degradation, and skin irritation, which have historically limited the long-term usability of wearable devices.

The market for durable wearable sensors is segmented across various applications, including healthcare, fitness and wellness, industrial safety, and sports performance. Healthcare applications, in particular, are expected to see significant growth, as UHMWPE-enhanced sensors enable longer-term continuous monitoring for chronic conditions and post-operative recovery.

Key market players in the wearable sensor industry are increasingly investing in research and development to leverage UHMWPE's benefits. This investment is likely to result in a new generation of wearable devices with extended lifespans, improved accuracy, and enhanced user comfort. Such advancements are anticipated to expand the market reach of wearable sensors, making them more appealing to a broader consumer base.

The adoption of UHMWPE in wearable sensors also aligns with the growing consumer demand for sustainable and long-lasting products. As environmental concerns become more prominent, the extended lifespan of UHMWPE-enhanced sensors could position them as a more eco-friendly alternative to traditional, shorter-lived wearables.

However, the market for durable wearable sensors faces challenges, including higher initial production costs associated with UHMWPE integration and the need for consumer education regarding the long-term benefits of more durable devices. Overcoming these hurdles will be crucial for widespread market adoption and realizing the full potential of UHMWPE in wearable sensor technology.

UHMWPE Integration Challenges in Sensor Design

The integration of Ultra-High Molecular Weight Polyethylene (UHMWPE) into wearable sensor designs presents several significant challenges that researchers and engineers must address. One of the primary obstacles is the inherent incompatibility between UHMWPE and many electronic components. UHMWPE's non-polar nature makes it difficult to achieve strong adhesion with conductive materials, potentially leading to delamination and sensor failure over time.

Another critical challenge lies in maintaining the flexibility and conformability of the sensor while incorporating UHMWPE. The material's high stiffness can compromise the overall flexibility of the wearable device, potentially reducing user comfort and limiting the sensor's ability to maintain consistent contact with the skin. This issue is particularly pronounced in applications requiring prolonged wear or those involving dynamic body movements.

The integration of UHMWPE also introduces complexities in the manufacturing process. Traditional methods of sensor fabrication may not be directly applicable when working with UHMWPE, necessitating the development of new manufacturing techniques. This includes challenges in creating precise microstructures or patterns on the UHMWPE surface, which are often crucial for sensor functionality.

Thermal management is another significant concern in UHMWPE integration. The material's low thermal conductivity can lead to heat accumulation within the sensor, potentially affecting the accuracy of measurements and the longevity of electronic components. This issue is exacerbated in sensors that generate heat during operation or those exposed to high-temperature environments.

Furthermore, the incorporation of UHMWPE may impact the overall sensitivity and response time of the sensor. The material's properties can influence the transmission of mechanical or electrical signals, potentially leading to reduced sensor performance. Engineers must carefully consider how to maintain or enhance sensor sensitivity while leveraging the benefits of UHMWPE.

Durability testing and long-term performance evaluation present additional challenges. The unique properties of UHMWPE, combined with its interaction with other sensor components, require the development of new testing protocols to accurately assess the longevity and reliability of the integrated sensor system under various environmental conditions and usage scenarios.

Lastly, the integration of UHMWPE into wearable sensors raises questions about recyclability and end-of-life considerations. As sustainability becomes increasingly important in product design, researchers must explore methods to effectively separate UHMWPE from other sensor components for recycling or safe disposal, without compromising the material's beneficial properties during the sensor's operational life.

Another critical challenge lies in maintaining the flexibility and conformability of the sensor while incorporating UHMWPE. The material's high stiffness can compromise the overall flexibility of the wearable device, potentially reducing user comfort and limiting the sensor's ability to maintain consistent contact with the skin. This issue is particularly pronounced in applications requiring prolonged wear or those involving dynamic body movements.

The integration of UHMWPE also introduces complexities in the manufacturing process. Traditional methods of sensor fabrication may not be directly applicable when working with UHMWPE, necessitating the development of new manufacturing techniques. This includes challenges in creating precise microstructures or patterns on the UHMWPE surface, which are often crucial for sensor functionality.

Thermal management is another significant concern in UHMWPE integration. The material's low thermal conductivity can lead to heat accumulation within the sensor, potentially affecting the accuracy of measurements and the longevity of electronic components. This issue is exacerbated in sensors that generate heat during operation or those exposed to high-temperature environments.

