V16 engines as a testbed for anti-lock braking system (ABS) advancements

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V16 ABS Evolution

The evolution of V16 engines as a testbed for anti-lock braking system (ABS) advancements represents a fascinating intersection of automotive engineering and safety technology. This unique pairing has its roots in the early 1990s when high-performance luxury vehicles began incorporating more sophisticated braking systems to match their increased power output.

V16 engines, known for their smooth operation and immense power, provided an ideal platform for testing and refining ABS technologies. The extreme conditions created by these powerful engines, including high speeds and rapid acceleration, allowed engineers to push the boundaries of ABS capabilities. This symbiotic relationship between engine power and braking technology drove significant advancements in both fields.

Throughout the 1990s and early 2000s, the evolution of V16 ABS systems focused primarily on improving response times and reducing intervention thresholds. Engineers worked to develop more sensitive wheel speed sensors and faster-acting hydraulic units, capable of modulating brake pressure with greater precision. These improvements were crucial in maintaining vehicle stability during high-speed maneuvers and emergency braking situations.

As computational power increased, so did the sophistication of ABS algorithms. The V16 platform allowed for the implementation of more complex control strategies, taking into account not just wheel speed, but also factors such as lateral acceleration, yaw rate, and steering angle. This holistic approach to vehicle dynamics led to the development of integrated systems that combined ABS with traction control and electronic stability control.

The advent of drive-by-wire technology in the mid-2000s marked another significant milestone in V16 ABS evolution. This technology enabled even faster and more precise control over both engine output and braking force, further enhancing the synergy between power delivery and safety systems. It also paved the way for the introduction of advanced driver assistance features, such as autonomous emergency braking.

In recent years, the focus of V16 ABS development has shifted towards predictive systems and integration with other vehicle technologies. Machine learning algorithms are being employed to anticipate braking needs based on driver behavior, road conditions, and environmental factors. Additionally, the integration of ABS with regenerative braking systems in hybrid and electric vehicles has opened up new avenues for energy recovery and efficiency improvements.

The legacy of V16 engines as a testbed for ABS advancements continues to influence modern automotive safety systems. The lessons learned and technologies developed through this unique pairing have cascaded down to a wide range of vehicles, improving safety and performance across the automotive industry. As we move towards an era of autonomous vehicles, the principles established through V16 ABS evolution remain foundational to the development of advanced vehicle control systems.

V16 engines, known for their smooth operation and immense power, provided an ideal platform for testing and refining ABS technologies. The extreme conditions created by these powerful engines, including high speeds and rapid acceleration, allowed engineers to push the boundaries of ABS capabilities. This symbiotic relationship between engine power and braking technology drove significant advancements in both fields.

Throughout the 1990s and early 2000s, the evolution of V16 ABS systems focused primarily on improving response times and reducing intervention thresholds. Engineers worked to develop more sensitive wheel speed sensors and faster-acting hydraulic units, capable of modulating brake pressure with greater precision. These improvements were crucial in maintaining vehicle stability during high-speed maneuvers and emergency braking situations.

As computational power increased, so did the sophistication of ABS algorithms. The V16 platform allowed for the implementation of more complex control strategies, taking into account not just wheel speed, but also factors such as lateral acceleration, yaw rate, and steering angle. This holistic approach to vehicle dynamics led to the development of integrated systems that combined ABS with traction control and electronic stability control.

The advent of drive-by-wire technology in the mid-2000s marked another significant milestone in V16 ABS evolution. This technology enabled even faster and more precise control over both engine output and braking force, further enhancing the synergy between power delivery and safety systems. It also paved the way for the introduction of advanced driver assistance features, such as autonomous emergency braking.

In recent years, the focus of V16 ABS development has shifted towards predictive systems and integration with other vehicle technologies. Machine learning algorithms are being employed to anticipate braking needs based on driver behavior, road conditions, and environmental factors. Additionally, the integration of ABS with regenerative braking systems in hybrid and electric vehicles has opened up new avenues for energy recovery and efficiency improvements.

The legacy of V16 engines as a testbed for ABS advancements continues to influence modern automotive safety systems. The lessons learned and technologies developed through this unique pairing have cascaded down to a wide range of vehicles, improving safety and performance across the automotive industry. As we move towards an era of autonomous vehicles, the principles established through V16 ABS evolution remain foundational to the development of advanced vehicle control systems.