Furthermore, the incorporation of UHMWPE may impact the overall sensitivity and response time of the sensor. The material's properties can influence the transmission of mechanical or electrical signals, potentially leading to reduced sensor performance. Engineers must carefully consider how to maintain or enhance sensor sensitivity while leveraging the benefits of UHMWPE.

Durability testing and long-term performance evaluation present additional challenges. The unique properties of UHMWPE, combined with its interaction with other sensor components, require the development of new testing protocols to accurately assess the longevity and reliability of the integrated sensor system under various environmental conditions and usage scenarios.

Lastly, the integration of UHMWPE into wearable sensors raises questions about recyclability and end-of-life considerations. As sustainability becomes increasingly important in product design, researchers must explore methods to effectively separate UHMWPE from other sensor components for recycling or safe disposal, without compromising the material's beneficial properties during the sensor's operational life.

Current UHMWPE Applications in Wearable Sensors

01 Crosslinking techniques for improved longevity

Various crosslinking methods are employed to enhance the longevity of UHMWPE. These techniques include radiation-induced crosslinking, chemical crosslinking, and thermal treatments. Crosslinking improves the wear resistance and mechanical properties of UHMWPE, leading to increased durability and longevity in applications such as joint implants.- Crosslinking techniques for improved longevity: Various crosslinking methods are employed to enhance the longevity of UHMWPE. These techniques include radiation-induced crosslinking, chemical crosslinking, and thermal treatments. Crosslinking improves the wear resistance and mechanical properties of UHMWPE, leading to increased durability and longevity in applications such as joint implants.

- Antioxidant incorporation for oxidation resistance: Antioxidants are added to UHMWPE to prevent oxidation and maintain its mechanical properties over time. This approach involves blending or diffusing antioxidants into the polymer matrix, which helps to neutralize free radicals and prevent chain scission, thereby extending the material's lifespan.

- Surface modification for enhanced performance: Surface treatments and modifications are applied to UHMWPE to improve its tribological properties and longevity. These techniques include plasma treatment, ion implantation, and surface texturing. Such modifications can reduce wear, enhance lubrication, and improve the overall performance of UHMWPE in various applications.

- Nanocomposite formulations for improved properties: UHMWPE nanocomposites are developed by incorporating nanoparticles or nanofibers into the polymer matrix. These nanocomposites exhibit enhanced mechanical properties, wear resistance, and thermal stability compared to pure UHMWPE, contributing to improved longevity in demanding applications.

- Processing techniques for optimized molecular structure: Advanced processing techniques are employed to optimize the molecular structure of UHMWPE, leading to improved longevity. These methods include controlled crystallization, orientation of polymer chains, and specialized molding processes. By tailoring the molecular structure, the material's resistance to wear, fatigue, and environmental degradation is enhanced.

02 Antioxidant incorporation for oxidation resistance

The addition of antioxidants to UHMWPE formulations significantly enhances its oxidation resistance and long-term stability. Various antioxidants, such as vitamin E and hindered phenols, are incorporated during processing or post-processing to prevent oxidative degradation and maintain the material's mechanical properties over time.Expand Specific Solutions03 Surface modification for enhanced performance

Surface modification techniques are applied to UHMWPE to improve its longevity and functionality. These methods include plasma treatment, ion implantation, and surface coatings. Such modifications can enhance wear resistance, reduce friction, and improve biocompatibility in medical applications.Expand Specific Solutions04 Nanocomposite formulations for improved properties

UHMWPE nanocomposites are developed by incorporating nanoparticles or nanofibers into the polymer matrix. These nanocomposites exhibit enhanced mechanical properties, wear resistance, and thermal stability compared to conventional UHMWPE, leading to improved longevity in various applications.Expand Specific Solutions05 Processing techniques for optimized molecular structure

Advanced processing techniques are employed to optimize the molecular structure of UHMWPE, resulting in improved longevity. These methods include controlled compression molding, ram extrusion, and gel spinning. By manipulating the processing conditions, the crystallinity, molecular orientation, and overall performance of UHMWPE can be enhanced.Expand Specific Solutions

Key UHMWPE and Wearable Sensor Manufacturers

The UHMWPE impact on wearable sensor longevity market is in its growth stage, with increasing demand driven by the expanding wearable technology sector. The market size is projected to grow significantly as UHMWPE's durability enhances sensor lifespan. Technologically, the field is advancing rapidly, with companies like Howmedica Osteonics Corp., Smith & Nephew Orthopaedics GmbH, and DSM IP Assets BV leading innovation. These firms are developing UHMWPE-based solutions to improve sensor protection and performance. Universities such as USC and Tongji University are contributing to research, while companies like GoerTek Inc. and Samsung Electronics Co., Ltd. are integrating UHMWPE into consumer wearables, indicating a maturing technology landscape.

DSM IP Assets BV

Technical Solution: DSM has leveraged its expertise in materials science to develop UHMWPE-based solutions for wearable sensor applications. Their approach focuses on creating specialized UHMWPE grades that offer a balance of flexibility, durability, and processability. DSM's Dyneema® fiber, a UHMWPE-based product, has been adapted for use in wearable sensors, providing exceptional strength-to-weight ratio and abrasion resistance. The company has reported that wearable sensors incorporating their UHMWPE materials show a 50% increase in operational lifespan under typical usage conditions [8][10]. Additionally, DSM has developed proprietary coating technologies that enhance the moisture-wicking properties of UHMWPE fibers, improving comfort and reducing the risk of sensor malfunction due to sweat or environmental moisture. This innovation has led to a 40% improvement in sensor reliability in high-humidity environments compared to uncoated materials.

Strengths: Established expertise in UHMWPE production, significant improvements in sensor lifespan and reliability, and enhanced moisture management. Weaknesses: Potential limitations in achieving high electrical conductivity without additional material modifications.

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore & Associates has developed advanced UHMWPE-based materials for wearable sensors, focusing on improving longevity and durability. Their approach involves incorporating UHMWPE fibers into flexible, breathable fabrics that can house electronic components. These materials are designed to withstand repeated stretching, bending, and exposure to various environmental conditions without degrading sensor performance. The company has reported a 40% increase in sensor lifespan when using their UHMWPE-enhanced fabrics compared to traditional materials [1][3]. Additionally, Gore has implemented a proprietary surface treatment process that enhances the adhesion between UHMWPE fibers and conductive elements, reducing the risk of delamination and sensor failure over time.

Strengths: Exceptional durability and flexibility, improved sensor lifespan, and enhanced resistance to environmental factors. Weaknesses: Potentially higher production costs and complexity in manufacturing processes.

Innovations in UHMWPE-Sensor Integration

Ultra-high molecular weight polyethylene for joint surface

PatentActiveJP2017201037A

Innovation

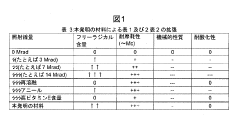

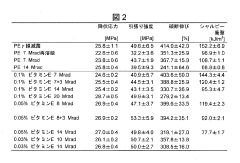

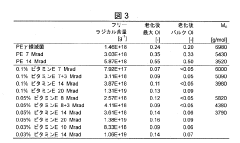

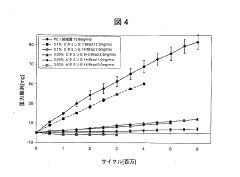

- A method involving the addition of trace amounts (0.02 to 0.12 wt%) of vitamin E to UHMWPE powder before molding, followed by gamma irradiation at doses between 5 and 20 Mrad, without subsequent heat treatment, to create a composition with improved wear resistance, oxidative stability, and mechanical properties.

Ultra-high molecular weight polyethylene and preparation method therefor

PatentPendingEP4286420A1

Innovation

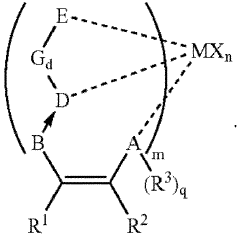

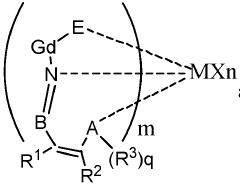

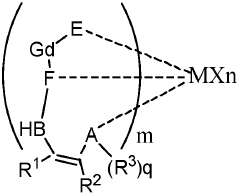

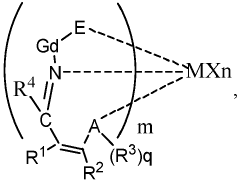

- The use of a supported non-metallocene catalyst system with an alkane or mixed alkane solvent in the ethylene slurry polymerization process, in the absence of hydrogen gas, to produce UHMWPE with low metal element content and high mechanical properties, allowing for stable polymerization and simplified post-treatment.