Market Demand Analysis

The market demand for anti-lock braking system (ABS) advancements using V16 engines as testbeds is driven by several key factors in the automotive industry. Primarily, the push for enhanced vehicle safety continues to be a major driver, with consumers and regulatory bodies alike demanding more sophisticated and reliable braking systems. The use of V16 engines as testbeds for ABS advancements offers a unique opportunity to develop and refine these systems under extreme conditions, potentially leading to breakthroughs in performance and reliability.

The luxury and high-performance vehicle segments, where V16 engines are most commonly found, represent a significant market for advanced ABS technologies. These segments are characterized by consumers who prioritize cutting-edge technology and are willing to pay premium prices for enhanced safety features. As such, there is a strong demand for ABS systems that can handle the power and weight of V16-equipped vehicles while providing optimal braking performance under various driving conditions.

Furthermore, the motorsport industry presents another substantial market for ABS advancements developed through V16 engine testbeds. Racing teams and manufacturers are constantly seeking ways to improve vehicle performance and safety, making them early adopters of innovative braking technologies. The extreme conditions encountered in motorsports provide an ideal testing ground for ABS systems, with potential applications extending to consumer vehicles.

The commercial vehicle sector, particularly in the heavy-duty truck and bus markets, also shows growing interest in advanced ABS technologies. While V16 engines are not common in this sector, the learnings from high-performance testbeds can be adapted to improve braking systems for large, powerful vehicles that require exceptional stopping power and stability.

Additionally, the increasing focus on autonomous and semi-autonomous vehicles has created a new demand for highly sophisticated ABS systems. These vehicles rely heavily on advanced braking technologies to ensure safe operation under various road conditions and potential emergency situations. The insights gained from V16 engine testbeds can contribute significantly to the development of ABS systems capable of meeting the stringent requirements of autonomous driving technologies.

The global ABS market is expected to grow steadily in the coming years, driven by these factors and the overall trend towards increased vehicle electrification and automation. While the specific market size for ABS advancements using V16 engines as testbeds is difficult to quantify, it represents a crucial niche within the broader ABS market, particularly in the high-end and performance vehicle segments.

The luxury and high-performance vehicle segments, where V16 engines are most commonly found, represent a significant market for advanced ABS technologies. These segments are characterized by consumers who prioritize cutting-edge technology and are willing to pay premium prices for enhanced safety features. As such, there is a strong demand for ABS systems that can handle the power and weight of V16-equipped vehicles while providing optimal braking performance under various driving conditions.

Furthermore, the motorsport industry presents another substantial market for ABS advancements developed through V16 engine testbeds. Racing teams and manufacturers are constantly seeking ways to improve vehicle performance and safety, making them early adopters of innovative braking technologies. The extreme conditions encountered in motorsports provide an ideal testing ground for ABS systems, with potential applications extending to consumer vehicles.

The commercial vehicle sector, particularly in the heavy-duty truck and bus markets, also shows growing interest in advanced ABS technologies. While V16 engines are not common in this sector, the learnings from high-performance testbeds can be adapted to improve braking systems for large, powerful vehicles that require exceptional stopping power and stability.

Additionally, the increasing focus on autonomous and semi-autonomous vehicles has created a new demand for highly sophisticated ABS systems. These vehicles rely heavily on advanced braking technologies to ensure safe operation under various road conditions and potential emergency situations. The insights gained from V16 engine testbeds can contribute significantly to the development of ABS systems capable of meeting the stringent requirements of autonomous driving technologies.

The global ABS market is expected to grow steadily in the coming years, driven by these factors and the overall trend towards increased vehicle electrification and automation. While the specific market size for ABS advancements using V16 engines as testbeds is difficult to quantify, it represents a crucial niche within the broader ABS market, particularly in the high-end and performance vehicle segments.

Technical Challenges

The development of anti-lock braking systems (ABS) using V16 engines as a testbed presents several significant technical challenges. These challenges stem from the unique characteristics of V16 engines and the complex requirements of ABS technology.

One of the primary challenges is the integration of ABS with the high-performance nature of V16 engines. These engines, typically found in luxury and high-performance vehicles, generate substantial power and torque. This creates a need for an ABS system that can effectively manage the increased forces during braking while maintaining optimal vehicle control.

The complexity of the V16 engine layout also poses challenges for ABS development. With 16 cylinders arranged in a V-configuration, the engine's weight distribution and center of gravity differ significantly from more common engine types. This unique configuration requires specialized calibration of the ABS to ensure proper functionality across various driving conditions and vehicle dynamics.

Another technical hurdle is the development of sensors and actuators capable of responding to the rapid changes in wheel speed and road conditions associated with high-performance V16-powered vehicles. The ABS must be able to process information and react in milliseconds to prevent wheel lock-up, especially during high-speed braking scenarios.

The heat management of the braking system presents an additional challenge. V16 engines often power vehicles capable of reaching high speeds, which in turn generates substantial heat during braking. The ABS must be designed to operate efficiently under these extreme temperature conditions without compromising performance or safety.

Calibrating the ABS for optimal performance across a wide range of driving conditions is particularly challenging with V16 engines. The system must be able to adapt to various road surfaces, weather conditions, and driving styles while considering the unique power delivery characteristics of the V16 engine.

The integration of electronic stability control (ESC) systems with ABS in V16-powered vehicles adds another layer of complexity. The ABS must work seamlessly with ESC to provide comprehensive vehicle stability, especially during cornering and emergency maneuvers, while accounting for the high power output of the V16 engine.

Furthermore, the development of ABS for V16 engines must address the challenge of minimizing system weight and complexity. Given the already substantial weight of V16 engines, engineers must strive to create lightweight yet robust ABS components that do not significantly impact the vehicle's overall weight distribution or performance.

Lastly, ensuring the reliability and durability of ABS components in the high-performance environment of V16-powered vehicles is crucial. The system must withstand the stresses associated with frequent high-speed braking and maintain consistent performance over extended periods, requiring advanced materials and manufacturing techniques.

One of the primary challenges is the integration of ABS with the high-performance nature of V16 engines. These engines, typically found in luxury and high-performance vehicles, generate substantial power and torque. This creates a need for an ABS system that can effectively manage the increased forces during braking while maintaining optimal vehicle control.

The complexity of the V16 engine layout also poses challenges for ABS development. With 16 cylinders arranged in a V-configuration, the engine's weight distribution and center of gravity differ significantly from more common engine types. This unique configuration requires specialized calibration of the ABS to ensure proper functionality across various driving conditions and vehicle dynamics.

Another technical hurdle is the development of sensors and actuators capable of responding to the rapid changes in wheel speed and road conditions associated with high-performance V16-powered vehicles. The ABS must be able to process information and react in milliseconds to prevent wheel lock-up, especially during high-speed braking scenarios.

The heat management of the braking system presents an additional challenge. V16 engines often power vehicles capable of reaching high speeds, which in turn generates substantial heat during braking. The ABS must be designed to operate efficiently under these extreme temperature conditions without compromising performance or safety.

Calibrating the ABS for optimal performance across a wide range of driving conditions is particularly challenging with V16 engines. The system must be able to adapt to various road surfaces, weather conditions, and driving styles while considering the unique power delivery characteristics of the V16 engine.

The integration of electronic stability control (ESC) systems with ABS in V16-powered vehicles adds another layer of complexity. The ABS must work seamlessly with ESC to provide comprehensive vehicle stability, especially during cornering and emergency maneuvers, while accounting for the high power output of the V16 engine.

Furthermore, the development of ABS for V16 engines must address the challenge of minimizing system weight and complexity. Given the already substantial weight of V16 engines, engineers must strive to create lightweight yet robust ABS components that do not significantly impact the vehicle's overall weight distribution or performance.

Lastly, ensuring the reliability and durability of ABS components in the high-performance environment of V16-powered vehicles is crucial. The system must withstand the stresses associated with frequent high-speed braking and maintain consistent performance over extended periods, requiring advanced materials and manufacturing techniques.