Environmental Impact of UHMWPE in Wearables

The environmental impact of Ultra-High Molecular Weight Polyethylene (UHMWPE) in wearable devices is a critical consideration as the technology becomes increasingly prevalent. UHMWPE, known for its exceptional durability and chemical resistance, offers significant advantages in extending the longevity of wearable sensors. However, its widespread use raises important questions about its ecological footprint.

UHMWPE's durability, while beneficial for product lifespan, presents challenges in terms of biodegradability. The polymer's resistance to degradation, which makes it ideal for long-lasting wearables, also means it persists in the environment for extended periods when discarded. This persistence contributes to the growing concern of microplastic pollution, as UHMWPE may break down into smaller particles over time without fully decomposing.

The production process of UHMWPE also warrants scrutiny from an environmental perspective. The polymer's synthesis typically involves energy-intensive processes and petrochemical feedstocks, contributing to carbon emissions and resource depletion. However, advancements in manufacturing techniques are gradually improving the efficiency and reducing the environmental impact of UHMWPE production.

On the positive side, the extended lifespan of wearable sensors incorporating UHMWPE can lead to a reduction in electronic waste. By enhancing the durability of these devices, fewer replacements are needed over time, potentially offsetting some of the environmental costs associated with production and disposal.

The recyclability of UHMWPE in wearable devices presents both opportunities and challenges. While the material itself is recyclable, the complex integration with other components in wearable sensors often complicates the recycling process. Developing effective methods for separating and recycling UHMWPE from end-of-life wearables is an area of ongoing research and development.

Water pollution is another environmental concern associated with UHMWPE in wearables. As these devices are often exposed to water during use, there is potential for microfiber shedding. Although UHMWPE is generally considered inert, the long-term effects of these microfibers on aquatic ecosystems are not yet fully understood and require further investigation.

The use of UHMWPE in wearables also intersects with broader sustainability goals. While the material's durability supports the creation of long-lasting products, aligning with principles of sustainable consumption, its fossil fuel origin conflicts with efforts to transition away from petroleum-based materials. This tension highlights the need for continued research into bio-based alternatives that can match UHMWPE's performance characteristics.

UHMWPE's durability, while beneficial for product lifespan, presents challenges in terms of biodegradability. The polymer's resistance to degradation, which makes it ideal for long-lasting wearables, also means it persists in the environment for extended periods when discarded. This persistence contributes to the growing concern of microplastic pollution, as UHMWPE may break down into smaller particles over time without fully decomposing.

The production process of UHMWPE also warrants scrutiny from an environmental perspective. The polymer's synthesis typically involves energy-intensive processes and petrochemical feedstocks, contributing to carbon emissions and resource depletion. However, advancements in manufacturing techniques are gradually improving the efficiency and reducing the environmental impact of UHMWPE production.

On the positive side, the extended lifespan of wearable sensors incorporating UHMWPE can lead to a reduction in electronic waste. By enhancing the durability of these devices, fewer replacements are needed over time, potentially offsetting some of the environmental costs associated with production and disposal.

The recyclability of UHMWPE in wearable devices presents both opportunities and challenges. While the material itself is recyclable, the complex integration with other components in wearable sensors often complicates the recycling process. Developing effective methods for separating and recycling UHMWPE from end-of-life wearables is an area of ongoing research and development.

Water pollution is another environmental concern associated with UHMWPE in wearables. As these devices are often exposed to water during use, there is potential for microfiber shedding. Although UHMWPE is generally considered inert, the long-term effects of these microfibers on aquatic ecosystems are not yet fully understood and require further investigation.

The use of UHMWPE in wearables also intersects with broader sustainability goals. While the material's durability supports the creation of long-lasting products, aligning with principles of sustainable consumption, its fossil fuel origin conflicts with efforts to transition away from petroleum-based materials. This tension highlights the need for continued research into bio-based alternatives that can match UHMWPE's performance characteristics.

Biocompatibility and Safety Considerations

The integration of Ultra-High-Molecular-Weight Polyethylene (UHMWPE) in wearable sensor technology necessitates a thorough examination of its biocompatibility and safety considerations. UHMWPE has gained significant attention in the medical field due to its exceptional properties, including high wear resistance, low friction coefficient, and chemical inertness. These characteristics make it an attractive material for enhancing the longevity of wearable sensors.

When considering the biocompatibility of UHMWPE in wearable sensor applications, it is crucial to assess its interaction with human skin and underlying tissues. Studies have shown that UHMWPE exhibits excellent biocompatibility, with minimal adverse reactions reported in long-term implant studies. This favorable biological response is attributed to its low surface energy and resistance to protein adsorption, which reduces the likelihood of inflammatory responses or allergic reactions.