Current V16 ABS Solutions

01 Improved ABS control algorithms

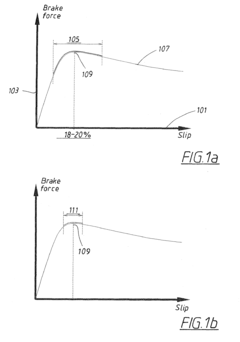

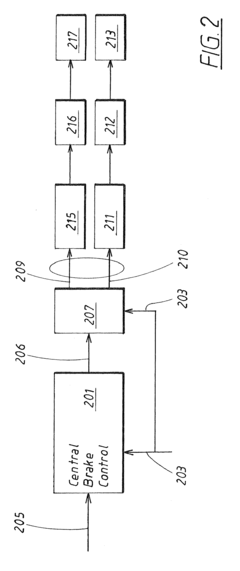

Advanced control algorithms are developed to enhance the performance of anti-lock braking systems. These algorithms optimize brake pressure modulation, wheel slip control, and vehicle stability during emergency braking situations. By incorporating sophisticated software and sensor data processing, the ABS can more accurately detect and respond to various road conditions and vehicle dynamics, resulting in shorter stopping distances and improved vehicle control.- Improved ABS control algorithms: Advanced control algorithms are developed to enhance the performance of anti-lock braking systems. These algorithms optimize brake pressure modulation, wheel slip control, and vehicle stability during emergency braking situations. By incorporating sophisticated software and sensor data processing, the ABS can more accurately detect and respond to various road conditions and vehicle dynamics, resulting in shorter stopping distances and improved vehicle control.

- Integration with other vehicle safety systems: ABS is integrated with other vehicle safety systems such as electronic stability control (ESC), traction control, and brake assist to provide a comprehensive safety package. This integration allows for better coordination between different systems, enhancing overall vehicle stability and braking performance. The combined systems can work together to prevent skidding, maintain directional control, and optimize braking force distribution across all wheels.

- Enhanced sensor technology: Improved sensor technology is utilized to provide more accurate and real-time data to the ABS control unit. Advanced wheel speed sensors, accelerometers, and yaw rate sensors offer precise information about vehicle motion and wheel behavior. This enhanced sensor data allows the ABS to make more informed decisions and react faster to changing road conditions, ultimately improving braking performance and vehicle stability.

- Adaptive braking force distribution: ABS systems incorporate adaptive braking force distribution mechanisms to optimize braking performance across different road conditions and vehicle load distributions. These systems can dynamically adjust brake pressure to individual wheels based on factors such as weight transfer during braking, road surface friction, and cornering forces. This adaptive approach ensures maximum braking efficiency while maintaining vehicle stability and steering control.

- Fail-safe and self-diagnostic features: Modern ABS systems are equipped with fail-safe mechanisms and self-diagnostic capabilities to ensure reliable operation and quick identification of potential issues. These features include continuous system monitoring, fault detection algorithms, and backup power supplies. In case of a malfunction, the system can alert the driver and, if necessary, revert to a basic braking mode to maintain a minimum level of safety performance.

02 Integration with other vehicle safety systems

ABS is integrated with other vehicle safety systems such as electronic stability control (ESC), traction control, and brake assist to provide a comprehensive approach to vehicle safety. This integration allows for better coordination between different systems, enhancing overall braking performance and vehicle stability. The combined systems can work together to prevent wheel lock-up, maintain directional stability, and optimize braking force distribution across all wheels.Expand Specific Solutions03 Sensor technology advancements

Improvements in sensor technology contribute to enhanced ABS performance. Advanced wheel speed sensors, accelerometers, and yaw rate sensors provide more accurate and real-time data to the ABS control unit. This allows for faster and more precise detection of wheel lock-up conditions and vehicle dynamics, enabling the system to respond more effectively to various braking scenarios and road conditions.Expand Specific Solutions04 Hydraulic system enhancements

Advancements in hydraulic components and systems improve the overall performance of ABS. These enhancements include faster-acting solenoid valves, more efficient hydraulic pumps, and optimized brake fluid circuits. The improved hydraulic systems allow for quicker and more precise modulation of brake pressure, resulting in better control of wheel slip and reduced stopping distances.Expand Specific Solutions05 Adaptation to electric and hybrid vehicles

ABS systems are adapted to work effectively with electric and hybrid vehicle powertrains. These adaptations take into account the unique characteristics of regenerative braking systems and the different weight distribution of electric vehicles. The modified ABS algorithms and hardware ensure optimal braking performance while maximizing energy recovery through regenerative braking, contributing to both safety and efficiency in modern electric and hybrid vehicles.Expand Specific Solutions

Key Industry Players

The V16 engine as a testbed for anti-lock braking system (ABS) advancements represents a niche area in automotive technology. The market is in a mature stage, with ABS being a standard feature in most vehicles. However, the use of V16 engines for ABS testing is limited, primarily confined to high-end luxury and performance vehicles. Key players like Robert Bosch GmbH, ADVICS Co., Ltd., and Continental AG dominate the ABS market, while luxury automakers such as Honda Motor Co., Ltd. and BMW might be interested in V16 engine applications. The technology's maturity is high for ABS in general, but the specific V16 engine testbed approach is still evolving, offering potential for innovation in performance and safety enhancements.

Robert Bosch GmbH

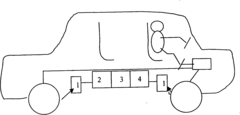

Technical Solution: Robert Bosch GmbH has developed an advanced ABS system specifically designed for V16 engines, utilizing high-performance Electronic Control Units (ECUs) capable of processing complex algorithms. Their system incorporates multiple wheel speed sensors and hydraulic modulators to precisely control brake pressure on each wheel. The company has implemented a novel predictive braking algorithm that anticipates wheel lock-up based on engine torque output and road conditions, allowing for more responsive ABS intervention[1]. Bosch's V16 ABS testbed also features an integrated stability control system, which uses the engine's multiple cylinders to provide finer torque vectoring, enhancing overall vehicle stability during braking[3].

Strengths: Highly advanced predictive algorithms, integration with stability control systems, and extensive experience in ABS development. Weaknesses: Potentially higher cost due to complex components and limited market for V16 engines.

GM Global Technology Operations LLC

Technical Solution: GM Global Technology Operations LLC has developed a sophisticated ABS testbed for V16 engines, leveraging their extensive experience in high-performance vehicle systems. Their approach focuses on integrating the ABS with other vehicle systems for holistic performance optimization. GM's system utilizes a high-speed CAN (Controller Area Network) to facilitate rapid communication between the ABS module and the engine control unit, allowing for real-time adjustments based on engine output[5]. The company has also implemented an AI-driven predictive maintenance feature, which analyzes brake system performance data to anticipate potential issues before they occur, ensuring consistent ABS functionality in demanding V16 applications[6].

Strengths: Holistic integration with vehicle systems, predictive maintenance capabilities, and extensive testing resources. Weaknesses: Potential over-reliance on proprietary technologies may limit compatibility with third-party components.

Core ABS Innovations

A braking system and a method for braking a vehicle

PatentInactiveEP1935737A1

Innovation

- A braking system that uses wheel torque actuators to selectively add or subtract torque to each wheel during braking, controlled by a Central Brake Control unit that integrates information from vehicle, wheel, and tire status sensors to optimize friction braking and additional braking force distribution, allowing for more precise regulation of slip and adhesion.

ABS emulation system for automobile brake durability test

PatentInactiveCN201053923Y

Innovation

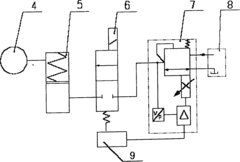

- An ABS simulation system including a regulated hydraulic circuit, isolation cylinder, digital high-speed switch, fast proportional pressure reducing valve and hydraulic station is designed. The digital high-speed switch and fast proportional pressure reducing valve are controlled by the controller to achieve rapid pressure adjustment and response. The time is less than 70ms.

Safety Regulations

Safety regulations play a crucial role in the development and implementation of anti-lock braking systems (ABS) for V16 engines. These regulations are designed to ensure that ABS technology meets stringent safety standards and provides optimal performance in various driving conditions.

The National Highway Traffic Safety Administration (NHTSA) in the United States has established Federal Motor Vehicle Safety Standards (FMVSS) that directly impact ABS development. FMVSS No. 126, for instance, mandates electronic stability control systems, which often incorporate ABS functionality. This regulation has driven manufacturers to continually improve ABS technology, using V16 engines as a testbed for advanced systems.