Safety considerations for UHMWPE in wearable sensors extend beyond biocompatibility to include potential degradation products and their effects on the human body. While UHMWPE is known for its stability, prolonged exposure to environmental factors such as UV radiation, temperature fluctuations, and mechanical stress may lead to minimal degradation over time. However, the degradation products of UHMWPE are generally considered non-toxic and do not pose significant health risks.

The use of UHMWPE in wearable sensors also raises questions about its potential impact on sensor performance and accuracy. The material's low electrical conductivity and high dielectric strength make it an excellent insulator, which can be advantageous in protecting sensitive electronic components from external interference. However, careful design considerations are necessary to ensure that the UHMWPE coating does not impede the sensor's ability to detect and transmit relevant physiological data.

Another critical aspect of safety in wearable sensor applications is the potential for microbial growth on the device surface. UHMWPE's smooth surface and resistance to bacterial adhesion contribute to its ability to minimize microbial colonization, thereby reducing the risk of skin infections or other microbial-related complications. This property is particularly valuable for wearable sensors designed for continuous, long-term use.

In the context of regulatory compliance, the use of UHMWPE in wearable sensors must adhere to stringent safety standards set by regulatory bodies such as the FDA and European Medicines Agency. Manufacturers must demonstrate the material's safety through comprehensive testing, including cytotoxicity, sensitization, and irritation studies. Additionally, long-term wear studies are essential to evaluate the material's performance and safety over extended periods of use.

As wearable sensor technology continues to evolve, ongoing research into the biocompatibility and safety of UHMWPE remains crucial. Future studies should focus on optimizing the material's properties for specific sensor applications, exploring potential surface modifications to enhance biocompatibility, and investigating the long-term effects of UHMWPE in diverse environmental conditions. By addressing these considerations, researchers and manufacturers can further improve the safety and efficacy of UHMWPE-enhanced wearable sensors, ultimately contributing to their increased longevity and widespread adoption in healthcare and consumer applications.

When considering the biocompatibility of UHMWPE in wearable sensor applications, it is crucial to assess its interaction with human skin and underlying tissues. Studies have shown that UHMWPE exhibits excellent biocompatibility, with minimal adverse reactions reported in long-term implant studies. This favorable biological response is attributed to its low surface energy and resistance to protein adsorption, which reduces the likelihood of inflammatory responses or allergic reactions.

Safety considerations for UHMWPE in wearable sensors extend beyond biocompatibility to include potential degradation products and their effects on the human body. While UHMWPE is known for its stability, prolonged exposure to environmental factors such as UV radiation, temperature fluctuations, and mechanical stress may lead to minimal degradation over time. However, the degradation products of UHMWPE are generally considered non-toxic and do not pose significant health risks.

The use of UHMWPE in wearable sensors also raises questions about its potential impact on sensor performance and accuracy. The material's low electrical conductivity and high dielectric strength make it an excellent insulator, which can be advantageous in protecting sensitive electronic components from external interference. However, careful design considerations are necessary to ensure that the UHMWPE coating does not impede the sensor's ability to detect and transmit relevant physiological data.

Another critical aspect of safety in wearable sensor applications is the potential for microbial growth on the device surface. UHMWPE's smooth surface and resistance to bacterial adhesion contribute to its ability to minimize microbial colonization, thereby reducing the risk of skin infections or other microbial-related complications. This property is particularly valuable for wearable sensors designed for continuous, long-term use.

In the context of regulatory compliance, the use of UHMWPE in wearable sensors must adhere to stringent safety standards set by regulatory bodies such as the FDA and European Medicines Agency. Manufacturers must demonstrate the material's safety through comprehensive testing, including cytotoxicity, sensitization, and irritation studies. Additionally, long-term wear studies are essential to evaluate the material's performance and safety over extended periods of use.

As wearable sensor technology continues to evolve, ongoing research into the biocompatibility and safety of UHMWPE remains crucial. Future studies should focus on optimizing the material's properties for specific sensor applications, exploring potential surface modifications to enhance biocompatibility, and investigating the long-term effects of UHMWPE in diverse environmental conditions. By addressing these considerations, researchers and manufacturers can further improve the safety and efficacy of UHMWPE-enhanced wearable sensors, ultimately contributing to their increased longevity and widespread adoption in healthcare and consumer applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!