In the European Union, the United Nations Economic Commission for Europe (UNECE) Regulation No. 13 sets standards for braking systems, including ABS. This regulation specifies performance requirements for ABS on various vehicle types, influencing the development of ABS for high-performance engines like V16s.

The use of V16 engines as testbeds for ABS advancements has led to the creation of more sophisticated safety regulations. These engines, with their high power output and complex dynamics, provide an ideal platform for testing ABS under extreme conditions. Regulatory bodies have responded by developing more nuanced standards that address the unique challenges posed by high-performance vehicles.

One key area of focus in safety regulations is the integration of ABS with other advanced driver assistance systems (ADAS). As V16 engines often power luxury and high-performance vehicles, regulators have emphasized the need for seamless interaction between ABS and features like adaptive cruise control, lane-keeping assist, and autonomous emergency braking.

Safety regulations also address the environmental impact of ABS technology. With V16 engines serving as testbeds, regulators have introduced standards that require ABS to optimize not only safety but also fuel efficiency and emissions reduction. This has led to the development of more intelligent ABS systems that can adapt to different driving modes and conditions.

The testing and certification processes for ABS have become more rigorous due to the insights gained from V16 engine testbeds. Regulatory bodies now require extensive real-world testing and simulation data to ensure that ABS can perform effectively across a wide range of scenarios, including extreme weather conditions and challenging road surfaces.

As ABS technology continues to evolve, safety regulations are becoming more forward-looking. Anticipating future advancements, regulators are developing standards for next-generation ABS that may incorporate artificial intelligence, machine learning, and vehicle-to-vehicle communication. The lessons learned from V16 engine testbeds are instrumental in shaping these future-oriented regulations.

The National Highway Traffic Safety Administration (NHTSA) in the United States has established Federal Motor Vehicle Safety Standards (FMVSS) that directly impact ABS development. FMVSS No. 126, for instance, mandates electronic stability control systems, which often incorporate ABS functionality. This regulation has driven manufacturers to continually improve ABS technology, using V16 engines as a testbed for advanced systems.

In the European Union, the United Nations Economic Commission for Europe (UNECE) Regulation No. 13 sets standards for braking systems, including ABS. This regulation specifies performance requirements for ABS on various vehicle types, influencing the development of ABS for high-performance engines like V16s.

The use of V16 engines as testbeds for ABS advancements has led to the creation of more sophisticated safety regulations. These engines, with their high power output and complex dynamics, provide an ideal platform for testing ABS under extreme conditions. Regulatory bodies have responded by developing more nuanced standards that address the unique challenges posed by high-performance vehicles.

One key area of focus in safety regulations is the integration of ABS with other advanced driver assistance systems (ADAS). As V16 engines often power luxury and high-performance vehicles, regulators have emphasized the need for seamless interaction between ABS and features like adaptive cruise control, lane-keeping assist, and autonomous emergency braking.

Safety regulations also address the environmental impact of ABS technology. With V16 engines serving as testbeds, regulators have introduced standards that require ABS to optimize not only safety but also fuel efficiency and emissions reduction. This has led to the development of more intelligent ABS systems that can adapt to different driving modes and conditions.

The testing and certification processes for ABS have become more rigorous due to the insights gained from V16 engine testbeds. Regulatory bodies now require extensive real-world testing and simulation data to ensure that ABS can perform effectively across a wide range of scenarios, including extreme weather conditions and challenging road surfaces.

As ABS technology continues to evolve, safety regulations are becoming more forward-looking. Anticipating future advancements, regulators are developing standards for next-generation ABS that may incorporate artificial intelligence, machine learning, and vehicle-to-vehicle communication. The lessons learned from V16 engine testbeds are instrumental in shaping these future-oriented regulations.

Performance Benchmarking

Performance benchmarking is a critical aspect of evaluating the effectiveness of anti-lock braking system (ABS) advancements using V16 engines as a testbed. This process involves comprehensive testing and analysis to measure the performance improvements achieved through various ABS innovations.

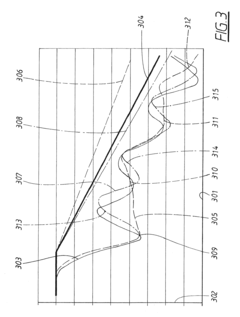

One key metric in ABS performance benchmarking is stopping distance. Tests are conducted on various road surfaces, including dry asphalt, wet concrete, and low-friction surfaces like ice or gravel. The stopping distances achieved with different ABS configurations are compared to baseline measurements without ABS intervention. These tests typically involve multiple runs at different speeds to ensure consistency and reliability of results.

Another important benchmark is vehicle stability during emergency braking. This is assessed through standardized maneuvers such as the moose test or sudden lane-change scenarios. Sensors and high-speed cameras are used to capture vehicle behavior, measuring factors like yaw rate, lateral acceleration, and steering angle. The ability of the ABS to maintain directional control while maximizing braking force is a crucial performance indicator.

Brake pedal feel and modulation are also essential benchmarks. Test drivers evaluate the responsiveness and consistency of brake pedal feedback across various braking scenarios. This subjective assessment is complemented by objective measurements of pedal force, travel, and system response time.

Wheel slip control efficiency is a technical benchmark that directly relates to ABS performance. Advanced data acquisition systems are used to monitor individual wheel speeds and calculate slip ratios during braking events. The ability of the ABS to maintain optimal slip levels for maximum traction is analyzed across different surface conditions and vehicle speeds.

Durability and reliability testing form another crucial aspect of performance benchmarking. This involves subjecting the ABS components to prolonged testing cycles, simulating years of real-world usage. Factors such as heat dissipation, component wear, and system response under extreme conditions are evaluated to ensure long-term performance and safety.

The unique characteristics of V16 engines, such as their high power output and complex vibration patterns, present specific challenges for ABS integration. Benchmarking tests are designed to assess how well the ABS adapts to these engine-specific factors, ensuring optimal performance across the entire operating range of the powertrain.

Comparative analysis is also conducted against leading ABS systems in the market. This involves side-by-side testing of different ABS technologies under identical conditions, providing valuable insights into the relative strengths and weaknesses of each system. Such benchmarking helps identify areas for further improvement and validates the effectiveness of new ABS advancements.

One key metric in ABS performance benchmarking is stopping distance. Tests are conducted on various road surfaces, including dry asphalt, wet concrete, and low-friction surfaces like ice or gravel. The stopping distances achieved with different ABS configurations are compared to baseline measurements without ABS intervention. These tests typically involve multiple runs at different speeds to ensure consistency and reliability of results.

Another important benchmark is vehicle stability during emergency braking. This is assessed through standardized maneuvers such as the moose test or sudden lane-change scenarios. Sensors and high-speed cameras are used to capture vehicle behavior, measuring factors like yaw rate, lateral acceleration, and steering angle. The ability of the ABS to maintain directional control while maximizing braking force is a crucial performance indicator.

Brake pedal feel and modulation are also essential benchmarks. Test drivers evaluate the responsiveness and consistency of brake pedal feedback across various braking scenarios. This subjective assessment is complemented by objective measurements of pedal force, travel, and system response time.

Wheel slip control efficiency is a technical benchmark that directly relates to ABS performance. Advanced data acquisition systems are used to monitor individual wheel speeds and calculate slip ratios during braking events. The ability of the ABS to maintain optimal slip levels for maximum traction is analyzed across different surface conditions and vehicle speeds.

Durability and reliability testing form another crucial aspect of performance benchmarking. This involves subjecting the ABS components to prolonged testing cycles, simulating years of real-world usage. Factors such as heat dissipation, component wear, and system response under extreme conditions are evaluated to ensure long-term performance and safety.

The unique characteristics of V16 engines, such as their high power output and complex vibration patterns, present specific challenges for ABS integration. Benchmarking tests are designed to assess how well the ABS adapts to these engine-specific factors, ensuring optimal performance across the entire operating range of the powertrain.

Comparative analysis is also conducted against leading ABS systems in the market. This involves side-by-side testing of different ABS technologies under identical conditions, providing valuable insights into the relative strengths and weaknesses of each system. Such benchmarking helps identify areas for further improvement and validates the effectiveness of new ABS advancements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!